Professional Documents

Culture Documents

ThoughtSpot Manufacturing Fortune 500 Case Study

ThoughtSpot Manufacturing Fortune 500 Case Study

Uploaded by

Shahnawaz JavedCopyright:

Available Formats

You might also like

- Itunes Gifted Card Format-1Document1 pageItunes Gifted Card Format-1Mr Naijatim89% (281)

- Ceb The New It Operating Model For Digital ItlexDocument17 pagesCeb The New It Operating Model For Digital ItlexMario Morales RodriguezNo ratings yet

- How Can The Law Be Used As An Instrument For Creating Social Change - IpleadersDocument13 pagesHow Can The Law Be Used As An Instrument For Creating Social Change - IpleadersLeelakrishna VemuruNo ratings yet

- Alang Ship BreakersDocument29 pagesAlang Ship Breakerspureman35100% (1)

- Data-Driven Manufacturer: Managing Operations With Search-Driven AnalyticsDocument2 pagesData-Driven Manufacturer: Managing Operations With Search-Driven AnalyticsDavid VillalobosNo ratings yet

- LogiAnalytics BuildingvsBuyingDocument21 pagesLogiAnalytics BuildingvsBuyingHafidz Ash ShidieqyNo ratings yet

- Tech Weirdo ProfileDocument13 pagesTech Weirdo ProfileAnonymous pl7BvPDNo ratings yet

- Digital Manufacturing: "Enabling Lean For More Flexible Manufacturing"Document12 pagesDigital Manufacturing: "Enabling Lean For More Flexible Manufacturing"Anonymous MN9BRMNo ratings yet

- Miskuf 2016Document5 pagesMiskuf 2016Lê NaNo ratings yet

- Business Analytics MDS Enablement-CompressedDocument28 pagesBusiness Analytics MDS Enablement-CompressedWaleed BahgatNo ratings yet

- Become A Digital Industrial Company: GE Digital's Portfolio OverviewDocument8 pagesBecome A Digital Industrial Company: GE Digital's Portfolio Overviewjoko sumarionoNo ratings yet

- Styles of Enteprise BI and Analyics PDFDocument8 pagesStyles of Enteprise BI and Analyics PDFSyeda FarwaNo ratings yet

- Manufacturing 4.0Document36 pagesManufacturing 4.0msavioNo ratings yet

- Industrial IoT WhitepaperDocument11 pagesIndustrial IoT WhitepaperRony JamesNo ratings yet

- Business Intelligence PresentationDocument42 pagesBusiness Intelligence Presentationahmed abotalebNo ratings yet

- 91social Company Overview and CapabilitiesDocument22 pages91social Company Overview and CapabilitiesMahesh SharmaNo ratings yet

- CredentialDocument17 pagesCredentialJAMstack Vietnam Nhân VõNo ratings yet

- Pentaho Expands European OperationsDocument57 pagesPentaho Expands European OperationselizdelimaNo ratings yet

- Analytic FactoryDocument1 pageAnalytic FactoryJohn JiménezNo ratings yet

- Digital Product Development 2025Document45 pagesDigital Product Development 2025IswandiNo ratings yet

- Power BI BrochureDocument16 pagesPower BI BrochurePreetam ShettyNo ratings yet

- Business Analytics ToolsDocument22 pagesBusiness Analytics ToolsAna-Maria Nicoleta VladNo ratings yet

- Introducing Acies - SnapshotDocument1 pageIntroducing Acies - Snapshotsubhashm.dasariNo ratings yet

- Digital Factory: The Information Systems AspectDocument17 pagesDigital Factory: The Information Systems AspectMona IbrahimNo ratings yet

- 69892business Intelligence Redefining ManufacturingDocument11 pages69892business Intelligence Redefining Manufacturingsahendra4673No ratings yet

- Connect Your Data To Your Decision Making: Ebook SeriesDocument20 pagesConnect Your Data To Your Decision Making: Ebook SeriesovirogerNo ratings yet

- ARC View Honeywell Forge Production InsightsDocument9 pagesARC View Honeywell Forge Production InsightsRafia Afzal Muhammad AfzalNo ratings yet

- Powerapps Innovation For Everyone HandoutDocument1 pagePowerapps Innovation For Everyone Handouthj7nfx8bz2No ratings yet

