Professional Documents

Culture Documents

Thermaline 4700 VOC Aluminum PDS

Thermaline 4700 VOC Aluminum PDS

Uploaded by

Esakki muthuCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Job Spec - Package - B224-114-80-43-SP-7204Document11 pagesJob Spec - Package - B224-114-80-43-SP-7204Esakki muthuNo ratings yet

- Design Basis - Package - B224-999-80-43 EDB-1002Document12 pagesDesign Basis - Package - B224-999-80-43 EDB-1002Esakki muthu100% (1)

- Job Spec - Static - B224-114-80-43-SP-7204Document27 pagesJob Spec - Static - B224-114-80-43-SP-7204Esakki muthuNo ratings yet

- Static Design Basis - B224-999-80-43-EDB-1001Document14 pagesStatic Design Basis - B224-999-80-43-EDB-1001Esakki muthuNo ratings yet

- Article - 7Document11 pagesArticle - 7Esakki muthuNo ratings yet

- 6-12-0003 - Supplementary Spec For LAS Vessels - Rev - 5Document7 pages6-12-0003 - Supplementary Spec For LAS Vessels - Rev - 5Esakki muthuNo ratings yet

- AATF62U81383Document2 pagesAATF62U81383Esakki muthuNo ratings yet

- 18apr 13me64Document3 pages18apr 13me64Esakki muthuNo ratings yet

- 17apr 13me64Document4 pages17apr 13me64Esakki muthuNo ratings yet

- Thermaline 4700 Aluminum PDSDocument4 pagesThermaline 4700 Aluminum PDSEsakki muthuNo ratings yet

- 14nov 13me35Document2 pages14nov 13me35Esakki muthuNo ratings yet

- Carbozinc 11 HS PDSDocument5 pagesCarbozinc 11 HS PDSEsakki muthuNo ratings yet

- CUENCAS Allen - Classification - 2015Document52 pagesCUENCAS Allen - Classification - 2015Camila AldereteNo ratings yet

- Ogata Root LocusDocument32 pagesOgata Root Locusvignesh0617100% (1)

- United States v. Colonial Motor Inn, Inc., and Maurice Shear, 440 F.2d 1227, 1st Cir. (1971)Document3 pagesUnited States v. Colonial Motor Inn, Inc., and Maurice Shear, 440 F.2d 1227, 1st Cir. (1971)Scribd Government DocsNo ratings yet

- Service Standard 05 Prevention and Control of InfectionDocument25 pagesService Standard 05 Prevention and Control of InfectionSuhaimeNo ratings yet

- Alg Review Quiz 2.1-2.4Document3 pagesAlg Review Quiz 2.1-2.4jornelasNo ratings yet

- Barbita Company Data 2021Document93 pagesBarbita Company Data 2021Saidul Islam WashimNo ratings yet

- Burj DubaiDocument27 pagesBurj DubaiInche Helmi Dori DoriNo ratings yet

- Elevation: Section of Approach SlabDocument1 pageElevation: Section of Approach Slabfevahe756No ratings yet

- Utilization of Regrind Materials in PVC Extrusion ProcessingDocument1 pageUtilization of Regrind Materials in PVC Extrusion ProcessingAntonius PrakosaNo ratings yet

- Experiment #4 Title: Testing of Reinforcing Steel BarsDocument9 pagesExperiment #4 Title: Testing of Reinforcing Steel BarsAnne Kristel Dela RosaNo ratings yet

- Safari BagDocument1 pageSafari BagZikoNo ratings yet

- Rocket Stove & Rocket Stove HeaterDocument9 pagesRocket Stove & Rocket Stove Heaterdonx03100% (1)

- Identification and Prediction of Piping System NoiseDocument7 pagesIdentification and Prediction of Piping System NoisejjirwinNo ratings yet

- Crim 4 Week 6Document2 pagesCrim 4 Week 6Rose Jane JuanNo ratings yet

- TOPIC 1: (Vibration Measurement) : Vibration Measurement, From The Word Itself Measures Vibration. "Vibration MeasurementDocument5 pagesTOPIC 1: (Vibration Measurement) : Vibration Measurement, From The Word Itself Measures Vibration. "Vibration MeasurementShanks XDNo ratings yet

