Professional Documents

Culture Documents

Silo - Tips - Environment Management Plan

Silo - Tips - Environment Management Plan

Uploaded by

Kenneth JapsonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Silo - Tips - Environment Management Plan

Silo - Tips - Environment Management Plan

Uploaded by

Kenneth JapsonCopyright:

Available Formats

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

ENVIRONMENT MANAGEMENT PLAN

The Environment Management Plan (EMP) would consist of all mitigation measures for each

component of the environment due to the activities increased during the construction, operation

and the entire life cycle to minimize adverse environmental impacts resulting from the activities

of the project. It would also delineate the environmental monitoring plan for compliance of

various environmental regulations. It will state the steps to be taken in case of emergency such as

accidents at the sites including fire. The detailed EMP for the project is given below.

Environmental Management Plan

The Environment Management Plan (EMP) is a site specific plan developed to ensure that the

project is implemented in an environmental sustainable manner where all contractors and

subcontractors, including consultants, understand the potential environmental risks arising from

the project and take appropriate actions to properly manage that risk. EMP also ensures that the

project implementation is carried out in accordance with the design by taking appropriate

mitigation actions to reduce adverse environmental impacts during its life cycle. The plan outlines

existing and potential problems that may adversely impact the environment and recommends

corrective measures where required. Also, the plan outlines roles and responsibility of the key

personnel and contractors who will be in-charge of the responsibilities to manage the project site.

The EMP is generally

Prepared in accordance with rules and requirements of the MoEF and CPCB/ SPCB

To ensure that the component of facility are operated in accordance with the design

A process that confirms proper operation through supervision and monitoring

A system that addresses public complaints during construction and operation of the

facilities and

M/s Rashmi Exports Pvt. Ltd 1

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

A plan that ensures remedial measures is implemented immediately.

The key benefits of the EMP are that it offers means of managing its environmental performance

thereby allowing it to contribute to improved environmental quality. The other benefits include

cost control and improved relations with the stakeholders.

EMP includes four major elements:

Commitment & Policy: The management will strive to provide and implement the

Environmental Management Plan that incorporates all issues related to air, water, land and

noise.

Planning: This includes identification of environmental impacts, legal requirements and

setting environmental objectives.

Implementation: This comprises of resources available to the developers, accountability of

contractors, training of operational staff associated with environmental control facilities

and documentation of measures to be taken.

Measurement & Evaluation: This includes monitoring, counteractive actions and record

keeping.

It is suggested that as part of the EMP, a monitoring committee would be formed by M/s. Rashmi

Exports Pvt. Ltd.comprising of the site in-charge/coordinator, environmental group representative

and project implementation team representative. The committee’s role would be to ensure proper

operation and management of the EMP including the regulatory compliance.

The components of the environmental management plan, potential impacts arising, out of the

project and remediation measures are summarized below in Table 1.

M/s Rashmi Exports Pvt. Ltd 2

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

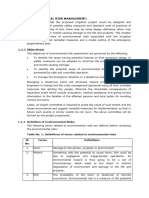

TABLE 1: SUMMARY OF POTENTIAL IMPACTS AND REMEDIAL MEASURES

SI. Environmental Potential Impacts Potential Source of Controls Through Impact Evaluation Remedial Measures

No. components Impact EMP & Design

1. Ground Water Ground Water Construction Phase No surface No significant impact as

Quality Contamination Wastewater generated accumulation will be majority of labors would

from temporary labor allowed. be locally deployed

tents.

Operation Phase Project will provide No negative impact on

Discharge from the the STP to treat ground water quality

project wastewater envisaged. Not

significant.

2. Ground Water Ground Water Construction Phase Ground water will No significant impact on

Quantity Depletion Use of Private water not be used for ground water quantity

Tanker. construction purposes. envisaged.

Operation Phase Rain water No significant impact on In an unlikely event

The source of water harvesting scheme. surface/ground water of non-availability of

during operation quantity envisaged. water supply, water

phase is Delhi Jal Black and Grey will be brought using

Board (DJB). water treatment and tankers.

reuse.

Storm water

collection for water

harvesting.

M/s Rashmi Exports Pvt. Ltd 3

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Percolation well to

be introduced in

landscape plan.

Awareness

Campaign to reduce

the water consumption

3. Surface Water Surface water Construction Phase Silt traps and No off-site impact

Quality contamination Surface runoff from other measures such envisaged as no surface

site during as additional on site water receiving body is

construction activity. diversion ditches will present in the core zone.

be constructed to

control surface run-off

during site

development

Operation Phase Domestic No off-site impact

Discharge of wastewater will be envisaged

domestic wastewater treated in STP

to STP.

4. Air Quality Dust Emissions Construction Phase Suitable control Not significant because During construction

All heavy measures will be dust generation will be phase, contractors

construction adopted for mitigating temporary and will settle are advised to

activities the PMlevel in the air fast due to dust facilitate masks for

as per air pollution suppression techniques. the labors. Water

control plan. sprinklers will be

M/s Rashmi Exports Pvt. Ltd 4

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

used for suppression

of dust during

construction phase.

Emissions of PM, Construction Phase Rapid on-site Not significant. Regular monitoring

SO2, NO2 and CO Operation of construction and of emissions and

construction improved maintenance control measures will

equipment and of equipment be taken to reduce

vehicles during site the emission levels.

development. Use of Personal

Protective

Running D.G. set Equipment (PPE)

(back up) like earmuffs and

earplugs

Operation Phase Use of low sulphur Not significant. Stack height of

Power generation by diesel if available DG set would be used as DG set above the

DG Set during power Providing Footpath power back-up (approx tallest building as

failure and pedestrian ways 6 hours) per CPCB

within the site for the standards

Emission from persons. No significant increase

vehicular traffic in Green belt will be in ambient air quality

use developed with level is expected from

specific species to the project’s activities.

help to reduce There are no sensitive

PMlevel receptors located within

Use of equipment the vicinity of site.

M/s Rashmi Exports Pvt. Ltd 5

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

fitted with silencers

Proper maintenance

of equipment

5. Noise Construction phase Provision of noise

Environment Concrete shields near the

mixing & heavy construction

operation of DG operations and

sets acoustic enclosures

Movement of for DG set.

heavy vehicles Construction

activity will be

limited to day time

hours only

Noise

absorbing material

& layers will be

provided to

attenuate the noise

generated from

concrete mixed

grinder.

