Professional Documents

Culture Documents

Chapter 9 LinearBucklingAnalysis

Chapter 9 LinearBucklingAnalysis

Uploaded by

GeoWest MHGeoLKNEGAOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 9 LinearBucklingAnalysis

Chapter 9 LinearBucklingAnalysis

Uploaded by

GeoWest MHGeoLKNEGACopyright:

Available Formats

Benchmarks&Verifications Chapter 9.

Linear Buckling Analysis

9.1

1.1 Column buckling

1

REFERENCE Gerel et al.

ELEMENTS Bar elements, Shell elements, Solid elements

MODEL FILENAME Buckling01_CASE1.fea

Buckling01_CASE2.fea

Buckling01_CASE3.fea

Buckling01_CASE4.fea

Figure 9.1.1 shows a straight column model. Linear buckling analysis is carried out to determine the buckling modes

and the corresponding critical loads of a column subjected to a vertical load. Four kinds of boundary conditions are

considered. The lowest buckling modes are presented in Figure 9.1.2.

Figure 9.1.1 1 tonf 1 tonf 1 tonf 1 tonf

Column model

15

0.25

X

1

Top : Roller Top : Free Top : Laterally guided Top : Roller

Units : m

Bottom : Pin Bottom : Fixed Bottom : Fixed Bottom : Fixed

Picture 1.1.1

Strip footing model

Figure 9.1.2

Buckling mode shapes

Case 1 Case 2 Case 3 Case 4

2

Material data Young’s modulus 10,000 tonf/m

Section property Rectangular cross-section 0.25 m 1.0m

236 | Column buckling

Benchmarks&Verifications Chapter 9. Linear Buckling Analysis

Table 9.1.1 Critical loads in tonf obtained using bar elements

Case number 1 2 3 4

Reference 0.5712 0.1428 2.2846 1.1684

Number of

Element type

elements

Bar-2 15 0.5714 0.1428 2.2891 1.1695

Table 9.1.2 Critical loads in tonf obtained using shell elements

Case number 1 2 3 4

Reference 0.5712 0.1428 2.2846 1.1684

Number of

Element type

elements

Tria-3 30 0.5739 0.1430 2.3293 1.1804

Quad-4 15 0.5736 0.1429 2.3245 1.1790

Tria-6 30 0.5698 0.1427 2.2628 1.1621

Quad-8 15 0.5705 0.1428 2.2749 1.1656

Table 9.1.3 Critical loads in tonf obtained using solid elements

Case number 1 2 3 4

Reference 0.5712 0.1428 2.2846 1.1684

Number of

Element type

elements

Hexa-8 15 0.5747 0.1430 2.3421 1.1841

Tetra-10 90 0.5725 0.1429 2.3065 1.1747

Penta-15 40 0.5711 0.1428 2.2835 1.1681

Hexa-20 15 0.5710 0.1428 2.2827 1.1678

Column buckling | 237

Benchmarks&Verifications Chapter 9. Linear Buckling Analysis

9.2 Three member frame

2

REFERENCE Timoshenko et al.

ELEMENTS Bar elements

MODEL FILENAME Buckling02.fea

Figure 9.2.1 shows a plane frame structure subjected to two vertical point forces. The buckling load is determined

for different cases in which different numbers of elements per member are considered. In Figure 9.2.2, the typical

buckling mode is depicted.

1 lbf 1 lbf

Figure 9.2.1

Three-member frame ③ ④

model

② ⑤

100

① ⑥

100

Units : in

Figure 9.2.2

Buckling mode shape

E = 1 10 psi

6

Material data Conductivity

2

Section property Area A = 1.0 in

4

Moment of inertia I = 1.0 in

Three member frame | 239

Benchmarks&Verifications Chapter 9. Linear Buckling Analysis

Table 9.2.1 Critical loads in Ibf obtained using bar elements

Reference 737.9

Number of

Element type

elements

2 per member 739.8

Bar-2 4 per member 737.6

8 per member 737.5

240 | Three member frame

Benchmarks&Verifications Chapter 9. Linear Buckling Analysis

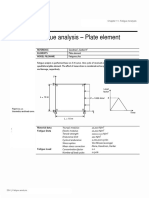

9.3 Uniaxially compressed clamped square

plate

3

REFERENCE Chajes

ELEMENTS Shell elements, Solid elements

MODEL FILENAME Buckling03.fea

Figure 9.3.1 shows a square plate subjected to a compressive load. The linear buckling analysis is carried out to

determine the critical load with a clamped boundary condition. One quarter model is used due to the symmetric

boundary condition.

