Professional Documents

Culture Documents

UFX PHT Series

UFX PHT Series

Uploaded by

Lalit VashistaCopyright:

Available Formats

You might also like

- Presentation (Drinking Water)Document19 pagesPresentation (Drinking Water)Lalit VashistaNo ratings yet

- KCBDocument10 pagesKCBMarcos CarvalhoNo ratings yet

- Valve Inspection and Test PlanDocument1 pageValve Inspection and Test PlanClarkFedele27100% (1)

- UF RC SeriesDocument2 pagesUF RC SeriesLalit VashistaNo ratings yet

- UF-ETNA SeriesDocument2 pagesUF-ETNA SeriesLalit VashistaNo ratings yet

- UF-PE SeriesDocument3 pagesUF-PE SeriesLalit VashistaNo ratings yet

- UF-FS SeriesDocument2 pagesUF-FS SeriesLalit VashistaNo ratings yet

- Sani-Pro HPHT HFK Ultrafiltration ElementsDocument2 pagesSani-Pro HPHT HFK Ultrafiltration ElementsjeffersonfriasNo ratings yet

- UF-pHt SeriesDocument4 pagesUF-pHt SeriesLalit VashistaNo ratings yet

- Uf Pes Data SheetDocument1 pageUf Pes Data SheetLevent ToprakNo ratings yet

- Magpowr High Efficiency Brake: General SpecificationsDocument4 pagesMagpowr High Efficiency Brake: General Specificationsccorp0089No ratings yet

- Filtro TavlitDocument5 pagesFiltro TavlitKhhg AgddsNo ratings yet

- HFK131 Food and DairyDocument2 pagesHFK131 Food and DairyjeffersonfriasNo ratings yet

- En Alfa Laval UF PE Data Sheet 2012.03.09Document4 pagesEn Alfa Laval UF PE Data Sheet 2012.03.09jdk18No ratings yet

- QCLP-110 Tech DataDocument2 pagesQCLP-110 Tech Datalewis 5550No ratings yet

- Trigear Brochure - 2121 PDFDocument5 pagesTrigear Brochure - 2121 PDFDeep PatelNo ratings yet

- Appendix A Specifications and InstallationDocument2 pagesAppendix A Specifications and InstallationryoNo ratings yet

- Co Duct: Carbon Monoxide Duct SensorDocument2 pagesCo Duct: Carbon Monoxide Duct SensorREFRIFAMA SASNo ratings yet

- Outside - in Hollow Fiber Ultrafiltration Membranes: Pure TechnologyDocument2 pagesOutside - in Hollow Fiber Ultrafiltration Membranes: Pure TechnologyParvinder KaurNo ratings yet

- Multilog: Flow, Pressure Fast Response Temperature Electronic Memory GaugeDocument3 pagesMultilog: Flow, Pressure Fast Response Temperature Electronic Memory GaugeNeilton JuniorNo ratings yet

- M&EUR310ENDocument3 pagesM&EUR310ENRizqi AchsanulNo ratings yet

- FireBall Grease Pump SpecificationsDocument1 pageFireBall Grease Pump SpecificationsInstruktur MesinNo ratings yet

- ACE Reliance Sensor Ops Manual - V2.4 - CompressedDocument38 pagesACE Reliance Sensor Ops Manual - V2.4 - CompressedAdamNo ratings yet

- Audio TestDocument12 pagesAudio TestLeonardo GutierrezNo ratings yet

- Dow Specialty Membranes High Temperature RO and NFDocument28 pagesDow Specialty Membranes High Temperature RO and NFAlejandro OdioNo ratings yet

- DS-2CE16D0T-IRPF HD 1080p IR Bullet Camera: Key FeaturesDocument3 pagesDS-2CE16D0T-IRPF HD 1080p IR Bullet Camera: Key Featuressam perezNo ratings yet

- Engine Control Fuel SystemDocument154 pagesEngine Control Fuel Systemdothicamvan101No ratings yet

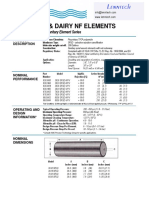

- Koch SR3D Food Dairy Elements LDocument2 pagesKoch SR3D Food Dairy Elements LFacundo RiffelNo ratings yet

- Asco Valve 8298a002 ReplacementDocument4 pagesAsco Valve 8298a002 ReplacementAugusto Leudo AngelNo ratings yet

- DS-2CD2723G0-IZS 2 MP IR Vari-Focal Dome Network Camera: Key FeaturesDocument4 pagesDS-2CD2723G0-IZS 2 MP IR Vari-Focal Dome Network Camera: Key FeaturesPippo BaudoNo ratings yet