- Astm E94 2004Document14 pagesAstm E94 2004Adam GrajewskiNo ratings yet

- Mitac 8066mpDocument154 pagesMitac 8066mpcosminconstantinNo ratings yet

- Renewable Sources of Energy Question BankDocument2 pagesRenewable Sources of Energy Question BankGeorge Oliver100% (1)

- Robin CVDocument6 pagesRobin CVAulya MuctNo ratings yet

- SolarPro 8.3Document72 pagesSolarPro 8.3lgv2No ratings yet

- CALP Glossary 2023 ENDocument41 pagesCALP Glossary 2023 ENHendra WijayaNo ratings yet

- Universal Precautions in Infection PreventionDocument18 pagesUniversal Precautions in Infection PreventionadiNo ratings yet

- Finale Manuscript1 3.1Document14 pagesFinale Manuscript1 3.1Emmanuel BaccarayNo ratings yet

- Juggernaut MethodDocument7 pagesJuggernaut MethodPhil EichNo ratings yet

- Using A ComputerDocument30 pagesUsing A ComputerJEEHANDSOME RANDOMNo ratings yet

- Syllabus DJT 50110Document3 pagesSyllabus DJT 50110Sharizal SanikNo ratings yet

- A Tale of Two CountriesDocument36 pagesA Tale of Two CountriesSAMIR ARTURO IBARRA BOLAÑOSNo ratings yet

- Uso Cursores Anidados PDFDocument7 pagesUso Cursores Anidados PDFIvan AlvaradoNo ratings yet

- MTE 220 Course - NotesDocument163 pagesMTE 220 Course - NotesqNo ratings yet

- Career Planning ToolkitDocument15 pagesCareer Planning ToolkitGökçe EkenNo ratings yet

Thermaline 4700 VOC Aluminum PDS

Thermaline 4700 VOC Aluminum PDS

Uploaded by

Esakki muthuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermaline 4700 VOC Aluminum PDS

Thermaline 4700 VOC Aluminum PDS

Uploaded by

Esakki muthuCopyright:

Available Formats

®

Thermaline 4700 VOC Aluminum

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

Generic Type Single-package silicone finish

High-performance finish for areas exposed to extreme temperatures. Suitable for service from

Description 400°F-1004°F (204°C-540°C) Color stability at maximum temperature will depend on color

selected. .

• Resistant to severe thermal shock

• Provides outstanding long-term performance when applied over Carbozinc inorganic zinc primers

Features • Provides barrier protection prior to heat curing (full film physical properties occur after heat curing)

• VOC compliant

• Approved MPI #22

Aluminum (C901) only

The alignment of aluminum flakes in aluminum-filled finishes is very dependent on application

conditions and techniques. Care must be taken to keep conditions as constant as possible to

Color

reduce variations in final appearance. It is also advisable to work from a single batch of material

since variations can occur from batch to batch. For more information consult Carboline Technical

Service Department.

Gloss

Finish

Initially (flat after heat curing)

Primer Inorganic zincs. None needed for stainless steel or aluminum.

4.0 mils (100 microns)

Wet Film Thickness

Two coats are recommended over bare steel and one or two coats over inorganic zincs.

1.5 - 2 mils (38 - 51 microns) per coat

Dry Film Thickness

Do not exceed 2.0 mils (51 mils) in a single coat. One or two coats are typical. Two coats are

recommended over stainless steel.

Solids Content By Volume 40% +/- 2%

642 ft²/gal at 1.0 mils (15.7 m²/l at 25 microns)

Theoretical Coverage 428 ft²/gal at 1.5 mils (10.5 m²/l at 38 microns)

Rate 321 ft²/gal at 2.0 mils (7.9 m²/l at 50 microns)

Allow for loss in mixing and application.

