Professional Documents

Culture Documents

K Gopinadth

K Gopinadth

Uploaded by

GEOGIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

K Gopinadth

K Gopinadth

Uploaded by

GEOGICopyright:

Available Formats

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

EVALUATION OF RIPPER AND DOZER IN METALLIC AND

NON METALLIC SURFACE MINES

1

K GOPINATH, 2Mr.K.MANOJ, 3Mr. K.S. RAMBABU

1

M.Tech Student, 2,3Assistant Professor

Department of Mechanical Engineering

KAKINADA INSTITUTE OF TECHNOLOGICAL SCIENCES, Ramachandrapuram

ABSTRACT When this idea made its way to Europe, new

Drilling and blasting activities are needed in open cast technologies were brought into play as well. Then, in

mining in order to recover ore or coal while also the late middle period and the beginning of the modern

freeing the strata. Drilling and blasting activities are age, the development of dynamite accelerated the

linked to a variety of issues, including the creation of speed of mining.

dust, the evolution of hazardous gases, ground The usage of ammonium nitrate and many other

vibrations, crack development, and noise production. explosives has miraculously boosted the amount of

As a consequence, these operations aren't seen as food produced these days.

environmentally beneficial. As a result, we're looking

for a blast-free mining technique. These procedures However, the correct use of drilling patterns and the

are also excessively expensive since they need a lot of positioning of holes with the appropriate quantity of

equipment and labour. To save the environment, blast- explosives ensures the effectiveness of rock breaking.

free mining is the era's need. Ripper dozer has been The development of different blasting and drilling

identified as a potential option as a consequence of methods was also linked with the advancement of

different types of investigations and research. Ripper transportation and loading procedures, which allowed

is mostly used for the removal of overburden. It not for greater production rates to be achieved. With such

only lowers the number of machines on the job, but it a change in technology, we can see open cast mining

also provides a more effective solution to the techniques being used to mine to greater depths in the

difficulties that drilling and blasting operations may near future, allowing for deeper mining. As a

cause. As a consequence, thorough rippability consequence, we can see that open cast mining

measurement of the stratum with the current accounts for 70% of the overall mining output in the

equipment to be installed must be done correctly globe. It is necessary to conduct drilling and blast

before installing any ripper or dozer. The rippability of operations during the open cast method of ore mining

rocks is influenced by a number of factors. The in order to achieve a high level of output. However, it

relationship between ripper restrictions and is well recognised that these activities have a variety

productivity is investigated. Rippers are used in mines of adverse impacts on the environment. As a result, in

to account for all of these limitations. today's environmentally aware society, there is a need

for alternative technologies for explosion-free,

1. INTRODUCTION environmentally friendly, and environmentally

LAYOUT: friendly mining. The combination of a ripper and a

dozer may provide a powerful and appropriate

It has been discovered via different studies and response to today's needs. It not only minimises the

investigations that mining activities date back negative impact on the environment, but it also lowers

thousands of years. Back in history, the Romans used the cost of manufacturing by reducing the mining

hydraulic mining to fracture rocks, but it really took activities.

off when the Chinese developed black powder as an

explosive during the mediaeval era, and the rest is

history.

Vol 12, Issue4, 2021 www.jrmat.com Page No:290

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

Objective: prompted the development of solutions such as the

ripper-dozer combo. It not only helps to decrease air,

The only purpose of this research is to examine the

noise, and dust pollution, but it also helps to eliminate

usability and performance of a ripper-dozer

ground vibration, which is a significant danger to the

combination in coal and metal opencast mines, as well

preservation of surface characteristics. Due to the

as to propose some contemporary advancements.

advancements in science and technology, the usage of

Research Approach: high-capacity rippers with high power has made it

feasible to utilise them as an alternative to traditional

I. In order to identify the different limitations and their drilling and blasting methods. Due to the fact that it

impact on the performance of the ripper-dozer employs the same method that ancient people

combination, a significant quantity of literature employed for plough pulled by oxen in order to

research has been conducted, as shown in Figure 1. cultivate crops, we may date the invention of rippers

to about 312 B.C. As time progressed, many

II. C++ applications are implemented in order to save

advancements were achieved, and now we can see that

computation time and update the research method.

we have rippers that can lift up to 1000 tonnes and

III. A comparison of the many Ripper dozers now operate on a tractor with a horsepower of 1000

available on the market, as well as their specifications, horsepower.

has been given.