- Power BiDocument39 pagesPower BiKase Hija IndiaNo ratings yet

- PLM Application Acceleration: Optimize Performance in Distributed R&D EnvironmentsDocument6 pagesPLM Application Acceleration: Optimize Performance in Distributed R&D EnvironmentsMTNo ratings yet

- Modern Guide To PLM EbookDocument14 pagesModern Guide To PLM EbookChamakmak MokazkazNo ratings yet

- Connected Factories IotDocument2 pagesConnected Factories IotvitrahulNo ratings yet

- Rapid Fire BI A New Approach To Business Intelligence TableauDocument16 pagesRapid Fire BI A New Approach To Business Intelligence TableauMichaël MemeteauNo ratings yet

- Modern Guide To PLM EbookDocument14 pagesModern Guide To PLM Ebookanoop krNo ratings yet

- Introduction of Data Analysis Product IODocument28 pagesIntroduction of Data Analysis Product IOAlejandro ArteagaNo ratings yet

- Upskill TechnologiesDocument6 pagesUpskill TechnologiesAmresh MehtaNo ratings yet

- Forrester - The Total Economic Impact™ of IBM Cognos AnalyticsDocument21 pagesForrester - The Total Economic Impact™ of IBM Cognos AnalyticsDave CashinNo ratings yet

- Cognos Right Architecture For BiDocument13 pagesCognos Right Architecture For BiGaurav GargNo ratings yet

- IBM - Big Data AnalyticsDocument22 pagesIBM - Big Data AnalyticsJohn AngelopoulosNo ratings yet

- Michael R. Resume - ProductDocument2 pagesMichael R. Resume - ProductMichael RobertsNo ratings yet

- Brochure NeoDigital USADocument10 pagesBrochure NeoDigital USALuis Enrique CastroNo ratings yet

- Manufacturing Industry FinalDocument15 pagesManufacturing Industry FinalBhakti Mehta100% (1)

- BrochureCosmetics-Lascom Lime CloudDocument27 pagesBrochureCosmetics-Lascom Lime Cloudnguyen hong loanNo ratings yet

- Acies Global - IntroductionDocument1 pageAcies Global - IntroductionGIRIDHAR ANo ratings yet

- DTI Digital-Engineering201806122 V07Document40 pagesDTI Digital-Engineering201806122 V07lourineb89No ratings yet

- Chris Caputo Product ManagerDocument1 pageChris Caputo Product ManagerMukund MakhijaNo ratings yet

- En AU CNTNT Ebook How To Supercharge Your Application With Embedded AnalyticsDocument7 pagesEn AU CNTNT Ebook How To Supercharge Your Application With Embedded AnalyticsernestoNo ratings yet

- How To Supercharge Your Application With Embedded AnalyticsDocument7 pagesHow To Supercharge Your Application With Embedded AnalyticsParag GargNo ratings yet

- Knowledge Management in Manufacturing SectorDocument22 pagesKnowledge Management in Manufacturing SectorVaishnavi PreranaNo ratings yet

- SAP BI Material (1) .Document150 pagesSAP BI Material (1) .Girish HNo ratings yet

- 2024 MAQ Software - Job Description - Software Engineer 1 - High PotDocument4 pages2024 MAQ Software - Job Description - Software Engineer 1 - High Potagain00rahulNo ratings yet

- Digitally Transforming Innovation and ExperienceDocument13 pagesDigitally Transforming Innovation and ExperienceMohammad Yasser Ramzan100% (1)

- Certificate in Business Intelligence With Power BiDocument6 pagesCertificate in Business Intelligence With Power BiNadesh BhandoyNo ratings yet

- Dhanyan T MDocument1 pageDhanyan T MDoze uncleNo ratings yet

- Business Process Automation in Manufacturing PDFDocument4 pagesBusiness Process Automation in Manufacturing PDFRohitNo ratings yet

- The Data Dividend Fueling Generative AiDocument9 pagesThe Data Dividend Fueling Generative Aifrank.ogata7837No ratings yet

- Case Study 2Document15 pagesCase Study 2Abdullah ghauriNo ratings yet

- Mark Progano: ExperienceDocument2 pagesMark Progano: ExperienceDaniyal Ali SyedNo ratings yet

- Businessintelligence Overview (5373)Document26 pagesBusinessintelligence Overview (5373)Arwin SomoNo ratings yet