1

Figure 9.3.1

Clamped square plate

model t = 0.01

P = 1.0 lbf/in. P 1

Modelled portion Units : in.

Figure 9.3.2

Buckling mode shape

E = 11.064 10 psi

5

Material data Young’s modulus

Poisson’s ratio = 0.3

Section property Thickness t = 0.01 in

Uniaxially compressed clamped square plate | 241

Benchmarks&Verifications Chapter 9. Linear Buckling Analysis

Table 9.3.1 Critical distributed load in lbf. Obtained using shell elements

Reference 100.7

Number of

Element type

elements

Tria-3 32 111.7

Quad-4 16 107.3

Tria-6 32 97.2

Quad-8 16 100.6

Table 9.3.2 Critical distributed load in lbf. Obtained using solid elements

Reference 100.7

Number of

Element type

elements

Hexa-8 16 98.0

Penta-15 32 127.8

Hexa-20 16 111.8

242 | Uniaxially compressed clamped square plate

Benchmarks&Verifications Chapter 9. Linear Buckling Analysis

9.4 Rectangular plate under concentrated

center load

2

REFERENCE Timoshenko et al.

ELEMENTS Shell elements

MODEL FILENAME Buckling04.fea

Figure 9.4.1 shows a rectangular plate subjected to a point force. All the sides are simply supported, and the edge

AD is constrained in the Y direction. A concentrated force is applied at the center of BC (point E). The linear buckling

analysis is carried out to obtain the lowest critical load.

P = 1 kN t = 0.01

B E C

Figure 9.4.1

Simply supported

rectangular plate model

Y

X

Z A D

2

Units : m

Material data Young’s modulus E = 200 GPa

Poisson’s ratio = 0.3

Section property Thickness t = 0.01 m

Rectangular plate under concentrated center load | 243

Benchmarks&Verifications Chapter 9. Linear Buckling Analysis

Table 9.4.1 Critical load in kN obtained using shell elements

Reference 330

Number of

Element type

elements

Tria-3 144 342

Quad-4 72 327

Tria-6 36 316

Quad-8 18 320

Table 9.4.2 Critical load in kN obtained using solid elements

Reference 330

Number of

Element type

elements

Hexa-8 72 298

Penta-15 36 377

Hexa-20 18 330

244 | Rectangular plate under concentrated center load

Benchmarks&Verifications Chapter 9. Linear Buckling Analysis

9.5 Axially compressed cylinder

4

REFERENCE Simo et al.

ELEMENTS Shell elements, Solid elements

MODEL FILENAME Buckling05.fea

Figure 9.5.1 shows a cylindrical shell model subjected to a distributed compressive load. Both ends of the cylinder

are clamped in the transverse direction. One eighth portion of the cylinder is modeled with a symmetric boundary

condition. The linear buckling analysis is carried out to determine the lowest critical load factor. The typical mode

shape is depicted in Figure 9.5.2.

P = 0.209 N/m

Figure 9.5.1

Axially compressed

cylinder model

R = 100

Clamped

L = 35.95

Units : m

Figure 9.5.2

Buckling mode shape

Material data Young’s modulus E = 567 Pa

Poisson’s ratio = 0.3

Section property Thickness t = 0.247 m

Axially compressed cylinder | 245

Benchmarks&Verifications Chapter 9. Linear Buckling Analysis

Table 9.5.1 Critical load factor obtained using shell elements

Reference 1.0833

Number of

Element type

elements

Tria-3 840 1.1129

Quad-4 420 1.1370

Tria-6 840 1.0123

Quad-8 420 1.0148

Table 9.5.2 Critical load factor obtained using solid elements

Reference 1.0833

Number of

Element type

elements

Hexa-8 420 1.0630

Hexa-20 420 0.9950

246 | Axially compressed cylinder

Benchmarks&Verifications Chapter 9. Linear Buckling Analysis

9.6 L-bracket plate under in-plane load

4 5

REFERENCE Simo et al. and Argyris et al.

ELEMENTS Shell elements, Solid elements

MODEL FILENAME Buckling06.fea

Figure 9.6.1 shows a clamped L-shape plate subjected to an in-plane bending load. Linear buckling analysis is

performed to obtain the critical load. The critical load induces lateral buckling of which the mode shape is depicted

in Figure 9.6.2.

