Professional Documents

Culture Documents

CM - ASS2 - Gr2 - HERIL JAIN - UG190554

CM - ASS2 - Gr2 - HERIL JAIN - UG190554

Uploaded by

Heril JainCopyright:

Available Formats

You might also like

- JKR Schedule of Unit RatesDocument50 pagesJKR Schedule of Unit RatesCheng76% (29)

- Tests For BricksDocument31 pagesTests For BricksTeddy0% (1)

- A Project Report: Marketing Strategy For M Sand Company (Triveni Sands)Document34 pagesA Project Report: Marketing Strategy For M Sand Company (Triveni Sands)karan N100% (1)

- V-1 BOQ - Intake & SitewokDocument136 pagesV-1 BOQ - Intake & Sitewokkandeepan100% (1)

- Ug190554 - Foundation Design ReportDocument33 pagesUg190554 - Foundation Design ReportHeril JainNo ratings yet

- DSR 2021 Vol II English DirDocument337 pagesDSR 2021 Vol II English DirKaranjeet Singh45% (11)

- C3 Fresh and Hardened Concrete TestDocument11 pagesC3 Fresh and Hardened Concrete TestSyukri Abd KadirNo ratings yet

- Brick TestingDocument25 pagesBrick TestingVivek BhardwajNo ratings yet

- ASTM C1403-13 Standard Test Method For Rate of Water AbsorptionDocument4 pagesASTM C1403-13 Standard Test Method For Rate of Water AbsorptionEdwin R Ruiz100% (1)

- CM - Ass2 - Ug190554 - Heril JainDocument9 pagesCM - Ass2 - Ug190554 - Heril JainHeril JainNo ratings yet

- C-309 MT Lab Manual Civil Engineering Material Testing LaboratoryDocument57 pagesC-309 MT Lab Manual Civil Engineering Material Testing LaboratoryVineel ParadesiNo ratings yet

- Concrete and Highway LabDocument42 pagesConcrete and Highway LabProf. Manjunath V. C.No ratings yet

- 637804338746085603ce 20ce33pt W3 S5 SyDocument5 pages637804338746085603ce 20ce33pt W3 S5 SyKavya kNo ratings yet

- CementDocument20 pagesCementHeril JainNo ratings yet

- AGREY MAO - Presentation 2Document25 pagesAGREY MAO - Presentation 2Moses KaswaNo ratings yet

- Yogesh Rana (A62)Document50 pagesYogesh Rana (A62)Yogeshwar singhNo ratings yet

- Material Testing Lab Manual-Expt-1to 14Document50 pagesMaterial Testing Lab Manual-Expt-1to 14rajat debnathNo ratings yet

- Lab 1 Chapter 3: Methodology Slump Test 2.1 Flow Chart: StartDocument18 pagesLab 1 Chapter 3: Methodology Slump Test 2.1 Flow Chart: StartHaiqal RafiqNo ratings yet

- Session 7 PlasterDocument43 pagesSession 7 PlasterlavNo ratings yet

- Experiment 07 Field Tests On BricksDocument3 pagesExperiment 07 Field Tests On Brickssiddharthsawant7768No ratings yet

- Khowpa Engineering College: Constructional MaterialDocument5 pagesKhowpa Engineering College: Constructional MaterialReal BahunNo ratings yet

- Metal Scrap in Paver BlockDocument17 pagesMetal Scrap in Paver BlockAadhiNo ratings yet

- Slump TestDocument8 pagesSlump TestEn Long Bglong100% (2)

- LBYME19 - ConcreteDocument18 pagesLBYME19 - ConcreteAlexis CabigtingNo ratings yet

- Chapter Three 3.0 Methodology: 3.2.1 Aggregates of Requirement in EssentialDocument11 pagesChapter Three 3.0 Methodology: 3.2.1 Aggregates of Requirement in EssentialAsghar Hussain Shah S/o Zubair Shah MS Engg. Management (Swat Campus)No ratings yet

- Civil Engineering Materials Lab ReportDocument17 pagesCivil Engineering Materials Lab ReportSuman SapkotaNo ratings yet

- Concrete Manual 2023Document31 pagesConcrete Manual 2023amdaNo ratings yet

- Engineering Material Brick: Cee, KuktemDocument39 pagesEngineering Material Brick: Cee, KuktemPrateek Banerjee100% (1)

- Building Materials Lab ManualDocument21 pagesBuilding Materials Lab Manualapi-348488925100% (3)

- Report On Laboratory and Site Visit 2Document9 pagesReport On Laboratory and Site Visit 2Vijay JamadarNo ratings yet

- Testing of Material-Lab-Report-5Document6 pagesTesting of Material-Lab-Report-5Mariefel Therese AlsaNo ratings yet

- Group 11 B FinalDocument33 pagesGroup 11 B FinalJatin CoolNo ratings yet

- Report Project Osha PDFDocument27 pagesReport Project Osha PDFSky FireNo ratings yet

- J C Bose University of Science and Technology, Ymca, FaridabadDocument30 pagesJ C Bose University of Science and Technology, Ymca, FaridabadRahul Singh PariharNo ratings yet

