Professional Documents

Culture Documents

m400 Datasheet

m400 Datasheet

Uploaded by

Franco MaderaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

m400 Datasheet

m400 Datasheet

Uploaded by

Franco MaderaCopyright:

Available Formats

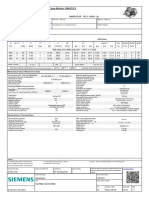

Data Sheet 106 P-Q Controls, Inc., 95 Dolphin Rd.

, Bristol, CT 06010, Phone 860-583-6994, Fax 860-583-6011

Omni-directional Level Sensor

Model 400

for monitoring the level attitude of platforms

Application:

The purpose of P-Q’s Model 400 & 401

Omnidirectional Level Sensors is to monitor the level

condition of a platform. A signal is provided to the

operator whenever the base upon which the sensor is

mounted is out of level in any direction. Typical

applications include manlifts, cranes and mobile

platforms.

Features:

Sensors come with two adjustments. The first is for

setting the trip angle and is adjustable from 1.5° to 6.0°.

The second is for varying the electronic time delay from

0.5 to 5.5 seconds. Both parameters will be factory set to

your specifications. Single and dual trip point options

are available.

The sensing mechanism is a gimbal-mounted pendu-

lum which is inductively coupled to the position-sensing

electronics. The pendulum is viscously damped with a

silicone fluid to prevent constant oscillation due to

vibration.

An indicator lamp located between the adjustments

gives an "ON" signal whenever the trip angle is reached

or exceeded. This lamp (LED) is undamped and assists

in system connection and checkout.

The self-contained electronics are protected against

reverse polarity and short circuiting of output. The

output is "fail-safe", live at supply voltage level (1.5

amp maximum) until the Sensor is tipped beyond its trip Specifications:

angle. The Sensor can also be supplied with inverted • Supply Voltage: 10 - 30 VDC or

output, "OFF" (Model 401) until trip angle. Other 10-60 VDC

options include ground switching and low output current • Output Current: 1.5 amp continuous, 10-30v

models. 0.5 amp continuous, 10-60v

• Trip Angle: 1.5° to 5.0° or

3.0° to 6.0° (field adjustable)

Other models: • Trip Delay: 0.5 to 5.5 seconds

• The Di-axial Level Sensor, Model 420 (Data Sheet (field adjustable)

107) has separately adjustable "X" and "Y" axis trip • Accuracy: Trip repeatable within 0.2°

angles. • Hysteresis: 0.3°

• The Platform Leveler, Model 410 (Data Sheet • Idle Current Draw: 30mA (no load)

108) can be used to level a platform. • Operating Temperature: -40° C to +70° C

• Model 425 (Data Sheet 114) provides proportional

"X" and "Y" axis output.

P-Q Controls, Inc. Doc. No: M400CallOut.doc

Phone (860) 583-6994 95 Dolphin Road Rev: A Date: 04/06/2000

Fax (860) 583-6011 Bristol, CT, 06010 Author: HGK Page: 1 of 1

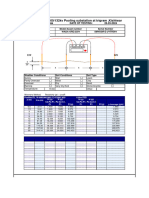

Level Sensor Part Numbering

Example: M400B-30-20TR Normally closed, sourcing, 3° trip angle, 2 sec time

delay on reset with Bubble Level

TYPE OF TIME DELAY

M400 B 30 20 TR NONE Delay on trip (Standard)

R Delay on reset

TR Delay on trip & reset

DURATION OF TIME DELAY

05 0.5 Seconds

10 1.0 Seconds

15 1.5 Seconds

etc…. Range = 0-5 seconds

TRIP ANGLE (M420 X axis) Trip Angle

15 1.5 Degrees (M420 Y axis)

20 2.0 Degrees 15 1.5 °

25 2.5 Degrees 20 2.0 °

etc…. Range = 1.5-8.0 degrees 25 2.5 °

Degrees

OUTPUT TYPE

Blank Sourcing

G Sinking

B Bubble

F Fixed Time Delay

MODELS

M400 Normally closed

M401 Normally open

M404 Normally closed, Fixed time delay

M405 Normally open, Fixed time delay

M406 Dual Trip, NC

M407 Dual Trip. NO

M410 Platform Leveler

M420 Di-axial Level Sensor, NC

M421 Di-axial Level Sensor, NO

4E0X Custom Products

M425 42 6VDC

Supply Voltage

Models Signal Swing

M415 X Axis 30 10%

M425 X & Y 42 30% (Standard)

