Professional Documents

Culture Documents

Wall Chart

Wall Chart

Uploaded by

Valmir LimaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wall Chart

Wall Chart

Uploaded by

Valmir LimaCopyright:

Available Formats

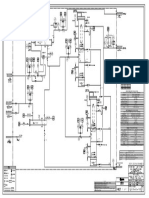

Manufacturer of

Round & Profile Wire

AWS / APPROX TYPICALLY CHOSEN FOR

APPLICABLE CHEMICAL HEAT TREATMENT OF FINISHED PARTS

ALLOY W.Nr / STANDARDS COMPOSITION HIGH CORROSION KEY FEATURES

UNS (%) TEMPERATURE RESISTANT AS SUPPLIED TYPE TEMP ºC (ºF) TIME (Hr) COOLING

AMS 5687

Inconel AWS 010

2.4816

ASTM B166

Ni bal

Cr 14 – 17

• Good oxidation resistance

• Good corrosion resistance at high temperatures Annealed or

Stress Relieve 460 (860) 1 Air

600• N06600

BS 3075 NA 14

BS 3076 NA 14

Fe 6 - 10 *High temperature static applications

Spring Temper

Fe bal

Inconel AWS 011

2.4851 ASTM B166

Ni 58 - 63

• Outstanding resistance to oxidation & other forms of high temperature corrosion

• Higher mechanical properties at elevated temperatures than Inconel 600 Annealed or

Stress Relieve 480 (900) 1 Air

601• N06601

Cr 21 – 25

Al 1 – 1.7 *High temperature static applications

Spring Temper

AMS 5666

Ni bal

Inconel AWS 012

2.4856

ASTM B446

BS 3076 NA 21

Cr 20 – 23

• Excellent corrosion resistance in a wide range of corrosive media

• Especially resistant to pitting and crevice corrosion Annealed or

Stress Relieve

260-370

0.5-1 Air

625• N06625 NACE MRO175

ISO 15156

Mo 8 – 10

Nb 3.15 – 4.15 • Good for sea water applications

Spring Temper (500-700)

AMS 5662 Fe bal Anneal 980 (1800) 1 Air

AMS 5663 Ni 50 – 55

• Good creep rupture strength at high temperatures

Age Harden 720 (1330) 8 Furnace

Inconel AWS 013

2.4668

AMS 5832

AMS 5962

Cr 17 – 21

Nb+Ta 4.75 – 5.5

• Higher strength than Inconel X-750

• Better mechanical properties at lower temperatures than Nimonic 90 & Inconel X-750 No.1 or Spring

Total Age 620 (1150) 18 Air SIZE RANGE:

718• N07718 ASTM B637

NACE MRO175

Mo 2.8 – 3.3

Ti 0.65 – 1.15

• Age hardenable Temper Anneal 1010 (1850) 2 Air 21.0mm to 0.025mm

#

High temperature dynamic applications Age Harden 790 (1455) 6 Air

ISO 15156 Al 0.2 – 0.8

(.827” to .001”)

AMS 5667

Spring Temper Age Harden 650 (1200) 4 Air

AMS 5698

Ni 70 min • Good creep rupture strength at high temperatures

Cr 14 – 17

Inconel AWS 014

2.4669

AMS 5699

ASTM B637

Fe 5 – 9

• Not as strong as Nimonic 90

• Very good at cryogenic temperatures 3 Part: Spring

Anneal

Stabilize

1150 (2100)

843 (1550)

∆

2

24

Air

Air

X-750• N07750 BS HR 505

NACE MRO175

Ti 2.25 – 2.75

Nb+Ta 0.7 – 1.2 • Age hardenable

Temper

Age Harden 704 (1300) 20 Air

ISO 15156

Al 0.4 – 1.0 #

High temperature dynamic applications

No 1 Temper Age Harden 730 (1350) 16 Air

Ni bal

AWS 032

Nimonic 2.4951 BS HR 5

Cr 18 – 21

Fe 2 - 5

• Good corrosion resistance

• Good heat resistance Annealed or Stress Relieve

450-470

0.5-1 Air

75• 2.4630

N06075

BS HR 504

Ti 0.2 – 0.6

C 0.08 – 0.2

*High temperature static applications

Spring Temper (840-880)