- Technical ValueDocument30 pagesTechnical ValueAmine El PachoNo ratings yet

- Agile AI Crunching Time To MarketDocument6 pagesAgile AI Crunching Time To MarkethydblueNo ratings yet

- Unit 1 - Introduction To Business Intelligence and Big Data AnalyticsDocument36 pagesUnit 1 - Introduction To Business Intelligence and Big Data AnalyticsNile SethNo ratings yet

- Alilin v. Petron Corp.Document12 pagesAlilin v. Petron Corp.AnnieNo ratings yet

- Beginners Guide To Voip WP 2016Document13 pagesBeginners Guide To Voip WP 2016sharnobyNo ratings yet

- Lab Report 2 - Corrosion of IronDocument5 pagesLab Report 2 - Corrosion of IronATHALIAH JENINE TABUCLIN BANTUGNo ratings yet

- TCW Modules MidtermsDocument11 pagesTCW Modules MidtermsSTEM-PERALTA RYZA M.No ratings yet

- Kumar Sabnani Org CultureDocument2 pagesKumar Sabnani Org CultureAayushi SinghNo ratings yet

- Group 1 - OfW RemittancesDocument22 pagesGroup 1 - OfW RemittancesFLORENCE MAY SUMINDOLNo ratings yet

- DEVELOPMENT BANK OF RIZAL vs. SIMA WEIDocument2 pagesDEVELOPMENT BANK OF RIZAL vs. SIMA WEIelaine bercenioNo ratings yet

- Disklavier Mark III DGC1B Basic Operation ManualDocument74 pagesDisklavier Mark III DGC1B Basic Operation ManualDr. Emmett Lathrop "Doc" Brown100% (1)

- South Indian RecipesDocument7 pagesSouth Indian RecipesJagannath AcharyaNo ratings yet

- Role of It in Banking ReportDocument27 pagesRole of It in Banking ReportPrathmesh JambhulkarNo ratings yet

- English To Telugu Vegetables NamesDocument6 pagesEnglish To Telugu Vegetables NamesUbed Ahmed73% (15)

- Brigham Chap 11 Practice Questions Solution For Chap 11Document11 pagesBrigham Chap 11 Practice Questions Solution For Chap 11robin.asterNo ratings yet

- Mtz28je5ave MTZ28 5viDocument6 pagesMtz28je5ave MTZ28 5viIRAN FREONNo ratings yet

- 6 - Benign Breast DiseaseDocument10 pages6 - Benign Breast DiseasebernijesiNo ratings yet

- Cuttack Chapter 2Document38 pagesCuttack Chapter 2jagadeeshnayakNo ratings yet

- Ketlie Augustin, A097 199 166 (BIA March 17, 2017)Document2 pagesKetlie Augustin, A097 199 166 (BIA March 17, 2017)Immigrant & Refugee Appellate Center, LLC0% (1)

- FansDocument5 pagesFansJoydev Ganguly100% (1)

- Why We Need The Individual MandateDocument3 pagesWhy We Need The Individual MandateCenter for American ProgressNo ratings yet

- Seeing Women As Objects (European Journal of Social Psychology, 2012)Document11 pagesSeeing Women As Objects (European Journal of Social Psychology, 2012)incaudasemperNo ratings yet

- Manual de Instruções Marantz SR-7500 DFU - 00 - CoverDocument56 pagesManual de Instruções Marantz SR-7500 DFU - 00 - CoverAntonio VidalNo ratings yet

- Marki DuvanaDocument27 pagesMarki DuvanamijpedjapedjaNo ratings yet

- Metroparks Magazine, Spring-Summer '11Document32 pagesMetroparks Magazine, Spring-Summer '11MyMetroparksNo ratings yet

- (Environmental Pollution 16) Kai Bester, Christa S. McArdell, Cajsa Wahlberg, Thomas D. Bucheli (Auth.), Despo Fatta-Kassinos, Kai Bester, Klaus Kümmerer (Eds.) - Xenobiotics in The Urban WaterDocument521 pages(Environmental Pollution 16) Kai Bester, Christa S. McArdell, Cajsa Wahlberg, Thomas D. Bucheli (Auth.), Despo Fatta-Kassinos, Kai Bester, Klaus Kümmerer (Eds.) - Xenobiotics in The Urban WaterKarlysson JorddanNo ratings yet