240

240

t = 0.6 Y

Figure 9.6.1 X

L-bracket plate model

P=1N

30

Units : mm

Figure 9.6.2

Buckling mode shape

Material data Young’s modulus E = 71.240 GPa

Poisson’s ratio = 0.3

Section property Thickness t = 0.6 mm

L-bracket plate under in-plane load | 247

Benchmarks&Verifications Chapter 9. Linear Buckling Analysis

Table 9.6.1 Critical load in N obtained using shell elements

Reference 1.137 (Simo et al.) 1.155(Argyris et al.)

Number of

Element type

elements

Tria-3 136 1.183

Quad-4 68 1.199

Tria-6 34 1.120

Quad-8 17 1.189

Table 9.6.2 Critical load in N obtained using solid elements

Reference 1.137 (Simo et al.) 1.155(Argyris et al.)

Number of

Element type

elements

Hexa-8 68 1.198

Penta-15 34 1.238

Hexa-20 17 1.188

248 | L-bracket plate under in-plane

Benchmarks&Verifications Chapter 9. Linear Buckling Analysis

References

1 J.M. Gere and S.P. Timoshenko, Mechanics of Materials, 2nd Edition, Thomson Brooks/Cole, California,

New York, 1984

2 S.P. Timoshenko and J.M. Gere, Theory of Elastic Stability, 2nd Edition, McGraw-Hill, New York, 1961

3 A. Chajes, Principles of Structural Stability Theory, Prentice-Hall, Englewood Cliffs, N.J,1974

4 J.C. Simo, D.D. Fox and M.S. Rifai, “On a Stress Resultant Geometrically Exact Shell Model. Part III: The

Computational Aspects of the Nonlinear Theory,” Computer Methods in Applied Mechanics and

Engineering, Vol. 79, pp. 21-70, 1990

5 J.H. Argyris, H. Balmer, J.St. Doltsinis, P.C. Dunne, M. Haase, M. Hasse, M. Kleiber, G.A. Malejannakis, H.P.

Mlejenek, M. Muller and D.W. Scharpf, “Finite Element Method – The natural approach,” Computer

Methods in Applied Mechanics and Engineering, Vol. 17/18, pp. 1-106, 1979

References | 249

You might also like

- NIST-5031 Lighting and Power Installations Rev 1Document20 pagesNIST-5031 Lighting and Power Installations Rev 1CK TangNo ratings yet

- Seismic Analysis: CategoryDocument7 pagesSeismic Analysis: CategoryAnil kumar RNo ratings yet

- RMS Australian NSW QA Specifications ListDocument35 pagesRMS Australian NSW QA Specifications ListSubhash ChavaNo ratings yet

- Chapter 4 DynamicsDocument40 pagesChapter 4 DynamicsGeoWest MHGeoLKNEGANo ratings yet

- Summary Report: Model File: STRUKTUR ETABS JAMBI, Revision 0Document10 pagesSummary Report: Model File: STRUKTUR ETABS JAMBI, Revision 0Archi MuktiNo ratings yet

- Cyclone Upper PartDocument26 pagesCyclone Upper PartArielNo ratings yet

- Transverse Vibration TestingDocument8 pagesTransverse Vibration Testingsonnu151No ratings yet

- Pushover Curve - FEMA 440 Equivalent Linearization: ETABS 2016 16.0.2 License # 1XE56Y53VR7VRLBDocument2 pagesPushover Curve - FEMA 440 Equivalent Linearization: ETABS 2016 16.0.2 License # 1XE56Y53VR7VRLBAdam JrNo ratings yet

- Temp Cuptor Potential Vpt100 Rpt100 Potentialul V2/3 Potentialul Va05 Potentialul V2Document8 pagesTemp Cuptor Potential Vpt100 Rpt100 Potentialul V2/3 Potentialul Va05 Potentialul V2Schiopu GeorgeNo ratings yet

- Stress WorksheetDocument7 pagesStress WorksheetAditya KoutharapuNo ratings yet

- 3.6 Guidelines For Electrical Design For SHP Plants Including SwitchyardDocument160 pages3.6 Guidelines For Electrical Design For SHP Plants Including SwitchyardFarid Ahmad Shalahuddin100% (1)

- Summary ReportkkkDocument10 pagesSummary ReportkkkMariappan .PNo ratings yet

- Lab Report #5Document5 pagesLab Report #5Aisha NurymgaliNo ratings yet

- Portal 1 PDFDocument21 pagesPortal 1 PDFAyodele Oluwaseyi DinaNo ratings yet

- Summary Report-GOKUL PRABHU PERUMBAKKAMDocument11 pagesSummary Report-GOKUL PRABHU PERUMBAKKAMMariappan .PNo ratings yet

