Professional Documents

Culture Documents

J2149-Machining Process Plan

J2149-Machining Process Plan

Uploaded by

harikrishnanCopyright:

Available Formats

You might also like

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- Mahabal Manpower PlanningDocument4 pagesMahabal Manpower PlanningNitin KambleNo ratings yet

- tECHNICAL REPORTDocument5 pagestECHNICAL REPORTAqil HadifNo ratings yet

- Inspection & Test Plan - Site ClearanceDocument1 pageInspection & Test Plan - Site ClearanceJohan BurgerNo ratings yet

- Technical Review:: Program: Mahindra Oil Pump Part No.: M0106066 Description: VALVE Supplier: Bhagwan Precision (P) LTDDocument17 pagesTechnical Review:: Program: Mahindra Oil Pump Part No.: M0106066 Description: VALVE Supplier: Bhagwan Precision (P) LTDhandakeshav7321No ratings yet

- DPR Itp CPCC 13.03.2024Document2 pagesDPR Itp CPCC 13.03.2024lahiru sudeeshaNo ratings yet

- CNC Machining: Workshop TechnologyDocument11 pagesCNC Machining: Workshop Technologymews03No ratings yet

- JC - Boq - Civil & Str. Work - Revised After 1st Meet Held On Dated-26.08.2022Document11 pagesJC - Boq - Civil & Str. Work - Revised After 1st Meet Held On Dated-26.08.2022Shanti KumarNo ratings yet

- FANUC Series 16 FANUC Series 16: i/18i-TB i/18i/21i-MBDocument31 pagesFANUC Series 16 FANUC Series 16: i/18i-TB i/18i/21i-MBmikeNo ratings yet

- Product Pump P428-BDocument3 pagesProduct Pump P428-BHaitham YoussefNo ratings yet

- CNC Tapping CenterDocument6 pagesCNC Tapping CenterJovelyn MillaresNo ratings yet

- Technical Data - Appendix B2: JCB162895 Imagro Construction SRL TPD-FPO-NAC-E-015-2016Document9 pagesTechnical Data - Appendix B2: JCB162895 Imagro Construction SRL TPD-FPO-NAC-E-015-2016Mena KamelNo ratings yet

- Jig Inspection Check SheetDocument2 pagesJig Inspection Check SheetAbhishek YadavNo ratings yet

- Shic A 0007Document3 pagesShic A 000701095902062ahmedNo ratings yet

- AFI 125 HCl-NaOH SystemDocument3 pagesAFI 125 HCl-NaOH Systempepenapao1217No ratings yet

- Tramo2 PDFDocument2 pagesTramo2 PDFAhmed MyfaceNo ratings yet

- Icl Condensate TrapDocument5 pagesIcl Condensate TrapAlberto CamposNo ratings yet

- FD Tial: Servicetechnical ReportDocument11 pagesFD Tial: Servicetechnical Reportnhatnguyen101No ratings yet

- Quotation With AnnexturesDocument11 pagesQuotation With Annexturessiddharth JoshiNo ratings yet

- 2024.4.24 BL-GM2016 BL-HMC100B Price list-BLIN MACHINERYDocument2 pages2024.4.24 BL-GM2016 BL-HMC100B Price list-BLIN MACHINERYah1.darwashaaNo ratings yet

- CoroPlusToolGuide Report 2021-05-31Document4 pagesCoroPlusToolGuide Report 2021-05-31Dorin MacaruNo ratings yet

- Ge Sill PFD PDFDocument1 pageGe Sill PFD PDFRavikumar BojjaNo ratings yet

- 08 SzivkovicDocument6 pages08 SzivkovicbuttercupniceNo ratings yet

- NX CAM Errors Machine DataDocument7 pagesNX CAM Errors Machine DataRamNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- NX CAM Post Processing Errors Machine Data File Ge PDFDocument7 pagesNX CAM Post Processing Errors Machine Data File Ge PDFSHARAD CHANDRANo ratings yet

- Product Flyer English 06Document2 pagesProduct Flyer English 06Syafizad AswadNo ratings yet

- Sadas SDocument123 pagesSadas SspencermapuaNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- General Formate of EstimationDocument16 pagesGeneral Formate of Estimationsaiful islamNo ratings yet