- Experiment No. 1 Fineness of Cement by Hand SievingDocument22 pagesExperiment No. 1 Fineness of Cement by Hand SievingUmed Abd-alsatarNo ratings yet

- Midterm RaporDocument15 pagesMidterm RaporSena ÇınarNo ratings yet

- Building Materials LabDocument23 pagesBuilding Materials LababelNo ratings yet

- CT Lab ManualDocument54 pagesCT Lab ManualAxumawi Ebuy TekaNo ratings yet

- Fresh ConcreteDocument34 pagesFresh Concreteahmedalkastawy19No ratings yet

- C3-Fresh & Harden Concrete TestDocument12 pagesC3-Fresh & Harden Concrete TestMuhamad Farhan100% (1)

- Lab Report Exp. 1,2,4,5Document20 pagesLab Report Exp. 1,2,4,5232449045No ratings yet

- Robo Sand (2) - 2Document21 pagesRobo Sand (2) - 2Shaik ShareefNo ratings yet

- Civil Engineering Materials Lab ReportDocument16 pagesCivil Engineering Materials Lab ReportSuman SapkotaNo ratings yet

- 05) CE 304 Lec 3 (Compatibility Mode)Document21 pages05) CE 304 Lec 3 (Compatibility Mode)priyadarshanNo ratings yet

- Bme LatestDocument10 pagesBme LatestDanial AriffNo ratings yet

- Concrete &highway Lab New ManualDocument40 pagesConcrete &highway Lab New Manualshruthicivil100% (4)

- Procedures of TestingsDocument54 pagesProcedures of TestingsSK Emran AliNo ratings yet

- Cement Concrete Hollow Block and ConcreteDocument99 pagesCement Concrete Hollow Block and ConcreteEchanez, Gem Krian0% (1)

- Muddasar Ahmed (Cms Id 6139) Material Engineering Lab PracticalsDocument15 pagesMuddasar Ahmed (Cms Id 6139) Material Engineering Lab PracticalsAafaq Ur RehmanNo ratings yet

- CementsDocument11 pagesCementsmd nasirNo ratings yet

- CH 5 PlasteringDocument22 pagesCH 5 PlasteringEyoatem TeferiNo ratings yet

- IS Standard Bricks TestDocument7 pagesIS Standard Bricks TestYasirNo ratings yet

- Conrete Mix Design & Making and Curing of Test SpecimenDocument15 pagesConrete Mix Design & Making and Curing of Test SpecimenBlesNo ratings yet

- Test On Cement PDFDocument6 pagesTest On Cement PDFIrfan NazirNo ratings yet

- 3495 Part 1 Bricks PDFDocument10 pages3495 Part 1 Bricks PDFVb SeriesNo ratings yet

- 1-Flow & Slump Test-1Document35 pages1-Flow & Slump Test-1ismailNo ratings yet

- A Case Study On BricksDocument7 pagesA Case Study On BricksAritro Roy MitraNo ratings yet

- Slumptest 170922081141Document12 pagesSlumptest 170922081141MohammedNo ratings yet

- Material Testing ManualDocument56 pagesMaterial Testing ManualJithin Benny JithinNo ratings yet

- Lecture Eight: Basic Characteristics of ConcreteDocument13 pagesLecture Eight: Basic Characteristics of Concretea_j_sanyal259No ratings yet

- Introduction To Concrete TechnologyDocument31 pagesIntroduction To Concrete TechnologyMahendra Kumar PalNo ratings yet

- MASIKADocument33 pagesMASIKAGabriel OmondiNo ratings yet

- Bricks: Require Little MaintenanceDocument39 pagesBricks: Require Little MaintenanceGirmaye KebedeNo ratings yet

- DraftDocument27 pagesDraftNaveen SNo ratings yet

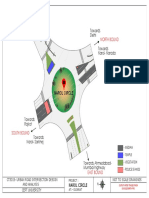

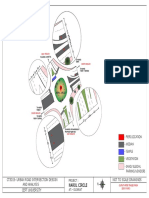

- Towards Narol RD.: West BoundDocument1 pageTowards Narol RD.: West BoundHeril JainNo ratings yet

- Height of Light Pole - 7.50MDocument1 pageHeight of Light Pole - 7.50MHeril JainNo ratings yet

- Towards Narol RD.: West BoundDocument1 pageTowards Narol RD.: West BoundHeril JainNo ratings yet

- Narol Circle: Ct3015-Urban Road Intersection Design Cept University and Analysis Not To Scale DrawingsDocument1 pageNarol Circle: Ct3015-Urban Road Intersection Design Cept University and Analysis Not To Scale DrawingsHeril JainNo ratings yet

- ConcreteDocument8 pagesConcreteHeril JainNo ratings yet

- CementDocument20 pagesCementHeril JainNo ratings yet

- 4736 PDFDocument82 pages4736 PDFHeril JainNo ratings yet

- Fine AggregateDocument9 pagesFine AggregateHeril JainNo ratings yet

- CM - Ass2 - Ug190554 - Heril JainDocument9 pagesCM - Ass2 - Ug190554 - Heril JainHeril JainNo ratings yet