AWS 031

Ni bal • Largely superseded by Nimonic 90 & Inconel X-750

Nimonic 2.4952

ASTM B637

BS HR 601

Cr 18 – 21

Ti 1.8 – 2.7

• Still specified for nuclear applications due to low cobalt content Annealed Age Harden 700 (1290) 16 Air

80A• 2.4631

N07080

BS 3076 NA 20 Al 1 – 1.8

C 0.04 – 0.1

• Age hardenable

#

High temperature dynamic applications

Spring Temper Age Harden 600 (1110) 16 Air

AMS 5829

BS HR 501 Annealed Age Harden 750 (1380) 4 Air

AWS 030 BS HR 502

Ni bal • High stress rupture strength and high creep resistance at high temperatures

Nimonic 2.4632 BS HR 503

Cr 18 – 21

Co 15 – 21

• Good resistance to high-temperature corrosion and oxidation

Spring Temper Age Harden 650 (1200) 4 Air

90• 2.4969

N07090

NCK 20TA

BS 3075 NA 19

Ti 2 – 3

Al 1 - 2

• Age hardenable

#

High temperature dynamic applications

NACE MRO175 Spring Temper Age Harden 600 (1110) 16 Air

ISO 15156

ASTM B164

AWS 040

BS 3075 NA 13 • Excellent corrosion resistance in a wide range of acidic & alkaline environments

Monel 2.4361

BS 3076 NA 13

DTD 204B

Ni+Co 63 – 70 • Especially suitable for reducing conditions Annealed or Stress Relieve

300-320

0.5-1 Air

400• 2.4360

N04400

NACE MRO175

ISO 15156

Cu 28 – 34 • Good ductility & thermal conductivity

• Good for sea water applications

Spring Temper (570-610)

QQ-N-281

BS 3075 NA 18 • Corrosion resistance similar to Monel 400 but with higher strength and hardness Annealed 580-590

Ni 63 min

∆

Age Harden 8-10 Air

Monel AWS 041

2.4375

BS 3076 NA 18

NACE MRO175

Cu 27 – 33 • Low permeability and is non-magnetic to temperatures as low as -101°C (-150°F ) (1075-1095)

K-500• N05500 ISO 15156

Al 2.3 – 3.15

Ti 0.35 – 0.85

• Age hardenable

Spring Temper ∆

Age Harden 530-540

4-6 Air ORDER QUANTITY:

QQ-N-286 • Good for sea water applications (985-1005)

from 3m (10ft) to

Hastelloy AWS 051

ASTM B335

Ni bal

Mo 27 – 32

• Excellent corrosion resistance to hydrochloric acid at all concentrations and temperatures

Annealed or 400-450 2000kg (4,400 lbs)

2.4600

ASTM B619 Cr 1 – 3 • Withstands sulphuric, acetic, formic & phosphoric acids & other non-oxidising media Spring Temper Stress Relieve

(750-840)

2 Air

B-3

q

N10675 • Excellent resistance to pitting corrosion & stress corrosion cracking

Fe 1 – 3

Hastelloy AWS 052

2.4610

ASTM B574

Ni bal

Cr 14 – 18

• Excellent resistance to stress-corrosion cracking and to oxidizing atmospheres at high temperature

• Exceptional resistance to a wide variety of chemical process environments including, hot contaminated Annealed or

Stress Relieve

400-450

2 Air

ASTM B619 Spring Temper (750-840)

C-4

q

N06455 Mo 14 – 17 mineral acids, solvents, chlorine, formic and acetic acids, and salt waters.