- Shic A 0005Document2 pagesShic A 000501095902062ahmedNo ratings yet

- Kick Off Meeting InternalDocument26 pagesKick Off Meeting Internaldeden ibnuNo ratings yet

- 1707317897899-BOQ Tulimani Road Improvement .Pdf1Document4 pages1707317897899-BOQ Tulimani Road Improvement .Pdf1marabsagenciesltdNo ratings yet

- Cm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)Document3 pagesCm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)ali morisyNo ratings yet

- 05 Hardware IdentificationDocument17 pages05 Hardware IdentificationRaul quispe quispeNo ratings yet

- 77R00Document2 pages77R00SanjayNo ratings yet

- 9 The Use of Dynamic Analysis in Optimising Machining OperationsDocument34 pages9 The Use of Dynamic Analysis in Optimising Machining Operationsaenyma100% (1)

- DPR Itp CPCC 14.03.2024Document2 pagesDPR Itp CPCC 14.03.2024lahiru sudeeshaNo ratings yet

- Vertical Machining Center: CNC (Computer Numerical Control)Document23 pagesVertical Machining Center: CNC (Computer Numerical Control)Rohith BayyaNo ratings yet

- Faldic BDocument24 pagesFaldic BgsNo ratings yet

- L - 1 - 2 - Emerging Trends in Artificial Intelligence and Data ScienceDocument106 pagesL - 1 - 2 - Emerging Trends in Artificial Intelligence and Data ScienceScion Of VirikvasNo ratings yet

- IE-JMS-001 - 18 Survey BCOT FireWater Line Rev.1Document4 pagesIE-JMS-001 - 18 Survey BCOT FireWater Line Rev.1i24026096No ratings yet

- Bill of QuantitiesDocument55 pagesBill of QuantitiesAnonymous 7NWXRyuNo ratings yet

- Transmission Tunnel: Transmission Pipeline-İletim HattiDocument2 pagesTransmission Tunnel: Transmission Pipeline-İletim Hattisilence_10007No ratings yet

- Complete Operating and Programming 802Dsl en A TM Sw1 4Document447 pagesComplete Operating and Programming 802Dsl en A TM Sw1 4Freddy Mamani AtayupanquiNo ratings yet

- MF-QA-001 PDIR ReportDocument2 pagesMF-QA-001 PDIR ReportBHUSHAN BAGULNo ratings yet

- Beam 1Document16 pagesBeam 1Nurul SyafiqahNo ratings yet

- IFC Closure Approval ReportDocument12 pagesIFC Closure Approval ReportAjayNo ratings yet

- Based On Aws d1.5Document48 pagesBased On Aws d1.5Altaf HussainNo ratings yet

- Punzonadora Boschert CU Flex para CobreDocument2 pagesPunzonadora Boschert CU Flex para CobreBoschert MéxicoNo ratings yet

- Confiden Ial: Servicetechnical ReportDocument5 pagesConfiden Ial: Servicetechnical Reportnhatnguyen101No ratings yet

- Meter: Meter: Meter: Meter: Meter: MeterDocument93 pagesMeter: Meter: Meter: Meter: Meter: MeterCh BilalNo ratings yet

- Inspection Test Plan For Grouting-230 MWac Garadagh Solar PV Plant (Area 60)Document1 pageInspection Test Plan For Grouting-230 MWac Garadagh Solar PV Plant (Area 60)Adil HasanovNo ratings yet

- Royal Commission For Jubail and Yanbu 021-C19: Document No: Rev. I C - 0 3 3 0 - F - 1 0 2Document12 pagesRoyal Commission For Jubail and Yanbu 021-C19: Document No: Rev. I C - 0 3 3 0 - F - 1 0 2arshad iqbalNo ratings yet

- Die Assessment Check Sheet-Plate Type - For Physical AssessmentDocument2 pagesDie Assessment Check Sheet-Plate Type - For Physical AssessmentshinuNo ratings yet

- CNC MachiningDocument14 pagesCNC MachiningAl Fredo100% (13)

- Work Allocation For Welder: Welder Name: ID No.: WAW No.Document1 pageWork Allocation For Welder: Welder Name: ID No.: WAW No.harikrishnanNo ratings yet

- Kennametal Stellite - Cored Weld Wire DatasheetDocument2 pagesKennametal Stellite - Cored Weld Wire DatasheetharikrishnanNo ratings yet

