Professional Documents

Culture Documents

1a1-Metal Drum - Non Removabe Head

1a1-Metal Drum - Non Removabe Head

Uploaded by

MASTER SOURCECopyright:

Available Formats

You might also like

- IWCF Well Control Practice Test (ENFORM)Document12 pagesIWCF Well Control Practice Test (ENFORM)Houssam Adjina88% (8)

- ASME VIII Open Book ExamDocument8 pagesASME VIII Open Book Examraymondpayson447No ratings yet

- 1H1 Plastic Drum Non Removable HeadDocument1 page1H1 Plastic Drum Non Removable HeadMASTER SOURCENo ratings yet

- 1H1 Plastic PailDocument1 page1H1 Plastic PailMASTER SOURCENo ratings yet

- Aiv Test For AggregateDocument2 pagesAiv Test For AggregateQuality JamNo ratings yet

- Asme Sec Viii Closed QB (106-120)Document15 pagesAsme Sec Viii Closed QB (106-120)slxanto100% (1)

- Api 598Document13 pagesApi 598SurachaiAumongkolNo ratings yet

- Mechanical Q1Document8 pagesMechanical Q1Ahmed HaridiNo ratings yet

- Determination of Penetration Value of Bitumen: ObjectiveDocument5 pagesDetermination of Penetration Value of Bitumen: ObjectiveSudip Shrestha100% (1)

- Sprinkel PDFDocument38 pagesSprinkel PDFAlex S. RahalusNo ratings yet

- Cavitation Characteristics of Restriction OrificesDocument8 pagesCavitation Characteristics of Restriction Orificesrogel_ganaNo ratings yet

- BASIC CIVIL ENGINEERING MANUAL Updated On 28.6.22Document14 pagesBASIC CIVIL ENGINEERING MANUAL Updated On 28.6.22Not RookieNo ratings yet

- Test (2) 1Document3 pagesTest (2) 1Tefelo TsimaneNo ratings yet

- Questions - Mechanical Engineering Principle Lecture and Tutorial - Covering Basics On Distance, Velocity, Time, Pendulum, Hydrostatic Pressure, Fluids, Solids, EtcDocument8 pagesQuestions - Mechanical Engineering Principle Lecture and Tutorial - Covering Basics On Distance, Velocity, Time, Pendulum, Hydrostatic Pressure, Fluids, Solids, EtcshanecarlNo ratings yet

- Shell Minimum Thickness Calculations: D (FT) G E Fill Height (FT)Document2 pagesShell Minimum Thickness Calculations: D (FT) G E Fill Height (FT)trijaya landscapeNo ratings yet

- Determination of PenetrationDocument57 pagesDetermination of Penetrationtunlaji0% (2)

- TilesDocument84 pagesTilesgagan raoNo ratings yet

- Subjuct/Module: Level: Lab / Experiment NameDocument8 pagesSubjuct/Module: Level: Lab / Experiment NameTEDDYNo ratings yet

- Some Basic Questions2Document11 pagesSome Basic Questions2sys02No ratings yet

- 510 Daily PointsDocument12 pages510 Daily Pointscengiz88No ratings yet

- Acoustic Emission Testing and Structural Evaluation of Seamless Steel Tubs in Compressed Gas ServiceDocument7 pagesAcoustic Emission Testing and Structural Evaluation of Seamless Steel Tubs in Compressed Gas ServiceJosePPMolinaNo ratings yet

- CMT Assignment2Document25 pagesCMT Assignment2Rogelio Mordeno100% (1)

- l6ll2l20L8: Fifth 2018Document16 pagesl6ll2l20L8: Fifth 2018dileepNo ratings yet

- 1 Homework-3Document1 page1 Homework-3ANDREA DANIELA VARGAS MEDINANo ratings yet