Ni bal

ASTM B619

Hastelloy AWS 053

2.4602

ASTM B574

Cr 20 – 22.5

Mo 12.5 – 14.5

• Better overall corrosion resistance than Hastelloy C-4 & C-276 and Inconel 625 Annealed or Stress Relieve

400-450

2 Air

NACE MRO175 • Outstanding resistance to pitting, crevice corrosion and stress corrosion cracking Spring Temper (750-840)

C-22

q

N06022 Fe 2 – 6

ISO 15156

W 2.5 – 3.5

ASTM B619

Ni bal • Excellent corrosion resistance in a wide range of corrosive media including, sulphur compounds and chloride ions

Hastelloy AWS 054

2.4819

ASTM B574

Mo 15 – 17

Cr 14.5 – 16.5

• Excellent resistance to pitting, crevice corrosion and stress corrosion cracking Annealed or

Stress Relieve

400-450

2 Air

NACE MRO175 • Withstands the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide Spring Temper (750-840)

C-276

q

N10276 Fe 4 – 7

ISO 15156

W 3 – 4.5 • Good for sea water applications.

• Developed to resist corrosion in a wider range of media

Ni bal

Hastelloy AWS 055

2.4675

ASTM B619 Cr 22 – 24

• Resistant to an extensive range of corrosive chemicals including sulphuric, hydrochloric & hydrofluoric acids

• Superior pitting resistance and crevice corrosion resistance to Hastelloy C-276 Annealed or Stress Relieve

400-450

2 Air

ASTM B574 Mo 15 – 17 Spring Temper (750-840)

C-2000

q

N06200 • Excellent corrosion resistance to reducing media

Cu 1.3 – 1.9

• Good oxidising resistance

AMS 5796 Co bal

Haynes 25 • Good resistance to oxidising environments at high temperatures for long exposures

q

AWS 060 AMS 5759 Cr 19 – 21

Annealed or 400-450

2.4964 ASTM F90 W 14 – 16 • Excellent resistance to sulphidation Spring Temper

Stress Relieve

(750-840)

2 Air

• Trade names of Special Metals Group of Companies.

/ L605 R30605 NACE MRO175

ISO 15156

Ni 9 – 11

Mn 1 – 2

*High temperature static applications

Fe bal

AWS 021 Ni 30 – 35 • Higher creep rupture strength than Incoloy 800 due to close control of C, Al, Ti

Incoloy 1.4958

BS 3076 NA 15H

Cr 19 – 23 • Excellent resistance to oxidation and carburisation at high temperatures Annealed or

Stress Relieve

450-470

0.5-1 Air

800HT• 1.4959

N08811

Al 0.15 – 0.6

Ti 0.15 – 0.6

• Corrosion resistant in many aqueous environments

*High temperature static applications

Spring Temper (840-880)

C 0.05 – 0.1

Fe bal

Ni 38 – 46 • Resistant to reducing environments such as those containing sulphuric and phosphoric acids

Incoloy AWS 022

2.4858

BS 3076 NA 16 Cr 19.5 – 23.5 • Resistant to a variety of oxidising substances such as nitric acid and nitrates Annealed or

Stress Relieve

450-470

0.5-1 Air

825• N08825

ASTM B425 Mo 2.5 – 3.5

Cu 1.5 -3

• Resistant to chloride-ion stress corrosion cracking and, pitting and crevice corrosion

• Good for chemical processing.

Spring Temper (840-880)

Ti 0.6 – 1.2

AMS 5731

AMS 5734 SUPPLIED IN:

q

Fe bal • High strength and good corrosion resistance at high temperatures

Trade names of Haynes International.

Incoloy AWS 023

1.4944

AMS 5737

AMS 5853

Ni 24 – 27 • Age hardenable Annealed or 705-760 coil / spools

Cr 13.5 – 16 Age Harden 16 Air

A-286• 1.4980

S66286

BS HR 52

BS HR 650

Ti 1.9 – 2.35

Mo 1 – 1.5

• Good for high temperature fasteners

*High temperature static applications

Spring Temper (1300-1400) / straight cut lengths

NACE MRO175

ISO 15156

General Props ∆ Age Harden 650 (1200) 2 Air

Fe bal • Outstanding controllable thermoelastic coefficient characteristics

Spring Temper

Ni-Span AWS 080

AMS 5225

AMS 5221

Ni+Co 41 – 43.5

Cr 4.9 – 5.75

• Can be processed to have constant modulus of elasticity from from -45 to +65ºC (-50 to +150ºF)