- Coarse AggregateDocument11 pagesCoarse AggregateHeril JainNo ratings yet

- FEWEFDocument3 pagesFEWEFHeril JainNo ratings yet

- Coarse Aggregate1Document14 pagesCoarse Aggregate1Heril JainNo ratings yet

- CM - Ass4 - Ug190554 - Heril JainDocument8 pagesCM - Ass4 - Ug190554 - Heril JainHeril JainNo ratings yet

- Site InvestigationDocument42 pagesSite InvestigationHeril JainNo ratings yet

- CementDocument10 pagesCementHeril JainNo ratings yet

- CM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554 - MATERIAL CSDocument45 pagesCM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554 - MATERIAL CSHeril JainNo ratings yet

- CM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554 - SCSDocument9 pagesCM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554 - SCSHeril JainNo ratings yet

- Ug190554 - Heril Jain - PanelDocument1 pageUg190554 - Heril Jain - PanelHeril JainNo ratings yet

- Sieve Analysis: Construction MaterialsDocument10 pagesSieve Analysis: Construction MaterialsHeril JainNo ratings yet

- CM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554 - STRUCTURE CSDocument9 pagesCM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554 - STRUCTURE CSHeril JainNo ratings yet

- Ug190554 - Mini PortfolioDocument11 pagesUg190554 - Mini PortfolioHeril JainNo ratings yet

- 10 PagesDocument11 pages10 PagesHeril JainNo ratings yet

- CM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554Document3 pagesCM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554Heril JainNo ratings yet

- Ug190554 - Site InvestigationDocument42 pagesUg190554 - Site InvestigationHeril JainNo ratings yet

- Presentation For JuryDocument15 pagesPresentation For JuryHeril JainNo ratings yet

- Soil ImprovementDocument34 pagesSoil ImprovementHeril JainNo ratings yet

- UG190554 - HERIL JAIN - FOUNDATION DESIGN FinalDocument37 pagesUG190554 - HERIL JAIN - FOUNDATION DESIGN FinalHeril JainNo ratings yet

- 3.SP-5828 ReportDocument26 pages3.SP-5828 ReportHorizon InfradesignsNo ratings yet

- Composition and Techniques of The Ticinese StuccoDocument21 pagesComposition and Techniques of The Ticinese StuccoTaso Gvantsa PotskhishviliNo ratings yet

- Thin Bed MortarDocument20 pagesThin Bed Mortarrajeshji_000No ratings yet

- MS For Brick WorkDocument7 pagesMS For Brick WorkSumit Omar100% (1)

- Experiment No 03 TITLE:Efflorescence Causes Prevention and Remedial MeasureDocument15 pagesExperiment No 03 TITLE:Efflorescence Causes Prevention and Remedial MeasureOmkar JambhaleNo ratings yet

- Interaction of A Viscous Biopolymer From Cactus Extract With Cement Paste To Produce Sustainable ConcreteDocument8 pagesInteraction of A Viscous Biopolymer From Cactus Extract With Cement Paste To Produce Sustainable ConcreteTuğçe VuralNo ratings yet

- Best Practices Guide For High-Volume Fly Ash Concretes:: Assuring Properties and PerformanceDocument66 pagesBest Practices Guide For High-Volume Fly Ash Concretes:: Assuring Properties and PerformanceE Hammam El MissiryNo ratings yet

- FA Fineness - Comparing Residue On 45 and Blaine PDFDocument5 pagesFA Fineness - Comparing Residue On 45 and Blaine PDFTran Huynh NamNo ratings yet

- C 452 - 95 Qzq1mi1sruq - PDFDocument4 pagesC 452 - 95 Qzq1mi1sruq - PDFAlejandro MuñozNo ratings yet

- General Specifications: 1. EarthworksDocument7 pagesGeneral Specifications: 1. Earthworksenvironmental100% (1)

- 106 - Sika Waterproofing MortarDocument2 pages106 - Sika Waterproofing MortarZack de la RezaNo ratings yet

- Sraddha Builders2Document43 pagesSraddha Builders2Sampanna 37No ratings yet

- Sail GIDocument40 pagesSail GInitin chaudharyNo ratings yet

- M - 006 - Analysis of Rates PDFDocument101 pagesM - 006 - Analysis of Rates PDFAye Myat KhaingNo ratings yet

- Ncma Tek: Bracing Concrete Masonry Walls During Construction TEK 3-4BDocument6 pagesNcma Tek: Bracing Concrete Masonry Walls During Construction TEK 3-4BjerryNo ratings yet

- Schedule QuantityDocument6 pagesSchedule QuantityRNVNo ratings yet

- Length Change C 157Document7 pagesLength Change C 157Vaguiner VieiraNo ratings yet

- Lafarge ProjectDocument103 pagesLafarge ProjectgoswamiphotostatNo ratings yet

- 22 WaterproofingDocument25 pages22 WaterproofingAjithkumar100% (1)

- Cetorex GroutDocument2 pagesCetorex GroutMosaad KeshkNo ratings yet

- Type BOQ For Construction of 2 Units of Toilet & 1 Unit of Barthroom Drawing No.06Document8 pagesType BOQ For Construction of 2 Units of Toilet & 1 Unit of Barthroom Drawing No.06Yashika Bhathiya JayasingheNo ratings yet