- Operating Characteristics Membranes: Donald H. Hagerbaumer and Karl KammermeyerDocument5 pagesOperating Characteristics Membranes: Donald H. Hagerbaumer and Karl KammermeyerGustavo Gabriel JimenezNo ratings yet

- HOME WORK 4 Source ModelsDocument2 pagesHOME WORK 4 Source ModelsANDREA DANIELA VARGAS MEDINANo ratings yet

- Durable Asphalt Roads Construction & Repair: Proven System. Proven Performance. Proven Cost SavingsDocument52 pagesDurable Asphalt Roads Construction & Repair: Proven System. Proven Performance. Proven Cost SavingsNajmieNo ratings yet

- Mechanical Engineering Department: Gargi Memorial Institute of TechnologyDocument2 pagesMechanical Engineering Department: Gargi Memorial Institute of Technologydream11 fightersNo ratings yet

- Procedure To Determine Water Absorption of AggregatesDocument5 pagesProcedure To Determine Water Absorption of AggregatesEr Santosh KaparNo ratings yet

- Falling Head Permeability Lab ReportDocument11 pagesFalling Head Permeability Lab ReportfatinNo ratings yet

- Aljunied - Soil Test Report PDFDocument71 pagesAljunied - Soil Test Report PDFVasaNo ratings yet

- Guide To Fire Protection in Malaysia (2006) - 8. Dry Riser System PDFDocument4 pagesGuide To Fire Protection in Malaysia (2006) - 8. Dry Riser System PDFMFaiz RHamiraNo ratings yet

- KFD Test Paper Sample Questions 1Document25 pagesKFD Test Paper Sample Questions 1ragulNo ratings yet

- Aggregate Impact ValueDocument4 pagesAggregate Impact ValueAmira Ab RahmanNo ratings yet

- API 510 PC 20 31 Aug05 Final Exam OpenDocument4 pagesAPI 510 PC 20 31 Aug05 Final Exam OpennikafiqNo ratings yet

- Viscosity Lab ReportDocument7 pagesViscosity Lab Reportcharishma takkallapalliNo ratings yet

- Aashto T283 PDFDocument7 pagesAashto T283 PDFguru nathNo ratings yet

- Hydrostatic Testing ProceduresDocument2 pagesHydrostatic Testing Proceduresomar sadiqNo ratings yet

- QM 34 - TanksDocument10 pagesQM 34 - Tanksmohamed elmasryNo ratings yet

- Drainage - TestingDocument5 pagesDrainage - TestingAnduel SELAMAJNo ratings yet

- Test Procedure-25-08-06Document49 pagesTest Procedure-25-08-06Hariom GuptaNo ratings yet

- 236 1Document30 pages236 1anon_836654017No ratings yet

- Shock Tube Example ProblemDocument1 pageShock Tube Example ProblemThomas JohnsonNo ratings yet

- CRD - c48 CRD-C48-92 Standard Test Method For Water Permeability of ConcreteDocument4 pagesCRD - c48 CRD-C48-92 Standard Test Method For Water Permeability of ConcreteazharbNo ratings yet

- Tests of AggregatesDocument18 pagesTests of AggregatesadamuNo ratings yet

- Description of FailureDocument10 pagesDescription of FailureSanjayaPremaratneNo ratings yet

- TransportationmmDocument25 pagesTransportationmmUaj AvhaNo ratings yet

- Failure Analysis and Remaining Life Assessment of Service Exposed Primary Reformer Heater TubesDocument21 pagesFailure Analysis and Remaining Life Assessment of Service Exposed Primary Reformer Heater TubesOwais MalikNo ratings yet

- SSRPL PRECAST - Test ProcedureDocument16 pagesSSRPL PRECAST - Test Procedureshankarnarayanan525No ratings yet

- Pauig - Fa : Farabaugh Engineering and TestingDocument7 pagesPauig - Fa : Farabaugh Engineering and TestingkajaqcNo ratings yet