- Juicy Fruits and Whipped Creme AfghanDocument2 pagesJuicy Fruits and Whipped Creme AfghankbaisieNo ratings yet

- Ap Lang Syllabus 2013 PDFDocument9 pagesAp Lang Syllabus 2013 PDFjbk23No ratings yet

- BinggrisDocument11 pagesBinggrisDina Putri RachmandariNo ratings yet

- 001Document2 pages001Adnan DizdarNo ratings yet

ThoughtSpot Manufacturing Fortune 500 Case Study

ThoughtSpot Manufacturing Fortune 500 Case Study

Uploaded by

Shahnawaz JavedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ThoughtSpot Manufacturing Fortune 500 Case Study

ThoughtSpot Manufacturing Fortune 500 Case Study

Uploaded by

Shahnawaz JavedCopyright:

Available Formats

INDUSTRY SUCCESS STORY

Data-Driven Manufacturer: Managing

Operations with Search-Driven Analytics

FORTUNE

500 MANUFACTURING

Data-Driven Operations

Manufacturers are faced with razor-thin margins. They

Highlights

work hard to bring the best products to market faster

and more efficiently than their competitors. From supply

chain and facilities management to product design and

100 Users

HR, they are always looking to identify bottlenecks and Product Delivery,

Operations,

optimize production operations. Data captured at all

Customer Care

levels of production help drive these efficiencies.

One global semiconductor manufacturer produces

billions of computer chips each year. The faster and 200 GB

more efficiently they can move new ideas through the

Production

development process and into the hands of customers, Design, Microsoft,

the more revenue they can generate. Salesforce.com

Limited Views Slow Production 1300 Searches

Ad hoc searches

For this semiconductor manufacturing company, weekly across the

engineering operations teams are tasked with analyzing organization

project plans and product design data to build higher-

performing products, reduce operational costs, and beat

competitor devices. The teams used multiple BI tools—

including Cognos, Oracle OBIEE, and QlikView—to try

and get visibility into product and operations data.

Unfortunately, because these tools were too complex

for the engineers to use, they relied heavily on the

BI team to set up their data and produce reports for 10% Cost Reduction

them. The overworked BI team struggled to get data

into engineers’ hands fast enough. And this proved to Engineers identified opportunities to

be a bottleneck of it’s own, slowing production across reduce costs in product materials.

product lines.

Using Search to Analyze Data in Seconds

“

Eliminating Bottlenecks

To give engineers faster visibility into operational data,

the company needed a BI solution that would be easy Now our BI team

enough for anyone to use, but would still allow for

analysis across multiple data sources.

can focus on

Now engineering management can analyze headcount, strategic projects,

design goals, and project milestones by product and tier

to optimize the entire delivery process. instead of being

With ThoughtSpot they no longer have to wait for the BI distracted by a

team to create reports for them, anyone can use search

to analyze and drill down into any metric. backlog of report

- HEAD OF BI,

Self-Service Analytics for All FORTUNE 500 MANUFACTURER

Now ThoughtSpot is an integral part of the BI stack at

this manufacturer:

• The product delivery team is using ThoughtSpot to

analyze test result data from the subcomponents of

microchips. They are performing root-cause analysis by

component and defect to see what areas are causing

the biggest problems and fix them quickly. They are now

delivering products to customers 10% faster.

• The engineering operations team is using

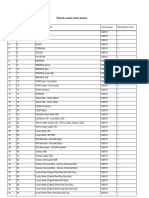

ThoughtSpot to optimize the supply chain, and have Total Material Cost, Avg Chip Area by Day

eliminated delays in the product pipeline.

• The customer service team is using ThoughtSpot to

identify trends around cases by customer, product and

region—they have improved productivity and customer

satisfaction by 15%.

With access to search-driven analytics, business users

at this manufacturing company are performing 1,300

searches a week. Teams have been able to increase

productivity, reduce material waste, and streamlining

operations at all levels of the business.