- Aiw 101 1-1Document5 pagesAiw 101 1-1harikrishnanNo ratings yet

- Weld Control Check ListDocument1 pageWeld Control Check ListharikrishnanNo ratings yet

- Base Metal and WeldingDocument3 pagesBase Metal and WeldingharikrishnanNo ratings yet

- 195 EL8 3.15mm Feb 20Document1 page195 EL8 3.15mm Feb 20harikrishnanNo ratings yet

- RMT465477 OK Flux 1071L F7A4 F7P5 EH14 DSDocument1 pageRMT465477 OK Flux 1071L F7A4 F7P5 EH14 DSharikrishnanNo ratings yet

- TWI Enrolment Form: Twi India Csa No 6000691Document4 pagesTWI Enrolment Form: Twi India Csa No 6000691harikrishnanNo ratings yet

- Certificate of Conformance: Qa@nouveaux - in WWW - Nouveaux.inDocument1 pageCertificate of Conformance: Qa@nouveaux - in WWW - Nouveaux.inharikrishnanNo ratings yet

- Summary ISO TR 15608 Metallic Materials Grouping SystemDocument3 pagesSummary ISO TR 15608 Metallic Materials Grouping SystemharikrishnanNo ratings yet

- Certificate of Conformance: Qa@nouveaux - in WWW - Nouveaux.inDocument1 pageCertificate of Conformance: Qa@nouveaux - in WWW - Nouveaux.inharikrishnanNo ratings yet

- fm82 1Document1 pagefm82 1harikrishnanNo ratings yet

- NAVEDTRA 14250A Steelworker Basic Part 3Document409 pagesNAVEDTRA 14250A Steelworker Basic Part 3harikrishnanNo ratings yet

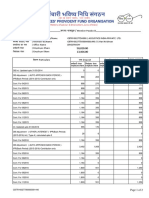

- LNL Iklcqd /: Employee Share Employer Share Employee Share Employer ShareDocument2 pagesLNL Iklcqd /: Employee Share Employer Share Employee Share Employer ShareharikrishnanNo ratings yet

- M C D 8 - D W: 1. GlassDocument7 pagesM C D 8 - D W: 1. GlassEm PeeNo ratings yet

- 18th Century Workbench Plans-Part 1 PDFDocument5 pages18th Century Workbench Plans-Part 1 PDFsergio50% (2)

- Cabled Flora MittsDocument8 pagesCabled Flora MittsRoganNo ratings yet

- Major Defects Found in Woven FabricDocument15 pagesMajor Defects Found in Woven FabricTuan Nguyen MinhNo ratings yet

- Metal Cutting TechnologyDocument22 pagesMetal Cutting Technologydema_diasNo ratings yet

- Aql StandardDocument13 pagesAql StandardVaradhan Stylewiz-incNo ratings yet

- Brasive Industries: Wood Coating & Paint ProductsDocument2 pagesBrasive Industries: Wood Coating & Paint ProductsPrince KumarNo ratings yet

- Fabric Pricing:: Order Analysis SheetDocument2 pagesFabric Pricing:: Order Analysis SheetMirza Zahidul AlamNo ratings yet

- Edward Jumper: Willow & Lark 2017 Designed UsingDocument9 pagesEdward Jumper: Willow & Lark 2017 Designed UsingMiraNo ratings yet

- Heat TreatmentDocument16 pagesHeat TreatmentHukam ChandNo ratings yet

- EmbroideryDocument3 pagesEmbroideryBhaswati PandaNo ratings yet

- Nut and BoltsDocument10 pagesNut and BoltsSam33% (3)

- B1 2001Document41 pagesB1 2001praghavannairNo ratings yet

- DJJ10033 DJJ1043 Workshop TechnologyDocument4 pagesDJJ10033 DJJ1043 Workshop Technologykumar21189No ratings yet

- Activity # 8Document2 pagesActivity # 8Mariella Alyzza InciongNo ratings yet

- Jis G4051Document7 pagesJis G4051tnchsgNo ratings yet

- Errata To ASME B47.1-2007 Gage BlanksDocument2 pagesErrata To ASME B47.1-2007 Gage BlanksMark D VillanuevaNo ratings yet

- Hoooked Zpagetti BasketDocument2 pagesHoooked Zpagetti BasketTatu AradiNo ratings yet