- Fluidmechanics PYQ's 1990-2022Document171 pagesFluidmechanics PYQ's 1990-2022Ayan MurmuNo ratings yet

- Blowdown of Vessels and Pipelines: S.M. Richardson & G. SavilleDocument15 pagesBlowdown of Vessels and Pipelines: S.M. Richardson & G. SavillefaisalmuradNo ratings yet

- CE-Board-Exam-1997 Hydrau Geo OnlyDocument10 pagesCE-Board-Exam-1997 Hydrau Geo OnlyNekat EvalsNo ratings yet

- Chapter 19 Piping Handbook-DoneDocument14 pagesChapter 19 Piping Handbook-DonemrNo ratings yet

- Geotextiles and Its PropertiesDocument38 pagesGeotextiles and Its PropertiesAbhishek TrivediNo ratings yet

- 03 - MS - Pull-Out Test For TEKIZAMPA 12dec2023Document13 pages03 - MS - Pull-Out Test For TEKIZAMPA 12dec2023Dragon FramesNo ratings yet

- Test Procedure For Tantaline ValvesDocument1 pageTest Procedure For Tantaline Valves111vincent111No ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- 8356 1993 Reff2020Document11 pages8356 1993 Reff2020MASTER SOURCENo ratings yet

- Ect TestDocument105 pagesEct TestMASTER SOURCENo ratings yet

- 2508 2016 AMD3 Reff2022Document12 pages2508 2016 AMD3 Reff2022MASTER SOURCENo ratings yet

- Scope: CautionDocument4 pagesScope: CautionMASTER SOURCENo ratings yet

- AppfromDocument2 pagesAppfromMASTER SOURCENo ratings yet

- Scope: Approved by The Standard Specific Interest Group For This Test MethodDocument6 pagesScope: Approved by The Standard Specific Interest Group For This Test MethodMASTER SOURCENo ratings yet

- 1H1 Plastic Drum Non Removable HeadDocument1 page1H1 Plastic Drum Non Removable HeadMASTER SOURCENo ratings yet

- Caution:: 1. ScopeDocument4 pagesCaution:: 1. ScopeMASTER SOURCENo ratings yet

- Scope: CautionDocument6 pagesScope: CautionMASTER SOURCENo ratings yet

- Novel Method For Testing The Grease Resistance of Plastic-Based Dry Pet Food PackagingDocument8 pagesNovel Method For Testing The Grease Resistance of Plastic-Based Dry Pet Food PackagingMASTER SOURCENo ratings yet

- 1H1 Plastic PailDocument1 page1H1 Plastic PailMASTER SOURCENo ratings yet

- D61-75 (2010) Standard Test Method For Softening Point of Pitches (Cube-in-Water Method)Document3 pagesD61-75 (2010) Standard Test Method For Softening Point of Pitches (Cube-in-Water Method)MASTER SOURCENo ratings yet

1a1-Metal Drum - Non Removabe Head

1a1-Metal Drum - Non Removabe Head

Uploaded by

MASTER SOURCEOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1a1-Metal Drum - Non Removabe Head

1a1-Metal Drum - Non Removabe Head

Uploaded by

MASTER SOURCECopyright:

Available Formats

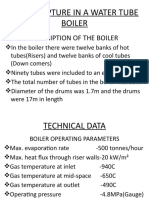

1A1-METAL DRUM–NONREMOVABLE HEAD- UN

CERTIFICATION TEST

SAMPLE One set (15 Nos.) of 20 litre capacity, non-removable head type Steel drums. The drums

DESCRIPTION were said to be used for the Packaging of product reflected in the Certificate mentioned

above.

For testing purposes, each drum was filled with water up to 98% of its total capacity. The

opening of the drum was closed by metallic screw cap provided with rubber washer.

Maximum external height of the drum (mm) : 377.00

Maximum external diameter of the drum (mm) : 277.00

(Sampling done by the Party. Total 15 Steel Drums were brought to the Institute.)