- Lta320w2 L03Document33 pagesLta320w2 L03antoNo ratings yet

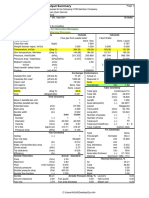

- Capacity CalculationDocument9 pagesCapacity CalculationmosesNo ratings yet

- Steel Braided Hose: Limusnunggal Rubber IndustryDocument5 pagesSteel Braided Hose: Limusnunggal Rubber IndustryIndra MaulanaNo ratings yet

- TSC Ttp243 Plus v2 enDocument2 pagesTSC Ttp243 Plus v2 enluizspinozaNo ratings yet

- Vortex Flow Meters: RNS Series Insertion Steam Flow MeterDocument4 pagesVortex Flow Meters: RNS Series Insertion Steam Flow Metercampana02No ratings yet

- s7200 Data SheetDocument3 pagess7200 Data SheetVamsi KumarNo ratings yet

- MEUR310 ENaDocument3 pagesMEUR310 ENaAbhijeet PandeyNo ratings yet

- FDT21WDocument2 pagesFDT21WThat's HimNo ratings yet

- 04 Series: Now Incorporates New R Sensor For Durability and Advanced FunctionsDocument2 pages04 Series: Now Incorporates New R Sensor For Durability and Advanced FunctionspcatruongNo ratings yet

- SM 5Document107 pagesSM 5Dery Lelana SaputraNo ratings yet

- SCAC - Inverter - ASIA - T Đ NGDocument3 pagesSCAC - Inverter - ASIA - T Đ NGDuy ChuNo ratings yet

- Audiopipe TXX bd2 Series Subwoofer Instruction ManualDocument12 pagesAudiopipe TXX bd2 Series Subwoofer Instruction ManualJose Matos BatistaNo ratings yet

- WD Watson Marlowpumps Flexmag4050cflowmeter En2Document3 pagesWD Watson Marlowpumps Flexmag4050cflowmeter En2probity2001-2No ratings yet

- Medidores AMERICAN METERSDocument17 pagesMedidores AMERICAN METERSRaúl PalomoNo ratings yet

- Multilog4 PDFDocument2 pagesMultilog4 PDFPajaroloco CarpinteroNo ratings yet

- Multilog4: Flow, Pressure Fast Response Temperature Electronic Memory GaugeDocument2 pagesMultilog4: Flow, Pressure Fast Response Temperature Electronic Memory GaugePajaroloco CarpinteroNo ratings yet

- Calculation Economizer - PL ProjectDocument12 pagesCalculation Economizer - PL ProjectXuan Man NguyenNo ratings yet

- Ds-2Ce16D0T-Ire HD 1080P Poc Ir Bullet Camera: Key FeaturesDocument3 pagesDs-2Ce16D0T-Ire HD 1080P Poc Ir Bullet Camera: Key FeaturesnicmaxxusNo ratings yet

- MAGNETOM Avanto-Fit Data Sheet E11C-MinDocument152 pagesMAGNETOM Avanto-Fit Data Sheet E11C-MinRafaelNo ratings yet

- 07 SL Rev. 2019 000Document2 pages07 SL Rev. 2019 000AkhmadiNo ratings yet

- Catalog SMT Series Transformers Solahd en Us 7438562Document1 pageCatalog SMT Series Transformers Solahd en Us 7438562ale348hotmail.comNo ratings yet

- File - AGR Field Operations TD Handy-Scan Data Sheet - 051210Document2 pagesFile - AGR Field Operations TD Handy-Scan Data Sheet - 051210Dhanasekaran RNo ratings yet

- Ds 2ce16d0t IrfDocument3 pagesDs 2ce16d0t IrfEricson Kelvin N. OcampoNo ratings yet

- DS-2CE16D0T-IRF HD 1080p IR Bullet Camera: Key FeaturesDocument3 pagesDS-2CE16D0T-IRF HD 1080p IR Bullet Camera: Key FeatureswarutsgsNo ratings yet

- Amiad Plastic FiltersDocument11 pagesAmiad Plastic FiltersWayne SeamanNo ratings yet

- SATO CL4NX Specification SheetDocument4 pagesSATO CL4NX Specification SheetEric StrangerNo ratings yet

- UHP-M Dualband 0.6m Single&single Polarized C3 Antenna Datasheet (AXXSYYS06CC)Document4 pagesUHP-M Dualband 0.6m Single&single Polarized C3 Antenna Datasheet (AXXSYYS06CC)Nikola VuckovicNo ratings yet

