Professional Documents

Culture Documents

Product Brochure - English Version

Product Brochure - English Version

Uploaded by

Kit Woo0 ratings0% found this document useful (0 votes)

13 views20 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

13 views20 pagesProduct Brochure - English Version

Product Brochure - English Version

Uploaded by

Kit WooCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 20

HAIRODOTICS

HAI ROBOTICS

Next-Gen Warehouse Automation with

Autonomous Case-handling Robotic System

(E] Product Manual

‘www.hairobotics.com

Cea Orr)

HAI ROBOTICS

DoaecC UM Cen run cnt te ia)

IAL ROBOTICS isthe pioncer and leader in autonomous <3

Dey en cee)

pers

eee eee eee)

Bee eee eed

ui Det ee eee ae eet ee See

Se ee eee ee eee ee eee eee

Re ee ee na eee ae ee et eee

BOTICS is expanaing its business and technical service centers globally and cooperates with integrators to develop tailored solution:

Sea

Strong R&D Capabilities

Global Sales &

(60% R&D Workforce)

Customized Solution

Services Netwo

Planning

Completed Manufac-

Whole Process Quality Customer

turing System

Global

Patents

Monitoring Service

Our Partners

Pr Tle ad

One-stop Services

System Integration Manufacturing

Deployment Cutover Customer Service

Industry

Applications

© Hescquarers

© Plans

5 . . . Se

2 © cians

Partners

{ 2225| EERE] Panasonic | Q A ]Srccns] fun

HAIPICK SYSTEM

HAI ROBOTICS successfully launched the first ACR system, HAIPICK, in

aU Cec

intelligent picking, handling, sorting, and accept customized require-

eee a nee eae

at

HAIPICK 442, HAIPICK A42D HAIPICK A42N HAIPICK Aa2T HAIPICK A42 SLAM

ix

7 days for deployment, Increases operational

‘month to go live efficiency by 3- 4 times

Easy to transform Intelligent picking,

and upgrade and hanling

.

——

‘conning

bras)

Increases storage density by Flexible customization Rapid ROI

80% - 130%

Covers a broader storage space Suitable fora vatiety of Significantly shortens the

range (0.25m - 65m) application scenarios return period of investment

Dedicated to R&D of autonomous case-hanaling robotic system, HAI ROBOTICS has successfully developed innovative technol

‘gies that include HAIPICK robots, charging stations, customizable storage units, workstations, and HAIQ software platform. The

company provides customized solutions according to customers’ warehouse automation transformation requirements and

tions in different scenatios.

appl

HAIPICK Robots

Product Advantages

oe

2 Se, i=

Dads siavespeed ae wh ad

P mumi-case banding: Each robe store up to 8 cases at the same time

Dari commanleo: pp 5 bnd ad WF sua Smee option

CN ee

Pinte orien Soran ee

Psa a cntemizbe Sopot ter somite auras dng hip ond abo oar |

Doh

meet ferent application senais ta dle the best sla

HAIPICK A42

ACR

‘Standard height 4.52m

Customizable im

‘Accurate picking & placing _Stable speed with/without load

Reaches 18m

First commercial project in March 2018,

HAIPICK A42D a

Double-deep ACR

‘Standard height 452m Customizable telescopic fork =

Customizable im - 5m Suitable for double-deep shelving

Intelligent algorithm optimization Increases storage density by up to 130%

Guarantees operational efficiency _ Reduces the numberof aisles by up to 50% — 2

First commercial project in March 2020

HAIPICK A42N

Carton-picking ACR

‘Standard height 452m Recognition of goods without a code

Customizable im - 5m Adopts technol:

Supports mixed picking of Compatible with multi-size

‘cartons and totes ‘cartons and totes

First commercial project in May 2020

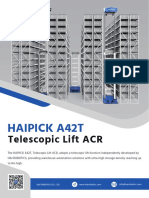

HAIPICK A42T

Telescopic Lift ACR

Standard height 3.7m —_Ultra-wide storage space range

rom 023m to 648m

Convenient transportation Flexibly shuttles between

and rapid deployment different floors and fire zones

Small body size

Intelligent litting, meeting diferent height requirements

hirregular heights

HAIPICK A42 SLAM

Laser SLAM ACR

Efficient handling Laser SLAM,

‘Accurate picking and placing System access

Flexible interaction with other platforms

Workstations

HAI ROBOTICS provides customized workstation solutions, including on-robot picking workstation, on-conveyor picking

workstation, on-shelving picking workstation, and HAIPORT-powered workstation, adaptable to diferent business scenarios.

eer

On-robot picking workstation

On-shelving picking workstation

HAIPORT-powered workstation

More Docking Methods

-_

h

Latent AGV

Robotic arm

Pet lee le pe ety

d

i

)

8

a

E

=

HAIPORT- “powered V Workstation

HAIPORT-n6

conveyor work

‘multiple cases at one time from the robot onto the conveyor, effectively increasing the c

workstation is an automatic machine that powers c

usly from the conveyor onto the robot's

ions, loading multiple cases simul

Benefits

as O

@

Multi-case Efficient & fast Flexible & adjustable Safe & Comfortable

loading/unloading

Automatic loadi

Storage Units

Easy to build, transform, and upgrade

Charging Station

Carton/tote _ Muli-size carton/tote

charging. suport fal haying modes to

Ah operation

SO 3%

Shelving Charging Stati

Customizable shelves

(height, size & type)

HAIQ Software Platform

The HAIQ software platform is the intelligent brain of HAI ROBOTICS HAIPICK system, It can be connected to the external

‘management systems, deal with relevant business requirements, perform data analysis and visual management to ensure the

simultaneous dispatch of multiple robots and various equipment. It realizes system health prediction and monitoring, and

‘optimizes the system based on reinforcement learning and deep learning,

ERP/WMS/MES/.

Work Data

Station Center

ESS Algorithm Platform

xs mm comer | Manipuor | More

A A A A A

IWMS - Intelligent

Warehouse Management,

System

ESS - Equipment Schedule

System

RCS - Robot Control

System

Intelligent Algorithm,

Platform

WMS integrates with the company’s management system to realize business data manage-

‘ment, warehouse operation management, inventory location management, equipment

‘management monitoring, and intelligent report management, performing sell-optimization

‘based on operational data collected over time.

Business data management Coordinate inventory management

ESS manages the scheduling of robots, conveyor systems, rollers, mechanical arms, and

‘other components. It deals with order tasks and interacts with workstations and data

centers, realizing inteligent order allocation, intelligent task allocation, inbound/return

location, dynamic inventory checking, and other functions.

CS can support 600 robots working simultaneously. It manages the HAIPICK route

planning, transportation, and charging, RCS guarantees to increase the efficiency of the

robot task executions, predicts, and monitors the robot's conditions.

‘The Inteligent Algorithm Platform can accurately calculate the most efficient transportation,

path and sorting plan based on the warehouses cargo quantity, regional location, inbound

‘and outbound trafic, performing real-time task assignments for each robot. At the same

time it provides data analysis of commodity flow, high demand, and relevance to optimize

business processes.

aoe anetions

tite + commas demand nae

Solutions

Smart Warehouse Logistics Solution

Cost-saving and high-efficiency, enabling smart warehouse

‘smart warehouse logistics olution covers HAIPICK ACR and HIQ software platform, provicing customers with

ficient "ase-te-person* and automated full process solutions, carrying out csital and information management

‘upgrades, reducing costs and increasing efficiency

Efficient care-to-person Increased storage density xtc tron imho mint ren

©

(Muttibusiness support Rapid and flexible daployment

ible solution cost-saving and high-efficiency

Solutions

Smart In-plant Logistics Solution

Ra ter aap es

The new era of manufacturing creates flexible and intelligent logistics

The combination of HAIPICK ACR and HAIQ software platform flexibly meets the needs of various production lines. It enables access to the raw