TEST CONDITION RESULT ENTRY REMARKS

DROP TEST a) First set of samples were The drums were dented at the (Drop height :mtrs.)

dropped diagonally on top. dropped point, but no leakage was

b) Second set of samples observed from the drums.

were dropped flat on body

wall.

HYDRAULIC Drums were subjected for a Neither rupture nor leakage was

PRESSURE period of 5 minutes to a observed from the drums.

TEST hydraulic gauge pressure of

100 kPa.

LEAKAGE TEST The drums were subjected No leakage was observed from the

to an air pressure of 20 kPa closures & seams.

STACKING A superimposed weight was Neither deformation nor leakage was (stack height : 3.00

TEST

placed on a flat surface observed from the drums. mtrs.)

resting on the top of the

drum for a period of 24

hours. The weight was

equivalent to the total

weight of filled identical

drums, which could be

stacked on it during the

transport.

Note: Hydraulic PG 2&3 - (100 KPA) – 5 MINUTES,

PG 1 - 250 KPA - 5 MINUTES.

Air Leakage PG1 – 30 KPA,

PG2 & 3 -20 KPA– 5 MINUTES.

DROP HEIGHT IF DENSITY MORE THAN 1.2 THEN X = Dx1.5, Y = Dx1, Z = Dx0.67m.

You might also like

- IWCF Well Control Practice Test (ENFORM)Document12 pagesIWCF Well Control Practice Test (ENFORM)Houssam Adjina88% (8)

- ASME VIII Open Book ExamDocument8 pagesASME VIII Open Book Examraymondpayson447No ratings yet

- 1H1 Plastic Drum Non Removable HeadDocument1 page1H1 Plastic Drum Non Removable HeadMASTER SOURCENo ratings yet

- 1H1 Plastic PailDocument1 page1H1 Plastic PailMASTER SOURCENo ratings yet

- Aiv Test For AggregateDocument2 pagesAiv Test For AggregateQuality JamNo ratings yet

- Asme Sec Viii Closed QB (106-120)Document15 pagesAsme Sec Viii Closed QB (106-120)slxanto100% (1)

- Api 598Document13 pagesApi 598SurachaiAumongkolNo ratings yet

- Mechanical Q1Document8 pagesMechanical Q1Ahmed HaridiNo ratings yet

- Determination of Penetration Value of Bitumen: ObjectiveDocument5 pagesDetermination of Penetration Value of Bitumen: ObjectiveSudip Shrestha100% (1)

- Sprinkel PDFDocument38 pagesSprinkel PDFAlex S. RahalusNo ratings yet

- Cavitation Characteristics of Restriction OrificesDocument8 pagesCavitation Characteristics of Restriction Orificesrogel_ganaNo ratings yet

- BASIC CIVIL ENGINEERING MANUAL Updated On 28.6.22Document14 pagesBASIC CIVIL ENGINEERING MANUAL Updated On 28.6.22Not RookieNo ratings yet

- Test (2) 1Document3 pagesTest (2) 1Tefelo TsimaneNo ratings yet

- Questions - Mechanical Engineering Principle Lecture and Tutorial - Covering Basics On Distance, Velocity, Time, Pendulum, Hydrostatic Pressure, Fluids, Solids, EtcDocument8 pagesQuestions - Mechanical Engineering Principle Lecture and Tutorial - Covering Basics On Distance, Velocity, Time, Pendulum, Hydrostatic Pressure, Fluids, Solids, EtcshanecarlNo ratings yet

- Shell Minimum Thickness Calculations: D (FT) G E Fill Height (FT)Document2 pagesShell Minimum Thickness Calculations: D (FT) G E Fill Height (FT)trijaya landscapeNo ratings yet

- Determination of PenetrationDocument57 pagesDetermination of Penetrationtunlaji0% (2)