Max Stability ∆

Stress Equalise 400 (750) 2 Air

C-902• N09902

HS 261 Ti 2.2 – 2.75

Al 0.3 – 0.8

• Good for springs in watches and weighing equipment

• Age hardenable

Age Harden 650 (1200) 2 Air

Min Hysterisis ∆ Stress Equalise 400 (750) 2 Air

† Trade name of Imphy Ugine Precision. * Trade name of SPS Technologies. ∞ Trade name of General Electric Inc.

AWS 151 • Good tensile properties at ambient temperatures compared with other titaniums

Titanium Gr.5 3.7165 ASTM B348

Ti bal

Al 5.5 – 6.75

• Good creep resistance up to approx 300ºC (570ºF). Annealed or

Stress Relieve

250-650

0.5-4 Air

3.7164 AMS 4928 • Outstanding resistance to corrosion in most natural and many industrial process environments Spring Temper (482-1200)

/ 6Al4V UNS R56400

V 3.5 – 4.5

• Approx half the density of nickel alloys

• Combination of high strength, ductility and good mechanical properties at ambient temperatures

Fe bal

AMS 5833

Co 39 – 41 • Excellent fatigue life Annealed - - - -

AWS 100 ISO 5832 • Excellent corrosion resistance in numerous environments

† Cr 19 – 21

Phynox 2.4711

R30003

AMS 5834

NACE MRO175

Ni 14 – 16 • Non magnetic

Mo 6 – 8 Spring Temper Age Harden 520 (970) 5 Air

ISO 15156

Mn 1.5 – 2.5

• Age hardenable (Spring Temper only)

• Good for sea water applications

AMS 5844 Co bal • Combination of high strength, ductility and good mechanical properties at ambient temperatures

AWS 110 ASTM F562 Ni 33 – 37 • Excellent corrosion resistance in hydrogen sulphide Annealed - - - -

*

MP35N R30035 NACE MRO175 Cr 19 – 21 • Excellent resistance to crevice and stress corrosion cracking in sea water

ISO 15156 Mo 9 – 10.5 Spring Temper Age Harden 650 (1200) 4 Air

• Age hardenable (Spring Temper only)

Ni bal Annealed Age Harden 760 (1400) 16 Air

Cr 18 – 20 • Very high strength at elevated temperatures

AWS 120 • Good oxidation resistance

∞ AMS 5545 Co 10 – 12 Solution Anneal 1065 (1950) 4 Air

Rene 41 2.4973

N07041

AMS 5800 Mo 9 – 10.5 • Age hardenable

Spring Temper

Age Harden 760 (1400) 16 Air

Ti 3 – 3.3

Al 1.4 – 1.6

#

High temperature dynamic applications

Spring Temper Age Harden 760 (1400) 16 Air

Ni bal Stabilize 843 (1550) 4 Air

Annealed

AWS 170 AMS 5544

Cr 18 – 21 • Very high strength at elevated temperatures

• Strength is generally comparable to that of Rene 41 and generally superior to Inconel 718

Age Harden 760 (1400) 16 Air MANUFACTURED

Co 12 – 15

Waspaloy P 2.4654

N07001

AMS 5708

AMS 5828

Mo 3.5 – 5 • Age hardenable Anneal 1050 (1920) 4 Air / STOCKED TO

Ti 2.75 – 3.25

Al 1.2 – 1.6

#

High temperature dynamic applications Spring Temper Stabilize

Age Harden

843 (1550)

760 (1400)

24

16

Air

Air

CUSTOMER

Fe bal

SPECIFICATION

Cr 16 – 18

Nitronic AWS 166 Ni 8 – 9

• Anti galling

Annealed or

P Trade

UNS S21800

-

Mn 7 – 9 • Wear resistant Spring Temper

Stress Relieve 250 (480) 1 Air

60

6

Si 3.5 – 4.5 • Good for thread inserts

name of United Technologies Corp.