- Grabber Screws 5280Document0 pagesGrabber Screws 5280murdicksNo ratings yet

- Llavero CupcakeDocument14 pagesLlavero CupcakeDaniela Ribba100% (2)

- Brighto Ready Mix Price ListDocument2 pagesBrighto Ready Mix Price ListGallery ExploringNo ratings yet

- Z4-Giraffe Sparrow DreamerDocument13 pagesZ4-Giraffe Sparrow Dreamerplayingwithyarn.coNo ratings yet

- Technology and Livelihood in EDUCATION IN Carpentry and MasonryDocument105 pagesTechnology and Livelihood in EDUCATION IN Carpentry and MasonryLignerrac Anipal UtadNo ratings yet

- Rain Drops Sweater UsDocument8 pagesRain Drops Sweater UsEliza CodreaNo ratings yet

- AngelBabyPattern in A Star CradleDocument18 pagesAngelBabyPattern in A Star CradlevuillermozvalerieNo ratings yet

- Technology of Machine Tools: Thread-Cutting Tools and ProceduresDocument21 pagesTechnology of Machine Tools: Thread-Cutting Tools and ProceduresAnibal DazaNo ratings yet

- Yoshi Amigurumi Stitching PatternDocument9 pagesYoshi Amigurumi Stitching PatternMiro100% (3)

- Fancy Yarn - An Overview - ScienceDirect TopicsDocument12 pagesFancy Yarn - An Overview - ScienceDirect TopicskabuNo ratings yet

- Classification of The Metal Cutting ProcessDocument3 pagesClassification of The Metal Cutting ProcessfatmafarahNo ratings yet

- Eastern Visayas State University: Republic of The Philippines Province of LeyteDocument2 pagesEastern Visayas State University: Republic of The Philippines Province of LeyteRouel Francis Salas DadullaNo ratings yet

J2149-Machining Process Plan

J2149-Machining Process Plan

Uploaded by

harikrishnanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

J2149-Machining Process Plan

J2149-Machining Process Plan

Uploaded by

harikrishnanCopyright:

Available Formats

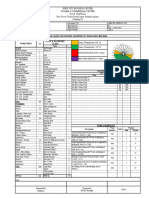

MACHINING PROCESS PLAN (CRITICAL/MAJOR)

J2149/PPC/MPP/01 -Rev-00

Job No J2149 Customer M/s TPL Ref No

Date: 28.09.2020

Qty 01 No Job Description VARIABLE DIFFUSER Project ISRO

ACTIVITY OUTSOURCING ACCURACY (mm)

SCOPE OF MACHINING ACTIVITY AVAILABLE STOCK (mm) MACHINING OPERATION REF.DRAWING

No REQUIREMENT GD&T

1 UPPER / LOWER WELDMENT

1A Material Details

1A01 Matl Spec: IS 2062 - - - -

1A02 Size: L -9800 mm x W - 3430mm x H-816mm - - - -

1B Stock Verification Details

Sufficient machine stock shall be provided before

1B01 - - - -

start up the fabrication work

Ensure the enough stock available after welding

1B02 completion prior to final machining due to happened - - - -

that welding distortion

1C Pre-Machining activity check points

1C01 Machining Drawing study and clarification if any - - - -

Component visual inspection and check if any

1C02 - - - -

transit damages

Verification of before machining dimension report

1C03 - - - -

(Fabrication parts)

Ensure the actual dimensions before taking final

1C04 - - - -

machining

Check straightness, bend and twist dimensions

1C05 whether it can be able to achieve final machining - - - -

dimension as per drawing. (before loading)

Job loading on the appropriate machining center

1C06 - CNC HBM - -

(work center)

Setting inspection shall be carried out prior to start

any machining activity and ensure the straightness,

1C07 - CNC HBM - -

bend, twist, parallelism and verticality and

machining feasibility.