M/s Rashmi Exports Pvt. Ltd 6

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Operation Phase Green Belt No significant impact

Development due to suitable width of

Noise from Development of Greenbelt.

vehicular movement silence zones to

check the traffic

Noise from DG set movement

operation DG set rooms

will be equipped

with acoustic

enclosures

6. Land Soil contamination Construction Phase Construction debris No significant impact.

Environment will be collected and Impact will be local, as

Disposal of suitably used on site waste generated will be

construction debris as per the solid waste reused for filling of

management plan for low lying areas etc.

construction phase

Operation Phase It is proposed that Since solid waste is

the solid waste handled by the

Generation of generated will be authorized agency,

municipal solid managed as per waste dumping is not

waste MSW Rules, 2000 going to be allowed.

Used oil generated and amended Rules, Not significant.

from D.G. set 2008.

Collection, Negligible impact.

segregation,

M/s Rashmi Exports Pvt. Ltd 7

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

transportation and

disposal will be done

as per MSW

Management Rules,

2000 by the

authorized agency

Used oil

generated will be

sold to authorized

recyclers

E-waste will

be managed as per

E-waste

(Management &

Handling) Rules,

2011.

7. Biological Displacement of Construction Phase Important The site has shrubs as

Environment Flora and Fauna on Site Development species of trees, if vegetation

(Flora and site during construction any, will be

Fauna) identified and

marked and will be

merged with

landscape plan

Operation Phase

Increase in green Suitable green belts

M/s Rashmi Exports Pvt. Ltd 8

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

covered area will be developed Beneficial impact.

as per landscaping

plan in and around

the site using local

flora

8. Socio- Population Construction Phase Project will No negative impact.

Economic displacement and Construction provide employment

Environment loss of income activities leading to opportunities.

relocation

Operation Phase Project will

Site operation provide employment Beneficial impact

opportunities

9. Traffic Pattern Increase of Construction Phase Heavy Vehicular No negative impact

vehicular traffic Heavy Vehicular movement will be

movement during restricted to daytime

construction only and adequate

parking facility will

be provided

Operation Phase Vehicular No major significant

Traffic due to movement will be impact as green belt

persons once the regulated inside the will be developed

project is project with which will help in

operational adequate roads and minimizing the impact

parking lots in the on environment.

project.

M/s Rashmi Exports Pvt. Ltd 9

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

ENVIRONMENT MANAGEMENT PLAN

An Environmental Management Plan (EMP) will be required to mitigate the predicted

adverse environmental impacts during construction and operation phase of the project

and these are discussed in later subsections.

EMP for Air Environment

Construction Phase

To mitigate the impacts of PMduring the construction phase of the project, the following

measures are recommended for implementation:

A dust control plan

Procedural changes to construction activities

Dust Control Plan

The most cost-effective dust suppressant is water because water is easily available on

construction site. Water can be applied using water trucks, handled sprayers and

automatic sprinkler systems. Furthermore, incoming loads could be covered to avoid loss

of material in transport, especially if material is transported off-site.

Procedural Changes to Construction Activities

Idle time reduction: Construction equipment is commonly left idle while the operators

are on break or waiting for the completion of another task. Emission from idle equipment

tends to be high, since catalytic converters cools down, thus reducing the efficiency of

hydrocarbon and carbon monoxide oxidation. Existing idle control technologies

comprises of power saving mode, which automatically off the engine at preset time and

reduces emissions, without intervention from the operators.

M/s Rashmi Exports Pvt. Ltd 10

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Improved Maintenance: Significant emission reductions can be achieved through

regular equipment maintenance. Contractors will be asked to provide maintenance

records for their fleet as part of the contract bid, and at regular intervals throughout the

life of the contract. Incentive provisions will be established to encourage contractors to

comply with regular maintenance requirements.

Reduction of On-Site Construction Time: Rapid on-site construction would reduce the

duration of traffic interference and therefore, will reduce emissions from traffic delay.

Operation Phase

To mitigate the impacts of pollutants from DG set and vehicular traffic during the

operational phase of the institutional project, following measures are recommended for

implementation:

DG set emission control measures

Vehicular emission controls and alternatives

Greenbelt development

Diesel Generator Set Emission Control Measures

Adequate stack height will be maintained to disperse the air pollutants generated from the

operation of DG set to dilute the pollutants concentration within the immediate vicinity.

Hence no additional emission control measures have been suggested.

Vehicle Emission Controls and Alternatives

During construction, vehicles will be properly maintained to reduce emission. Also,

vehicles will be generally having “PUC” certificate.

Footpaths and Pedestrian ways: Adequate footpaths and pedestrian ways would be

provided at the site to encourage non-polluting methods of transportation.

M/s Rashmi Exports Pvt. Ltd 11

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Greenbelt Development

Increased vegetation in the form of greenbelt is one of the preferred methods to mitigate

air and noise pollution. Plants serve as a sink for pollutants, act as a barrier to break the

wind speed as well as allow the dust and other particulates to settle on the leaves. It also

helps to reduce the noise level at large extent. The following table indicates various

species of the greenbelt that can be used to act as a barrier.

Table 9: Trees to be planted in the Project

Evergreen Trees Ornamental Trees

Botanical Name Common Name Botanical Name

Delonixregtia Gulmohar Areca palm

Azadirachtaindica Neem Prunusarmeniaca

Callistemon lanceolatus Bottle Brush Bougainvillea torch glow

Cassia fistula Amaltas Cleredendroninerme

Gravelliarobusta Silver Oak Cycascircinalis

Ficusbengalensis Bargad Euphorbia carcasana

EMP FOR NOISE ENVIRONMENT

Construction Phase

To mitigate the impacts of noise from construction equipment during the construction

phase on the site, the following measures are recommended for implementation.

Time of Operation: Noisy construction equipment would not be allowed to use at night

time.

M/s Rashmi Exports Pvt. Ltd 12

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Job Rotation and Hearing Protection: Workers employed in high noise areas will be

employed on shift basis. Hearing protection such as earplugs/muffs will be provided to

those working very close to the noise generating machinery.