- HK Ds2ce16d0t IrpfDocument3 pagesHK Ds2ce16d0t IrpfpepeNo ratings yet

- AGR Field Operations TD ScanDocument2 pagesAGR Field Operations TD ScanhusamettinturNo ratings yet

- A-627 B&G Field Adjustable Venturi Valves For All HVAC Systems BrochureDocument2 pagesA-627 B&G Field Adjustable Venturi Valves For All HVAC Systems Brochurekeith dietrichNo ratings yet

- Flyer Segmented Cement BondDocument2 pagesFlyer Segmented Cement BondarmandoplcNo ratings yet

- Flyer Compact Production Logging ToolDocument2 pagesFlyer Compact Production Logging ToolmortizNo ratings yet

- Datasheet HCL Small Systems 4Document4 pagesDatasheet HCL Small Systems 4Lalit VashistaNo ratings yet

- Datasheet HCL Medium SystemsDocument4 pagesDatasheet HCL Medium SystemsLalit VashistaNo ratings yet

- UF RC SeriesDocument2 pagesUF RC SeriesLalit VashistaNo ratings yet

- UF-PE SeriesDocument3 pagesUF-PE SeriesLalit VashistaNo ratings yet

- Microsoft PowerPoint - HemicelluloseDocument16 pagesMicrosoft PowerPoint - HemicelluloseLalit VashistaNo ratings yet

- Uf Sse20Document2 pagesUf Sse20Lalit VashistaNo ratings yet

- UF-FS SeriesDocument2 pagesUF-FS SeriesLalit VashistaNo ratings yet

- UF-ETNA SeriesDocument2 pagesUF-ETNA SeriesLalit VashistaNo ratings yet

- The 8-Step Premium Guide To Linkedin GeniusDocument16 pagesThe 8-Step Premium Guide To Linkedin GeniusLalit Vashista100% (1)

- LG Multi V 5 2017 - 086-096Document1 pageLG Multi V 5 2017 - 086-096Ahmed Salah Abd EL-WahedNo ratings yet

- CE-3203 Hydrology: Dr. Mohammed Alauddin, DUET, GazipurDocument25 pagesCE-3203 Hydrology: Dr. Mohammed Alauddin, DUET, GazipurRafiq RehanNo ratings yet

- Sand Filter BrochureDocument2 pagesSand Filter BrochureadrianioantomaNo ratings yet

- DBR For PipingDocument50 pagesDBR For Pipingrajachem100% (1)

- Transportable Gas: LPG RecoveryDocument8 pagesTransportable Gas: LPG Recoveryzarar saleemNo ratings yet

- Surge CalculationsDocument7 pagesSurge CalculationsSameer MinhajNo ratings yet

- FD Fan Sizing CalculationDocument3 pagesFD Fan Sizing CalculationkumarananyarupeshNo ratings yet

- Falling Ball ViscometerDocument5 pagesFalling Ball ViscometerAbdullah AhmadNo ratings yet

- Hanoi Chirdren Culture ERACS1722E-N1-Z5Document9 pagesHanoi Chirdren Culture ERACS1722E-N1-Z5수이광No ratings yet

- Falling Film Evaporator-MEng-ThesisDocument206 pagesFalling Film Evaporator-MEng-ThesisElza Febrianty AngrainiNo ratings yet

- Tds Contro Heat RecoverylDocument31 pagesTds Contro Heat RecoverylHélder PascoalNo ratings yet

- Lecture Three: Process DesignDocument57 pagesLecture Three: Process DesignAsasira IradNo ratings yet

- Production and Test Packer - Retrievable PDFDocument30 pagesProduction and Test Packer - Retrievable PDFcomar85No ratings yet

- Understanding Boussinesq ApproximationDocument1 pageUnderstanding Boussinesq ApproximationHsu Tien-YiaoNo ratings yet

- Interior Air Flow Simulation in Railway Rolling STDocument12 pagesInterior Air Flow Simulation in Railway Rolling STOptimuz TsNo ratings yet

- Kidde Fire Systems HPCO2 Component Description: Stop (Directional) Valves, 1/2-Inch Thru 2-InchDocument1 pageKidde Fire Systems HPCO2 Component Description: Stop (Directional) Valves, 1/2-Inch Thru 2-InchElemsa InstalacionesNo ratings yet

- Thermodynamics of The Single-Step SynthesisDocument9 pagesThermodynamics of The Single-Step SynthesischemmmmmNo ratings yet