Advantages of ripping operation:

IV. Two distinct case studies have been carried out in

An increase in both output and productivity is

order to investigate the performance and application of

achieved when we utilise the ripper-dozer combo since

the ripper dozer in question. In this study, case studies

the job is never stopped. There is no need for drilling

from the Panchpatmali mines (bauxite), the National

holes, charging the holes, and then conducting blasting

Aluminium and Limestone Corporation of India, the

operations thereafter. In contrast to this, the tearing

Damanjodi and Talabira coal OCP, and HINDALCO

process continues unbroken. As a consequence, the

were examined.

amount of idle time at work is reduced. There is no

V. This thesis also includes a discussion of recent requirement for the moving of equipment that is

technological. needed in the blasting process to occur. As a result, as

the amount of time spent working rises, so does the

2. LITERATURE REVIEW amount of output and productivity. Extraction of Rock

Contextual: with the Required Size: The size of the rock removed

during a blasting operation may vary greatly, ranging

The ripping-dozer combo first appeared in the late from boulder size to a few millimetres in size. On the

1950s. Previously, it was primarily used for the other hand, by selecting the appropriate size of the

removal of overburden. However, because to ripping machine, we may get the required size of rock

advancements in its structural design, it is currently in the quarry.

being used for the extraction of ores as well. A

bulldozer's ripper is used to cut, break, or remove rock Lowered power: As a result of the decrease in the

with the assistance of tynes that are connected to the number of machines, the amount of power needed to

rear side of the machine. The Tyne is dropped into the operate them is also reduced.

rock or soil to be removed, and after it has penetrated Profitable: Because ripping requires a less quantity of

deep into the strata, the bulldozer is pushed ahead in equipment, the cost is cheaper because there are no

order to take the dirt or rock from the ground. It costs associated with operation, labour, or machine

operates in the same manner as a plough in terms of maintenance.

technique. Ripping operations are often preferred over

drilling and blasting operations for relatively soft The different kinds of Rippers available: (P. K Panda

rocks because they are less disruptive. The increasing and S. K Misra , 1989)

global concern over the preservation of ecosystems, as

well as the execution of different regulations, has

Vol 12, Issue4, 2021 www.jrmat.com Page No:291

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

The following are the many types of rippers and dozers In order to choose the most suitable ripper, we must

available on the market, which are categorised first determine the rippability of the rock being

according to their working methodology: worked. Various studies have determined that the

rippability of rock is dependent on a variety of

Hinge Kind Of Ripper Parallelogram Kind Of Ripper

variables. In the table below, it has been shown which

Adjustable Parallelogram Kind Of Ripper Adjustable researcher is responsible for whatever parameter in the

Radial Kind Of Ripper study

Calculation for rippability of a rock

Table 2.1: Distinct researchers take into account a variety of different factors.

The following are the factors that influence the • Moisture content is present:

rippability of rock:

• Grain size: the larger the grain size, the better it is

• Ripping type: Sedimentary rocks are simple to for tearing.

tear, while igneous and metamorphic rocks are

• Combination of several types of rock.

more challenging.

• Energy that is specific.

• Rock fragility and crystalline structure.

• Compressive strength, tensile strength, shear

• Fracture plane that is well-known.

strength, and other physical characteristics of stratum

Vol 12, Issue4, 2021 www.jrmat.com Page No:292

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

Fig.2.2: Types of rock extraction based on stratum conditions.

Table 2.2: Extent of ripping, taking different features into consideration (Rock excavation techniques, MnE-415 notes,

university of Arizuana mining and geological engineering.)

Fig.2.6: Relationship for seismic velocity and ripping conditions to ripping (Basis: Caterpillar, 2008).

Vol 12, Issue4, 2021 www.jrmat.com Page No:293

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

3.VARIOUS RIPPER-DOZER SPECIFICATIONS AND THEIR APPLICABILITY

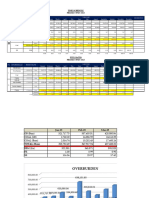

Table 3.1 shows the specifications of several ripper dozers available in India from various manufacturers.

Ripping is influenced by a variety of variables, however there is a connection between the quantity of production and

the ease of ripping, as seen below:

Table 3.2: Relationship between ease of ripping and production ( by Fiona MacGregor)

4. FIELD STUDY 1: PACHPATMALI BAUXITE million tonnes of overburden. Rippers of a large size

MINES, N.A.L.C.O have been used as an alternative to drilling and

blasting. The deposits discovered here are

4.1. Introduction:

Precambrian in age. Hard ferruginous laterite with a

National Aluminum Company Limited (N.A.L.C.O) thickness ranging from 0 to 3.5 m makes up the

manages the Panchpatmali bauxite mine, which overburden, which is followed by a layer with a

produces 4.8 million tones of bauxite ore and 1.6 thickness ranging from 10 to 35 m and an average

Vol 12, Issue4, 2021 www.jrmat.com Page No:294

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

thickness of 14 m. According to NGRI Hyderabad's rock formations. After blasting or tearing the OB, the

study of seismic wave velocity of various formations, mineralized top is cleaned with a wheel loader and

it varies from 1100 m/s to 2600 m/s, with more than dozer. With the assistance of a loader, the overburden

80% of deposits falling within the 1100 -1300 m/s is subsequently placed into a 50/55 tonne dumper. It is

velocity range and 15% falling between the 1300 to then transported to a location where overburden is

2600 m/s velocity range and above. needed for reclamation.