- Item 1018Document5 pagesItem 1018Ester MarianNo ratings yet

- Bills of Quantities - Classroom Block With Offie RevisedDocument32 pagesBills of Quantities - Classroom Block With Offie RevisedMwesigwa AllanNo ratings yet

- 6 BrickworkDocument42 pages6 BrickworkSiti Nurul SyakinahNo ratings yet

- 07 16 13 - Polymer Modified Cement WaterproofingDocument4 pages07 16 13 - Polymer Modified Cement WaterproofingMutaz Hashim MirganyNo ratings yet

CM - ASS2 - Gr2 - HERIL JAIN - UG190554

CM - ASS2 - Gr2 - HERIL JAIN - UG190554

Uploaded by

Heril JainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CM - ASS2 - Gr2 - HERIL JAIN - UG190554

CM - ASS2 - Gr2 - HERIL JAIN - UG190554

Uploaded by

Heril JainCopyright:

Available Formats

MONSOON SEMESTER 2021 CT2614- CONSTRUCTION MATERIALS

GROUP 2: CONVENTIONAL BRICK-

SECOND CLASS

Test 1: To find the distance from first to the last brick

Test 2: Efflorescence Test

Test 3: Water Absorption test

Test 4: Compressive Test

HERIL JAIN | UG190554 1

MONSOON SEMESTER 2021 CT2614- CONSTRUCTION MATERIALS

Test: To find the distance from first to the last brick

• Aim: To determine the distance of 20 bricks by placing it once horizontally and also placing it vertically.

• Apparatus & Materials: 20 first class conventional brick and a measuring tape

• Procedure:

STEP 1: Firstly, place all the 20 bricks in a straight line in rowlock course as shown in fig.1.

STEP 2: Take a measuring tape and calculate the distance from the first brick to the end of last brick.

STEP 3: Then place all the 20 bricks in a straight line in header course as shown in fig.2.

STEP 4: Take a measuring tape and calculate the distance from the first brick to the end of last brick.

STEP 5: Then place all the 20 bricks in a straight line in stretcher course as shown in fig.3.

STEP 6: Take a measuring tape and calculate the distance from the first brick to the end of last brick.

Figure 1: Placing the brick in line in rowlock course Figure 2: Placing the brick in header course.

Figure 3: Placing the brick in line in stretcher course

HERIL JAIN | UG190554 2

MONSOON SEMESTER 2021 CT2614- CONSTRUCTION MATERIALS

• Observations/Observation Table: The length*breath*height of conventional brick used here is

230.5*108.5*77.5 mm. The following table shows the distance from one brick to the last end brick as per it’s

different courses.

Different courses Distance to distance (mm)

1. Rowlock courses 1550 mm

2. Header course 2170 mm

3. Stretcher course 4610 mm

• Calculations:

Result (from your observation):

1. Rowlock Course: The height of one brick is 77.5 mm.

So, 77.5*20= 1550 mm

2. Header Course: The header of one brick is 108.5 mm.

So, 108.5*20= 2170 mm

3. Stretcher Course: The stretcher of one brick is 230.5 mm.

So, 230,5*20= 4610 mm

HERIL JAIN | UG190554 3

MONSOON SEMESTER 2021 CT2614- CONSTRUCTION MATERIALS

Test: Efflorescence Test

• Aim: To determine the efflorescence of burnt clay building brick.

• Reference IS Code for testing: IS 3495 (Part:3), 1992

• Apparatus and Materials: A shallow level base dish containing adequate refined water to totally soak the

examples. The dish will be made of glass, porcelain, or frosted stoneware and of size 180 mm x 150 mm X 40

mm profundity for square molded and 200 mm dia X 40 mm profundity for round and hollow formed.

• Procedure:

STEP 1: Place the block in a glass square or barrel shaped dish.

STEP 2: Immerse the brick 25 mm deep in water as shown in fig.1.

STEP 3: Place the dish with the water and the brick in it in, warm temperature conditions (ideally 20° - 30°C).

STEP 4: Cover the plan to forestall unnecessary vanishing.

STEP 5: Let the plan normally evaporate and afterward rehash the interaction.

Figure 1: Immerse brick Figure 2: Place the brick

in 25 mm deep water one by one in water

HERIL JAIN | UG190554 4

MONSOON SEMESTER 2021 CT2614- CONSTRUCTION MATERIALS

• Observation:

Responsibility of blossoming will be accounted for as:

1. Nil: No salt deposit found.

2. Slight: Deposit found on under 10% of uncovered brick region.

3. Moderate: Deposit found on up to half of surface unaccompanied by powdering of surface.

4. Heavy: Deposit found on over half of surface unaccompanied by powdering of surface.

5. Serious: Heavy store joined by powdering of surface.

• Observation table:

Gr. No. Brick type Efflorescence test effect

Group 1 Conventional Brick- Class 1 <15% Moderate

Group 2 Conventional Brick- Class 2 0-10% Slight

Group 3 Exposed Brick 2-3% Very Slight

Group 4 Cement Mortar Brick 0 Nil

Group 5 Fly Ash Brick <15% Moderate

Group 6 AAC Block 0% Nil

• Specification: The test is fundamentally performed to know the Efflorescence effect and find out with

regards to the bricks that up till what time effect can be seen on this brick.