N 0.08 – 0.18

Fe bal • Greater corrosion resistance than stainless steel 300 series.

Duplex AWS 167

1.4462

NACE MRO175

Cr 21 – 23

Ni 4.5 – 6.5

• Greater pitting resistance and uniform corrosion resistance to stress corrosion cracking than Annealed or

Stress Relieve 250 (480) 1 Air

ISO 15156 stainless steel 300 series Spring Temper

2205 S31803 Mo 2.5 – 3.4

N 0.1 – 0.22 • Good weldability

Fe bal

Alloy 20 AWS 130

2.4660

NACE MRO175

Cr 19 – 21

Ni 32.5 – 35

• Excellent resistance to hot sulphuric acid & many other aggressive environments that would attack ST/ST 316 Annealed or

Stress Relieve

250-530

1 Air

ISO 15156 • Superior resistance to stress corrosion cracking in boiling 20 – 40% sulphuric acid Spring Temper (480-990)

CB3 N08020 Cu 3 – 4

Mo 2 – 3

6

Trade name of AK Steel.

2.4869 Ni 80 • ’Electrical Resistance’ alloy (108 microhms.cm), used at operating temperatures up to approx. 1200º C (2200º F)

80/20 NiCr N06003

-

Cr 20 • Good for electric heating elements, control resistors

- - - - -

• ’Electrical Resistance’ alloy, used mainly for its medium range electrical resistivity (49 microhms.cm). VERY low

Ni 45

45/55 NiCu 2.0842 -

Cu 55 temperature-coefficient of resistance. - - - - -

• Good for precision resistors

Required mechanical properties can be achieved through a combination of cold work and / or heat treatment #

Dynamic applications = active / lively / changing *Static applications = still / fixed / motionless / rigid ∆

See Alloy Wire technical brochure

Other Alloys - Nickel: 200, 201, 205, 212, 270 | Nilo•: 36, 42, 48, 52, K | Stainless Steel: 302, 304, 316, 316LVM, 316Ti, DTD189A | Beryllium Copper: CB101

e : sales@alloywire.com t : +44 (0) 1384 262 022 f : +44 (0) 1384 263 022

Tel: USA Toll Free 1-866-482-5569 Fax: 401-384-6757 International Sales Offices: for your local office see International Contacts at www.alloywire.com

www.alloywire.com Narrowboat Way, Hurst Business Park, Brierley Hill,

West Midlands DY5 1UF, UK.

AS 9100 ISO 9001

DFARS

compliant

You might also like

- AMS5688Document7 pagesAMS5688Federica FiorentiniNo ratings yet

- LEA 1601 Curing Monolithics Containing Hydraulic CementDocument4 pagesLEA 1601 Curing Monolithics Containing Hydraulic CementMichelle Wilson100% (1)

- Heavy Metal Intoxication and Chelators MCQ Answer SheetDocument4 pagesHeavy Metal Intoxication and Chelators MCQ Answer SheetPatrick Dycoco67% (6)

- SAE - AMS 5759lv003Document6 pagesSAE - AMS 5759lv003Nilesh PatilNo ratings yet

- Principles of Fracture MechanicsDocument49 pagesPrinciples of Fracture MechanicsgodzillafoodNo ratings yet

- Spirax Sarco (TI) - Valvula Cheque DCV4 (TI-P134-04-EN)Document4 pagesSpirax Sarco (TI) - Valvula Cheque DCV4 (TI-P134-04-EN)Nestor LozanoNo ratings yet

- Electrode Dan Welding Wires 1646204294Document7 pagesElectrode Dan Welding Wires 1646204294Gibran RamadhanNo ratings yet

- XHS310 DatasheetDocument4 pagesXHS310 Datasheetsooraj1234No ratings yet

- Aluminium Aluminum 6061 Alloy (UNS A96061)Document4 pagesAluminium Aluminum 6061 Alloy (UNS A96061)HARIPRASATH PNo ratings yet