Operation Phase

To mitigate the impacts of noise from diesel generator set during operational phase, the

following measures are recommended:

Adoption of Noise emission control technologies

Greenbelt development

Noise Emission Control Technologies

It would be ensured that the manufacturer provides acoustic enclosure as an integral part

along with the diesel generators set. Further, enclosure of the services area with 4 m high

wall will reduce noise levels and ensure that noise is at a permissible limit for persons of

the site and surrounding receptors.

EMP FOR WATER ENVIRONMENT

Construction Phase

To prevent degradation and to maintain the quality of the water source, adequate control

measures have been proposed. To check the surface run-off as well as uncontrolled flow

of water into any water body check dams with silt basins are proposed. The following

management measures are suggested to protect the water source being polluted during the

construction phase:

Care would be taken to avoid soil erosion

Common toilets was provided earlier,on site during construction phase and the

wastewater would be channelized to the septic tanks in order to prevent waste

water to enter into the water bodies

M/s Rashmi Exports Pvt. Ltd 13

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

To prevent surface and ground water contamination by oil and grease, leak-

proof containers would be used for storage and transportation of oil and

grease. The floors of oil and grease handling area would be kept effectively

impervious. Any wash off from the oil and grease handling area or workshop

shall be drained through imperious drains

Collection and settling of storm water, prohibition of equipment wash downs

and prevention of soil loss and toxic release from the construction site are

necessary measure to be taken to minimize water pollution.

All stacking and loading area will be provided with proper garland drains,

equipped with baffles, to prevent run off from the site, to enter into any water

body.

Operation Phase

In the operation phase of the project, water conservation and development measures will

be taken, including all possible potential for rain water harvesting. Following measures

will be adopted:

Water source development.

Minimizing water consumption.

Promoting reuse of water after treatment and development of closed loopsystems

for different water streams.

Water Source Development

Water source development shall be practiced by installation of scientifically designed

Rain Water Harvesting system. Rainwater harvesting promotes self-sufficiency and

fosters an appreciation for water as a resource.

M/s Rashmi Exports Pvt. Ltd 14

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Minimizing Water Consumption

Consumption of fresh water will be minimized by combination of water saving devices

and other domestic water conservation measures. Further, to ensure ongoing water

conservation, an awareness program will be introduced for the persons.The following

section discusses the specific measures, which shall be implemented:

Domestic and Institutional Usage

Use of water efficient plumbing fixtures. Water efficient plumbing fixtures uses

less water with no marked reduction in quality and service

Leak detection and repair techniques.

Sweep with a broom and pan where possible, rather than hose down for external

areas.

Meter water usage: Implies measurement and verification methods.

Monitoring of water uses is a precursor for management.

Landscape

Drip irrigation system shall be used for the lawns and other green area. Drip irrigation

can save 15-40% of the water, compared with other watering techniques.

Plants with similar water requirements shall be grouped on common zones to match

precipitation heads and emitters.

Use of low-angle sprinklers for lawn areas.

Select controllers with adjustable watering schedules and moisture sensors to account

for seasonal variations and calibrate them during commissioning.

Place 3 to 5 inches of mulch on planting beds to minimize evaporation.

Promoting Reuse of Water after Treatment and Development of Closed Loop

Systems

M/s Rashmi Exports Pvt. Ltd 15

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

To promote reuse of waste water and development of closed loop system for waste water

segregation. Two wastewater conservation schemes are suggested, namely:

1) Storm Water Harvest 2) Waste water recycling.

Storm water harvest as discussed in earlier, will be utilized for artificial recharge of

ground water sources; and waste water will be reused on site after treatment.

The treated water generated from STP will be recycled for Landscaping, Flushing and

DG cooling during non-rainy season and flushing, HVAC cooling and filter backwash

during rainy season resulting zero exit discharge.Following section discuss the scheme of

waste water treatment.

Waste Water Treatment Scheme

Proponent will treat the wastewater of the Project premises in well-designed sewage

treatment plant of capacity 150KLD based on FABtechnology.

Storm Water Management

Most of the storm water produced on site will be harvested for ground water recharge.

Thus proper management of this resource is a must to ensure that it is free from

contamination.

Contamination of Storm Water is possible from the following sources:

Diesel and oil spills in the diesel power generator and fuel storage area

Waste spills in the solid / hazardous waste storage area

Oil spills and leaks in vehicle parking lots

Silts from soil erosion in gardens

Spillage of sludge from sludge drying area of sewage treatment plant

M/s Rashmi Exports Pvt. Ltd 16

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

A detailed storm water management plan will be developed which will consider the

possible impacts from above sources. The plan will incorporate best management

practices which will include following:

Regular inspection and cleaning of storm drains

Clarifiers or oil/separators will be installed in all the parking areas. Oil /

grease separators installed around parking areas and garages will be sized

according to peak flow guidelines. Both clarifiers and oil/water separators

will be periodically pumped in order to keep discharges within limits

Covered waste storage areas

Avoid application of pesticides and herbicides before wet season

Secondary containment and dykes in fuel/oil storage facilities

Conducting routine inspection to ensure cleanliness

Provision of slit traps in storm water drains

Good housekeeping in the above areas

EMP FOR LAND ENVIRONMENT

Construction Phase

The waste generated from construction activity includes construction debris, biomass

from land clearing activities. Following section discuss the management of each type of

waste. Besides waste generation, management of the topsoil is an important area for

which management measures are required.

Construction Debris

Construction debris is bulky and heavy and re-utilization and recycling is an important

strategy for management of such waste. As concrete and masonry constitute the majority

of waste generated, recycling of this waste by conversion to aggregate can offer benefits

M/s Rashmi Exports Pvt. Ltd 17

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

of reduced landfill space and reduced extraction of raw material for new construction

activity. This is particularly applicable to the project site as the construction is to be

completed in a phased manner.

Mixed debris with high gypsum, plaster, shall not be used as fill, as they are highly

susceptible to contamination, and will be send to designated solid waste landfill site.

Metal scrap from structural steel, piping, concrete reinforcement and sheet metal work

shall be removed from the site by construction contractors. A significant portion of wood

scrap will be reused on site. Recyclable wastes such as plastics, glass fiber insulation,

roofing etc. shall be sold to govt. approved recyclers.