- TilesDocument84 pagesTilesgagan raoNo ratings yet

- Subjuct/Module: Level: Lab / Experiment NameDocument8 pagesSubjuct/Module: Level: Lab / Experiment NameTEDDYNo ratings yet

- Some Basic Questions2Document11 pagesSome Basic Questions2sys02No ratings yet

- 510 Daily PointsDocument12 pages510 Daily Pointscengiz88No ratings yet

- Acoustic Emission Testing and Structural Evaluation of Seamless Steel Tubs in Compressed Gas ServiceDocument7 pagesAcoustic Emission Testing and Structural Evaluation of Seamless Steel Tubs in Compressed Gas ServiceJosePPMolinaNo ratings yet

- CMT Assignment2Document25 pagesCMT Assignment2Rogelio Mordeno100% (1)

- l6ll2l20L8: Fifth 2018Document16 pagesl6ll2l20L8: Fifth 2018dileepNo ratings yet

- 1 Homework-3Document1 page1 Homework-3ANDREA DANIELA VARGAS MEDINANo ratings yet

- Operating Characteristics Membranes: Donald H. Hagerbaumer and Karl KammermeyerDocument5 pagesOperating Characteristics Membranes: Donald H. Hagerbaumer and Karl KammermeyerGustavo Gabriel JimenezNo ratings yet

- HOME WORK 4 Source ModelsDocument2 pagesHOME WORK 4 Source ModelsANDREA DANIELA VARGAS MEDINANo ratings yet

- Durable Asphalt Roads Construction & Repair: Proven System. Proven Performance. Proven Cost SavingsDocument52 pagesDurable Asphalt Roads Construction & Repair: Proven System. Proven Performance. Proven Cost SavingsNajmieNo ratings yet

- Mechanical Engineering Department: Gargi Memorial Institute of TechnologyDocument2 pagesMechanical Engineering Department: Gargi Memorial Institute of Technologydream11 fightersNo ratings yet

- Procedure To Determine Water Absorption of AggregatesDocument5 pagesProcedure To Determine Water Absorption of AggregatesEr Santosh KaparNo ratings yet

- Falling Head Permeability Lab ReportDocument11 pagesFalling Head Permeability Lab ReportfatinNo ratings yet

- Aljunied - Soil Test Report PDFDocument71 pagesAljunied - Soil Test Report PDFVasaNo ratings yet

- Guide To Fire Protection in Malaysia (2006) - 8. Dry Riser System PDFDocument4 pagesGuide To Fire Protection in Malaysia (2006) - 8. Dry Riser System PDFMFaiz RHamiraNo ratings yet

- KFD Test Paper Sample Questions 1Document25 pagesKFD Test Paper Sample Questions 1ragulNo ratings yet

- Aggregate Impact ValueDocument4 pagesAggregate Impact ValueAmira Ab RahmanNo ratings yet

- API 510 PC 20 31 Aug05 Final Exam OpenDocument4 pagesAPI 510 PC 20 31 Aug05 Final Exam OpennikafiqNo ratings yet

- Viscosity Lab ReportDocument7 pagesViscosity Lab Reportcharishma takkallapalliNo ratings yet

- Aashto T283 PDFDocument7 pagesAashto T283 PDFguru nathNo ratings yet

- Hydrostatic Testing ProceduresDocument2 pagesHydrostatic Testing Proceduresomar sadiqNo ratings yet

- QM 34 - TanksDocument10 pagesQM 34 - Tanksmohamed elmasryNo ratings yet

- Drainage - TestingDocument5 pagesDrainage - TestingAnduel SELAMAJNo ratings yet

- Test Procedure-25-08-06Document49 pagesTest Procedure-25-08-06Hariom GuptaNo ratings yet

- 236 1Document30 pages236 1anon_836654017No ratings yet

- Shock Tube Example ProblemDocument1 pageShock Tube Example ProblemThomas JohnsonNo ratings yet