‘material area, buffer are, fished and semi-finished product storage areas, and production lines, realizing information management and creating a

fully automated intelligent manufacture logistics solution

©

Operation process Facilitate efficient Flexible ‘Whole automation

tii interact process

Reduces operating Material information Wide range of

ay

Case Studies

BEST Supply Chain

Hospital in Shenzhen smart Meshal Xinning Logistics

Supply Warehouse

ERAL. Apparel

Application Results

Increace storage space: ft can realize drm shelving, increasing Rapid deployment: within one week, and commissioning in

storage density by 80% cone month

Kanban visual management system: easy to operate, achieving Improve labor efficiency: inbound efficiency is improved 20,

sfficent and accurate information management ‘times, outbound efficiency is improved 35 times

Ping Zhifeng, General Manager of FMICG/Retal Business Unit of SF-DHL

inne ils ROBT t c

intel Sf 7

hilips Zhuhai

OMEN SIC elacla

Application Results

lit orders to meet diferent business needs

nT

Xin Hee

Large Clothing Logistics Center in Xiamen

Application Results

HAIPICK robots improve manual work and the process of pacing

and handling cases

Rational planing, warehouse storage utilization reaches 90%

Perfect case-to-person design to meet the needs of efficient

storage warehouse

‘Seamless connection with WMS system to optimize the location,

path, and task allocation

Customized robots and totes to better meat custome

Flexible and expandable to meet the demand during peak periods

and business development

Product Specifications

HNIPICK r z

dle ard

Basic Parameters,

‘communication

Deployment

Emvonment

Performance

Battery “

safety Z a

rae ea AD z z

Customized HAIPICK A42L HAIPICK A42LN

HAIPICK Robots ts *

HAIPICK A42N

LN le aU ae

HAIPICK A42 SLAM

I i Lift I

worse pe 0-528 atta ptm ey i 80 worsen

‘efor apie = >

tonto oot oi >

(eo 0-0 HOS

econo

ee)

Die apaameniani poem)

me we we

oven st Feros aero 08

Intelligent Charging Station

ron Dimersionof Charging Satin (fm:

ele mensions of Chars (Hm

755-23208112

Transform Warehousing

with Robotics + Al Ready Solutions

HAI ROBOTICS CO., LTD.

Contact Us

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HAI ROBOTICS Introduction ENV2022.0829 MarketingDocument40 pagesHAI ROBOTICS Introduction ENV2022.0829 MarketingKit WooNo ratings yet

- JDLAR2021AR enDocument214 pagesJDLAR2021AR enKit WooNo ratings yet

- SF 2021 ArDocument331 pagesSF 2021 ArKit WooNo ratings yet

- JD2022q1 HighlightDocument13 pagesJD2022q1 HighlightKit WooNo ratings yet

- SF 2021 HalfyearreportDocument326 pagesSF 2021 HalfyearreportKit WooNo ratings yet

- SfeiDocument156 pagesSfeiKit WooNo ratings yet

- 2020年中国智慧物流产业研究报告Document31 pages2020年中国智慧物流产业研究报告Kit WooNo ratings yet

- Jdlar2021 enDocument34 pagesJdlar2021 enKit WooNo ratings yet

- JDLQR2022Q2Document38 pagesJDLQR2022Q2Kit WooNo ratings yet

- Full Year Results Presentation 2022Document39 pagesFull Year Results Presentation 2022Kit WooNo ratings yet

- D. Roy - Mobile Racks and RobotsDocument20 pagesD. Roy - Mobile Racks and RobotsKit WooNo ratings yet

- GS1Summit RickyWong FinalDocument33 pagesGS1Summit RickyWong FinalKit WooNo ratings yet

- Haipick A42T: Telescopic Lift ACRDocument2 pagesHaipick A42T: Telescopic Lift ACRKit WooNo ratings yet

- Product Brochure Global v.20220825 - compressed 複製Document13 pagesProduct Brochure Global v.20220825 - compressed 複製Kit WooNo ratings yet