Hazardous waste

Construction sites are sources of many toxic substances such as paints, solvents wood

preservatives, pesticides, adhesives and sealants. Hazardous waste generated during

construction phase shall be stored in sealed containers and disposed off as per The

Hazardous Wastes (Management & Handling) Rules, 1989.

Some management practices to be developed are:

Herbicides and pesticide will not be over applied (small-scale applications) and not

applied prior to rain

Paintbrushes and equipment for water and oil based paints shall be cleaned within a

contained area and will not be allowed to contaminate site soils, water courses or

drainage systems

Provision of adequate hazardous waste storage facilities. Hazardous waste collection

containers will be located as per safety norms and designated hazardous waste storage

areas will be away from storm drains or watercourses

Segregationofpotentially hazardous waste from non-hazardous construction site

debris

M/s Rashmi Exports Pvt. Ltd 18

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Well labeled all hazardous waste containers with the waste being stored and the date

of generation

Instruct employees and subcontractors in identification of hazardous and solid waste

Even with careful management, some of these substances are released into air, soil and

water and many are hazardous to workers. With these reasons, the best choice is to avoid

their use as much as possible by using low-toxicity substitutes and low VOC (Volatile

Organic Compound) materials.

Top Soil Management

To minimize disruption of soil and for conservation of top soil, the contractor shall keep

the top soil cover separately and stockpile it. After the construction activity is over, top

soil will be utilized for landscaping activity. Other measures, which would be followed to

prevent soil erosion and contamination include:

Maximize use of organic fertilizer for landscaping and green belt development.

To prevent soil contamination by oil/grease, leaf proof containers would be used for

storage and transportation of oil/grease and wash off from the oil/grease handling area

shall be drained through impervious drains and treated appropriately before disposal

Working in a small area at a point of time (phase wise construction)

Construction of erosion prevention troughs/berms.

Operational Phase

The philosophy of solid waste management at the Project premises will be to encouraging

the four R’s of waste i.e. Reduction, Reuse, Recycling and Recovery (materials &

energy). Regular public awareness meetings will be conducted to involve the persons in

the proper segregation and storage techniques. The Environmental Management Plan for

the solid waste focuses on three major components during the life cycle of the waste

M/s Rashmi Exports Pvt. Ltd 19

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

management system i.e., collection and transportation, treatment or disposal and closure

and post-closure care of treatment/disposal facility.

Collection and Transportation

During the collection stage, the solid waste of the project will be segregated into

biodegradable waste and non-biodegradable. Biodegradable waste and non

biodegradable waste will be collected in separate bins. Biodegradable waste will be

treated in the project premises by organic waste converter. The recyclable wastes will

be sent off to govt. approved recyclabers. Proper guidelines for segregation,

collection and storage will be prepared as per MSW Rules, 2000 and amended Rules,

2008.

To minimize littering and odour, waste will be stored in well-designed containers/

bins that will be located at strategic locations to minimize disturbance in traffic flow

Care would be taken such that the collection vehicles are well maintained and

generate minimum noise and emissions. During transportation of the waste, it will be

covered to avoid littering.

M/s Rashmi Exports Pvt. Ltd 20

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Figure 1: Solid Waste Management Scheme (Operation Phase)

Disposal

With regards to the disposal/treatment of waste, the management will take the services of

the authorized agency for waste management and disposal of the same on the project site

during its operational phase.

10.2.5 EMP FOR ECOLOGICAL ENVIRONMENT

Construction activity changes the natural environment. But Project premises also creates

a built environment for its inhabitants. The project requires the implementation of

following choices exclusively or in combination.

Construction Stage

Restriction of construction activities to defined project areas, which are ecologically

sensitive

M/s Rashmi Exports Pvt. Ltd 21

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Restrictions on location of temporary labor tents and offices for project staff near the

project area to avoid human induced secondary additional impacts on the flora and

fauna species

Cutting, uprooting, coppicing of trees or small trees if present in and around the

project site for cooking, burning or heating purposes by the labors will be prohibited

and suitable alternatives for this purpose will be made

Along with the construction work, the peripheral green belt would be developed with

suggested native plant species, as they will grow to a full-fledged covered at the time

of completion.

Operation Stage

Improvement of the current ecology of the project site will entail the following measures:

Plantation and Landscaping

Green Belt Development

Avenue Plantation

The section below summarizes the techniques to be applied to achieve the above

objectives:

Plantation and landscaping

Selection of the plant species would be done on the basis of their adaptability to the

existing geographical conditions and the vegetation composition of the forest type of the

region earlier found or currently observed.

Green Belt Development Plan

The plantation matrix adopted for the green belt development includes pit of 0.3m × 0.3m

size with a spacing of 2 m x 2 m. In addition, earth filling and manure may also be

required for the proper nutritional balance and nourishment of the sapling. It is also

M/s Rashmi Exports Pvt. Ltd 22

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

recommended that the plantation has to be taken up randomly and the landscaping

aspects could be taken into consideration.

Plantation comprising of medium height trees (7 m to 10 m) and shrubs (5 m height) are

proposed for the green belt. In addition creepers will be planted along the boundary wall

to enhance its insulation capacity.

Selection of Plant Species for Green Belt Development

The selection of plant species for the development depends on various factors such as

climate, elevation and soil. The plants would exhibit the following desirable

characteristics in order to be selected for plantation

1. The species should be fast growing and providing optimum penetrability

2. The species should be wind-firm and deep rooted

3. The species should form a dense canopy

4. As far as possible, the species should be indigenous and locally available

5. Species tolerance to air pollutants like SO2 and NO2 should be preferred

6. The species should be permeable to help create air turbulence and mixing within

the belt

7. There should be no large gaps for the air to spill through

8. Trees with high foliage density, leaves with larger leaf area and hairy on both the

surfaces

9. Ability to withstand conditions like inundation and drought

10. Soil improving plants (Nitrogen fixing rapidly decomposable leaf litter)

11. Attractive appearance with good flowering and fruit bearing

12. Bird and insect attracting tree species

13. Sustainable green cover with minimal maintenance.

M/s Rashmi Exports Pvt. Ltd 23

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Avenue Plantation

Gardens maintained for recreational and ornamental purposes will not only

improve the quality of existing ecology at the project site but also will improve

the aesthetic value.