Per EPA Method 24: 2.67 lbs./gal (320 g/l)

16.0 oz/gal of Thinner 236 E (12.5% thinned): 2.67 lbs/gal (320 g/l)

VOC Value(s)

This product contains US EPA VOC-exempt solvent(s).

Continuous: 1004°F (540°C)

Non-Continuous: 1200°F (649°C)

Dry Temp. Resistance

with surges to 1200 °F (649 °C)

December 2021 4704 Page 1 of 4

®

Thermaline 4700 VOC Aluminum

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

• Do not use for immersion service

• Do not exceed thickness recommendation.

Limitations

• Excessive film thickness may result in blistering and delamination when the temperature is

increased.

S U B S T R AT E S & S U R F A C E P R E PA R AT I O N

General Remove all contaminants in accordance with SSPC-SP 1.

Follow surface preparation for recommended or specified primer. When using direct to steel

Steel surfaces abrasive blast to minimum NACE No. 2/SSPC-SP10 with a 0.5 to 1.0 mil (12-25 microns)

surface profile.

Stainless Steel Clean and abrade per SSPC-SP 16 to achieve a 0.5 to 1.0 mil (12-25 microns) surface profile.

Aluminum Clean and abrade per SSPC-SP 16 to achieve 0.5 to 1.0 mil (12 to 25 microns) surface profile.

MIXING & THINNING

Mixing Power mix until uniform in consistency. Avoid air entrapment.

Normally not required. May be thinned up to 32 oz./gal. (25%) by volume with Thinner 236E for

“hot” applications exceeding 150 °F (66 °C) and for mist coating. Use of thinners other than those

Thinning

supplied or recommended by Carboline may adversely affect product performance and void product

warranty, whether expressed or implied.

A P P L I C AT I O N E Q U I P M E N T G U I D E L I N E S

Listed below are general equipment guidelines for the application of this product. Job site conditions may require modifications

to these guidelines to achieve the desired results.

The following spray equipment has been found suitable for application of this material.

Spray Application

Conventional spray application is preferred.

(General)

Note: Different application procedures or methods may result in non-uniform appearance.

Use DeVilbiss P-MBC, E-needle and tip, and a 704 air cap or equal. Use adequate air volume for

Conventional Spray proper equipment operation. Hold gun 10-12” from the surface and at right angles. Overlap each

pass 50%. Apply 3.0-3.5 wet mils to obtain desired dry film.

Airless Spray Not Recommended.

Recommended for touch up of small areas or where spray application is not permitted. Avoid

Brush & Roller excessive brushing or rolling as this may result in a non-uniform appearance.

(General) Brush & roller application may result in a streaky appearance due to orientation of the aluminum

pigment. For the best aesthetic appearance, spray application is required.

Brush Use a medium bristle brush.

Roller Use a short-nap mohair roller cover with solvent resistant core.

December 2021 4704 Page 2 of 4

®

Thermaline 4700 VOC Aluminum

PRODUCT DATA SHEET

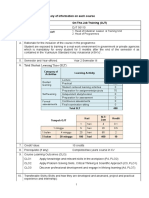

A P P L I C AT I O N C O N D I T I O N S

Condition Material Surface Ambient Humidity

Minimum 55°F (13°C) 40°F (4°C) 40°F (4°C) 0%

Maximum 95°F (35°C) 300°F (149°C) 120°F (49°C) 90%

This product simply requires the substrate temperature to be above the dew point. Condensation due to substrate temperatures

below the dew point can cause flash rusting on prepared steel and interfere with proper adhesion to the substrate.

CURING SCHEDULE

Surface Temp. Dry to Handle Dry to Topcoat with Itself Dry to Touch

77°F (25°C) 8 Hours 4 Hours 1 Hour

These times are based on a 2.0 mil (51 microns) dry film thickness. Higher film thickness, insufficient ventilation or cooler

temperatures will require longer cure times and could result in solvent entrapment and premature failure. Excessive humidity

or condensation on the surface during curing can interfere with the cure and may cause discoloration. During high humidity

conditions, it is recommended that the application be done while temperatures are increasing. If the final cure time is exceeded, the

surface must be abraded prior to the application of additional coats.