It demonstrates the deposit's suitability for efficient Bauxite excavation: Bauxite mining is now done in

and cost-effective production ripping, and it allowed two stages: top bench mining and bottom bauxite

the engineers to choose suitable equipment for the mining. Drilling and blasting are used to dig the upper

different sizes of rocks from among the current benches, which have an average height of 8 metres and

rippers. drill holes that are 150 mm in diameter and bored by

DTH drills. To loosen the ore, it is charged with indo–

The main mineral constituents of Khondalites and

boost, indo–gel, and blasted. The 8.7 m3 wheel loader

Chanockite rocks include granet, sillimanite

loads the blasted material into 50/55 tonne dumpers,

Corundum feldspar quartz, and also opaque ore

which transport it to the crusher. For entire bauxite

minerals limonite and graphite.

extraction, the final bench of bauxite is selectively

Slopes of less than 10%, although steeper across 2/5 mined using a back hoe. Bauxite ore is crushed using

of the deposit, and a highly uneven contact between a double roll toothed crusher until it reaches a size of

ore and bottom provide little relief. 150 mm, after which it is transported. It is transported

to a recycling facility by a 14.6-kilometer-long belt

Mining techniques conveyor.

Mining is carried out in three stages at the same time: Reclamation of the removed area: Reclamation is

carried out at the same time as the chosen mining

Excavation of overburden: Overburden is mined in

technique, trench mining. When the bauxite extraction

two phases and is made up of top soil and laterite. Top

is finished, the land is cleared for backfilling with

soil is dug and transported ahead of laterite, then stored

overburden, which consists of rich soil and laterite that

separately for use in reclaimed area plantations. The

was previously mined. Laterite is delivered to the

whole quantity of laterite extracted is just on one

lowest level, with a thin layer of soil remaining on top

bench above bauxite, with a lead of 75 metres.

for planting operations. In the reclaimed area,

Because there is less overburden than ore and the rock

reservoirs and sumps are built to collect water and

is relatively soft, it may be broken by tearing. Ripping

avoid land deterioration due to soil erosion.

is linked to blasting, which is used to create tougher

Fig 4.1.Technique for reclamation of mined area of the mine

Vol 12, Issue4, 2021 www.jrmat.com Page No:295

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

Table 4.1.2: I.I.T Kharagpur is researching the physico-mechanical characteristics of laterite and bauxite.

This test revealed that the ore from Panchpatmali mine is very susceptible to tearing

Figure 4.1.2 Komatsu D-475 working the mine

All specs for all rippers and dozers may be found in the table of specifications.

On the basis of cost, drilling and blasting are compared to tearing.

Cost of drilling and blasting per tonne extracted

The average drilling operation per day is 560 metres.

So, because we had two working shifts of 280m each, we used three drilling machines and three operators to operate

them, and the actual working hour in a shift was four hours, interest for one drill machine was Rs. 4417.8469,

depreciation cost of machine was Rs. 6126.25, and rear and management expenditures were Rs. 5416.667.

Vol 12, Issue4, 2021 www.jrmat.com Page No:296

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

Table 4.1.3 Calculation for expenditure for drilling per MT

5. RECENT DEVELOPMENTS IN THE FIELD • Maximization of the use of the machine.

OF RIPPER DOZER

• Improved overall visibility for the operator.

5.1 Remote operation of ripper and dozer: (Remote

• Improved working conditions for the operator in

control technologies Pv.t Ltd, Australia)

terms of ergonomics.

Remote Control Technologies is the sole company

In between manufacturing cycles, there is less idle

responsible for the remotization of the ripper and the

time.

dozer. This firm developed several models for

Caterpillar, including the D5N, D8T, D9H, D10, The ability to maintain tighter control over key

D10N, D10R, D11N, D11R Series 1, 2, and 3, as well machine tolerances.

as the KOMATSU D475, D572-A2, D575A, D575A-

3, and the D275AX. When RCT installed the first • It is possible to do dangerous machine operations in

remote control system for a CAT D11NinPNG dozer a safe manner.

in 1989, it was a world first. RCT was the first

5.2 Mine APS Dozer

company in the world to remotely operate a CAT D8T

dozer in 2006. It serves as a model for the successful use of

contemporary technologies. It is a GPS+GLONASS

5.1.1 The following are some of the benefits of using

appliance monitoring solution for dozers, which

a remote control:

allows for faster, safer, and more productive operation

• Prevents repeated stress injuries from occurring. while reducing costs. Excellent accuracies A

Vol 12, Issue4, 2021 www.jrmat.com Page No:297

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

GPS+GLONASS surveillance system enables for • Decrease the amount of rework caused by over- or

precise dozing planning without the necessity for undercutting or underfilling.

rechecking or correcting.