• Significance: To determine efflorescence of the brick

• Conclusion: The final average gives the overall idea about the bricks and of all brick made in machine

together by testing 5 bricks and taking average of the efflorescence effect acting on the bricks.

HERIL JAIN | UG190554 5

MONSOON SEMESTER 2021 CT2614- CONSTRUCTION MATERIALS

Test: Water Absorption test

• Aim: Determination of water absorption.

• Reference IS code for testing: IS 3495 Part 2: 1992

• Apparatus and Materials: A touchy equilibrium equipped for gauging inside 0.1 percent of mass of the block

test System.

• Procedure:

STEP 1. Immerse totally dried block in clean water for 24 hours.

STEP 2: Remove the Brick and crash water with a soggy material and gauge the block.

STEP 3: Complete the gauging 3 minutes after the block has been eliminated from water.

• Calculation: Water ingestion, percent by mass, following 24-hour inundation in cold water is given by the

accompanying equation: (M2-M1)/M1 *100, The following is the observation table at down.

• Observation Table:

Gr. No. 2 Wet weight (gm) (M2) Dry weight (gm) (M1) Water Absorption (%)

Brick 2 3395 3208 5.83

Brick 3 3535 3450 2.46

Brick 4 3375 3267 3.31

Brick 5 3420 3309 3.35

Brick 6 3505 3352 4.56

Average 3.90%

• Comparing other types of bricks:

AAC Block: 7.82%

Fly Ash: 2.208%

Exposed Brick: 6.052%

Conventional First-class brick: 5.18%

Cement mortar block: 2.673%

Conventional Second-class brick: 3.90%

HERIL JAIN | UG190554 6

MONSOON SEMESTER 2021 CT2614- CONSTRUCTION MATERIALS

• Specification: The test is essentially performed to know the maximum water absorption capacity of the brick

and find out with regards to the bricks which can tolerate its maximum absorption capacity.

• Significance: To know the water absorption capacity of brick

• Conclusion: The water absorption test gives the general thought regarding the bricks and of the all the 5

bricks are then dipped inside water.

HERIL JAIN | UG190554 7

MONSOON SEMESTER 2021 CT2614- CONSTRUCTION MATERIALS

Test: Compressive Test

• Aim: To test the compressive test of the brick.

• Reference IS Code for testing: IS 3495, 1992

• Apparatus and Materials: A Compression testing machine, Compression plate.

• Procedure:

STEP 1: Preconditioning: Eliminating lopsidedness in the bed countenances to give two smooth and equal

appearances by crushing. Fill the frog and all voids in the bed face flush with concrete mortar as shown in

Fig.1.

STEP 2: Place the level even surface and mortar filled face up between two handle wood sheets with care to

be taken in putting midway in the compression testing machine as shown in fig.2.

STEP 3: Apply load pivotally at a uniform pace of 14 N/mm2. Each moment till disappointment happens and

note the greatest burden at which block comes up short as shown in Fig.3.

Figure 1: peconditioning or leveling the surface of brick

HERIL JAIN | UG190554 8

MONSOON SEMESTER 2021 CT2614- CONSTRUCTION MATERIALS

Figure 2: Compression test machine figure 3: Final Outcome

Observation/ observation table:

When the maximum load is given on the brick, it starts cracking. Then the brick fails and the test stops and the final

reading of the compressive strength can be taken.

Calculation:

Compressive strength (N/mm2 ):

Kgf/cm2= Max load at failure (kgf)

Avg. area of bed faces (cm2)

Gr. No. 2 Compressive strength (N/mm2)

Brick 1 2.91 N/mm2

Brick 2 2.91 N/mm2

Brick 3 2.9 N/mm2

Brick 4 2.11 N/mm2

Brick 5 2.51 N/mm2

Average Compressive strength 2.688 N/mm2

HERIL JAIN | UG190554 9

MONSOON SEMESTER 2021 CT2614- CONSTRUCTION MATERIALS

• Comparing other types of bricks:

AAC Block: 6.325 N/mm2

Fly Ash: 9.55 N/mm2

Exposed Brick: 10.646 N/mm2

Conventional First-class brick: 8.196 N/mm2

Cement mortar block: 2.405 N/mm2

Conventional Second-class brick: 2.668 N/mm2

• Specification: The test is essentially performed to know the compressive strength of the brick and find out

with regards to the bricks which are made in amount that up to what broaden the brick can tolerate it’s

maximum compressive strength.

• Significance: To know the strength of the brick

• Conclusion: The last normal compressive strength gives the general thought regarding the bricks and of the

all brick made in machine together by testing 4-5 blocks and taking normal of the strength.