- Meca Sheet: Overhaul Starting MotorDocument15 pagesMeca Sheet: Overhaul Starting MotorDe JavuNo ratings yet

- Electrical Wiring by Evon McgonigleDocument659 pagesElectrical Wiring by Evon McgonigleEVON MCGONIGLENo ratings yet

- Title: Ut501/Ut502 Operating ManualDocument32 pagesTitle: Ut501/Ut502 Operating ManualEmmanuel SkanavisNo ratings yet

- Bacolod Exp4Document16 pagesBacolod Exp4CLARENCE AVILANo ratings yet

- Ece-213 Lab5 OwenblairDocument7 pagesEce-213 Lab5 Owenblairapi-548288377No ratings yet

- Square Portal FrameDocument8 pagesSquare Portal FramenabilaNo ratings yet

- ABB Motors and Technical Data Sheet Generators: No. Data Unit RemarksDocument5 pagesABB Motors and Technical Data Sheet Generators: No. Data Unit RemarksRishi TandonNo ratings yet

- GATE HOUSE Project ReportDocument67 pagesGATE HOUSE Project ReportArianne GumabonNo ratings yet

- Lab Report - 02Document13 pagesLab Report - 02Ovi SahaNo ratings yet

- India Test House: SAMPLE: Steels For Piston Pins MEASURAND: Chromium TEST METHOD: IS 228 (Part 6) : 1987 (RA 2018)Document2 pagesIndia Test House: SAMPLE: Steels For Piston Pins MEASURAND: Chromium TEST METHOD: IS 228 (Part 6) : 1987 (RA 2018)Gaurav KumarNo ratings yet

- Pushover Curve - FEMA 440 Equivalent Linearization: ETABS 2016 16.0.2 License # 1XE56Y53VR7VRLBDocument2 pagesPushover Curve - FEMA 440 Equivalent Linearization: ETABS 2016 16.0.2 License # 1XE56Y53VR7VRLBAdam JrNo ratings yet

- NVFMCZ20DC12VDocument2 pagesNVFMCZ20DC12VPatrik GasparikNo ratings yet

- PHYS194 Report 1Document7 pagesPHYS194 Report 1AbdulNo ratings yet

- Automatic Fault Detection and Protection of Three Phase Induction MotorDocument65 pagesAutomatic Fault Detection and Protection of Three Phase Induction Motordivya kambleNo ratings yet

- K1010 Series: CosmoDocument11 pagesK1010 Series: CosmoAsad IqbalNo ratings yet

- Specific N°: OH071B4H2305PU: Motor Specification SheetDocument1 pageSpecific N°: OH071B4H2305PU: Motor Specification SheetChonlasith SongkongNo ratings yet

- IEEE9 Model Documentation R0Document13 pagesIEEE9 Model Documentation R0Nando LópezNo ratings yet

- Steel Staircase Quantity EstimateDocument12 pagesSteel Staircase Quantity Estimateramesh sitaulaNo ratings yet

- Thermit CatalogueDocument20 pagesThermit CatalogueJboy SchlossNo ratings yet

- 3G1F2043709296B JM JP KP 90LD4 400VY 50Hz 1,5kW 3GZF021009-138Document1 page3G1F2043709296B JM JP KP 90LD4 400VY 50Hz 1,5kW 3GZF021009-138Kidzoy ShopNo ratings yet

- Project ReportDocument45 pagesProject ReportGopal AcharyaNo ratings yet

- Scope:: About The Ballparam - Reverse Spreadsheet ..Document55 pagesScope:: About The Ballparam - Reverse Spreadsheet ..Monica Carolina Tobar BastiasNo ratings yet

- Sample 3 - TQDDocument12 pagesSample 3 - TQDbluuu1331No ratings yet

- Lab Report On TorsionDocument6 pagesLab Report On TorsionAhmed AliNo ratings yet

- Document 220KWDocument9 pagesDocument 220KWradesh.reddyNo ratings yet

- Lab 5-WorksheetDocument5 pagesLab 5-WorksheetShahid mailsiNo ratings yet

- Met PNL Strength PT2 C5Document818 pagesMet PNL Strength PT2 C5erolNo ratings yet

- Report 4, 8 9 10 Network LabDocument8 pagesReport 4, 8 9 10 Network LabJackie NguyenNo ratings yet