• Significantly decrease reliance on survey and grade-

5.2.1 Features: checking data collection.

• Represent the machine location in 3D accurately in • Machine-based production reporting eliminates

comparison with the CAD model. human error and increases the timeliness and quality

of management information over time.

Compact and versatile GPS+GLONASS receivers to

balance investments and application requirements. • 6. CONCLUSION

Open system technologies such as Microsoft

• As a result of the widespread use of reformed

Windows, SQL, XML, NMEA, and Share point

technology, ripping has risen in importance relative to

services are available.

drilling and blasting as a primary activity.

• Operator interface with a touch screen that is simple

• Its major drawback is that it is not suitable for use on

to use.

very hard rocks. As a result, it may be linked with

• The operator has the option of working on the design drilling and blasting in order to provide a more

surface or on offsets. satisfactory answer.

• Allow for several user selected surfaces to be • Based on the above results, we may infer that it is a

included inside a single file. cost-effective, safe, and economical operation.

• Diagnostics of the onboard system. • It has the potential to be used as a blast-free mining

system.

The use of fixed hazard and mobile equipment

proximity alerts is recommended. • Because ripping has no negative impact on the

environment, we can preserve the ecosystem as well

• Optional ripper sensor is available.

as animal habitats by using it.

• An optional blade guiding sensor is available.

In addition, since the retrieved ores or overburden are

• Communication interface that is open to all homogeneous in size, there is no need for additional

communication systems, including 3G cellular, operations such as secondary blasting.

802.11x wireless, mesh, and others.

• The development of methods and equipment has the

• Off-board and on-board production reporting options potential to provide a final solution for drilling and

by machine, area, group, or operator, including: blasting operations.

volumes, push lengths, cycles, re handle, idle vs. push

REFERENCES

vs. ripping, delays, export DTM of ‘as constructed'

surface, and a variety of other parameters. i. Amin Mohd For Mohd ; Huei Chan Sook ; Zuhairi

Abd. Hamid; Mohd Khairolden ndGhani.“Rippability

5.2.2 BENEFITS OF THE SYSTEM:

assessment of rock based on specific energy and

• It is feasible to mine selectively, which will result in production rate”,construction industry research

higher quality ore. achievement international conference (CIRAIC 2009).

Pp-3- 5.

• Fixed danger and proximity alerts have been

implemented to increase safety. ii. Panda P.K ; Misra S.K. “Ripping an aid to primary

mining system a N.A.L.C.O rdexperience”, 3 national

• Increased efficiency while also reducing mistakes. conference on surface mining, 1989.

• Produces outcomes in less time and with fewer

passes.

Vol 12, Issue4, 2021 www.jrmat.com Page No:298

JOURNAL OF RESOURCE MANAGEMENT AND TECHNOLOGY ISSN NO: 0745-6999

iii. Samal Subhrakanta ; Dash Ashish ; Murthy xiv. Basarir H.; Karpuz C.; Tutluoglu L. (2008).

V.M.S.R ; Mohanty P.R. “ Ripping –an excavation “Specific energy based rippability classification

technique of future promise” , I.S.M Dhanbad. system for coal measure rock”, a journal on terra

mechanics.

iv. Basarir H.; Karpuz C.; Tutluoglu L. (2007). “A

fuzzy logic based rippability classification system”. xv. Prof.Mishra G.B, “Surface mining”,

Template journal. Bhubaneswar; Geo mine tech publications, first

edition, 2007, chapter 8-”excavation and loading”,

v. Basarir H.; Karpuz C.; Tutluoglu L. (2008).

page- 405-406.

“Specific energy based rippability classification

system for coal measure rock”, Journal of xvi. www.rct.net.au; Remote control solutions for

terramechanics. dozer applications. Remote control Technologies

Pvt.Ltd.,Kewdale Western Australia.

vi. Prof.Mishra G.B, “Surface mining”, Bhubaneswar;

Geominetech publications, first edition, 2007, chapter xvii.

8-”excavation and loading”, page- 405-406. http://www.civil.utm.my/staff/file/116/file/Rippabilit

y%20Assessment%20of%20Rock

vii. www.rct.net.au; Remote control solutions for

%20Based%20on%20Specific%20Energy%20&%20

dozer applications, Remote control

Production%20Rate.pdf.