Avenue Plantation

1. Trees with colonial canopy with attractive flowering

2. Trees with branching at 7 feet and above

3. Trees with medium spreading branches to avoid obstruction to the traffic

4. Fruit trees to be avoided because children may obstruct traffic and general

movement of public

EMP for Socio-Economic Environment

The social management plan has been designed to take proactive steps and adopt best

practices, which are sensitive to the socio-cultural setting of the region. The Social

Management Plan for Project premises focuses on the following components:

Income Generation Opportunity during Construction and Operation Phase

The project would provide employment opportunity during construction and

operation phase. There would also be a wide economic impact in terms of

generating opportunities for secondary occupation within and around the Project

premises. The main principles considered for employment and income generation

opportunities are out lined below:

Employment strategy will provide for preferential employment of local

people.

M/s Rashmi Exports Pvt. Ltd 24

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Conditions of employment would address issues like minimum wages and

medical care for the workers. Contractors would be required to abide to

employment priority towards localsand abide.

By the labor laws regarding standards on employee terms and conditions.

Improved Working Environment for Employees

The project would provide safe and improved working conditions for the workers

employed at the facility during construction and operation phase. With the

proposed ambience and facilities provided, the Project premises will provide a

new experience in living and recreations. Following measures would be taken to

improve the working environment of the area:

Less use of chemicals and biological agents with hazard potential

Developing a proper interface between the work and the human resource

through a system of skill improvement

Provision of facilities for nature care and recreation e.g. indoor games

facilities

Measures to reduce the incidence of work related injuries, fatalities and

diseases

Maintenance and beautifications of the Project premises and the surrounding

roads

EMP FOR ENERGY CONSERVATION

Energy conservation program will be implemented through measures taken both on

energy demand and supply.

M/s Rashmi Exports Pvt. Ltd 25

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Supply Energy Conservation Demand

Utilize energy-efficient diesel Reduce consumption

genetators Use energy efficient appliances

Exploring the possibilities of Create Guest Awareness

introducing renewable energy

Energy conservation will be one of the main focus during the Project premises planning

and operation stages. The conservation efforts would consist of the following:

Architectural design

Maximum utilization of solar light will be done.

Maximize the use of natural lighting through design.

The orientation of the buildings will be done in such a way that maximum

daylight is available.

The green areas will be spaced, so that a significant reduction in the temperature

can take place.

Energy Saving Practices

Day light integration with occupancy / daylight sensors and dimming controls.

Constant monitoring of energy consumption and defining targets for energy

conservation.

Adjusting the settings and illumination levels to ensure minimum energy used for

desired comfort levels.

Behavioral Change on Consumption

M/s Rashmi Exports Pvt. Ltd 26

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Promoting persons awareness on energy conservation

Training staff on methods of energy conservation and to be vigilant to such

opportunities.

10.3 ENVIRONMENTAL MANAGEMENT SYSTEM AND MONITORING

PLAN

For the effective and consistent functioning of the Project premises, an Environmental

Management system (EMS) would be established at the site. The EMS would include the

following:

An Environmental management cell.

Environmental Monitoring.

Personnel Training.

Regular Environmental audits and Correction measures.

Documentation – standards operation procedures Environmental Management

Plan and other records.

ENVIRONMENTAL MANAGEMENT CELL

Apart from having an Environmental Management Plan, it is also proposed to have a

permanent organizational set up charged with the task of ensuring its effective

implementation of mitigation measures and to conduct environmental monitoring. The

major duties and responsibilities of Environmental Management Cell shall be as given

below:

To implement the Environmental Management Plan.

To assure regulatory compliance with all relevant rules and regulations.

To ensure regular operation and maintenance of pollution control devices.

M/s Rashmi Exports Pvt. Ltd 27

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

To minimize environmental impact of operations as by strict adherence to the

EMP.

To initiate environmental monitoring as per approved schedule.

Review and interpretation of monitored results and corrective measures in case

monitored results are above the specified limit.

Maintain documentation of good environmental practices and applicable

environmental laws for a ready reference.

Maintain environmental related records.

Coordination with regulatory agencies, external consultants, monitoring

laboratories.

Maintenance of log of public complaints and the action taken.

Hierarchical Structure of Environmental Management Cell

Normal activities of the EMP cell would be supervised by a dedicated person who will

report to the site manager/coordinator of the Intuitional Building. The hierarchical

structure of suggested Environmental Management Cell is given in following Figure 6.

M/s Rashmi Exports Pvt. Ltd 28

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Corporate Site Manager Rep from

Environmenta Corporate

l Division Planning group

Site Environmental

Coordinator

Waste water Greenbelt Dev.

Treatment Plant Incharge

Operator

Figure 6: Environnent Management Cell Structure

ENVIRONMENTAL MONITORING

The purpose of environmental monitoring is to evaluate the effectiveness of

implementation of Environmental Management Plan (EMP) by periodic monitoring. The

important environmental parameters within the impact area are selected so that any

adverse affects are detected and time action can be taken. The project proponent will

monitor ambient air Quality, Ground Water Quality and Quantity, and Soil Quality in

accordance with an approved monitoring schedule.

M/s Rashmi Exports Pvt. Ltd 29

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

Table 2: Suggested Monitoring Program for the Project

S. Type Locations Parameters Period and Frequency

No.

1. Ambient Air Project Site Criteria Pollutants: Quaterly (24 hr average

Quality SO2, NO2, PM, CO samples) during

construction phase and

annual during operation

phase.

2. Groundwater Ground water Drinking water Quarterly

will not be parameters as per

used for the IS:10500.

project site.

3. Ambient Noise Project site dB (A) levels Quaterly (Hourly day

and night time leq levels)

during construction

phase and every year

during operation phase.

4. Fresh water Delhi Jal As per IS:10500 Quarterly

quality Board fresh water

standards

5. Soil quality Project site Organic matter, C, Quarterly

H, N, Alkalinity,

Acidity, heavy

metals and trace

metal, Alkalinity,

Acidity.

M/s Rashmi Exports Pvt. Ltd 30

Revision & Expansion of Commercial Project

At Plot No. E-32, Okhla Industrial Area, Ph-II,

New Delhi

6. Waste Persons Physical and Daily

Characterization Chemical

composition

7. Treated water Outlet of STP BOD, MPN, Daily

coliform count, etc.