- Axit GNFC ReportDocument76 pagesAxit GNFC ReportAxit Patel100% (1)

- RC5 - Rocking Cell DatasheetDocument2 pagesRC5 - Rocking Cell DatasheetRoo FaNo ratings yet

- Startup and Shutdown ProceduresDocument1 pageStartup and Shutdown ProceduresShesharam ChouhanNo ratings yet

- Trainig Report For IoclDocument30 pagesTrainig Report For IoclAshish Jha67% (3)

- Types of Pressure Taps Used in Orifice - PIPING GUIDEDocument4 pagesTypes of Pressure Taps Used in Orifice - PIPING GUIDEVinodKumarNo ratings yet

- Intricacies in Gas Pipe DesigningDocument27 pagesIntricacies in Gas Pipe DesigningarunenggNo ratings yet

- Principles of Groundwater Flow PDFDocument64 pagesPrinciples of Groundwater Flow PDFJhe TaguinesNo ratings yet

- Basics of Steam GenerationDocument15 pagesBasics of Steam GenerationPravin KumarNo ratings yet

- MEC 2910 NewDocument7 pagesMEC 2910 Newsh1999No ratings yet

- H400 Check Valves CatalogDocument18 pagesH400 Check Valves CatalogDavis Zanki AqilNo ratings yet

- alhereDocument6 pagesalhereShameer MajeedNo ratings yet

UFX PHT Series

UFX PHT Series

Uploaded by

Lalit VashistaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UFX PHT Series

UFX PHT Series

Uploaded by

Lalit VashistaCopyright:

Available Formats

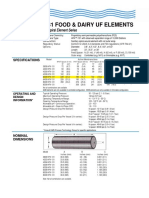

Alfa Laval UFX-pHt series

Spiral membranes for ultrafiltration

The elements are based on a unique construction of

polypropylene (PP) support material in a sanitary full-fit design

that provides optimum cleaning conditions.

They are available in different combinations of length, diameter,

spacer size and molecular weight cut-off value. All the materials

used for the production of these membranes comply with FDA

regulations (CFR) Title 21.

Designation Characteristics MWCO

UFX10 pHt Polysulphone permanently hydrophilic 10,000

UFX5 pHt Polysulphone permanently hydrophilic 5,000

Recommended operation limits:

UFX

Production

pH range 1 – 13

Pressure, bar (psi) 1 – 15 (15 – 218)

Temperature, °C (°F) 0 – 75 (32 – 167)

Max. element pressure drop, bar (psi) at cP 1 1.1 (16) for standard element size (38")

Cleaning (3 hours per day)*

Pressure, bar (psi) 1 – 5 (15 – 73)

Temperature, °C (°F) 0 – 75 (32 – 167)

Max. element pressure drop, bar (psi) at cP 1 1.1 (16) for standard element size (38")

pH range 1 – 13

NaOH, % 0.1 – 0.5

Na-EDTA, % 0.1 – 1.0

Mineral acid, % 0.1 – 0.5

Citric acid, % 0.1 – 1.0

Sanitation (1 hour per day)

Treated hot water water, only feed pump at 1 bar, °C (°F) 80 (176)

Chlorine (ppm) at 50°C (122°F) and pH 10 <200

Hydrogen peroxide (ppm) at 25°C <1000

* Please consult the Alfa Laval cleaning description

Note: The use of oxidation agents and similar chemicals might influence the actual membrane performance over time.

Typical cross-flow m3/h* (gpm)* and max. pressure drop bar (psi) at cP 1

Outer diameter 2.5" 3.8"

Spacer size m3/h bar (gpm) (psi) m3/h bar (gpm) (psi)

30 mil - - - - 6 1.1 (26.4) (16)

48 mil 1.3 0.6 (5.72) (9) 8 1.1 (35.2) (16)

80 mil - - - - 11 1.1 (48.4) (16)

Outer diameter 6.3" 8.0" 8.4"

Spacer size m3/h bar (gpm) (psi) m3/h bar (gpm) (psi) m3/h bar (gpm) (psi)

30 mil 17 1.1 (74.9) (16) 18 0.9 (79.3) (13) 25 0.8 (110.0) (12)

48 mil 23 1.1 (101.0) (16) 25 1.1 (110.0) (16) 30 1.1 (132.0) (16)

80 mil 30 1.1 (132.0) (16) 30 1.1 (132.0) (16) 35 1.1 (154.0) (16)

* Calculated at tight fit of spiral element and housing and by use of standard ATD system

Spiral membrane designation:

Alfa Laval

UFX-pHt-6338/48

Feed spacer thickness

Element length (38")

Outer diameter of element (6.3")

Membrane type

Dimensions

OD = outer diameter of element

Element configuration

HD = nominal inner diameter of housing*

Outer diameter 2.5" 3.8" 6.3" 8.0" 8.4"

L1 = total length of element

Length 17" 38" 38" 38" 38"

ID = diameter of ATD socket

Spacer size (mil) - 30 30 30 30

L2 = depth of ATD socket

48 48 48 48 48 * For specific measurements of Alfa Laval housings, please consult the product description

- 80 80 80 80

Element size OD mm (inches) HD mm (inches) L 1 mm (inches) ID mm (inches) L 2 mm (inches)

2517 64.0-65.0 (2.52-2.56) 66.00 (2.6) 432 (17.01) 21.00 (0.83) 26.0 (1.02)

3838 95.0-96.5 (3.74-3.80) 97.55 (3.84) 965 (37.99) 21.00 (0.83) 26.0 (1.02)

6338 160.0-162.0 (6.30-6.38) 163.10 (6.42) 965 (37.99) 28.90 (1.14) 26.0 (1.02)

8038 198.5-201.5 (7.82-7.93) 204.14 (8.04) 965 (37.99) 31.15 (1.23) 50.0 (1.97)

8038 198.5-201.5 (7.82-7.93) 204.14 (8.04) 965 (37.99) 28.58 (1.125) 51.0 (2.00)

8438 211.5-214.0 (8.33-8.43) 215.10 (8.47) 965 (37.99) 31.15 (1.23) 50.0 (1.97)

8438 211.5-214.0 (8.33-8.43) 215.10 (8.47) 965 (37.99) 28.90 (1.14) 50.0 (1.97)

Important information Operating guidelines

New spiral elements must be cleaned prior to first use. The Avoid any abrupt pressure or cross-flow variations on the spi-

cleaning procedure should be in accordance with the instruc- ral elements during startup, shutdown, cleaning or other

tions provided in the Alfa Laval cleaning description for the sequences, in order to prevent possible damage.

spiral element type concerned. Alfa Laval recommends the following start-up procedure from

The customer is fully responsible for the effects that any standstill to operating condition:

incompatible chemicals may have on the spiral elements. • The unpressurized plant should be refilled with water.

• After initial wetting, the spiral elements must be kept moist • Feed pressure should be gradually increased over a 30–60

at all times. second time scale.

• If the operating specifications provided in this product • Before initiating cross-flow at high permeate flux conditions

description are not strictly followed, the limited warranty will (e.g. start-up with high-temperature water), the set feed

be null and void. pressure should be maintained for 5–10 minutes.

• To prevent biological growth during system shutdowns, Alfa • Cross-flow velocity at the set operating point should be

Laval recommends that spiral elements should be gradually achieved over a period of 15–20 seconds.

immersed in a protective solution. • Temperature variations should be implemented gradually

• Avoid permeate-side back pressure at all times. over a period of 3–5 minutes.

• Alfa Laval recommends using a rigid stainless steel ATD

end device at the pressure vessel outlet end.

• Alfa Laval recommends that the inner diameter of the pres-

sure vessel be approx. 2 mm (0.08 inches) bigger than the

outer diameter of the spiral element in question.

PCM00068EN 0708 Alfa Laval reserves the right to change specifications without prior notification.

How to contact Alfa Laval

Up-to-date Alfa Laval contact details for

all countries are always available on our

website at www.alfalaval.com

You might also like

- Presentation (Drinking Water)Document19 pagesPresentation (Drinking Water)Lalit VashistaNo ratings yet

- KCBDocument10 pagesKCBMarcos CarvalhoNo ratings yet

- Valve Inspection and Test PlanDocument1 pageValve Inspection and Test PlanClarkFedele27100% (1)

- UF RC SeriesDocument2 pagesUF RC SeriesLalit VashistaNo ratings yet

- UF-ETNA SeriesDocument2 pagesUF-ETNA SeriesLalit VashistaNo ratings yet

- UF-PE SeriesDocument3 pagesUF-PE SeriesLalit VashistaNo ratings yet

- UF-FS SeriesDocument2 pagesUF-FS SeriesLalit VashistaNo ratings yet

- Sani-Pro HPHT HFK Ultrafiltration ElementsDocument2 pagesSani-Pro HPHT HFK Ultrafiltration ElementsjeffersonfriasNo ratings yet