Ensure the availability of machine tools for each and

1C08 - CNC HBM - -

every machining operation

1D Final Machining Sequence

Adequate stock shall be

1D01 First setting on big bottom plate side CNC HBM - -

provided

Page 1 of 2

Leveling the job and measure the dial reading through Adequate stock shall be

1D02 CNC HBM - -

out the length of 9.8 mtr provided

Skin cut on the big bottom plate Adequate stock shall be

1D03 CNC HBM Facing -

(Machine to 30mm thk) provided

Final facing operation on the big bottom plate Adequate stock shall be

1D04 CNC HBM Facing Datum A

(Machine to 30mm thk) provided

Perpendicularity

Adequate stock shall be

1D05 LH side facing with respect to big bottom plate facing CNC HBM Facing 0.13 w.r.t. datum

provided

A

Perpendicularity

LH Side Profile Plate 5 facing with respect to big Adequate stock shall be

1D06 CNC HBM Facing 0.05 w.r.t. datum

bottom plate facing provided

A

Perpendicularity

Adequate stock shall be

1D07 RH side facing with respect to big bottom plate facing CNC HBM Facing 0.05 w.r.t. datum

provided

A

Big Bottom plate - Grooving , Pressure tap holes

Boring,Drilling and 0.2/

1D08 drilling, Spot facing, counter boring, Slotting, Holes - CNC HBM

Tapping H7/r6 Press fit

drilling and tapping

RH side straight grooving, radius grooving, counter Slot finish 0.63 /

Boring,Drilling and

1D09 boring, holes drilling and tapping and wheel assembly - CNC HBM 0.2 / H7/r6 Press

Tapping

slotting fit

Boring,Drilling and

1D10 LH side counter boring, holes drilling and tapping - CNC HBM -

Tapping

Bottom Plate facing with reference to Big Bottom Adequate stock shall be Parallelism 0.05

1D11 CNC HBM Facing

Plate provided w.r.t datum A

Rectangular Plate 2 with reference to Big Bottom Adequate stock shall be

1D12 CNC HBM Facing -

plate provided

2nd setting on frame mounting block side(Opposite of Adequate stock shall be

1D13 CNC HBM - -

bottom plate) w.r.t bottom plate machined surface provided

Skin cut on the welded 'I' Beam top side drill area Adequate stock shall be

1D14 CNC HBM Facing 0.2 Max

surface if required (As per drawing not required) provided

Adequate stock shall be

1D15 Final Facing on the mounting block support CNC HBM Facing -

provided

1D16 Spot facing, Counter boring and drilling - CNC HBM Boring and Drilling -

Adequate stock shall be

1D17 3rd setting on Jack mount support base plate CNC HBM - -

provided

Adequate stock shall be

1D18 Facing and drilling on base plate CNC HBM Facing & Drilling -

provided

4th setting on another side of Jack mount support Adequate stock shall be

1D19 CNC HBM - -

base plate provided

Adequate stock shall be

1D20 Facing and drilling CNC HBM Facing & Drilling -

provided

Final machining inspection performing with Machine

1D21 - CNC HBM - -

Reading

Prepared by

Page 2 of 2

You might also like

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- Mahabal Manpower PlanningDocument4 pagesMahabal Manpower PlanningNitin KambleNo ratings yet

- tECHNICAL REPORTDocument5 pagestECHNICAL REPORTAqil HadifNo ratings yet

- Inspection & Test Plan - Site ClearanceDocument1 pageInspection & Test Plan - Site ClearanceJohan BurgerNo ratings yet

- Technical Review:: Program: Mahindra Oil Pump Part No.: M0106066 Description: VALVE Supplier: Bhagwan Precision (P) LTDDocument17 pagesTechnical Review:: Program: Mahindra Oil Pump Part No.: M0106066 Description: VALVE Supplier: Bhagwan Precision (P) LTDhandakeshav7321No ratings yet

- DPR Itp CPCC 13.03.2024Document2 pagesDPR Itp CPCC 13.03.2024lahiru sudeeshaNo ratings yet

- CNC Machining: Workshop TechnologyDocument11 pagesCNC Machining: Workshop Technologymews03No ratings yet

- JC - Boq - Civil & Str. Work - Revised After 1st Meet Held On Dated-26.08.2022Document11 pagesJC - Boq - Civil & Str. Work - Revised After 1st Meet Held On Dated-26.08.2022Shanti KumarNo ratings yet

- FANUC Series 16 FANUC Series 16: i/18i-TB i/18i/21i-MBDocument31 pagesFANUC Series 16 FANUC Series 16: i/18i-TB i/18i/21i-MBmikeNo ratings yet

- Product Pump P428-BDocument3 pagesProduct Pump P428-BHaitham YoussefNo ratings yet