10.3.3 Awareness and Training

Training and human resource development is an important link to achieve sustainable

operation of the facility and environment management. For successful functioning of the

project, relevant EMP would be communicated to:

Persons and Contractors

Persons must be made aware of the importance of waste segregation and disposal, water

and energy conservation. The awareness can be provided by periodic Integrated Society

meetings. They would be informed of their duties.

10.3.4 Environmental Audits and Corrective Action Plans

To assess whether the implemented EMP is adequate, periodic environmental audits will

be conducted by the project proponent’s Environmental division. These audits will be

followed by Correction Action Plan (CAP) to correct various issues identified during the

audits.

M/s Rashmi Exports Pvt. Ltd 31

You might also like

- Environmental Management Plan SampleDocument15 pagesEnvironmental Management Plan SampleBesim Ufuk BalcıNo ratings yet

- GDS User ManualDocument399 pagesGDS User ManualBá Đạt Đào Nguyễn100% (1)

- Preventive Maintenance ChecklistDocument3 pagesPreventive Maintenance ChecklistKenneth Japson100% (1)

- Pla511 AssignmentDocument19 pagesPla511 Assignmentcharlie ricardelNo ratings yet

- Ashe Sustainability Report FINALDocument34 pagesAshe Sustainability Report FINALTaraNo ratings yet

- TubewellDocument13 pagesTubewellmuhammad kamil shahNo ratings yet

- Compliance Report Rahul SirDocument4 pagesCompliance Report Rahul Sirrahul kumarNo ratings yet

- Proposed Museum Building Complex at Bhairon Marg Info 2Document6 pagesProposed Museum Building Complex at Bhairon Marg Info 2vindhya murthyNo ratings yet

- Environmental PlanDocument41 pagesEnvironmental PlanPlanning - Pappu ConstructionNo ratings yet

- Environment.: Brgy. Malabanban Sur, Candelaria, QuezonDocument4 pagesEnvironment.: Brgy. Malabanban Sur, Candelaria, QuezonkkNo ratings yet

- Portion E - TDP - R3Document21 pagesPortion E - TDP - R3Jacky TamNo ratings yet

- Environmental Performance Report and Management Plan: Buklod-Unlad Multi-Purpose Cooperative (Buklod)Document96 pagesEnvironmental Performance Report and Management Plan: Buklod-Unlad Multi-Purpose Cooperative (Buklod)Lei Ann BobadillaNo ratings yet

- EIA of Maxinne CompanyDocument10 pagesEIA of Maxinne CompanyEmmanuel CausonNo ratings yet

- Proposed Four-Storey Four-Building CondominiumDocument16 pagesProposed Four-Storey Four-Building CondominiumEmmanuel CausonNo ratings yet

- Future CitiesDocument7 pagesFuture CitiesAbhishek TatvawitNo ratings yet

- LeetDocument20 pagesLeetAmardeepNo ratings yet

- Sustainable Guide ch7Document16 pagesSustainable Guide ch7Usman BalaNo ratings yet

- Geographical Site LocationsDocument5 pagesGeographical Site LocationsvishantNo ratings yet

- EMP SampleDocument119 pagesEMP SampleJenson MagdaongNo ratings yet

- CHAPTER 7 With MitigationDocument11 pagesCHAPTER 7 With Mitigationgeraldiglesia121No ratings yet

- EmpDocument8 pagesEmpIan MooneNo ratings yet

- Appendix F Air Quality Management PlanDocument10 pagesAppendix F Air Quality Management PlanbakabakaNo ratings yet

- Controlling Slippage in Water Resources and Infrastructure ProjectsDocument7 pagesControlling Slippage in Water Resources and Infrastructure ProjectsAlbenmarMamalumpongAbdullahNo ratings yet

- Low Impact Development For Stormwater MANAGEMENT (Group ID: 317)Document1 pageLow Impact Development For Stormwater MANAGEMENT (Group ID: 317)Rohan LakhaniNo ratings yet

- D1B-Urban RoadsDocument11 pagesD1B-Urban RoadsArsalanPP33No ratings yet

- Guide Dewatering PDFDocument15 pagesGuide Dewatering PDFMarlou GonzalboNo ratings yet

- Finalised PHD Viva SheilaDocument16 pagesFinalised PHD Viva SheilaSheila BelayuthamNo ratings yet

- Environmental Management PlanDocument21 pagesEnvironmental Management PlanKecha TayeNo ratings yet

- Chapter 1 - Introduction: Zarina MD Ali, Mohd Shalahuddin Adnan & Siti Nazahiyah RahmatDocument38 pagesChapter 1 - Introduction: Zarina MD Ali, Mohd Shalahuddin Adnan & Siti Nazahiyah RahmatEncik ComotNo ratings yet

- WRU-Technical Sheet For Land Drainage SystemDocument5 pagesWRU-Technical Sheet For Land Drainage SystemRakesh HarahNo ratings yet

- The Integration of Production and Environmental Approaches in Managing Construction Site Water PollutionDocument16 pagesThe Integration of Production and Environmental Approaches in Managing Construction Site Water PollutionDR SHEILA BELAYUTHAMNo ratings yet

- 013 Eia 03cDocument156 pages013 Eia 03cRaza Muhammad SoomroNo ratings yet

- Citp Final - For ExcavationDocument39 pagesCitp Final - For ExcavationGAhr CeredonNo ratings yet

- 5.0 Environmental Management Plan: Proposed Domaine de Grand Baie Residential Development - EIA ReportDocument9 pages5.0 Environmental Management Plan: Proposed Domaine de Grand Baie Residential Development - EIA ReportProperty TwelveNo ratings yet

- SectionDocument1 pageSectionYOng ChoonNo ratings yet

- Geographical Site Locations: Factors Weightage (%) Site-A Site-B Site-CDocument5 pagesGeographical Site Locations: Factors Weightage (%) Site-A Site-B Site-CvishantNo ratings yet

- Section 2 Environmental Considerations For Port Development and OperationsDocument7 pagesSection 2 Environmental Considerations For Port Development and OperationsMeifeng LuoNo ratings yet

- Chapter 8Document25 pagesChapter 8aung0024No ratings yet

- CAPS BessatDocument239 pagesCAPS BessatJoefel BessatNo ratings yet

- Environmental Management PlanDocument14 pagesEnvironmental Management PlanAllan KhatasioNo ratings yet