HERIL JAIN | UG190554 10

You might also like

- JKR Schedule of Unit RatesDocument50 pagesJKR Schedule of Unit RatesCheng76% (29)

- Tests For BricksDocument31 pagesTests For BricksTeddy0% (1)

- A Project Report: Marketing Strategy For M Sand Company (Triveni Sands)Document34 pagesA Project Report: Marketing Strategy For M Sand Company (Triveni Sands)karan N100% (1)

- V-1 BOQ - Intake & SitewokDocument136 pagesV-1 BOQ - Intake & Sitewokkandeepan100% (1)

- Ug190554 - Foundation Design ReportDocument33 pagesUg190554 - Foundation Design ReportHeril JainNo ratings yet

- DSR 2021 Vol II English DirDocument337 pagesDSR 2021 Vol II English DirKaranjeet Singh45% (11)

- C3 Fresh and Hardened Concrete TestDocument11 pagesC3 Fresh and Hardened Concrete TestSyukri Abd KadirNo ratings yet

- Brick TestingDocument25 pagesBrick TestingVivek BhardwajNo ratings yet

- ASTM C1403-13 Standard Test Method For Rate of Water AbsorptionDocument4 pagesASTM C1403-13 Standard Test Method For Rate of Water AbsorptionEdwin R Ruiz100% (1)

- CM - Ass2 - Ug190554 - Heril JainDocument9 pagesCM - Ass2 - Ug190554 - Heril JainHeril JainNo ratings yet

- C-309 MT Lab Manual Civil Engineering Material Testing LaboratoryDocument57 pagesC-309 MT Lab Manual Civil Engineering Material Testing LaboratoryVineel ParadesiNo ratings yet

- Concrete and Highway LabDocument42 pagesConcrete and Highway LabProf. Manjunath V. C.No ratings yet

- 637804338746085603ce 20ce33pt W3 S5 SyDocument5 pages637804338746085603ce 20ce33pt W3 S5 SyKavya kNo ratings yet

- CementDocument20 pagesCementHeril JainNo ratings yet

- AGREY MAO - Presentation 2Document25 pagesAGREY MAO - Presentation 2Moses KaswaNo ratings yet

- Yogesh Rana (A62)Document50 pagesYogesh Rana (A62)Yogeshwar singhNo ratings yet

- Material Testing Lab Manual-Expt-1to 14Document50 pagesMaterial Testing Lab Manual-Expt-1to 14rajat debnathNo ratings yet

- Lab 1 Chapter 3: Methodology Slump Test 2.1 Flow Chart: StartDocument18 pagesLab 1 Chapter 3: Methodology Slump Test 2.1 Flow Chart: StartHaiqal RafiqNo ratings yet

- Session 7 PlasterDocument43 pagesSession 7 PlasterlavNo ratings yet

- Experiment 07 Field Tests On BricksDocument3 pagesExperiment 07 Field Tests On Brickssiddharthsawant7768No ratings yet

- Khowpa Engineering College: Constructional MaterialDocument5 pagesKhowpa Engineering College: Constructional MaterialReal BahunNo ratings yet

- Metal Scrap in Paver BlockDocument17 pagesMetal Scrap in Paver BlockAadhiNo ratings yet

- Slump TestDocument8 pagesSlump TestEn Long Bglong100% (2)

- LBYME19 - ConcreteDocument18 pagesLBYME19 - ConcreteAlexis CabigtingNo ratings yet

- Chapter Three 3.0 Methodology: 3.2.1 Aggregates of Requirement in EssentialDocument11 pagesChapter Three 3.0 Methodology: 3.2.1 Aggregates of Requirement in EssentialAsghar Hussain Shah S/o Zubair Shah MS Engg. Management (Swat Campus)No ratings yet

- Civil Engineering Materials Lab ReportDocument17 pagesCivil Engineering Materials Lab ReportSuman SapkotaNo ratings yet

- Concrete Manual 2023Document31 pagesConcrete Manual 2023amdaNo ratings yet

- Engineering Material Brick: Cee, KuktemDocument39 pagesEngineering Material Brick: Cee, KuktemPrateek Banerjee100% (1)

- Building Materials Lab ManualDocument21 pagesBuilding Materials Lab Manualapi-348488925100% (3)

- Report On Laboratory and Site Visit 2Document9 pagesReport On Laboratory and Site Visit 2Vijay JamadarNo ratings yet

- Testing of Material-Lab-Report-5Document6 pagesTesting of Material-Lab-Report-5Mariefel Therese AlsaNo ratings yet

- Group 11 B FinalDocument33 pagesGroup 11 B FinalJatin CoolNo ratings yet

- Report Project Osha PDFDocument27 pagesReport Project Osha PDFSky FireNo ratings yet

- J C Bose University of Science and Technology, Ymca, FaridabadDocument30 pagesJ C Bose University of Science and Technology, Ymca, FaridabadRahul Singh PariharNo ratings yet

- Experiment No. 1 Fineness of Cement by Hand SievingDocument22 pagesExperiment No. 1 Fineness of Cement by Hand SievingUmed Abd-alsatarNo ratings yet

- Midterm RaporDocument15 pagesMidterm RaporSena ÇınarNo ratings yet

- Building Materials LabDocument23 pagesBuilding Materials LababelNo ratings yet

- CT Lab ManualDocument54 pagesCT Lab ManualAxumawi Ebuy TekaNo ratings yet

- Fresh ConcreteDocument34 pagesFresh Concreteahmedalkastawy19No ratings yet

- C3-Fresh & Harden Concrete TestDocument12 pagesC3-Fresh & Harden Concrete TestMuhamad Farhan100% (1)