- CNC Tapping CenterDocument6 pagesCNC Tapping CenterJovelyn MillaresNo ratings yet

- Technical Data - Appendix B2: JCB162895 Imagro Construction SRL TPD-FPO-NAC-E-015-2016Document9 pagesTechnical Data - Appendix B2: JCB162895 Imagro Construction SRL TPD-FPO-NAC-E-015-2016Mena KamelNo ratings yet

- Jig Inspection Check SheetDocument2 pagesJig Inspection Check SheetAbhishek YadavNo ratings yet

- Shic A 0007Document3 pagesShic A 000701095902062ahmedNo ratings yet

- AFI 125 HCl-NaOH SystemDocument3 pagesAFI 125 HCl-NaOH Systempepenapao1217No ratings yet

- Tramo2 PDFDocument2 pagesTramo2 PDFAhmed MyfaceNo ratings yet

- Icl Condensate TrapDocument5 pagesIcl Condensate TrapAlberto CamposNo ratings yet

- FD Tial: Servicetechnical ReportDocument11 pagesFD Tial: Servicetechnical Reportnhatnguyen101No ratings yet

- Quotation With AnnexturesDocument11 pagesQuotation With Annexturessiddharth JoshiNo ratings yet

- 2024.4.24 BL-GM2016 BL-HMC100B Price list-BLIN MACHINERYDocument2 pages2024.4.24 BL-GM2016 BL-HMC100B Price list-BLIN MACHINERYah1.darwashaaNo ratings yet

- CoroPlusToolGuide Report 2021-05-31Document4 pagesCoroPlusToolGuide Report 2021-05-31Dorin MacaruNo ratings yet

- Ge Sill PFD PDFDocument1 pageGe Sill PFD PDFRavikumar BojjaNo ratings yet

- 08 SzivkovicDocument6 pages08 SzivkovicbuttercupniceNo ratings yet

- NX CAM Errors Machine DataDocument7 pagesNX CAM Errors Machine DataRamNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- NX CAM Post Processing Errors Machine Data File Ge PDFDocument7 pagesNX CAM Post Processing Errors Machine Data File Ge PDFSHARAD CHANDRANo ratings yet

- Product Flyer English 06Document2 pagesProduct Flyer English 06Syafizad AswadNo ratings yet

- Sadas SDocument123 pagesSadas SspencermapuaNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- General Formate of EstimationDocument16 pagesGeneral Formate of Estimationsaiful islamNo ratings yet

- Shic A 0005Document2 pagesShic A 000501095902062ahmedNo ratings yet

- Kick Off Meeting InternalDocument26 pagesKick Off Meeting Internaldeden ibnuNo ratings yet

- 1707317897899-BOQ Tulimani Road Improvement .Pdf1Document4 pages1707317897899-BOQ Tulimani Road Improvement .Pdf1marabsagenciesltdNo ratings yet

- Cm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)Document3 pagesCm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)ali morisyNo ratings yet

- 05 Hardware IdentificationDocument17 pages05 Hardware IdentificationRaul quispe quispeNo ratings yet

- 77R00Document2 pages77R00SanjayNo ratings yet

- 9 The Use of Dynamic Analysis in Optimising Machining OperationsDocument34 pages9 The Use of Dynamic Analysis in Optimising Machining Operationsaenyma100% (1)

- DPR Itp CPCC 14.03.2024Document2 pagesDPR Itp CPCC 14.03.2024lahiru sudeeshaNo ratings yet

- Vertical Machining Center: CNC (Computer Numerical Control)Document23 pagesVertical Machining Center: CNC (Computer Numerical Control)Rohith BayyaNo ratings yet

- Faldic BDocument24 pagesFaldic BgsNo ratings yet

- L - 1 - 2 - Emerging Trends in Artificial Intelligence and Data ScienceDocument106 pagesL - 1 - 2 - Emerging Trends in Artificial Intelligence and Data ScienceScion Of VirikvasNo ratings yet

- IE-JMS-001 - 18 Survey BCOT FireWater Line Rev.1Document4 pagesIE-JMS-001 - 18 Survey BCOT FireWater Line Rev.1i24026096No ratings yet

- Bill of QuantitiesDocument55 pagesBill of QuantitiesAnonymous 7NWXRyuNo ratings yet