Axis

Property of P-Q Controls, Inc. www.p-qcontrols.com

P-Q Controls, Inc. Doc. No: 400Cal.DOC

Phone (860) 583-6994 95 Dolphin Road Rev: - Date: 5/25/2000

Fax (860) 583-6011 Bristol, CT, 06010 Author: HGK Page: 1 of 1

M400 Series Omni Directional Level Sensor

Field Adjustment Procedure

Tools Needed: Digital Voltmeter Set On Low Scale (2VDC)

Torque Seal Locking Compound

Small Slotted Screwdriver

7/16 Nut Driver or Socket Wrench

NOTE:

As received, the level sensor has been calibrated for the trip angle and time delay necessary for your

application! If a minor adjustment is needed, please skip to Step #6.

Step 1: Final mount level sensor on machine.

Step 2: Rotate the time delay trimpot ccw until a click is heard.

Step 3: Connect the black lead of voltmeter to ground and the red lead to the small lead

protruding from the potting on the bottom of the sensor.

Step 4: Adjust the leveling nuts to obtain the highest possible voltage

reading.

Step 5: Check voltage at trip point in all 4 directions;

* If the voltage reading is not symmetrical, repeat Step #4.

Step 6: Slowly tilt sensor to desired trip angle;

* If the sensor is calibrated properly, the LED will turn on when the

sensor has reached the proper trip angle.

* If the LED turns on before the desired trip angle, turn the trip

angle pot cw until LED turns off (repeat Step #6).

* If the LED has not turned on at this point, proceed with Step #7.

Step 7: Rotate trip angle adjustment pot ccw until the LED comes on.

Step 8: Rotate the time delay trimpot cw until the desired time delay is achieved.

Step 9: Apply torque seal locking compound to the leveling nuts and adjustment

trimpots.

Property of P-Q Controls, Inc. www.p-qcontrols.com

P-Q Controls, Inc. Doc. No: LSTMOUNTING.DOC

Phone (860) 583-6994 95 Dolphin Road Rev: - Date: 3/7/2000

Fax (860) 583-6011 Bristol, CT, 06010 Author: HK Page: 1 of 1

LEVEL SENSOR MOUNTING PATTERNS

Property of P-Q Controls, Inc. www.p-qcontrols.com

You might also like

- 6-Speed Manual Gearbox 0B4 Four-Wheel DriveDocument159 pages6-Speed Manual Gearbox 0B4 Four-Wheel DriveergdegNo ratings yet

- Bigdog Section8 2002 Electrical RevisedDocument17 pagesBigdog Section8 2002 Electrical RevisedHOWARDB2010100% (1)

- NVF2 ManualDocument53 pagesNVF2 ManualGonzalo San Martin Leon83% (23)

- Service Manual: First Edition Second Printing Part No. 52709Document440 pagesService Manual: First Edition Second Printing Part No. 52709Jhon Hever Benitez100% (1)

- Part Numbering 400Document1 pagePart Numbering 400Zoran VujadinovicNo ratings yet

- m425 DatasheetDocument7 pagesm425 DatasheetFranco MaderaNo ratings yet

- N15TS 103a3030 - 531 N15TS 10KDocument6 pagesN15TS 103a3030 - 531 N15TS 10KRazvan MitruNo ratings yet

- TaperDocument8 pagesTapervishnu vishnu G.T.No ratings yet

- Wa0004 PDFDocument2 pagesWa0004 PDFCarlos Enrique González ÁlvarezNo ratings yet

- Features:: Technical SpecificationsDocument2 pagesFeatures:: Technical SpecificationsAmech SalesNo ratings yet

- 1LE1002-1CA13-4FA4 Datasheet enDocument1 page1LE1002-1CA13-4FA4 Datasheet enmaciejNo ratings yet

- Surface Preparation Check Tests Standards Requirements Results DecisionsDocument3 pagesSurface Preparation Check Tests Standards Requirements Results DecisionsSonia GuesmiNo ratings yet

- Dsc-Verticle DSC DDV Datasheet r3.1Document4 pagesDsc-Verticle DSC DDV Datasheet r3.1narinderNo ratings yet

- Future Tech FR e Series DatasheetDocument4 pagesFuture Tech FR e Series DatasheetRian Danang Eka PutraNo ratings yet