- Champion Spiral Wound Gasket-CatalogDocument2 pagesChampion Spiral Wound Gasket-Catalogsaravanaa212No ratings yet

- F-7.2.1.5 Specification Revision ListDocument11 pagesF-7.2.1.5 Specification Revision ListRam Parimalam0% (1)

- Extruded Alloy 6061Document2 pagesExtruded Alloy 6061muaadhNo ratings yet

- Outokumpu Therma Range DatasheetDocument16 pagesOutokumpu Therma Range Datasheetcehamos882No ratings yet

- Ak Steel Armco® PH 13-8 Mo Product Data Bulletin - Apr 2019 - 95Document44 pagesAk Steel Armco® PH 13-8 Mo Product Data Bulletin - Apr 2019 - 95Galuh Chandra KusumaNo ratings yet

- Astm A 703Document15 pagesAstm A 703hlagos123No ratings yet

- Aalco Metals LTD Stainless Steel 14571 Bar 40Document3 pagesAalco Metals LTD Stainless Steel 14571 Bar 40raduonoNo ratings yet

- Aisi E50100, E52100: 154/amoyDocument6 pagesAisi E50100, E52100: 154/amoyahmad hafizNo ratings yet

- Allowable Stresses of Typical ASME Materials - Stainless SteelDocument5 pagesAllowable Stresses of Typical ASME Materials - Stainless SteelChanchal K SankaranNo ratings yet

- Stainless Steels: Alloy 904L (UNS N08904)Document1 pageStainless Steels: Alloy 904L (UNS N08904)MV ABNo ratings yet

- Ams 4985CDocument13 pagesAms 4985CBacksniper100% (1)

- Avesta 310Document1 pageAvesta 310ulasNo ratings yet

- Alloy A286 Ams 5731 Ams 5732 Ams 5737Document2 pagesAlloy A286 Ams 5731 Ams 5732 Ams 5737gowtham raju buttiNo ratings yet

- Electric Heater EH-2113101/201/301/401: Train No. 2 Train No. 3 Train No. 4Document1 pageElectric Heater EH-2113101/201/301/401: Train No. 2 Train No. 3 Train No. 4Manuel SerranoNo ratings yet

- Fig 4923 GDocument1 pageFig 4923 GAsmaaNo ratings yet

- Steel Castings, General Requirements, For Pressure-Containing PartsDocument15 pagesSteel Castings, General Requirements, For Pressure-Containing Partsroberto diazNo ratings yet

- Inverted Bucket Idh Lf2Document2 pagesInverted Bucket Idh Lf2Roo FaNo ratings yet

- Welding of Stainless Steels & Duplex: Roshan RampureDocument74 pagesWelding of Stainless Steels & Duplex: Roshan Rampureapurva karleNo ratings yet

- Sa-530 For Flattening HeightDocument10 pagesSa-530 For Flattening HeightmaheshNo ratings yet

- Powder Metallurgy HSS: Chemical CompositionDocument4 pagesPowder Metallurgy HSS: Chemical CompositionSama UmateNo ratings yet

- Specification For Steel Castings, General Requirements, For Pressure-Containing PartsDocument19 pagesSpecification For Steel Castings, General Requirements, For Pressure-Containing Partsbyom18No ratings yet

- 317 Cast Iron PR 3asDocument1 page317 Cast Iron PR 3asAgung YudistiraNo ratings yet

- MF400 Datasheet: Standard Materials of ConstructionDocument4 pagesMF400 Datasheet: Standard Materials of Constructionامیر علیNo ratings yet

- 6061 Aluminum Plate - AMS 4027 - 6061-T651 PlateDocument3 pages6061 Aluminum Plate - AMS 4027 - 6061-T651 Platemini p shendeNo ratings yet

- Mud ValvesDocument4 pagesMud ValvesFabio Peres de LimaNo ratings yet

- Steam Trap Datasheet TLV Type P65SRNDocument2 pagesSteam Trap Datasheet TLV Type P65SRNAnonymous ThzA9zNo ratings yet