Full physical properties will be reached when heat curing has been completed. After a 2 hour flash off at 75°F (24°C), allow

temperature to increase at a maximum rate of 2°F per minute to 400°F (204°C). Hold at 350°F to 450°F (177°C to 232°C) for 2

hours.

CLEANUP & SAFETY

Use Thinner 2. In case of spillage, absorb and dispose of in accordance with local applicable

Cleanup

regulations.

Read and follow all caution statements on this Product Data Sheet and on the SDS for this product.

Safety Employ normal workmanlike safety precautions. Hypersensitive persons should wear protective

clothing, gloves and use protective cream on face, hands and all exposed areas.

When used in enclosed areas, thorough air circulation must be used during and after application

until the coating is cured. The ventilation system should be capable of preventing the solvent vapor

Ventilation concentration from reaching the lower explosion limit for the solvents used. User should test and

monitor exposure levels to ensure all personnel are below guidelines. If not sure or if not able to

monitor levels, use MSHA/NIOSH approved respirator.

PA C K A G I N G , H A N D L I N G & S T O R A G E

12 months at 77 °F (2 5°C)

Shelf Life

*Shelf Life: (actual stated shelf life) when kept at recommended storage conditions and in original

unopened containers.

Storage Temperature & Between 40-100°F (4-38°C)

Humidity 0-90% Humidity

Storage Store Indoors

Shipping Weight 1 Gallon - 13 lbs. (5.9 kg)

(Approximate) 5 Gallon - 64 lbs. (29 kg)

Flash Point (Setaflash) 72 °F (22 °C)

December 2021 4704 Page 3 of 4

®

Thermaline 4700 VOC Aluminum

PRODUCT DATA SHEET

WA R R A N T Y

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject

to change without prior notice. User must contact Carboline Company to verify correctness before specifying or ordering. No

guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no

responsibility for coverage, performance, injuries or damages resulting from use. Carbolines sole obligation, if any, is to replace

or refund the purchase price of the Carboline product(s) proven to be defective, at Carbolines option. Carboline shall not be liable

for any loss or damage. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE, EXPRESS OR

IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. All of the trademarks referenced above are the property of Carboline International Corporation unless

otherwise indicated.

December 2021 4704 Page 4 of 4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Job Spec - Package - B224-114-80-43-SP-7204Document11 pagesJob Spec - Package - B224-114-80-43-SP-7204Esakki muthuNo ratings yet

- Design Basis - Package - B224-999-80-43 EDB-1002Document12 pagesDesign Basis - Package - B224-999-80-43 EDB-1002Esakki muthu100% (1)

- Job Spec - Static - B224-114-80-43-SP-7204Document27 pagesJob Spec - Static - B224-114-80-43-SP-7204Esakki muthuNo ratings yet

- Static Design Basis - B224-999-80-43-EDB-1001Document14 pagesStatic Design Basis - B224-999-80-43-EDB-1001Esakki muthuNo ratings yet

- Article - 7Document11 pagesArticle - 7Esakki muthuNo ratings yet

- 6-12-0003 - Supplementary Spec For LAS Vessels - Rev - 5Document7 pages6-12-0003 - Supplementary Spec For LAS Vessels - Rev - 5Esakki muthuNo ratings yet

- AATF62U81383Document2 pagesAATF62U81383Esakki muthuNo ratings yet

- 18apr 13me64Document3 pages18apr 13me64Esakki muthuNo ratings yet

- 17apr 13me64Document4 pages17apr 13me64Esakki muthuNo ratings yet

- Thermaline 4700 Aluminum PDSDocument4 pagesThermaline 4700 Aluminum PDSEsakki muthuNo ratings yet

- 14nov 13me35Document2 pages14nov 13me35Esakki muthuNo ratings yet

- Carbozinc 11 HS PDSDocument5 pagesCarbozinc 11 HS PDSEsakki muthuNo ratings yet

- CUENCAS Allen - Classification - 2015Document52 pagesCUENCAS Allen - Classification - 2015Camila AldereteNo ratings yet