- Lab Report Exp. 1,2,4,5Document20 pagesLab Report Exp. 1,2,4,5232449045No ratings yet

- Robo Sand (2) - 2Document21 pagesRobo Sand (2) - 2Shaik ShareefNo ratings yet

- Civil Engineering Materials Lab ReportDocument16 pagesCivil Engineering Materials Lab ReportSuman SapkotaNo ratings yet

- 05) CE 304 Lec 3 (Compatibility Mode)Document21 pages05) CE 304 Lec 3 (Compatibility Mode)priyadarshanNo ratings yet

- Bme LatestDocument10 pagesBme LatestDanial AriffNo ratings yet

- Concrete &highway Lab New ManualDocument40 pagesConcrete &highway Lab New Manualshruthicivil100% (4)

- Procedures of TestingsDocument54 pagesProcedures of TestingsSK Emran AliNo ratings yet

- Cement Concrete Hollow Block and ConcreteDocument99 pagesCement Concrete Hollow Block and ConcreteEchanez, Gem Krian0% (1)

- Muddasar Ahmed (Cms Id 6139) Material Engineering Lab PracticalsDocument15 pagesMuddasar Ahmed (Cms Id 6139) Material Engineering Lab PracticalsAafaq Ur RehmanNo ratings yet

- CementsDocument11 pagesCementsmd nasirNo ratings yet

- CH 5 PlasteringDocument22 pagesCH 5 PlasteringEyoatem TeferiNo ratings yet

- IS Standard Bricks TestDocument7 pagesIS Standard Bricks TestYasirNo ratings yet

- Conrete Mix Design & Making and Curing of Test SpecimenDocument15 pagesConrete Mix Design & Making and Curing of Test SpecimenBlesNo ratings yet

- Test On Cement PDFDocument6 pagesTest On Cement PDFIrfan NazirNo ratings yet

- 3495 Part 1 Bricks PDFDocument10 pages3495 Part 1 Bricks PDFVb SeriesNo ratings yet

- 1-Flow & Slump Test-1Document35 pages1-Flow & Slump Test-1ismailNo ratings yet

- A Case Study On BricksDocument7 pagesA Case Study On BricksAritro Roy MitraNo ratings yet

- Slumptest 170922081141Document12 pagesSlumptest 170922081141MohammedNo ratings yet

- Material Testing ManualDocument56 pagesMaterial Testing ManualJithin Benny JithinNo ratings yet

- Lecture Eight: Basic Characteristics of ConcreteDocument13 pagesLecture Eight: Basic Characteristics of Concretea_j_sanyal259No ratings yet

- Introduction To Concrete TechnologyDocument31 pagesIntroduction To Concrete TechnologyMahendra Kumar PalNo ratings yet

- MASIKADocument33 pagesMASIKAGabriel OmondiNo ratings yet

- Bricks: Require Little MaintenanceDocument39 pagesBricks: Require Little MaintenanceGirmaye KebedeNo ratings yet

- DraftDocument27 pagesDraftNaveen SNo ratings yet

- Towards Narol RD.: West BoundDocument1 pageTowards Narol RD.: West BoundHeril JainNo ratings yet

- Height of Light Pole - 7.50MDocument1 pageHeight of Light Pole - 7.50MHeril JainNo ratings yet

- Towards Narol RD.: West BoundDocument1 pageTowards Narol RD.: West BoundHeril JainNo ratings yet

- Narol Circle: Ct3015-Urban Road Intersection Design Cept University and Analysis Not To Scale DrawingsDocument1 pageNarol Circle: Ct3015-Urban Road Intersection Design Cept University and Analysis Not To Scale DrawingsHeril JainNo ratings yet

- ConcreteDocument8 pagesConcreteHeril JainNo ratings yet

- CementDocument20 pagesCementHeril JainNo ratings yet

- 4736 PDFDocument82 pages4736 PDFHeril JainNo ratings yet

- Fine AggregateDocument9 pagesFine AggregateHeril JainNo ratings yet

- CM - Ass2 - Ug190554 - Heril JainDocument9 pagesCM - Ass2 - Ug190554 - Heril JainHeril JainNo ratings yet

- Coarse AggregateDocument11 pagesCoarse AggregateHeril JainNo ratings yet

- FEWEFDocument3 pagesFEWEFHeril JainNo ratings yet

- Coarse Aggregate1Document14 pagesCoarse Aggregate1Heril JainNo ratings yet

- CM - Ass4 - Ug190554 - Heril JainDocument8 pagesCM - Ass4 - Ug190554 - Heril JainHeril JainNo ratings yet

- Site InvestigationDocument42 pagesSite InvestigationHeril JainNo ratings yet

- CementDocument10 pagesCementHeril JainNo ratings yet

- CM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554 - MATERIAL CSDocument45 pagesCM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554 - MATERIAL CSHeril JainNo ratings yet