- CRD - c48 CRD-C48-92 Standard Test Method For Water Permeability of ConcreteDocument4 pagesCRD - c48 CRD-C48-92 Standard Test Method For Water Permeability of ConcreteazharbNo ratings yet

- Tests of AggregatesDocument18 pagesTests of AggregatesadamuNo ratings yet

- Description of FailureDocument10 pagesDescription of FailureSanjayaPremaratneNo ratings yet

- TransportationmmDocument25 pagesTransportationmmUaj AvhaNo ratings yet

- Failure Analysis and Remaining Life Assessment of Service Exposed Primary Reformer Heater TubesDocument21 pagesFailure Analysis and Remaining Life Assessment of Service Exposed Primary Reformer Heater TubesOwais MalikNo ratings yet

- SSRPL PRECAST - Test ProcedureDocument16 pagesSSRPL PRECAST - Test Procedureshankarnarayanan525No ratings yet

- Pauig - Fa : Farabaugh Engineering and TestingDocument7 pagesPauig - Fa : Farabaugh Engineering and TestingkajaqcNo ratings yet

- Fluidmechanics PYQ's 1990-2022Document171 pagesFluidmechanics PYQ's 1990-2022Ayan MurmuNo ratings yet

- Blowdown of Vessels and Pipelines: S.M. Richardson & G. SavilleDocument15 pagesBlowdown of Vessels and Pipelines: S.M. Richardson & G. SavillefaisalmuradNo ratings yet

- CE-Board-Exam-1997 Hydrau Geo OnlyDocument10 pagesCE-Board-Exam-1997 Hydrau Geo OnlyNekat EvalsNo ratings yet

- Chapter 19 Piping Handbook-DoneDocument14 pagesChapter 19 Piping Handbook-DonemrNo ratings yet

- Geotextiles and Its PropertiesDocument38 pagesGeotextiles and Its PropertiesAbhishek TrivediNo ratings yet

- 03 - MS - Pull-Out Test For TEKIZAMPA 12dec2023Document13 pages03 - MS - Pull-Out Test For TEKIZAMPA 12dec2023Dragon FramesNo ratings yet

- Test Procedure For Tantaline ValvesDocument1 pageTest Procedure For Tantaline Valves111vincent111No ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- 8356 1993 Reff2020Document11 pages8356 1993 Reff2020MASTER SOURCENo ratings yet

- Ect TestDocument105 pagesEct TestMASTER SOURCENo ratings yet

- 2508 2016 AMD3 Reff2022Document12 pages2508 2016 AMD3 Reff2022MASTER SOURCENo ratings yet

- Scope: CautionDocument4 pagesScope: CautionMASTER SOURCENo ratings yet

- AppfromDocument2 pagesAppfromMASTER SOURCENo ratings yet

- Scope: Approved by The Standard Specific Interest Group For This Test MethodDocument6 pagesScope: Approved by The Standard Specific Interest Group For This Test MethodMASTER SOURCENo ratings yet

- 1H1 Plastic Drum Non Removable HeadDocument1 page1H1 Plastic Drum Non Removable HeadMASTER SOURCENo ratings yet

- Caution:: 1. ScopeDocument4 pagesCaution:: 1. ScopeMASTER SOURCENo ratings yet

- Scope: CautionDocument6 pagesScope: CautionMASTER SOURCENo ratings yet

- Novel Method For Testing The Grease Resistance of Plastic-Based Dry Pet Food PackagingDocument8 pagesNovel Method For Testing The Grease Resistance of Plastic-Based Dry Pet Food PackagingMASTER SOURCENo ratings yet

- 1H1 Plastic PailDocument1 page1H1 Plastic PailMASTER SOURCENo ratings yet

- D61-75 (2010) Standard Test Method For Softening Point of Pitches (Cube-in-Water Method)Document3 pagesD61-75 (2010) Standard Test Method For Softening Point of Pitches (Cube-in-Water Method)MASTER SOURCENo ratings yet