- Transmission Tunnel: Transmission Pipeline-İletim HattiDocument2 pagesTransmission Tunnel: Transmission Pipeline-İletim Hattisilence_10007No ratings yet

- Complete Operating and Programming 802Dsl en A TM Sw1 4Document447 pagesComplete Operating and Programming 802Dsl en A TM Sw1 4Freddy Mamani AtayupanquiNo ratings yet

- MF-QA-001 PDIR ReportDocument2 pagesMF-QA-001 PDIR ReportBHUSHAN BAGULNo ratings yet

- Beam 1Document16 pagesBeam 1Nurul SyafiqahNo ratings yet

- IFC Closure Approval ReportDocument12 pagesIFC Closure Approval ReportAjayNo ratings yet

- Based On Aws d1.5Document48 pagesBased On Aws d1.5Altaf HussainNo ratings yet

- Punzonadora Boschert CU Flex para CobreDocument2 pagesPunzonadora Boschert CU Flex para CobreBoschert MéxicoNo ratings yet

- Confiden Ial: Servicetechnical ReportDocument5 pagesConfiden Ial: Servicetechnical Reportnhatnguyen101No ratings yet

- Meter: Meter: Meter: Meter: Meter: MeterDocument93 pagesMeter: Meter: Meter: Meter: Meter: MeterCh BilalNo ratings yet

- Inspection Test Plan For Grouting-230 MWac Garadagh Solar PV Plant (Area 60)Document1 pageInspection Test Plan For Grouting-230 MWac Garadagh Solar PV Plant (Area 60)Adil HasanovNo ratings yet

- Royal Commission For Jubail and Yanbu 021-C19: Document No: Rev. I C - 0 3 3 0 - F - 1 0 2Document12 pagesRoyal Commission For Jubail and Yanbu 021-C19: Document No: Rev. I C - 0 3 3 0 - F - 1 0 2arshad iqbalNo ratings yet

- Die Assessment Check Sheet-Plate Type - For Physical AssessmentDocument2 pagesDie Assessment Check Sheet-Plate Type - For Physical AssessmentshinuNo ratings yet

- CNC MachiningDocument14 pagesCNC MachiningAl Fredo100% (13)

- Work Allocation For Welder: Welder Name: ID No.: WAW No.Document1 pageWork Allocation For Welder: Welder Name: ID No.: WAW No.harikrishnanNo ratings yet

- Kennametal Stellite - Cored Weld Wire DatasheetDocument2 pagesKennametal Stellite - Cored Weld Wire DatasheetharikrishnanNo ratings yet

- Aiw 101 1-1Document5 pagesAiw 101 1-1harikrishnanNo ratings yet

- Weld Control Check ListDocument1 pageWeld Control Check ListharikrishnanNo ratings yet

- Base Metal and WeldingDocument3 pagesBase Metal and WeldingharikrishnanNo ratings yet

- 195 EL8 3.15mm Feb 20Document1 page195 EL8 3.15mm Feb 20harikrishnanNo ratings yet

- RMT465477 OK Flux 1071L F7A4 F7P5 EH14 DSDocument1 pageRMT465477 OK Flux 1071L F7A4 F7P5 EH14 DSharikrishnanNo ratings yet

- TWI Enrolment Form: Twi India Csa No 6000691Document4 pagesTWI Enrolment Form: Twi India Csa No 6000691harikrishnanNo ratings yet

- Certificate of Conformance: Qa@nouveaux - in WWW - Nouveaux.inDocument1 pageCertificate of Conformance: Qa@nouveaux - in WWW - Nouveaux.inharikrishnanNo ratings yet

- Summary ISO TR 15608 Metallic Materials Grouping SystemDocument3 pagesSummary ISO TR 15608 Metallic Materials Grouping SystemharikrishnanNo ratings yet

- Certificate of Conformance: Qa@nouveaux - in WWW - Nouveaux.inDocument1 pageCertificate of Conformance: Qa@nouveaux - in WWW - Nouveaux.inharikrishnanNo ratings yet

- fm82 1Document1 pagefm82 1harikrishnanNo ratings yet

- NAVEDTRA 14250A Steelworker Basic Part 3Document409 pagesNAVEDTRA 14250A Steelworker Basic Part 3harikrishnanNo ratings yet