- UF-pHt SeriesDocument4 pagesUF-pHt SeriesLalit VashistaNo ratings yet

- Uf Pes Data SheetDocument1 pageUf Pes Data SheetLevent ToprakNo ratings yet

- Magpowr High Efficiency Brake: General SpecificationsDocument4 pagesMagpowr High Efficiency Brake: General Specificationsccorp0089No ratings yet

- Filtro TavlitDocument5 pagesFiltro TavlitKhhg AgddsNo ratings yet

- HFK131 Food and DairyDocument2 pagesHFK131 Food and DairyjeffersonfriasNo ratings yet

- En Alfa Laval UF PE Data Sheet 2012.03.09Document4 pagesEn Alfa Laval UF PE Data Sheet 2012.03.09jdk18No ratings yet

- QCLP-110 Tech DataDocument2 pagesQCLP-110 Tech Datalewis 5550No ratings yet

- Trigear Brochure - 2121 PDFDocument5 pagesTrigear Brochure - 2121 PDFDeep PatelNo ratings yet

- Appendix A Specifications and InstallationDocument2 pagesAppendix A Specifications and InstallationryoNo ratings yet

- Co Duct: Carbon Monoxide Duct SensorDocument2 pagesCo Duct: Carbon Monoxide Duct SensorREFRIFAMA SASNo ratings yet

- Outside - in Hollow Fiber Ultrafiltration Membranes: Pure TechnologyDocument2 pagesOutside - in Hollow Fiber Ultrafiltration Membranes: Pure TechnologyParvinder KaurNo ratings yet

- Multilog: Flow, Pressure Fast Response Temperature Electronic Memory GaugeDocument3 pagesMultilog: Flow, Pressure Fast Response Temperature Electronic Memory GaugeNeilton JuniorNo ratings yet

- M&EUR310ENDocument3 pagesM&EUR310ENRizqi AchsanulNo ratings yet

- FireBall Grease Pump SpecificationsDocument1 pageFireBall Grease Pump SpecificationsInstruktur MesinNo ratings yet

- ACE Reliance Sensor Ops Manual - V2.4 - CompressedDocument38 pagesACE Reliance Sensor Ops Manual - V2.4 - CompressedAdamNo ratings yet

- Audio TestDocument12 pagesAudio TestLeonardo GutierrezNo ratings yet

- Dow Specialty Membranes High Temperature RO and NFDocument28 pagesDow Specialty Membranes High Temperature RO and NFAlejandro OdioNo ratings yet

- DS-2CE16D0T-IRPF HD 1080p IR Bullet Camera: Key FeaturesDocument3 pagesDS-2CE16D0T-IRPF HD 1080p IR Bullet Camera: Key Featuressam perezNo ratings yet

- Engine Control Fuel SystemDocument154 pagesEngine Control Fuel Systemdothicamvan101No ratings yet

- Koch SR3D Food Dairy Elements LDocument2 pagesKoch SR3D Food Dairy Elements LFacundo RiffelNo ratings yet

- Asco Valve 8298a002 ReplacementDocument4 pagesAsco Valve 8298a002 ReplacementAugusto Leudo AngelNo ratings yet

- DS-2CD2723G0-IZS 2 MP IR Vari-Focal Dome Network Camera: Key FeaturesDocument4 pagesDS-2CD2723G0-IZS 2 MP IR Vari-Focal Dome Network Camera: Key FeaturesPippo BaudoNo ratings yet

- Lta320w2 L03Document33 pagesLta320w2 L03antoNo ratings yet

- Capacity CalculationDocument9 pagesCapacity CalculationmosesNo ratings yet

- Steel Braided Hose: Limusnunggal Rubber IndustryDocument5 pagesSteel Braided Hose: Limusnunggal Rubber IndustryIndra MaulanaNo ratings yet

- TSC Ttp243 Plus v2 enDocument2 pagesTSC Ttp243 Plus v2 enluizspinozaNo ratings yet

- Vortex Flow Meters: RNS Series Insertion Steam Flow MeterDocument4 pagesVortex Flow Meters: RNS Series Insertion Steam Flow Metercampana02No ratings yet

- s7200 Data SheetDocument3 pagess7200 Data SheetVamsi KumarNo ratings yet

- MEUR310 ENaDocument3 pagesMEUR310 ENaAbhijeet PandeyNo ratings yet

- FDT21WDocument2 pagesFDT21WThat's HimNo ratings yet

- 04 Series: Now Incorporates New R Sensor For Durability and Advanced FunctionsDocument2 pages04 Series: Now Incorporates New R Sensor For Durability and Advanced FunctionspcatruongNo ratings yet