- A Basavaprabhu 3PD16AT001 Vii Sem B.ArchDocument1 pageA Basavaprabhu 3PD16AT001 Vii Sem B.ArchBasava prabhu prabhuNo ratings yet

- Harris County Low Impact Development & Green Infrastructure Design Criteria For Storm Water ManagementDocument53 pagesHarris County Low Impact Development & Green Infrastructure Design Criteria For Storm Water ManagementAkhid SidqiNo ratings yet

- Alta PresentationDocument68 pagesAlta PresentationBongga Ka DayNo ratings yet

- EIA Report of Malik Filling Station, RWP BestDocument85 pagesEIA Report of Malik Filling Station, RWP BestHenok mekuriaNo ratings yet

- Assignment 3Document3 pagesAssignment 3gracie koiNo ratings yet

- 4.0 Environmental Impacts and Mitigation Measures Potential Environmental ImpactsDocument6 pages4.0 Environmental Impacts and Mitigation Measures Potential Environmental ImpactsProperty TwelveNo ratings yet

- LEED Summary SheetDocument21 pagesLEED Summary SheetJadedT100% (4)

- Prensentation Slides For Industry BriefingDocument40 pagesPrensentation Slides For Industry BriefingkunalkhubaniNo ratings yet

- 28 Summary OF THE Assessment: 28.1 Summary of Potential Effects, Adverse Residual Effects and Their SignificanceDocument65 pages28 Summary OF THE Assessment: 28.1 Summary of Potential Effects, Adverse Residual Effects and Their SignificanceArdhi TaNo ratings yet

- Impact ManagementDocument61 pagesImpact ManagementJaguru Joyce NelsonNo ratings yet

- 07072018BL27YAISAnnexure RiskAssessmentDocument8 pages07072018BL27YAISAnnexure RiskAssessmentlokesh medhaNo ratings yet

- Chapter 7-Screening of Anticipated Impacts and Proposed MitigationDocument39 pagesChapter 7-Screening of Anticipated Impacts and Proposed MitigationBiswajit SikdarNo ratings yet

- Water Management Plan: NTPC GE Power Services Pvt. LTDDocument9 pagesWater Management Plan: NTPC GE Power Services Pvt. LTDsandeep220No ratings yet

- 4.0 Environmental Impacts and Mitigation Measures Potential Environmental ImpactsDocument7 pages4.0 Environmental Impacts and Mitigation Measures Potential Environmental ImpactsCirilo Jr. LagnasonNo ratings yet

- EIA Power PlantDocument31 pagesEIA Power PlantAnirudh KalliNo ratings yet

- Construction Activity Pollution Prevention Plan - 1 Oct2023Document18 pagesConstruction Activity Pollution Prevention Plan - 1 Oct2023JayaprakashNo ratings yet

- Site EMP A1 Plan (1) - Types and Locations of Environmental Protection MeasuresDocument3 pagesSite EMP A1 Plan (1) - Types and Locations of Environmental Protection MeasuresGilbert NdibeNo ratings yet

- 7.9 Potential Impacts and MitigationDocument1 page7.9 Potential Impacts and MitigationQ C ShamlajiNo ratings yet

- 6 Storied School Building Structural Ananlysis and Environmental AnalysisDocument142 pages6 Storied School Building Structural Ananlysis and Environmental AnalysisMD. SAKLINE MAHBUB CALVIN, 180051228No ratings yet

- Construction Activity Pollution Prevention Plan - 12oct2023Document17 pagesConstruction Activity Pollution Prevention Plan - 12oct2023JayaprakashNo ratings yet

- 201509151617590.meridian - CHP 9Document12 pages201509151617590.meridian - CHP 9Tan Kang YaoNo ratings yet

- WD 08 20b - ch4 PDFDocument135 pagesWD 08 20b - ch4 PDFprudhvi mahadevNo ratings yet

- Reducing Disaster Risk by Managing Urban Land Use: Guidance Notes for PlannersFrom EverandReducing Disaster Risk by Managing Urban Land Use: Guidance Notes for PlannersNo ratings yet

- Waste WaterDocument1 pageWaste WaterKenneth JapsonNo ratings yet

- 00.1 Appendix 1 List of Internal Documents Preview ENDocument1 page00.1 Appendix 1 List of Internal Documents Preview ENKenneth JapsonNo ratings yet

- Water SystemDocument1 pageWater SystemKenneth JapsonNo ratings yet

- TablesDocument1 pageTablesKenneth JapsonNo ratings yet

- Personal Data SheetDocument4 pagesPersonal Data SheetKenneth JapsonNo ratings yet

- Project Proposal ICTDocument5 pagesProject Proposal ICTKenneth JapsonNo ratings yet

- Letter - Toyota ButuanDocument1 pageLetter - Toyota ButuanKenneth JapsonNo ratings yet

- Sewage Treatment PlantDocument22 pagesSewage Treatment PlantKenneth JapsonNo ratings yet

- PVC 2021 11 24 23 51 06 954Document1 pagePVC 2021 11 24 23 51 06 954Kenneth JapsonNo ratings yet

- Module 5 HCWM Planning in A Health Care FacilityDocument42 pagesModule 5 HCWM Planning in A Health Care FacilityKenneth JapsonNo ratings yet

- Program Implementation ReviewDocument7 pagesProgram Implementation ReviewKenneth JapsonNo ratings yet

- Amortization Formula Excel TemplateDocument3 pagesAmortization Formula Excel TemplateKenneth JapsonNo ratings yet

- PHO SURIGAO - Analytical BalanceDocument2 pagesPHO SURIGAO - Analytical BalanceKenneth JapsonNo ratings yet

- FINAL - BH Environmental Management Plan - December 2013Document13 pagesFINAL - BH Environmental Management Plan - December 2013Kenneth JapsonNo ratings yet

- CWD QMS ManualDocument42 pagesCWD QMS ManualKenneth JapsonNo ratings yet

- Department of Microbiology: Uncontrolled When PrintedDocument3 pagesDepartment of Microbiology: Uncontrolled When PrintedKenneth JapsonNo ratings yet

- QAM Revision 12Document50 pagesQAM Revision 12Kenneth JapsonNo ratings yet

- Environmental Management Plan Final 2021 2026Document21 pagesEnvironmental Management Plan Final 2021 2026Kenneth JapsonNo ratings yet