- CM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554 - SCSDocument9 pagesCM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554 - SCSHeril JainNo ratings yet

- Ug190554 - Heril Jain - PanelDocument1 pageUg190554 - Heril Jain - PanelHeril JainNo ratings yet

- Sieve Analysis: Construction MaterialsDocument10 pagesSieve Analysis: Construction MaterialsHeril JainNo ratings yet

- CM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554 - STRUCTURE CSDocument9 pagesCM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554 - STRUCTURE CSHeril JainNo ratings yet

- Ug190554 - Mini PortfolioDocument11 pagesUg190554 - Mini PortfolioHeril JainNo ratings yet

- 10 PagesDocument11 pages10 PagesHeril JainNo ratings yet

- CM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554Document3 pagesCM - ASS1 (A) - Gr3 - HERIL JAIN - UG190554Heril JainNo ratings yet

- Ug190554 - Site InvestigationDocument42 pagesUg190554 - Site InvestigationHeril JainNo ratings yet

- Presentation For JuryDocument15 pagesPresentation For JuryHeril JainNo ratings yet

- Soil ImprovementDocument34 pagesSoil ImprovementHeril JainNo ratings yet

- UG190554 - HERIL JAIN - FOUNDATION DESIGN FinalDocument37 pagesUG190554 - HERIL JAIN - FOUNDATION DESIGN FinalHeril JainNo ratings yet

- 3.SP-5828 ReportDocument26 pages3.SP-5828 ReportHorizon InfradesignsNo ratings yet

- Composition and Techniques of The Ticinese StuccoDocument21 pagesComposition and Techniques of The Ticinese StuccoTaso Gvantsa PotskhishviliNo ratings yet

- Thin Bed MortarDocument20 pagesThin Bed Mortarrajeshji_000No ratings yet

- MS For Brick WorkDocument7 pagesMS For Brick WorkSumit Omar100% (1)

- Experiment No 03 TITLE:Efflorescence Causes Prevention and Remedial MeasureDocument15 pagesExperiment No 03 TITLE:Efflorescence Causes Prevention and Remedial MeasureOmkar JambhaleNo ratings yet

- Interaction of A Viscous Biopolymer From Cactus Extract With Cement Paste To Produce Sustainable ConcreteDocument8 pagesInteraction of A Viscous Biopolymer From Cactus Extract With Cement Paste To Produce Sustainable ConcreteTuğçe VuralNo ratings yet

- Best Practices Guide For High-Volume Fly Ash Concretes:: Assuring Properties and PerformanceDocument66 pagesBest Practices Guide For High-Volume Fly Ash Concretes:: Assuring Properties and PerformanceE Hammam El MissiryNo ratings yet

- FA Fineness - Comparing Residue On 45 and Blaine PDFDocument5 pagesFA Fineness - Comparing Residue On 45 and Blaine PDFTran Huynh NamNo ratings yet

- C 452 - 95 Qzq1mi1sruq - PDFDocument4 pagesC 452 - 95 Qzq1mi1sruq - PDFAlejandro MuñozNo ratings yet

- General Specifications: 1. EarthworksDocument7 pagesGeneral Specifications: 1. Earthworksenvironmental100% (1)

- 106 - Sika Waterproofing MortarDocument2 pages106 - Sika Waterproofing MortarZack de la RezaNo ratings yet

- Sraddha Builders2Document43 pagesSraddha Builders2Sampanna 37No ratings yet

- Sail GIDocument40 pagesSail GInitin chaudharyNo ratings yet

- M - 006 - Analysis of Rates PDFDocument101 pagesM - 006 - Analysis of Rates PDFAye Myat KhaingNo ratings yet

- Ncma Tek: Bracing Concrete Masonry Walls During Construction TEK 3-4BDocument6 pagesNcma Tek: Bracing Concrete Masonry Walls During Construction TEK 3-4BjerryNo ratings yet

- Schedule QuantityDocument6 pagesSchedule QuantityRNVNo ratings yet

- Length Change C 157Document7 pagesLength Change C 157Vaguiner VieiraNo ratings yet

- Lafarge ProjectDocument103 pagesLafarge ProjectgoswamiphotostatNo ratings yet

- 22 WaterproofingDocument25 pages22 WaterproofingAjithkumar100% (1)

- Cetorex GroutDocument2 pagesCetorex GroutMosaad KeshkNo ratings yet

- Type BOQ For Construction of 2 Units of Toilet & 1 Unit of Barthroom Drawing No.06Document8 pagesType BOQ For Construction of 2 Units of Toilet & 1 Unit of Barthroom Drawing No.06Yashika Bhathiya JayasingheNo ratings yet

- Item 1018Document5 pagesItem 1018Ester MarianNo ratings yet

- Bills of Quantities - Classroom Block With Offie RevisedDocument32 pagesBills of Quantities - Classroom Block With Offie RevisedMwesigwa AllanNo ratings yet

- 6 BrickworkDocument42 pages6 BrickworkSiti Nurul SyakinahNo ratings yet

- 07 16 13 - Polymer Modified Cement WaterproofingDocument4 pages07 16 13 - Polymer Modified Cement WaterproofingMutaz Hashim MirganyNo ratings yet