TechnologiesPvt.Ltd.,Kewdale Western Australia.

xviii.

viii.

http://www.saimm.co.za/Journal/v107n12p817.pdf.

http://www.civil.utm.my/staff/file/116/file/Rippabilit

y%20Assessment%20of%20Rock xix.

http://www.civil.utm.my/staff/file/116/file/Rippabilit

%20Based%20on%20Specific%20Energy%20&%20

y%20Assessment%20of%20Quart

Production%20Rate.pdf.

zite%20in%20Kenny%20Hill%20Formation%5B1%

ix. 5D.pdf.

http://www.saimm.co.za/Journal/v107n12p817.pdf.ht

xx. http://www.ethesis.nitrkl.ac.in

tp://www.civil.utm.my/staff/file/1

16/file/Rippability%20Assessment%20of%20Quartzi

te%20in%20Kenny%20Hill%20F

ormation%5B1%5D.pdf.

x. Amin Mohd For Mohd ; Huei Chan Sook ; Zuhairi

Abd. Hamid; Mohd Khairolden nd Ghani.

“Rippability assessment of rock based on specific

energy and production rate”, 2 construction industry

research achievement international conference

(CIRAIC2009). Pg-3- 5.

xi. Panda P.K ; Misra S.K. “Ripping an aid to primary

mining system a NALCO rdexperience”, 3 national

conference on surface mining, 1989.

xii. Samal Subhrakanta; Dash Ashish; Murthy

V.M.S.R; Mohanty P.R. “Ripping –an excavation

technique of future promise”, ISM Dhanbad.

xiii. Basarir H.; Karpuz C.; Tutluoglu L. (2007). “A

fuzzy logic based rippability classification system”.

Template journal.

Vol 12, Issue4, 2021 www.jrmat.com Page No:299

You might also like

- Rock CuttingDocument16 pagesRock CuttingHamit Aydın100% (2)

- Ripper Project, 2012 PDFDocument61 pagesRipper Project, 2012 PDFBismark Enoc Cruz AltamiranoNo ratings yet

- Suitability Study of Ripper-Dozer Combination in Indian MinesDocument58 pagesSuitability Study of Ripper-Dozer Combination in Indian MinesRavikanth AluriNo ratings yet

- Benchmark Drill and Blast and Mechanical Excavation Advance Rate For Underground Hard-Rock Mine DevelopmentDocument24 pagesBenchmark Drill and Blast and Mechanical Excavation Advance Rate For Underground Hard-Rock Mine DevelopmentJuniorMendoza97100% (1)

- Gpcccamanuscript 20012021Document38 pagesGpcccamanuscript 20012021Farhan AslamNo ratings yet

- One Phase Blasting ChuquicamataDocument10 pagesOne Phase Blasting Chuquicamatavlapostolle.27No ratings yet

- Benchmark Drill and Blast and Mechanical ExcavatioDocument24 pagesBenchmark Drill and Blast and Mechanical ExcavatioEduardo Mena100% (1)

- Design and Dimensioning of Sublevel Stoping For ExDocument7 pagesDesign and Dimensioning of Sublevel Stoping For ExBwalya BwalyaNo ratings yet

- Seventh Large Open Pit Mining Conference 2010-The Australasian Institute of Mining and Metallurgy (The AusIMM) (2010)Document116 pagesSeventh Large Open Pit Mining Conference 2010-The Australasian Institute of Mining and Metallurgy (The AusIMM) (2010)souou644No ratings yet

- Design Considerations For Waste Dumps in Indian Opencast CoalMines A Critical Appraisal-ICOMS-2019Document15 pagesDesign Considerations For Waste Dumps in Indian Opencast CoalMines A Critical Appraisal-ICOMS-2019Bhardwaj PanditNo ratings yet

- The Optimization of Mining Method and EquipmentDocument6 pagesThe Optimization of Mining Method and EquipmentkullieNo ratings yet

- Research Article: Implementation of Paste Backfill Mining Technology in Chinese Coal MinesDocument9 pagesResearch Article: Implementation of Paste Backfill Mining Technology in Chinese Coal MinesVanco AdziskiNo ratings yet

- Benchmark Drill and Blast and Mechanical ExcavatioDocument24 pagesBenchmark Drill and Blast and Mechanical ExcavatioHAMZA TAISNo ratings yet

- Blast Fragmentation For Maximising The Sag Mill Throughput at Porgera Gold MineDocument17 pagesBlast Fragmentation For Maximising The Sag Mill Throughput at Porgera Gold MineElías Bravo CortésNo ratings yet

- Article On Surface MinerDocument11 pagesArticle On Surface MinerANKIT SONI100% (1)

- Mining Weekly - Technology Set To Unleash Mining Innovation - Anglo's O'NeillDocument7 pagesMining Weekly - Technology Set To Unleash Mining Innovation - Anglo's O'NeillvivalpsNo ratings yet