- Film Capacitors: Interference Suppression Capacitors (MPX Class X2)Document7 pagesFilm Capacitors: Interference Suppression Capacitors (MPX Class X2)suriantoNo ratings yet

- LS 820Document2 pagesLS 8208819133No ratings yet

- MJB 250 MA4: 4 Poles 50 HZ - 1500 RPM / 60 HZ - 1800 RPMDocument5 pagesMJB 250 MA4: 4 Poles 50 HZ - 1500 RPM / 60 HZ - 1800 RPMJuan AlonsoNo ratings yet

- T 60 DiffsimulatorDocument5 pagesT 60 DiffsimulatorHector Raul VerizuetaNo ratings yet

- Soil Resistivity Test Report 5Document2 pagesSoil Resistivity Test Report 5S R SINGHNo ratings yet

- Unindo CB500 - RFQ001Document43 pagesUnindo CB500 - RFQ001Kalimkarawang321 Kalimkarawang321No ratings yet

- DS-011904 TO-Packaged Laser DiodeDocument2 pagesDS-011904 TO-Packaged Laser DiodePawan KumarNo ratings yet

- Etamic Prob KataloguDocument16 pagesEtamic Prob KataloguCarlos Ramirez100% (1)

- Main Protection: Parameter CT F1 CT M1Document11 pagesMain Protection: Parameter CT F1 CT M1budipppNo ratings yet

- U-GAGE QT50ULB Series Sensors With Analog Output: DatasheetDocument11 pagesU-GAGE QT50ULB Series Sensors With Analog Output: DatasheetjfcolunaNo ratings yet

- Vaf39a 1Document2 pagesVaf39a 1Global Teknik AbadiNo ratings yet

- D155a 2Document2 pagesD155a 2Naughty VongNo ratings yet

- Protocolo de Pruebas Tipo Transformador de Corriente: P2 - Nueva Línea 2X220 KV Encuentro Lagunas, Primer CircuitoDocument146 pagesProtocolo de Pruebas Tipo Transformador de Corriente: P2 - Nueva Línea 2X220 KV Encuentro Lagunas, Primer CircuitocomarkaliderNo ratings yet

- Diagnostic Tests On Transformer: By, Mr.B.L.Lingshettar Bright Engineers Services, HubliDocument62 pagesDiagnostic Tests On Transformer: By, Mr.B.L.Lingshettar Bright Engineers Services, HubliVepty whoops100% (1)

- Decon (Screw) WQ SeriesDocument4 pagesDecon (Screw) WQ Serieszuigh899gNo ratings yet

- T60 - SimulatorDocument5 pagesT60 - Simulatorshanthikumaravel0% (1)

- EA08A-WG (Manual) Rev.2Document10 pagesEA08A-WG (Manual) Rev.2Daiane MendesNo ratings yet

- Electronic Timer - Series Micon 480: 40MFS0 40AFS0 40SFS0 Cat. NoDocument2 pagesElectronic Timer - Series Micon 480: 40MFS0 40AFS0 40SFS0 Cat. NoTaThachNo ratings yet

- Force Transducer: Special FeaturesDocument2 pagesForce Transducer: Special FeaturesSoup PongsakornNo ratings yet

- Time Switches FM SeriesDocument2 pagesTime Switches FM SeriesBlank - CodeNo ratings yet

- 180.0 ° 50.01 HZ 49.99 HZ 230.2 V 228.1 V: Multi Function MeterDocument2 pages180.0 ° 50.01 HZ 49.99 HZ 230.2 V 228.1 V: Multi Function MeterMAYCON KOPELVSKINo ratings yet

- AU - iPERL (Intl) Data SheetDocument2 pagesAU - iPERL (Intl) Data SheetHC IngenierosNo ratings yet

- Ingedrive Mv500 EngDocument2 pagesIngedrive Mv500 EnginakigarateNo ratings yet

- S400MLTAC4MDocument1 pageS400MLTAC4Mjohn rangelNo ratings yet

- Engineering Calculations: Ampacity CriteriaDocument2 pagesEngineering Calculations: Ampacity Criteriarettore84No ratings yet

- GT3A Series - Analog Timers: Key FeaturesDocument23 pagesGT3A Series - Analog Timers: Key FeaturesPacho ReyNo ratings yet