- CHCB Environmental-Action-Plan 2019Document12 pagesCHCB Environmental-Action-Plan 2019Kenneth JapsonNo ratings yet

- OCA Template v3.0Document3 pagesOCA Template v3.0Kenneth JapsonNo ratings yet

- PHO SURIGAO Icp Oes SignedDocument4 pagesPHO SURIGAO Icp Oes SignedKenneth JapsonNo ratings yet

- Provincial City Health OfficeDocument5 pagesProvincial City Health OfficeKenneth JapsonNo ratings yet

- The Core Functions of Public Health Laboratories: Revised in 2014Document26 pagesThe Core Functions of Public Health Laboratories: Revised in 2014Kenneth JapsonNo ratings yet

- PoA 5979 - CPA19 ESMP Ver - June 2019Document31 pagesPoA 5979 - CPA19 ESMP Ver - June 2019Kenneth JapsonNo ratings yet

- CCF06092022Document9 pagesCCF06092022Kenneth JapsonNo ratings yet

- 1 PBDocument13 pages1 PBKenneth JapsonNo ratings yet

- 2022 Revised LETTER CONVENTION INVITATION and CONFIRMATION SLIPDocument2 pages2022 Revised LETTER CONVENTION INVITATION and CONFIRMATION SLIPKenneth JapsonNo ratings yet

- InstReq PlasmaQuant 9100 enDocument10 pagesInstReq PlasmaQuant 9100 enKenneth JapsonNo ratings yet

- Quality Manual. Quality Manual. Institute For Standardization and Control of Pharmaceuticals. SOP No. QM-01 - 02Document34 pagesQuality Manual. Quality Manual. Institute For Standardization and Control of Pharmaceuticals. SOP No. QM-01 - 02Kenneth Japson100% (1)

- Housekeeping & Waste Awareness Session 26.06.2021Document32 pagesHousekeeping & Waste Awareness Session 26.06.2021worlds funNo ratings yet

- Pub1664 Web-1Document706 pagesPub1664 Web-1Omar SuarezNo ratings yet

- Specifications - RSDPDocument58 pagesSpecifications - RSDPRamesh P KoiralaNo ratings yet

- HE BPP Module.8 Gr7-8Document23 pagesHE BPP Module.8 Gr7-8Julie Ann Carsula Cister IIINo ratings yet

- Pollution (Water, Land, Air)Document7 pagesPollution (Water, Land, Air)DASE GamingNo ratings yet

- Hazardous Waste ManagementDocument3 pagesHazardous Waste ManagementPravin KumarNo ratings yet

- 20yearsCRPM - Conference ConceptDocument6 pages20yearsCRPM - Conference ConceptZhidas DaskalovskiNo ratings yet

- 23478Document259 pages23478Dedy HermadyNo ratings yet

- Product Catalogue EN PDFDocument190 pagesProduct Catalogue EN PDFKhai Quang TranNo ratings yet

- LEED v4.1 Cities and Communities Plan and Design GuideDocument107 pagesLEED v4.1 Cities and Communities Plan and Design GuideAshutoshNo ratings yet

- GCC Waste To Energy TenderDocument662 pagesGCC Waste To Energy Tenderkarthikraja21No ratings yet

- Evaluation of Municipal Solid Waste Management in B/DAR CityDocument56 pagesEvaluation of Municipal Solid Waste Management in B/DAR Citytazebew txNo ratings yet

- Recyclability of Folding Cartons November 2020 Short ReportDocument14 pagesRecyclability of Folding Cartons November 2020 Short ReportmorchedNo ratings yet

- Growth Performance of Pechay (Brassica Rapa) in Household Derived CompostsDocument14 pagesGrowth Performance of Pechay (Brassica Rapa) in Household Derived CompostsMarc CastilloNo ratings yet

- Soild Waste Management Q and ADocument19 pagesSoild Waste Management Q and AHamed FaragNo ratings yet

- Material Safety Data Sheet MCDocument11 pagesMaterial Safety Data Sheet MCikhsan centralacNo ratings yet

- MSDS Jotun Jotamastic 80 STD Comp BDocument11 pagesMSDS Jotun Jotamastic 80 STD Comp BBùi Văn HợpNo ratings yet

- Bio PlasticDocument6 pagesBio PlasticMaliha JahanNo ratings yet

- Samsung SCX 4200 ManualDocument93 pagesSamsung SCX 4200 ManualAngela ScribnerNo ratings yet

- Waste Management: by Chandravati Koki Professor Kims ConDocument32 pagesWaste Management: by Chandravati Koki Professor Kims ConSagiraju SrinuNo ratings yet

- Database - Private Water Supply - Sewerage & Solid Waste Management Projects - Manthan Adhyayan Kendra - 2010Document189 pagesDatabase - Private Water Supply - Sewerage & Solid Waste Management Projects - Manthan Adhyayan Kendra - 2010Vishal SalveNo ratings yet

- Lecture Notes On Environmental Laws and Protection With Introduction To Cyber CrimeDocument54 pagesLecture Notes On Environmental Laws and Protection With Introduction To Cyber CrimeAngelie Regie EstorqueNo ratings yet

- BPG - A3Water Management For Hydrometallurgical Process PlantsDocument34 pagesBPG - A3Water Management For Hydrometallurgical Process PlantsLouisAucampNo ratings yet

- From A Pollution To A Solution Final NaDocument14 pagesFrom A Pollution To A Solution Final NaKezia LeehNo ratings yet

- Deta MSDSDocument10 pagesDeta MSDSDarin WilsonNo ratings yet

- Yamaha Motors CSR ReportDocument24 pagesYamaha Motors CSR ReportSameer JainNo ratings yet

- Solid Waste Management: CIE 442 Environmental Engineering Lecture Two Lecturer: Eng. Goodson MashekaDocument45 pagesSolid Waste Management: CIE 442 Environmental Engineering Lecture Two Lecturer: Eng. Goodson MashekaAnthony MulengaNo ratings yet

- Draft (SOP) For Characterisation and Assessment of Plastic Waste GenerationDocument216 pagesDraft (SOP) For Characterisation and Assessment of Plastic Waste Generationna.bhatti1981No ratings yet