DON’T BI. JUST SEARCH.

www.thoughtspot.com

(800)-508-7008

You might also like

- Itunes Gifted Card Format-1Document1 pageItunes Gifted Card Format-1Mr Naijatim89% (281)

- Ceb The New It Operating Model For Digital ItlexDocument17 pagesCeb The New It Operating Model For Digital ItlexMario Morales RodriguezNo ratings yet

- How Can The Law Be Used As An Instrument For Creating Social Change - IpleadersDocument13 pagesHow Can The Law Be Used As An Instrument For Creating Social Change - IpleadersLeelakrishna VemuruNo ratings yet

- Alang Ship BreakersDocument29 pagesAlang Ship Breakerspureman35100% (1)

- Data-Driven Manufacturer: Managing Operations With Search-Driven AnalyticsDocument2 pagesData-Driven Manufacturer: Managing Operations With Search-Driven AnalyticsDavid VillalobosNo ratings yet

- LogiAnalytics BuildingvsBuyingDocument21 pagesLogiAnalytics BuildingvsBuyingHafidz Ash ShidieqyNo ratings yet

- Tech Weirdo ProfileDocument13 pagesTech Weirdo ProfileAnonymous pl7BvPDNo ratings yet

- Digital Manufacturing: "Enabling Lean For More Flexible Manufacturing"Document12 pagesDigital Manufacturing: "Enabling Lean For More Flexible Manufacturing"Anonymous MN9BRMNo ratings yet

- Miskuf 2016Document5 pagesMiskuf 2016Lê NaNo ratings yet

- Business Analytics MDS Enablement-CompressedDocument28 pagesBusiness Analytics MDS Enablement-CompressedWaleed BahgatNo ratings yet

- Become A Digital Industrial Company: GE Digital's Portfolio OverviewDocument8 pagesBecome A Digital Industrial Company: GE Digital's Portfolio Overviewjoko sumarionoNo ratings yet

- Styles of Enteprise BI and Analyics PDFDocument8 pagesStyles of Enteprise BI and Analyics PDFSyeda FarwaNo ratings yet

- Manufacturing 4.0Document36 pagesManufacturing 4.0msavioNo ratings yet

- Industrial IoT WhitepaperDocument11 pagesIndustrial IoT WhitepaperRony JamesNo ratings yet

- Business Intelligence PresentationDocument42 pagesBusiness Intelligence Presentationahmed abotalebNo ratings yet

- 91social Company Overview and CapabilitiesDocument22 pages91social Company Overview and CapabilitiesMahesh SharmaNo ratings yet

- CredentialDocument17 pagesCredentialJAMstack Vietnam Nhân VõNo ratings yet

- Pentaho Expands European OperationsDocument57 pagesPentaho Expands European OperationselizdelimaNo ratings yet

- Analytic FactoryDocument1 pageAnalytic FactoryJohn JiménezNo ratings yet

- Digital Product Development 2025Document45 pagesDigital Product Development 2025IswandiNo ratings yet

- Power BI BrochureDocument16 pagesPower BI BrochurePreetam ShettyNo ratings yet

- Business Analytics ToolsDocument22 pagesBusiness Analytics ToolsAna-Maria Nicoleta VladNo ratings yet

- Introducing Acies - SnapshotDocument1 pageIntroducing Acies - Snapshotsubhashm.dasariNo ratings yet

- Digital Factory: The Information Systems AspectDocument17 pagesDigital Factory: The Information Systems AspectMona IbrahimNo ratings yet

- 69892business Intelligence Redefining ManufacturingDocument11 pages69892business Intelligence Redefining Manufacturingsahendra4673No ratings yet

- Connect Your Data To Your Decision Making: Ebook SeriesDocument20 pagesConnect Your Data To Your Decision Making: Ebook SeriesovirogerNo ratings yet

- ARC View Honeywell Forge Production InsightsDocument9 pagesARC View Honeywell Forge Production InsightsRafia Afzal Muhammad AfzalNo ratings yet

- Powerapps Innovation For Everyone HandoutDocument1 pagePowerapps Innovation For Everyone Handouthj7nfx8bz2No ratings yet

- Power BiDocument39 pagesPower BiKase Hija IndiaNo ratings yet

- PLM Application Acceleration: Optimize Performance in Distributed R&D EnvironmentsDocument6 pagesPLM Application Acceleration: Optimize Performance in Distributed R&D EnvironmentsMTNo ratings yet

- Modern Guide To PLM EbookDocument14 pagesModern Guide To PLM EbookChamakmak MokazkazNo ratings yet

- Connected Factories IotDocument2 pagesConnected Factories IotvitrahulNo ratings yet