- MJB 160MB4Document5 pagesMJB 160MB4Andres SorinNo ratings yet

- MJB 225 SB4: 4 Poles 50 HZ - 1500 RPM / 60 HZ - 1800 RPMDocument4 pagesMJB 225 SB4: 4 Poles 50 HZ - 1500 RPM / 60 HZ - 1800 RPMwondNo ratings yet

- Schedule 40 PVC Rigid Nonmetallic ConduitsDocument3 pagesSchedule 40 PVC Rigid Nonmetallic ConduitsPRABHU SHANKAR MNo ratings yet

- Catalogo FRL SMCDocument47 pagesCatalogo FRL SMCFreddy GoncalvezNo ratings yet

- Catalogo ParkerDocument40 pagesCatalogo ParkerengenheiroalencarNo ratings yet

- Decon (Screw) WT SeriesDocument4 pagesDecon (Screw) WT Serieszuigh899gNo ratings yet

- U-Gage QT50ULB Series Sensors With Analog Output: DatasheetDocument11 pagesU-Gage QT50ULB Series Sensors With Analog Output: DatasheetRuben Gaytan LealNo ratings yet

- T60diffsimulatorDocument8 pagesT60diffsimulatorAns MehmoodNo ratings yet

- 17.5mm DIN Rail Timer 600XU: FeaturesDocument2 pages17.5mm DIN Rail Timer 600XU: FeaturesHama AieaNo ratings yet

- Lecture 420 - Compensation of Op Amps-I: (READING: Text-Sec. 9.2, 9.3, 9.4)Document16 pagesLecture 420 - Compensation of Op Amps-I: (READING: Text-Sec. 9.2, 9.3, 9.4)Monika JindalNo ratings yet

- Servicio Argentum - Pruebas Baker Molino #2Document4 pagesServicio Argentum - Pruebas Baker Molino #2Emerson Quispe MendozaNo ratings yet

- Fuji-Round Indicator SeriesDocument12 pagesFuji-Round Indicator Seriesheri fauziNo ratings yet

- 33 KVDocument72 pages33 KVNestory NgelejaNo ratings yet

- Generator Synchronizing Relay: M M M M M M M MDocument2 pagesGenerator Synchronizing Relay: M M M M M M M MDINESH CHATAPNo ratings yet

- 208 P444 LATEHAR L-1:: Test Object - Device SettingsDocument20 pages208 P444 LATEHAR L-1:: Test Object - Device SettingsAmmu KuttiyNo ratings yet

- T 60 DiffsimulatorDocument3 pagesT 60 DiffsimulatorRandom NerdNo ratings yet

- Sensors SpeedhallDocument2 pagesSensors SpeedhallahmadshikemohmadNo ratings yet

- VF - Sensores Fotosensibles de ProximidadDocument8 pagesVF - Sensores Fotosensibles de ProximidadLuca BazzoliNo ratings yet

- TTRM 301 TTRM 302: ScopeDocument6 pagesTTRM 301 TTRM 302: ScopeMarco CornelioNo ratings yet

- ENVADocument42 pagesENVAkarim18aug09No ratings yet

- Manual EVR PDDocument4 pagesManual EVR PDAnonymous dH3DIEtzNo ratings yet

- Honeywell GLAC01A4J DatasheetDocument52 pagesHoneywell GLAC01A4J DatasheetFranco MaderaNo ratings yet

- Guia GForceDocument5 pagesGuia GForceFranco MaderaNo ratings yet

- Inverters ChopperDocument20 pagesInverters ChopperFranco MaderaNo ratings yet

- m425 DatasheetDocument7 pagesm425 DatasheetFranco MaderaNo ratings yet

- Semiconductor KTB1369: Technical DataDocument3 pagesSemiconductor KTB1369: Technical DataFranco MaderaNo ratings yet

- Weber 3236 DGV DrawingDocument1 pageWeber 3236 DGV DrawingFranco MaderaNo ratings yet

- S-60 S-65 S-60X S-60XC S-60HC S-60TRAX S-65TRAX: Serial Number RangeDocument358 pagesS-60 S-65 S-60X S-60XC S-60HC S-60TRAX S-65TRAX: Serial Number RangeFranco MaderaNo ratings yet

- X Series Electric Forklift Truck: The World of HangchaDocument3 pagesX Series Electric Forklift Truck: The World of HangchaFranco MaderaNo ratings yet