- Parts Manual Tb025 Pe3 102z5Document321 pagesParts Manual Tb025 Pe3 102z5SARAMQRNo ratings yet

- ABB Motors and Technical Data Sheet Generators: No. Data Unit RemarksDocument5 pagesABB Motors and Technical Data Sheet Generators: No. Data Unit RemarksUnicoNo ratings yet

- IEC LV Motors Technical Data Sheet: No. Data Unit RemarksDocument4 pagesIEC LV Motors Technical Data Sheet: No. Data Unit RemarksTanuj ShrivastavaNo ratings yet

- Le Cle I Re Foucault Final BDocument6 pagesLe Cle I Re Foucault Final BdanyNo ratings yet

- Laporan Struktur RS Bitunnur BloraDocument19 pagesLaporan Struktur RS Bitunnur BloraM Jaka GurnitaNo ratings yet

- Pushover Curve - FEMA 440 Equivalent Linearization: Summary DescriptionDocument2 pagesPushover Curve - FEMA 440 Equivalent Linearization: Summary Descriptionsidou yúyúNo ratings yet

- 45KW 4P DatasheetDocument5 pages45KW 4P Datasheetvitthal01No ratings yet

- ElectricCircuitsbyNoelM - morrisandFrankW.senior 1Document379 pagesElectricCircuitsbyNoelM - morrisandFrankW.senior 1Fabian Marian RaduNo ratings yet

- Experiment 9Document8 pagesExperiment 9Tayyab AliNo ratings yet

- Fem ReportDocument29 pagesFem ReportVarun JamesNo ratings yet

- Single Lane Speed Controller Manual - European Machines OnlyDocument4 pagesSingle Lane Speed Controller Manual - European Machines OnlyMatiasNo ratings yet

- اعطال الموتوراتDocument65 pagesاعطال الموتوراتmoathNo ratings yet

- DS M2bax 160KW 4P Ie2Document6 pagesDS M2bax 160KW 4P Ie2Rakesh ShinganeNo ratings yet

- Kumar SirDocument29 pagesKumar SirRoshan KejariwalNo ratings yet

- Alternator Data SheetDocument10 pagesAlternator Data SheetMuhammad RamishNo ratings yet

- Experiment 9 (Transducers)Document9 pagesExperiment 9 (Transducers)Bet3aNo ratings yet

- Chapter 12 MaterialViscoElasticityDocument38 pagesChapter 12 MaterialViscoElasticityGeoWest MHGeoLKNEGANo ratings yet

- Chapter 11 FatigueDocument9 pagesChapter 11 FatigueGeoWest MHGeoLKNEGANo ratings yet

- Chapter 10 ContactAnalysisDocument14 pagesChapter 10 ContactAnalysisGeoWest MHGeoLKNEGANo ratings yet

- Structure White Paper - Structural Design Guide For Prestressed SlabsDocument48 pagesStructure White Paper - Structural Design Guide For Prestressed SlabsGeoWest MHGeoLKNEGANo ratings yet

- Chapter 4 DynamicsDocument40 pagesChapter 4 DynamicsGeoWest MHGeoLKNEGANo ratings yet

- 03 Analysis Reference Chapter-3 ElementsDocument112 pages03 Analysis Reference Chapter-3 ElementsGeoWest MHGeoLKNEGANo ratings yet

- RC Shell Design As Per EC - 20190521 - enDocument63 pagesRC Shell Design As Per EC - 20190521 - enGeoWest MHGeoLKNEGANo ratings yet

- 02 - Analysis Reference - Chapter-2 Node DOF CoordinateSystemDocument5 pages02 - Analysis Reference - Chapter-2 Node DOF CoordinateSystemGeoWest MHGeoLKNEGANo ratings yet

- FEM Analysis of Steel Water Tank Using Midas nGENDocument35 pagesFEM Analysis of Steel Water Tank Using Midas nGENGeoWest MHGeoLKNEGANo ratings yet

- Analysis and Design Method of Structures Using Tension-Only ElementsDocument15 pagesAnalysis and Design Method of Structures Using Tension-Only ElementsGeoWest MHGeoLKNEGANo ratings yet

- Review Module 21 - Hydraulics 6 PDFDocument3 pagesReview Module 21 - Hydraulics 6 PDFKiki Do youNo ratings yet

- Viscosity of Newtonian and Non-Newtonian FluidsDocument9 pagesViscosity of Newtonian and Non-Newtonian FluidsAinsssNo ratings yet