- Rapid Fire BI A New Approach To Business Intelligence TableauDocument16 pagesRapid Fire BI A New Approach To Business Intelligence TableauMichaël MemeteauNo ratings yet

- Modern Guide To PLM EbookDocument14 pagesModern Guide To PLM Ebookanoop krNo ratings yet

- Introduction of Data Analysis Product IODocument28 pagesIntroduction of Data Analysis Product IOAlejandro ArteagaNo ratings yet

- Upskill TechnologiesDocument6 pagesUpskill TechnologiesAmresh MehtaNo ratings yet

- Forrester - The Total Economic Impact™ of IBM Cognos AnalyticsDocument21 pagesForrester - The Total Economic Impact™ of IBM Cognos AnalyticsDave CashinNo ratings yet

- Cognos Right Architecture For BiDocument13 pagesCognos Right Architecture For BiGaurav GargNo ratings yet

- IBM - Big Data AnalyticsDocument22 pagesIBM - Big Data AnalyticsJohn AngelopoulosNo ratings yet

- Michael R. Resume - ProductDocument2 pagesMichael R. Resume - ProductMichael RobertsNo ratings yet

- Brochure NeoDigital USADocument10 pagesBrochure NeoDigital USALuis Enrique CastroNo ratings yet

- Manufacturing Industry FinalDocument15 pagesManufacturing Industry FinalBhakti Mehta100% (1)

- BrochureCosmetics-Lascom Lime CloudDocument27 pagesBrochureCosmetics-Lascom Lime Cloudnguyen hong loanNo ratings yet

- Acies Global - IntroductionDocument1 pageAcies Global - IntroductionGIRIDHAR ANo ratings yet

- DTI Digital-Engineering201806122 V07Document40 pagesDTI Digital-Engineering201806122 V07lourineb89No ratings yet

- Chris Caputo Product ManagerDocument1 pageChris Caputo Product ManagerMukund MakhijaNo ratings yet

- En AU CNTNT Ebook How To Supercharge Your Application With Embedded AnalyticsDocument7 pagesEn AU CNTNT Ebook How To Supercharge Your Application With Embedded AnalyticsernestoNo ratings yet

- How To Supercharge Your Application With Embedded AnalyticsDocument7 pagesHow To Supercharge Your Application With Embedded AnalyticsParag GargNo ratings yet

- Knowledge Management in Manufacturing SectorDocument22 pagesKnowledge Management in Manufacturing SectorVaishnavi PreranaNo ratings yet

- SAP BI Material (1) .Document150 pagesSAP BI Material (1) .Girish HNo ratings yet

- 2024 MAQ Software - Job Description - Software Engineer 1 - High PotDocument4 pages2024 MAQ Software - Job Description - Software Engineer 1 - High Potagain00rahulNo ratings yet

- Digitally Transforming Innovation and ExperienceDocument13 pagesDigitally Transforming Innovation and ExperienceMohammad Yasser Ramzan100% (1)

- Certificate in Business Intelligence With Power BiDocument6 pagesCertificate in Business Intelligence With Power BiNadesh BhandoyNo ratings yet

- Dhanyan T MDocument1 pageDhanyan T MDoze uncleNo ratings yet

- Business Process Automation in Manufacturing PDFDocument4 pagesBusiness Process Automation in Manufacturing PDFRohitNo ratings yet

- The Data Dividend Fueling Generative AiDocument9 pagesThe Data Dividend Fueling Generative Aifrank.ogata7837No ratings yet

- Case Study 2Document15 pagesCase Study 2Abdullah ghauriNo ratings yet

- Mark Progano: ExperienceDocument2 pagesMark Progano: ExperienceDaniyal Ali SyedNo ratings yet

- Businessintelligence Overview (5373)Document26 pagesBusinessintelligence Overview (5373)Arwin SomoNo ratings yet

- Technical ValueDocument30 pagesTechnical ValueAmine El PachoNo ratings yet

- Agile AI Crunching Time To MarketDocument6 pagesAgile AI Crunching Time To MarkethydblueNo ratings yet

- Unit 1 - Introduction To Business Intelligence and Big Data AnalyticsDocument36 pagesUnit 1 - Introduction To Business Intelligence and Big Data AnalyticsNile SethNo ratings yet