- 3 Sraper SubterraneaDocument10 pages3 Sraper SubterraneaDavid Esteban Meneses RendicNo ratings yet

- E3sconf - Iims2018 - 01003 Rope Shovel or HydraulicDocument5 pagesE3sconf - Iims2018 - 01003 Rope Shovel or HydraulicОбо всём на светеNo ratings yet

- Bord and Pillar Stra MonitoringDocument17 pagesBord and Pillar Stra MonitoringvigneshNo ratings yet

- Directional-Drilling To Multilateral DrillingDocument10 pagesDirectional-Drilling To Multilateral Drillingbagus yosan setiawanNo ratings yet

- BlastDocument77 pagesBlastAshok KumarNo ratings yet

- Drilling and BlastingDocument2 pagesDrilling and BlastingAbdul Bari ZiaNo ratings yet

- Highwall Applicability CSIR Dhanbad)Document17 pagesHighwall Applicability CSIR Dhanbad)bikamlnclNo ratings yet

- OP or Block CavingDocument18 pagesOP or Block Cavingalvaroaac4No ratings yet

- 25864902Document9 pages25864902Bequer Inocente OchoaNo ratings yet

- A - 11 - A Rippability Classification System For Marls in Lignite MinesDocument17 pagesA - 11 - A Rippability Classification System For Marls in Lignite MinesjimmyNo ratings yet

- Sifferlinger - 2017 - The Importance of Research On AlternativeDocument10 pagesSifferlinger - 2017 - The Importance of Research On AlternativeLinh NhượcNo ratings yet

- Evaluation of Bulk Ore Sorting For Pre-Concentration of Copper Ore at PanAust Phu Kham OperationDocument11 pagesEvaluation of Bulk Ore Sorting For Pre-Concentration of Copper Ore at PanAust Phu Kham OperationEduardo CandelaNo ratings yet

- Deep Ocean Mining Technology DevelopmentDocument6 pagesDeep Ocean Mining Technology DevelopmentBalaji GanesanNo ratings yet

- E3sconf Icsf2021 08015Document6 pagesE3sconf Icsf2021 08015Désiré NiamienNo ratings yet

- Nanoparticles Promising Solution To Overcome SternDocument5 pagesNanoparticles Promising Solution To Overcome SternAl-Shargabi MohaNo ratings yet

- Clay Nanoparticles Modifed Drilling Fluids For Drilling of Deep Hydrocarcbon Wells PDFDocument7 pagesClay Nanoparticles Modifed Drilling Fluids For Drilling of Deep Hydrocarcbon Wells PDFJuliana BuelvasNo ratings yet

- Application and Development Trend of Flue Gas Desulfurization (FGD) ProcessDocument12 pagesApplication and Development Trend of Flue Gas Desulfurization (FGD) ProcesskangsungjinNo ratings yet

- Future of Mechanical Excavation in Underground Mining: JacklingDocument11 pagesFuture of Mechanical Excavation in Underground Mining: JacklingLuisSaavedraFloresNo ratings yet

- A Study of Cut Blasting For One-Step Raise Excavation Based On Numerical Simulation and Field Blast TestsDocument14 pagesA Study of Cut Blasting For One-Step Raise Excavation Based On Numerical Simulation and Field Blast TestsWei WangNo ratings yet

- Activity 6 - DAHUYLADocument14 pagesActivity 6 - DAHUYLAJef Michael L. DahuylaNo ratings yet

- International Journal of Mining Science and Technology: Syd S. PengDocument6 pagesInternational Journal of Mining Science and Technology: Syd S. PengPradhith KattaNo ratings yet

- Spe 1597 PaDocument8 pagesSpe 1597 PaBhupendra Singh XI CNo ratings yet

- optimizationLHD - IJMME5204Apeletal.3Document15 pagesoptimizationLHD - IJMME5204Apeletal.3Eduardo MenaNo ratings yet

- Article On Surface MinerDocument11 pagesArticle On Surface MinerShyamal Kumar Bag100% (1)

- Preprint 18-007: SME Annual Meeting Feb. 25 - 28, 2018, Minneapolis, MNDocument4 pagesPreprint 18-007: SME Annual Meeting Feb. 25 - 28, 2018, Minneapolis, MNKEVIN ROY RAMIREZ HUAÑANo ratings yet

- Study of Processing and Machinery in Cement Industry: ISO 9001:2008 CertifiedDocument9 pagesStudy of Processing and Machinery in Cement Industry: ISO 9001:2008 CertifiedsaedeNo ratings yet

- Stowing in Ug MinesDocument55 pagesStowing in Ug Minesbecome ambani100% (5)

- Cami2016 34Document7 pagesCami2016 34Morteza ParichehNo ratings yet

- International Journal of Surface Mining, Reclamation and EnvironmentDocument8 pagesInternational Journal of Surface Mining, Reclamation and EnvironmentJennifer GordonNo ratings yet