- SM 5Document107 pagesSM 5Dery Lelana SaputraNo ratings yet

- SCAC - Inverter - ASIA - T Đ NGDocument3 pagesSCAC - Inverter - ASIA - T Đ NGDuy ChuNo ratings yet

- Audiopipe TXX bd2 Series Subwoofer Instruction ManualDocument12 pagesAudiopipe TXX bd2 Series Subwoofer Instruction ManualJose Matos BatistaNo ratings yet

- WD Watson Marlowpumps Flexmag4050cflowmeter En2Document3 pagesWD Watson Marlowpumps Flexmag4050cflowmeter En2probity2001-2No ratings yet

- Medidores AMERICAN METERSDocument17 pagesMedidores AMERICAN METERSRaúl PalomoNo ratings yet

- Multilog4 PDFDocument2 pagesMultilog4 PDFPajaroloco CarpinteroNo ratings yet

- Multilog4: Flow, Pressure Fast Response Temperature Electronic Memory GaugeDocument2 pagesMultilog4: Flow, Pressure Fast Response Temperature Electronic Memory GaugePajaroloco CarpinteroNo ratings yet

- Calculation Economizer - PL ProjectDocument12 pagesCalculation Economizer - PL ProjectXuan Man NguyenNo ratings yet

- Ds-2Ce16D0T-Ire HD 1080P Poc Ir Bullet Camera: Key FeaturesDocument3 pagesDs-2Ce16D0T-Ire HD 1080P Poc Ir Bullet Camera: Key FeaturesnicmaxxusNo ratings yet

- MAGNETOM Avanto-Fit Data Sheet E11C-MinDocument152 pagesMAGNETOM Avanto-Fit Data Sheet E11C-MinRafaelNo ratings yet

- 07 SL Rev. 2019 000Document2 pages07 SL Rev. 2019 000AkhmadiNo ratings yet

- Catalog SMT Series Transformers Solahd en Us 7438562Document1 pageCatalog SMT Series Transformers Solahd en Us 7438562ale348hotmail.comNo ratings yet

- File - AGR Field Operations TD Handy-Scan Data Sheet - 051210Document2 pagesFile - AGR Field Operations TD Handy-Scan Data Sheet - 051210Dhanasekaran RNo ratings yet

- Ds 2ce16d0t IrfDocument3 pagesDs 2ce16d0t IrfEricson Kelvin N. OcampoNo ratings yet

- DS-2CE16D0T-IRF HD 1080p IR Bullet Camera: Key FeaturesDocument3 pagesDS-2CE16D0T-IRF HD 1080p IR Bullet Camera: Key FeatureswarutsgsNo ratings yet

- Amiad Plastic FiltersDocument11 pagesAmiad Plastic FiltersWayne SeamanNo ratings yet

- SATO CL4NX Specification SheetDocument4 pagesSATO CL4NX Specification SheetEric StrangerNo ratings yet

- UHP-M Dualband 0.6m Single&single Polarized C3 Antenna Datasheet (AXXSYYS06CC)Document4 pagesUHP-M Dualband 0.6m Single&single Polarized C3 Antenna Datasheet (AXXSYYS06CC)Nikola VuckovicNo ratings yet

- HK Ds2ce16d0t IrpfDocument3 pagesHK Ds2ce16d0t IrpfpepeNo ratings yet

- AGR Field Operations TD ScanDocument2 pagesAGR Field Operations TD ScanhusamettinturNo ratings yet

- A-627 B&G Field Adjustable Venturi Valves For All HVAC Systems BrochureDocument2 pagesA-627 B&G Field Adjustable Venturi Valves For All HVAC Systems Brochurekeith dietrichNo ratings yet

- Flyer Segmented Cement BondDocument2 pagesFlyer Segmented Cement BondarmandoplcNo ratings yet

- Flyer Compact Production Logging ToolDocument2 pagesFlyer Compact Production Logging ToolmortizNo ratings yet

- Datasheet HCL Small Systems 4Document4 pagesDatasheet HCL Small Systems 4Lalit VashistaNo ratings yet

- Datasheet HCL Medium SystemsDocument4 pagesDatasheet HCL Medium SystemsLalit VashistaNo ratings yet

- UF RC SeriesDocument2 pagesUF RC SeriesLalit VashistaNo ratings yet

- UF-PE SeriesDocument3 pagesUF-PE SeriesLalit VashistaNo ratings yet

- Microsoft PowerPoint - HemicelluloseDocument16 pagesMicrosoft PowerPoint - HemicelluloseLalit VashistaNo ratings yet