- LF311 Datasheet: Low-Flow Pressure RegulatorDocument4 pagesLF311 Datasheet: Low-Flow Pressure RegulatorIdehen KelvinNo ratings yet

- Material Cross Reference List 1Document3 pagesMaterial Cross Reference List 1vinothcdmNo ratings yet

- Catalog (Heavy Forging) PDFDocument6 pagesCatalog (Heavy Forging) PDFViệt Châu TháiNo ratings yet

- ASCO 223+junc - BoxDocument12 pagesASCO 223+junc - BoxRyuNo ratings yet

- Specification For Steel Bars, Carbon Ano Allov, Hot-Wrought, General Requirements ForDocument27 pagesSpecification For Steel Bars, Carbon Ano Allov, Hot-Wrought, General Requirements Foredisson_barreraNo ratings yet

- 2600series Data SheetDocument5 pages2600series Data SheetEnrique AssmannNo ratings yet

- Alloy 6063 Rev2012Document2 pagesAlloy 6063 Rev2012Hilbert FloresNo ratings yet

- Rapid Stress Relief and TemperingDocument8 pagesRapid Stress Relief and Temperingtbmari100% (1)

- IS ValvesR2Document14 pagesIS ValvesR2noelia lopez razukNo ratings yet

- Thermodynamic DC50 A105 PDFDocument2 pagesThermodynamic DC50 A105 PDFRoo FaNo ratings yet

- Asme Section Ii A Sa-450 Sa-450m PDFDocument12 pagesAsme Section Ii A Sa-450 Sa-450m PDFdavid perezNo ratings yet

- 500 Series: Submittal Sheet ASME Section VIII Safety Relief ValveDocument9 pages500 Series: Submittal Sheet ASME Section VIII Safety Relief Valveantony nirmalaNo ratings yet

- Stainless Steel: Aerospace Paper Food Processing Metalworking Petrochemical ChemicalDocument20 pagesStainless Steel: Aerospace Paper Food Processing Metalworking Petrochemical ChemicaljjdNo ratings yet

- INCONEL Alloy 600 BlogDocument4 pagesINCONEL Alloy 600 BlogRELIABLE PIPES & TUBESNo ratings yet

- Asme Section Ii A-2 Sa-985 Sa-985mDocument22 pagesAsme Section Ii A-2 Sa-985 Sa-985mAnonymous GhPzn1xNo ratings yet

- Sapa Alloy 6063Document2 pagesSapa Alloy 6063Sachith Praminda RupasingheNo ratings yet

- Aerospace Material SpecificationDocument8 pagesAerospace Material SpecificationDUNo ratings yet

- Steel Anal For High Pressure H2Document13 pagesSteel Anal For High Pressure H2pec21102002No ratings yet

- 910F Series: DescriptionDocument2 pages910F Series: DescriptionImtiyaz KhanNo ratings yet

- Bleed Valves and Purge ValvesDocument2 pagesBleed Valves and Purge ValvesdeckyirawansusantoNo ratings yet

- Astm A563Document9 pagesAstm A563mhmgola100% (1)

- Ari Trampas TermodinamicasDocument10 pagesAri Trampas TermodinamicasGregorio Mata MartínezNo ratings yet

- Astm A703 A703m 18Document6 pagesAstm A703 A703m 18VenkateshNo ratings yet

- Atlas Aluminium Datasheet 6063 Rev Oct 2013 PDFDocument2 pagesAtlas Aluminium Datasheet 6063 Rev Oct 2013 PDFAdamMitchellNo ratings yet

- MSDS Ethanol E100Document4 pagesMSDS Ethanol E100RinaRossoneRinaNo ratings yet

- Fundamentals of Chemistry and MineralogyDocument11 pagesFundamentals of Chemistry and MineralogyEvi Intan SariNo ratings yet

- Sae J 2045 2012-11-01Document16 pagesSae J 2045 2012-11-01GT-LUCAS BARCI100% (1)

- Top Chapters For MHT CET - MathonGoDocument3 pagesTop Chapters For MHT CET - MathonGoeducationvideos7415No ratings yet