- Stochastic Optimisation of Long-Term Block Cave Scheduling With Hang-Up and Grade UncertaintyDocument19 pagesStochastic Optimisation of Long-Term Block Cave Scheduling With Hang-Up and Grade UncertaintyMatías Ignacio Loyola GaldamesNo ratings yet

- A Practical Manual On Block Caving PDFDocument525 pagesA Practical Manual On Block Caving PDFJorge Ariel Osorio GuzmanNo ratings yet

- Hapugoda IMPC2010Document16 pagesHapugoda IMPC2010ParamesWaranNo ratings yet

- Fragblast VKHDocument12 pagesFragblast VKH2021mnm009.abhishekNo ratings yet

- 1 1 PDFDocument7 pages1 1 PDFsatishNo ratings yet

- Drilling and Blasting Practices in Nevada's Openpit Mines: Mining Engineering December 2003Document7 pagesDrilling and Blasting Practices in Nevada's Openpit Mines: Mining Engineering December 2003David HalomoanNo ratings yet

- Practical Training Ii - 2Document39 pagesPractical Training Ii - 2Suganthan SundharamNo ratings yet

- Optimization of Drilling and Blasting Operations in An Open Pit Mine-The SOMAIR ExperienceDocument4 pagesOptimization of Drilling and Blasting Operations in An Open Pit Mine-The SOMAIR ExperienceWilkhen ChuraNo ratings yet

- Fragblast12 2Document11 pagesFragblast12 2bel cpcychi porrasNo ratings yet

- 006 Blasting TechnologyDocument5 pages006 Blasting TechnologyKenny CasillaNo ratings yet

- Threshold Blasting: The Renaissance of Explosives in Narrow Reef MiningDocument8 pagesThreshold Blasting: The Renaissance of Explosives in Narrow Reef Miningmatias79No ratings yet

- Drilling and Blasting Practices in Nevada's Openpit Mines: Mining Engineering December 2003Document7 pagesDrilling and Blasting Practices in Nevada's Openpit Mines: Mining Engineering December 2003SzoszanaNo ratings yet

- Artigo 2 (Publicado)Document5 pagesArtigo 2 (Publicado)Emerson SilvaNo ratings yet

- Innovations in Sustainable Mining: Balancing Environment, Ecology and EconomyFrom EverandInnovations in Sustainable Mining: Balancing Environment, Ecology and EconomyKirtikumar RandiveNo ratings yet

- JETIR2003087Document7 pagesJETIR2003087GEOGINo ratings yet

- JETIR1908735Document9 pagesJETIR1908735GEOGINo ratings yet

- Acid TreatmentsDocument82 pagesAcid TreatmentsGEOGINo ratings yet

- IJRAR19K7734Document9 pagesIJRAR19K7734GEOGINo ratings yet

- JETIR1908730Document6 pagesJETIR1908730GEOGINo ratings yet

- Fileserve Sir 4Document9 pagesFileserve Sir 4GEOGINo ratings yet

- Fileserve Sir 1Document5 pagesFileserve Sir 1GEOGINo ratings yet

- Criteria 5 - Dr. N R N V Gowripathi RaoDocument32 pagesCriteria 5 - Dr. N R N V Gowripathi RaoGEOGINo ratings yet

- Jetti GopiDocument21 pagesJetti GopiGEOGINo ratings yet

- Fileserve Sir 2Document8 pagesFileserve Sir 2GEOGINo ratings yet

- Criteria 6Document10 pagesCriteria 6GEOGINo ratings yet

- Fileserve Sir 3Document8 pagesFileserve Sir 3GEOGINo ratings yet

- NBA Criteria Wise Files Reqd-09072021Document59 pagesNBA Criteria Wise Files Reqd-09072021GEOGINo ratings yet

- J Meenu VikasDocument17 pagesJ Meenu VikasGEOGINo ratings yet

- Criteria 2Document31 pagesCriteria 2GEOGINo ratings yet

- Criteria 2 & 6 - Files-GuidelinesDocument13 pagesCriteria 2 & 6 - Files-GuidelinesGEOGINo ratings yet

- Invistigation of Coal Mine FiresDocument58 pagesInvistigation of Coal Mine FiresGEOGINo ratings yet

- Modified Criteria-1Document22 pagesModified Criteria-1GEOGI100% (1)

- Formal Letter Writing: Rama Krishna TangellaDocument18 pagesFormal Letter Writing: Rama Krishna TangellaGEOGINo ratings yet

- Common Errors: Neelima TeluguDocument25 pagesCommon Errors: Neelima TeluguGEOGINo ratings yet