- LNL Iklcqd /: Employee Share Employer Share Employee Share Employer ShareDocument2 pagesLNL Iklcqd /: Employee Share Employer Share Employee Share Employer ShareharikrishnanNo ratings yet

- M C D 8 - D W: 1. GlassDocument7 pagesM C D 8 - D W: 1. GlassEm PeeNo ratings yet

- 18th Century Workbench Plans-Part 1 PDFDocument5 pages18th Century Workbench Plans-Part 1 PDFsergio50% (2)

- Cabled Flora MittsDocument8 pagesCabled Flora MittsRoganNo ratings yet

- Major Defects Found in Woven FabricDocument15 pagesMajor Defects Found in Woven FabricTuan Nguyen MinhNo ratings yet

- Metal Cutting TechnologyDocument22 pagesMetal Cutting Technologydema_diasNo ratings yet

- Aql StandardDocument13 pagesAql StandardVaradhan Stylewiz-incNo ratings yet

- Brasive Industries: Wood Coating & Paint ProductsDocument2 pagesBrasive Industries: Wood Coating & Paint ProductsPrince KumarNo ratings yet

- Fabric Pricing:: Order Analysis SheetDocument2 pagesFabric Pricing:: Order Analysis SheetMirza Zahidul AlamNo ratings yet

- Edward Jumper: Willow & Lark 2017 Designed UsingDocument9 pagesEdward Jumper: Willow & Lark 2017 Designed UsingMiraNo ratings yet

- Heat TreatmentDocument16 pagesHeat TreatmentHukam ChandNo ratings yet

- EmbroideryDocument3 pagesEmbroideryBhaswati PandaNo ratings yet

- Nut and BoltsDocument10 pagesNut and BoltsSam33% (3)

- B1 2001Document41 pagesB1 2001praghavannairNo ratings yet

- DJJ10033 DJJ1043 Workshop TechnologyDocument4 pagesDJJ10033 DJJ1043 Workshop Technologykumar21189No ratings yet

- Activity # 8Document2 pagesActivity # 8Mariella Alyzza InciongNo ratings yet

- Jis G4051Document7 pagesJis G4051tnchsgNo ratings yet

- Errata To ASME B47.1-2007 Gage BlanksDocument2 pagesErrata To ASME B47.1-2007 Gage BlanksMark D VillanuevaNo ratings yet

- Hoooked Zpagetti BasketDocument2 pagesHoooked Zpagetti BasketTatu AradiNo ratings yet

- Grabber Screws 5280Document0 pagesGrabber Screws 5280murdicksNo ratings yet

- Llavero CupcakeDocument14 pagesLlavero CupcakeDaniela Ribba100% (2)

- Brighto Ready Mix Price ListDocument2 pagesBrighto Ready Mix Price ListGallery ExploringNo ratings yet

- Z4-Giraffe Sparrow DreamerDocument13 pagesZ4-Giraffe Sparrow Dreamerplayingwithyarn.coNo ratings yet

- Technology and Livelihood in EDUCATION IN Carpentry and MasonryDocument105 pagesTechnology and Livelihood in EDUCATION IN Carpentry and MasonryLignerrac Anipal UtadNo ratings yet

- Rain Drops Sweater UsDocument8 pagesRain Drops Sweater UsEliza CodreaNo ratings yet

- AngelBabyPattern in A Star CradleDocument18 pagesAngelBabyPattern in A Star CradlevuillermozvalerieNo ratings yet

- Technology of Machine Tools: Thread-Cutting Tools and ProceduresDocument21 pagesTechnology of Machine Tools: Thread-Cutting Tools and ProceduresAnibal DazaNo ratings yet

- Yoshi Amigurumi Stitching PatternDocument9 pagesYoshi Amigurumi Stitching PatternMiro100% (3)

- Fancy Yarn - An Overview - ScienceDirect TopicsDocument12 pagesFancy Yarn - An Overview - ScienceDirect TopicskabuNo ratings yet

- Classification of The Metal Cutting ProcessDocument3 pagesClassification of The Metal Cutting ProcessfatmafarahNo ratings yet

- Eastern Visayas State University: Republic of The Philippines Province of LeyteDocument2 pagesEastern Visayas State University: Republic of The Philippines Province of LeyteRouel Francis Salas DadullaNo ratings yet