- Stunting Dan Stress Oksidatif - Aly 2018Document6 pagesStunting Dan Stress Oksidatif - Aly 2018Emmy KwonNo ratings yet

- Synthesis of Poly (L-Lactic Acid) by Direct PolycondensationDocument8 pagesSynthesis of Poly (L-Lactic Acid) by Direct PolycondensationandoajpwdwNo ratings yet

- Mineral Water PlantDocument44 pagesMineral Water Plantbiswajit pratap pradhanNo ratings yet

- (03241750 - Acta Medica Bulgarica) Solubility of Calcium Silicate Based Cements - A Comparative StudyDocument3 pages(03241750 - Acta Medica Bulgarica) Solubility of Calcium Silicate Based Cements - A Comparative StudyTeodorNo ratings yet

- An Overview of The Cycloaddition Chemistry of Fulvenes and Emerging ApplicationsDocument20 pagesAn Overview of The Cycloaddition Chemistry of Fulvenes and Emerging ApplicationsROBINSON ALZATE LONDOÑONo ratings yet

- Fundamentals of Spectrophotometry: ColorimetryDocument33 pagesFundamentals of Spectrophotometry: ColorimetryaliNo ratings yet

- Lembar Kerja Percobaan 1 No. Gambar Struktur 2D Dan Nama IUPAC Parameter Fisika Kimia Struktur 3D Yang Telah DiminisasiDocument3 pagesLembar Kerja Percobaan 1 No. Gambar Struktur 2D Dan Nama IUPAC Parameter Fisika Kimia Struktur 3D Yang Telah DiminisasiNur AmaliaNo ratings yet

- Thermodynamic Study On Density and Viscosity of Binary Mixtures of Ethyl Acetoacetate With (C4-C9) Aliphatic Ketones at (303.15 and 308.15) KDocument17 pagesThermodynamic Study On Density and Viscosity of Binary Mixtures of Ethyl Acetoacetate With (C4-C9) Aliphatic Ketones at (303.15 and 308.15) KInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dow Corning IE 2404 Emulsion Product Data 1127013Document2 pagesDow Corning IE 2404 Emulsion Product Data 1127013ShambhatiaNo ratings yet

- Fluid Mechanics I CE-407: Basic Concepts, Properties of Fluid and Fluid StaticsDocument26 pagesFluid Mechanics I CE-407: Basic Concepts, Properties of Fluid and Fluid Staticstaha zafarNo ratings yet

- Nalco BT-3000 MSDSDocument10 pagesNalco BT-3000 MSDSKathya CrusherNo ratings yet

- Phase Equilibria 200 SoftwareDocument29 pagesPhase Equilibria 200 SoftwareSuraj NairNo ratings yet

- EfflorescenceDocument2 pagesEfflorescenceMihaiu AdrianNo ratings yet

- 11 Chemistry Test Papers PDFDocument231 pages11 Chemistry Test Papers PDFAnonymous tdtTl8KypNo ratings yet

- Astm A370 1977Document58 pagesAstm A370 1977utreshwarmiskinNo ratings yet

- 2.1.2 Storyboard Launch PDFDocument25 pages2.1.2 Storyboard Launch PDFcjudebetanzorNo ratings yet

- Iso 24817-2017 2Document11 pagesIso 24817-2017 2muzamilarshad31No ratings yet

- Biocatalysis Questions and AnswersDocument9 pagesBiocatalysis Questions and Answerskumara guruparanNo ratings yet

- Makogon Gas Hydrates - 2010Document11 pagesMakogon Gas Hydrates - 2010Alfino Harun LubisNo ratings yet

- Etag 032 Part 8 May 2013 1 PDFDocument80 pagesEtag 032 Part 8 May 2013 1 PDFMalik AwanNo ratings yet

- 2.3. Periodic Table and Trends HWDocument29 pages2.3. Periodic Table and Trends HWchunkymonkey323No ratings yet

- AA10115Document8 pagesAA10115karri1963No ratings yet