- Often: J.Bala Raja Sekhar Asst Professor Aditya Engineering CollegeDocument23 pagesOften: J.Bala Raja Sekhar Asst Professor Aditya Engineering CollegeGEOGINo ratings yet

- Process Dynamics and ControlDocument88 pagesProcess Dynamics and ControlGEOGINo ratings yet

- PREHISTORIC SETTLEMENT PATTERNS OF SOUTH-CENTRAL GANGA VALLEY AN ETHNOARCHAEOLOGIAL PERSPECTIVE On JSTORDocument1 pagePREHISTORIC SETTLEMENT PATTERNS OF SOUTH-CENTRAL GANGA VALLEY AN ETHNOARCHAEOLOGIAL PERSPECTIVE On JSTORoishiki.nacNo ratings yet

- Reservoir EngineeringDocument178 pagesReservoir EngineeringElnur AskerovNo ratings yet

- Science 5-Q4-SLM2Document14 pagesScience 5-Q4-SLM2Rosario FuertezNo ratings yet

- Rocks I - Sed Key PDFDocument10 pagesRocks I - Sed Key PDFAchmad FahrizaNo ratings yet

- SanisidrositeearDocument178 pagesSanisidrositeearJuan Valdes GarzaNo ratings yet

- Img 0001Document11 pagesImg 0001Christopher ThomasNo ratings yet

- Familiarization With Apparatus and Equipment Used in Testing of MaterialsDocument11 pagesFamiliarization With Apparatus and Equipment Used in Testing of MaterialsDaryll ArnestoNo ratings yet

- 4 LiberationDocument24 pages4 LiberationJune ZamoraNo ratings yet

- SupercontinentsDocument6 pagesSupercontinentstricenNo ratings yet

- The Mohs Hardness Scale - Rade RaonićDocument12 pagesThe Mohs Hardness Scale - Rade RaonićРаде Раонић100% (1)

- Dakshina - Kannada - Brochure 2012Document28 pagesDakshina - Kannada - Brochure 2012maheshanischithaNo ratings yet

- Reading Comprehension MarathonDocument26 pagesReading Comprehension MarathonRenu ShrivastavaNo ratings yet

- Science10 - Q1 - Mod3of5 - Plate Tectonics - v2Document26 pagesScience10 - Q1 - Mod3of5 - Plate Tectonics - v2Fatimah D. Rubin-CansancioNo ratings yet

- GeographyDocument10 pagesGeographyhurairaNo ratings yet

- Seattle Central Library - Arch638 - AU15presDocument22 pagesSeattle Central Library - Arch638 - AU15presyaren taşNo ratings yet

- Chapter 1 - IntroductionDocument36 pagesChapter 1 - IntroductionChristian BonoanNo ratings yet

- Environmental-Geochemical Atlas of The Central-Northern Part of The Copperbelt Province of ZambiaDocument5 pagesEnvironmental-Geochemical Atlas of The Central-Northern Part of The Copperbelt Province of ZambiaShahrul AshariNo ratings yet

- Earths Structure AnswersheetDocument2 pagesEarths Structure AnswersheetHitakshi BhanushaliNo ratings yet

- Value of Pile Tests To Inform Detailed Design in Canada: September 2018Document9 pagesValue of Pile Tests To Inform Detailed Design in Canada: September 2018981002No ratings yet

- Plan Design PT. PMN - Oktober 2023Document23 pagesPlan Design PT. PMN - Oktober 2023sabilussalam95No ratings yet

- Fossils The Restless EarthDocument112 pagesFossils The Restless EarthPaleoantropologie DinamicaNo ratings yet

- Advances in Seismic AcquisitionDocument78 pagesAdvances in Seismic AcquisitioneesNo ratings yet

- DLP in Science 6-Q4W1Document5 pagesDLP in Science 6-Q4W1MARICEL JOCSONNo ratings yet

- GEOL20220 Exercise 2 QsDocument10 pagesGEOL20220 Exercise 2 QsLang Buana 2No ratings yet

- Determination of In-Situ Stress From Ori PDFDocument9 pagesDetermination of In-Situ Stress From Ori PDFLeon FouroneNo ratings yet

- Skripsi Tanpa Pembahasan - Yovan El ZikrianDocument71 pagesSkripsi Tanpa Pembahasan - Yovan El ZikrianRiahati HarefaNo ratings yet

- Barwani District: Ministry of Water ResourcesDocument14 pagesBarwani District: Ministry of Water ResourcesDinesh SinghNo ratings yet

- Civil Engg SyllabusDocument32 pagesCivil Engg SyllabusDeekshith SalianNo ratings yet

- Ocean FloorDocument11 pagesOcean FloorKhandoker mariatul IslamNo ratings yet

- Zoology Notes: 004 Chapter 1Document9 pagesZoology Notes: 004 Chapter 1humanupgrade100% (1)