- Banglieng 3 - INTAKE - KM 1 ADocument4 pagesBanglieng 3 - INTAKE - KM 1 AK'm VPsNo ratings yet

- 002a REFRESHER PLUMBING CODE PDFDocument601 pages002a REFRESHER PLUMBING CODE PDFDoms DominguezNo ratings yet

- LECTURE 2 RCC StairsDocument40 pagesLECTURE 2 RCC StairsArsh Chaudhary100% (1)

- JL-98-July-August Design of Segmental Bridges For Thermal GradientDocument18 pagesJL-98-July-August Design of Segmental Bridges For Thermal GradientMassimo Averardi RipariNo ratings yet

- 01.01.02.01 Spesifikasi-Soilfelt LSDocument2 pages01.01.02.01 Spesifikasi-Soilfelt LSjogja raya100% (1)

- Introducing New PCI Bridge Design ManualDocument78 pagesIntroducing New PCI Bridge Design ManualAshutosh Kumar SinghNo ratings yet

- Geotechnical Design ReportDocument142 pagesGeotechnical Design ReportHiep HoangNo ratings yet

- Construction Method BuildingDocument6 pagesConstruction Method BuildingLimuel PolisNo ratings yet

- Shear Strength TheoryDocument32 pagesShear Strength TheoryChikkanna TNo ratings yet

- Technical Data Sheet: Lasteek Rwe300Document2 pagesTechnical Data Sheet: Lasteek Rwe300Engr KamalNo ratings yet

- Cost Comparison Steel vs. ConcreteDocument20 pagesCost Comparison Steel vs. ConcreteHibozo82% (17)

- E3 BernoulliDocument16 pagesE3 BernoullikishoreNo ratings yet

- S5-17-Bridge Design W ECs Mancini 20121002-Ispra PDFDocument80 pagesS5-17-Bridge Design W ECs Mancini 20121002-Ispra PDFdmardetkNo ratings yet

- 2015 ENR Top 500 Design Firms Sourcebook 1Document57 pages2015 ENR Top 500 Design Firms Sourcebook 1iabhiuceNo ratings yet

- Design of Multistory Reinforced Concrete Buildings For Earthquake MotionsDocument322 pagesDesign of Multistory Reinforced Concrete Buildings For Earthquake MotionsRoberto Urrutia100% (6)

- Road Geometry & Transition CurveDocument8 pagesRoad Geometry & Transition CurveNann Kay Thari KyawNo ratings yet

- CE 370-Lecture-19 (Bond and Development Length) - Problems (Read-Only) PDFDocument31 pagesCE 370-Lecture-19 (Bond and Development Length) - Problems (Read-Only) PDFJamal RkhNo ratings yet

- Fineness of Portland CementDocument4 pagesFineness of Portland CementJose Marie BorbeNo ratings yet

- Quantity Calculation: DETAIL OF QUANTITY (Boundary Wall)Document6 pagesQuantity Calculation: DETAIL OF QUANTITY (Boundary Wall)SHOLAKA GET /PRILNo ratings yet

- 5150 PSV (Liquid Systems) ForcesDocument1 page5150 PSV (Liquid Systems) ForcesRamesh KrishnanNo ratings yet

- ARASMEN - TOWER 500KV TYPE CC-ModelDocument1 pageARASMEN - TOWER 500KV TYPE CC-Modelrintohidayat66No ratings yet

- 2020 BUILDING TECHNOLOGY 1 Module 2 Lecture 2 - Waterproofing and DampproofingDocument56 pages2020 BUILDING TECHNOLOGY 1 Module 2 Lecture 2 - Waterproofing and Dampproofinglia immie rigoNo ratings yet

- Use of Waste Plastic in Bituminous RoadsDocument27 pagesUse of Waste Plastic in Bituminous Roadssachin palNo ratings yet

- ASTM E8 E8M 2021 Tension Testing of Metallic MaterialsDocument30 pagesASTM E8 E8M 2021 Tension Testing of Metallic MaterialsSuvro ChakrabortyNo ratings yet

- Technical Schedule A To D (4) - CompressedDocument340 pagesTechnical Schedule A To D (4) - CompressedSai Teja ReddyNo ratings yet

- Use of Expanded Polystyrene Technology and Materials Recycling For Building Construction in KenyaDocument8 pagesUse of Expanded Polystyrene Technology and Materials Recycling For Building Construction in KenyaBao TruongNo ratings yet