- Uf Sse20Document2 pagesUf Sse20Lalit VashistaNo ratings yet

- UF-FS SeriesDocument2 pagesUF-FS SeriesLalit VashistaNo ratings yet

- UF-ETNA SeriesDocument2 pagesUF-ETNA SeriesLalit VashistaNo ratings yet

- The 8-Step Premium Guide To Linkedin GeniusDocument16 pagesThe 8-Step Premium Guide To Linkedin GeniusLalit Vashista100% (1)

- LG Multi V 5 2017 - 086-096Document1 pageLG Multi V 5 2017 - 086-096Ahmed Salah Abd EL-WahedNo ratings yet

- CE-3203 Hydrology: Dr. Mohammed Alauddin, DUET, GazipurDocument25 pagesCE-3203 Hydrology: Dr. Mohammed Alauddin, DUET, GazipurRafiq RehanNo ratings yet

- Sand Filter BrochureDocument2 pagesSand Filter BrochureadrianioantomaNo ratings yet

- DBR For PipingDocument50 pagesDBR For Pipingrajachem100% (1)

- Transportable Gas: LPG RecoveryDocument8 pagesTransportable Gas: LPG Recoveryzarar saleemNo ratings yet

- Surge CalculationsDocument7 pagesSurge CalculationsSameer MinhajNo ratings yet

- FD Fan Sizing CalculationDocument3 pagesFD Fan Sizing CalculationkumarananyarupeshNo ratings yet

- Falling Ball ViscometerDocument5 pagesFalling Ball ViscometerAbdullah AhmadNo ratings yet

- Hanoi Chirdren Culture ERACS1722E-N1-Z5Document9 pagesHanoi Chirdren Culture ERACS1722E-N1-Z5수이광No ratings yet

- Falling Film Evaporator-MEng-ThesisDocument206 pagesFalling Film Evaporator-MEng-ThesisElza Febrianty AngrainiNo ratings yet

- Tds Contro Heat RecoverylDocument31 pagesTds Contro Heat RecoverylHélder PascoalNo ratings yet

- Lecture Three: Process DesignDocument57 pagesLecture Three: Process DesignAsasira IradNo ratings yet

- Production and Test Packer - Retrievable PDFDocument30 pagesProduction and Test Packer - Retrievable PDFcomar85No ratings yet

- Understanding Boussinesq ApproximationDocument1 pageUnderstanding Boussinesq ApproximationHsu Tien-YiaoNo ratings yet

- Interior Air Flow Simulation in Railway Rolling STDocument12 pagesInterior Air Flow Simulation in Railway Rolling STOptimuz TsNo ratings yet

- Kidde Fire Systems HPCO2 Component Description: Stop (Directional) Valves, 1/2-Inch Thru 2-InchDocument1 pageKidde Fire Systems HPCO2 Component Description: Stop (Directional) Valves, 1/2-Inch Thru 2-InchElemsa InstalacionesNo ratings yet

- Thermodynamics of The Single-Step SynthesisDocument9 pagesThermodynamics of The Single-Step SynthesischemmmmmNo ratings yet

- Axit GNFC ReportDocument76 pagesAxit GNFC ReportAxit Patel100% (1)

- RC5 - Rocking Cell DatasheetDocument2 pagesRC5 - Rocking Cell DatasheetRoo FaNo ratings yet

- Startup and Shutdown ProceduresDocument1 pageStartup and Shutdown ProceduresShesharam ChouhanNo ratings yet

- Trainig Report For IoclDocument30 pagesTrainig Report For IoclAshish Jha67% (3)

- Types of Pressure Taps Used in Orifice - PIPING GUIDEDocument4 pagesTypes of Pressure Taps Used in Orifice - PIPING GUIDEVinodKumarNo ratings yet

- Intricacies in Gas Pipe DesigningDocument27 pagesIntricacies in Gas Pipe DesigningarunenggNo ratings yet

- Principles of Groundwater Flow PDFDocument64 pagesPrinciples of Groundwater Flow PDFJhe TaguinesNo ratings yet

- Basics of Steam GenerationDocument15 pagesBasics of Steam GenerationPravin KumarNo ratings yet

- MEC 2910 NewDocument7 pagesMEC 2910 Newsh1999No ratings yet

- H400 Check Valves CatalogDocument18 pagesH400 Check Valves CatalogDavis Zanki AqilNo ratings yet

- alhereDocument6 pagesalhereShameer MajeedNo ratings yet