- X Series Electric Forklift Truck: The World of HangchaDocument3 pagesX Series Electric Forklift Truck: The World of HangchaFranco MaderaNo ratings yet

- Technical Specifications: and Mechanical CapacityDocument1 pageTechnical Specifications: and Mechanical CapacitynemfogomNo ratings yet

- Exact Width Dado Jig PlanDocument5 pagesExact Width Dado Jig PlanMarco100% (1)

- BNWAS Le Guardian 2025 English Brochure PDFDocument6 pagesBNWAS Le Guardian 2025 English Brochure PDFyoungfpNo ratings yet

- Super EP Gear OilDocument2 pagesSuper EP Gear Oilchem KhanNo ratings yet

- Medium Voltage SwitchgearDocument5 pagesMedium Voltage SwitchgearGideon MoyoNo ratings yet

- RAIDER R150 High (FU150SCDX2L5-P31)Document70 pagesRAIDER R150 High (FU150SCDX2L5-P31)GAYLE GONo ratings yet

- K9LAG08U0M Memoria NANDDocument45 pagesK9LAG08U0M Memoria NANDrfernandoafr5734No ratings yet

- Parker Ash Probe User ManualDocument30 pagesParker Ash Probe User ManualDaniel Alberto Reyes RamirezNo ratings yet

- 3523R - 35 Ton Heavy Duty Haulage Truck Specifications - BharatBenzDocument5 pages3523R - 35 Ton Heavy Duty Haulage Truck Specifications - BharatBenzBalaji RathinavelNo ratings yet

- 2015-2018 Ford F-150 Fuse Box DiagramDocument8 pages2015-2018 Ford F-150 Fuse Box Diagramelttech666No ratings yet

- 1 848Document39 pages1 848Tawfiq ZidanNo ratings yet

- Fashion-FILM: Application Instructions ForDocument1 pageFashion-FILM: Application Instructions ForEmmanuelNo ratings yet

- Brake System Design For A Single Seater VehicleDocument27 pagesBrake System Design For A Single Seater VehicleAshraf Zulkafli100% (1)

- A Guide To Electric Drives and DC Motor ControlDocument8 pagesA Guide To Electric Drives and DC Motor ControlArunkumar Nambiraju100% (1)

- DE550018 BÜNOx 2Document5 pagesDE550018 BÜNOx 2seve1No ratings yet

- 11-SDMS-03 تلخيصDocument4 pages11-SDMS-03 تلخيصMohammed MadiNo ratings yet

- D55T - Standard Operating Maintenance Manuals (V 1 0)Document20 pagesD55T - Standard Operating Maintenance Manuals (V 1 0)julioNo ratings yet

- Low Dropout Linear Fixed Voltage RegulatorDocument26 pagesLow Dropout Linear Fixed Voltage RegulatorNur Aishi Putri SyarilNo ratings yet

- PR 4Document6 pagesPR 4John Paul MoradoNo ratings yet

- True Power - Servo StabilizerDocument2 pagesTrue Power - Servo StabilizerKrishan singhNo ratings yet

- Beosound 9000 MK-III Type 257x - 2580Document96 pagesBeosound 9000 MK-III Type 257x - 2580TestNo ratings yet

- A Project Report ON - " ": Automatic Street LightDocument8 pagesA Project Report ON - " ": Automatic Street LightPranjal Babar 25100% (1)

- Gowifi - Ahd - HLD - Rosario Maclang Bautista General Hospital Rev1Document32 pagesGowifi - Ahd - HLD - Rosario Maclang Bautista General Hospital Rev1Jhim MedinaNo ratings yet

- Components of Drip Irrigation System: February 2017Document34 pagesComponents of Drip Irrigation System: February 2017Varunika AgricultureNo ratings yet

- Catalogue ZapiDocument24 pagesCatalogue ZapiNitin ChavanNo ratings yet

- Data Acquisition Systems Communicate With Microprocessors Over 4 WiresDocument2 pagesData Acquisition Systems Communicate With Microprocessors Over 4 WiresAnonymous Y6EW7E1Gb3No ratings yet

- Application of PFD and PFMEA in Manufacturing of Clutch Release Fork of Heavy Motor VehiclesDocument12 pagesApplication of PFD and PFMEA in Manufacturing of Clutch Release Fork of Heavy Motor VehiclesAnand PathakNo ratings yet

- Wiring DiagramsDocument2 pagesWiring DiagramsshawnleegabrielNo ratings yet