- Ogata Root LocusDocument32 pagesOgata Root Locusvignesh0617100% (1)

- United States v. Colonial Motor Inn, Inc., and Maurice Shear, 440 F.2d 1227, 1st Cir. (1971)Document3 pagesUnited States v. Colonial Motor Inn, Inc., and Maurice Shear, 440 F.2d 1227, 1st Cir. (1971)Scribd Government DocsNo ratings yet

- Service Standard 05 Prevention and Control of InfectionDocument25 pagesService Standard 05 Prevention and Control of InfectionSuhaimeNo ratings yet

- Alg Review Quiz 2.1-2.4Document3 pagesAlg Review Quiz 2.1-2.4jornelasNo ratings yet

- Barbita Company Data 2021Document93 pagesBarbita Company Data 2021Saidul Islam WashimNo ratings yet

- Burj DubaiDocument27 pagesBurj DubaiInche Helmi Dori DoriNo ratings yet

- Elevation: Section of Approach SlabDocument1 pageElevation: Section of Approach Slabfevahe756No ratings yet

- Utilization of Regrind Materials in PVC Extrusion ProcessingDocument1 pageUtilization of Regrind Materials in PVC Extrusion ProcessingAntonius PrakosaNo ratings yet

- Experiment #4 Title: Testing of Reinforcing Steel BarsDocument9 pagesExperiment #4 Title: Testing of Reinforcing Steel BarsAnne Kristel Dela RosaNo ratings yet

- Safari BagDocument1 pageSafari BagZikoNo ratings yet

- Rocket Stove & Rocket Stove HeaterDocument9 pagesRocket Stove & Rocket Stove Heaterdonx03100% (1)

- Identification and Prediction of Piping System NoiseDocument7 pagesIdentification and Prediction of Piping System NoisejjirwinNo ratings yet

- Crim 4 Week 6Document2 pagesCrim 4 Week 6Rose Jane JuanNo ratings yet

- TOPIC 1: (Vibration Measurement) : Vibration Measurement, From The Word Itself Measures Vibration. "Vibration MeasurementDocument5 pagesTOPIC 1: (Vibration Measurement) : Vibration Measurement, From The Word Itself Measures Vibration. "Vibration MeasurementShanks XDNo ratings yet

- Astm E94 2004Document14 pagesAstm E94 2004Adam GrajewskiNo ratings yet

- Mitac 8066mpDocument154 pagesMitac 8066mpcosminconstantinNo ratings yet

- Renewable Sources of Energy Question BankDocument2 pagesRenewable Sources of Energy Question BankGeorge Oliver100% (1)

- Robin CVDocument6 pagesRobin CVAulya MuctNo ratings yet

- SolarPro 8.3Document72 pagesSolarPro 8.3lgv2No ratings yet

- CALP Glossary 2023 ENDocument41 pagesCALP Glossary 2023 ENHendra WijayaNo ratings yet

- Universal Precautions in Infection PreventionDocument18 pagesUniversal Precautions in Infection PreventionadiNo ratings yet

- Finale Manuscript1 3.1Document14 pagesFinale Manuscript1 3.1Emmanuel BaccarayNo ratings yet

- Juggernaut MethodDocument7 pagesJuggernaut MethodPhil EichNo ratings yet

- Using A ComputerDocument30 pagesUsing A ComputerJEEHANDSOME RANDOMNo ratings yet

- Syllabus DJT 50110Document3 pagesSyllabus DJT 50110Sharizal SanikNo ratings yet

- A Tale of Two CountriesDocument36 pagesA Tale of Two CountriesSAMIR ARTURO IBARRA BOLAÑOSNo ratings yet

- Uso Cursores Anidados PDFDocument7 pagesUso Cursores Anidados PDFIvan AlvaradoNo ratings yet

- MTE 220 Course - NotesDocument163 pagesMTE 220 Course - NotesqNo ratings yet

- Career Planning ToolkitDocument15 pagesCareer Planning ToolkitGökçe EkenNo ratings yet