- Alilin v. Petron Corp.Document12 pagesAlilin v. Petron Corp.AnnieNo ratings yet

- Beginners Guide To Voip WP 2016Document13 pagesBeginners Guide To Voip WP 2016sharnobyNo ratings yet

- Lab Report 2 - Corrosion of IronDocument5 pagesLab Report 2 - Corrosion of IronATHALIAH JENINE TABUCLIN BANTUGNo ratings yet

- TCW Modules MidtermsDocument11 pagesTCW Modules MidtermsSTEM-PERALTA RYZA M.No ratings yet

- Kumar Sabnani Org CultureDocument2 pagesKumar Sabnani Org CultureAayushi SinghNo ratings yet

- Group 1 - OfW RemittancesDocument22 pagesGroup 1 - OfW RemittancesFLORENCE MAY SUMINDOLNo ratings yet

- DEVELOPMENT BANK OF RIZAL vs. SIMA WEIDocument2 pagesDEVELOPMENT BANK OF RIZAL vs. SIMA WEIelaine bercenioNo ratings yet

- Disklavier Mark III DGC1B Basic Operation ManualDocument74 pagesDisklavier Mark III DGC1B Basic Operation ManualDr. Emmett Lathrop "Doc" Brown100% (1)

- South Indian RecipesDocument7 pagesSouth Indian RecipesJagannath AcharyaNo ratings yet

- Role of It in Banking ReportDocument27 pagesRole of It in Banking ReportPrathmesh JambhulkarNo ratings yet

- English To Telugu Vegetables NamesDocument6 pagesEnglish To Telugu Vegetables NamesUbed Ahmed73% (15)

- Brigham Chap 11 Practice Questions Solution For Chap 11Document11 pagesBrigham Chap 11 Practice Questions Solution For Chap 11robin.asterNo ratings yet

- Mtz28je5ave MTZ28 5viDocument6 pagesMtz28je5ave MTZ28 5viIRAN FREONNo ratings yet

- 6 - Benign Breast DiseaseDocument10 pages6 - Benign Breast DiseasebernijesiNo ratings yet

- Cuttack Chapter 2Document38 pagesCuttack Chapter 2jagadeeshnayakNo ratings yet

- Ketlie Augustin, A097 199 166 (BIA March 17, 2017)Document2 pagesKetlie Augustin, A097 199 166 (BIA March 17, 2017)Immigrant & Refugee Appellate Center, LLC0% (1)

- FansDocument5 pagesFansJoydev Ganguly100% (1)

- Why We Need The Individual MandateDocument3 pagesWhy We Need The Individual MandateCenter for American ProgressNo ratings yet

- Seeing Women As Objects (European Journal of Social Psychology, 2012)Document11 pagesSeeing Women As Objects (European Journal of Social Psychology, 2012)incaudasemperNo ratings yet

- Manual de Instruções Marantz SR-7500 DFU - 00 - CoverDocument56 pagesManual de Instruções Marantz SR-7500 DFU - 00 - CoverAntonio VidalNo ratings yet

- Marki DuvanaDocument27 pagesMarki DuvanamijpedjapedjaNo ratings yet

- Metroparks Magazine, Spring-Summer '11Document32 pagesMetroparks Magazine, Spring-Summer '11MyMetroparksNo ratings yet

- (Environmental Pollution 16) Kai Bester, Christa S. McArdell, Cajsa Wahlberg, Thomas D. Bucheli (Auth.), Despo Fatta-Kassinos, Kai Bester, Klaus Kümmerer (Eds.) - Xenobiotics in The Urban WaterDocument521 pages(Environmental Pollution 16) Kai Bester, Christa S. McArdell, Cajsa Wahlberg, Thomas D. Bucheli (Auth.), Despo Fatta-Kassinos, Kai Bester, Klaus Kümmerer (Eds.) - Xenobiotics in The Urban WaterKarlysson JorddanNo ratings yet

- Juicy Fruits and Whipped Creme AfghanDocument2 pagesJuicy Fruits and Whipped Creme AfghankbaisieNo ratings yet

- Ap Lang Syllabus 2013 PDFDocument9 pagesAp Lang Syllabus 2013 PDFjbk23No ratings yet

- BinggrisDocument11 pagesBinggrisDina Putri RachmandariNo ratings yet

- 001Document2 pages001Adnan DizdarNo ratings yet