Professional Documents

Culture Documents

Alpha Automotive Co

Alpha Automotive Co

Uploaded by

Himanshu Sharma0 ratings0% found this document useful (0 votes)

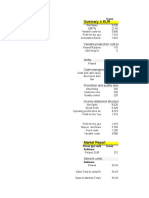

31 views2 pagesThe document compares two options for meeting an annual demand of 3200 units: purchasing from a supplier or producing in-house. For the purchasing option, it provides details to calculate the economic order quantity (EOQ), number of orders per year, cycle time, average and safety stock levels, reorder point, and total annual cost. For the in-house production option, it similarly provides details to calculate the economic production quantity (EPQ), number of production runs per year, cycle time, stock levels, and total annual cost. Both options are evaluated and compared to determine the best approach.

Original Description:

Alpha Automotive Co

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document compares two options for meeting an annual demand of 3200 units: purchasing from a supplier or producing in-house. For the purchasing option, it provides details to calculate the economic order quantity (EOQ), number of orders per year, cycle time, average and safety stock levels, reorder point, and total annual cost. For the in-house production option, it similarly provides details to calculate the economic production quantity (EPQ), number of production runs per year, cycle time, stock levels, and total annual cost. Both options are evaluated and compared to determine the best approach.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

31 views2 pagesAlpha Automotive Co

Alpha Automotive Co

Uploaded by

Himanshu SharmaThe document compares two options for meeting an annual demand of 3200 units: purchasing from a supplier or producing in-house. For the purchasing option, it provides details to calculate the economic order quantity (EOQ), number of orders per year, cycle time, average and safety stock levels, reorder point, and total annual cost. For the in-house production option, it similarly provides details to calculate the economic production quantity (EPQ), number of production runs per year, cycle time, stock levels, and total annual cost. Both options are evaluated and compared to determine the best approach.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 2

Option 1: Purchase from supplier

Inventory carrying cost

Annual demand 3200 Cost of capital

Days of operation/year (days) 250 Investment in Inventory

Tax+Insurance on Inv

Inventory shrinkage

Warehouse overhead

Additional cost incurred in inventory maintenance

Additional cost in % of Inventory investment

Total cost of Inventory in % item cost per year

Unit purchase cost

Inventory carrying cost per unit per year

EOQ 348.1553

No of orders per year 9.1913 Max Inventory

Cycle time in days 27.19963 Min Inventory

Avg demand during LT 64 Average Inventory

SD of demand during LT 10 Annual holding cost

Stockout% 0.108799 Annual ordering cost

Service level 0.891201 Annual purchase cost

Z 1.232943 Total annual cost

Safety stock 12.32943

Reorder point 76.32943

Option 2: Produce Inhouse

Annual demand 3200 Inventory carrying cost

Prod. Rate/month 1000 Production cost/unit

No of working days/month 20.83333 % Annual Inv carrying cost/unit

Prod. Rate/day (p) 48 Inventory carrying cost per unit per year

Demand/day (d) 12.8

EPQ 966.1253 Max Inventory

No. of prod. Runs 3.3122 Min Inventory

Cycle time in days 75.47854 Avg Inventory

Avg demand during LT 128 Annual Inventory carrying cost

SD of demand during LT 20 Annual setup cost

Stockout% 0.301914 Annual production cost

Service level 0.698086 Total annual cost

Z 0.518903

Safety stock 10.37806

Reorder point 138.3781

Ordering cost

14% Hours required to process one order 2

600,000 Salaries per hour 28

24,000 Employees cost for one order 56

9000 Stationery expenses per order 19

15000 Total ordering cost per order 75

48,000

0.08

22%

18

3.96

360.4847

12.32943

186.4071

738.1721

689.3475

57600

59027.52

Setup cost

17 Time needed for one setup (hour) 8

22% Cost of labour and lost prod time/hr 50

3.74 Setup cost per setup 400

718.87

10.37806

364.624

1363.694

1324.88

54400

57088.57

You might also like

- Bergerac Systems: The Challenge of Backward IntegrationDocument5 pagesBergerac Systems: The Challenge of Backward IntegrationSanthosh Selvam100% (2)

- Case Analysis: Wilkins, A Zurn Company: Aggregate Production PlanningDocument3 pagesCase Analysis: Wilkins, A Zurn Company: Aggregate Production PlanningSiddhant Singh100% (3)

- Renewbuy PDFDocument5 pagesRenewbuy PDFmilon1998100% (1)

- Bangladesh Bank Circular - FinalDocument2 pagesBangladesh Bank Circular - Finalmaka007No ratings yet

- Konys, Inc., Spreadsheet Supplement Harvard Business School Case N9-613-065 Courseware 9-613-703Document18 pagesKonys, Inc., Spreadsheet Supplement Harvard Business School Case N9-613-065 Courseware 9-613-703RohanMohapatraNo ratings yet

- Bergerac System Case Analysis-Group 1Document11 pagesBergerac System Case Analysis-Group 1Karan Trivedi100% (1)

- Prof. V.K. Unni Indian Institute of Management Calcutta E-Mail: Unniv@iimcal - Ac.inDocument74 pagesProf. V.K. Unni Indian Institute of Management Calcutta E-Mail: Unniv@iimcal - Ac.inSakshi VermaNo ratings yet

- IR1 CashcashEquivDocument4 pagesIR1 CashcashEquivMadielyn Santarin MirandaNo ratings yet

- KraljicDocument17 pagesKraljictrivindi100% (2)

- 11.bergerac SystemsDocument12 pages11.bergerac SystemsAviralNo ratings yet

- Bergerac XLS ENGDocument12 pagesBergerac XLS ENGTelmo Barros0% (1)

- Inventory OptimizationDocument5 pagesInventory OptimizationJai DeepNo ratings yet

- Aurora TextileDocument17 pagesAurora Textilexinz1313100% (1)

- Activity Based Costing - APO 9Document13 pagesActivity Based Costing - APO 9manan guptaNo ratings yet

- Tutorial 3 - SolutionsDocument11 pagesTutorial 3 - SolutionsLijing CheNo ratings yet

- Baldwin Bicycle CompanyDocument7 pagesBaldwin Bicycle CompanyIndustry ReportNo ratings yet

- Capacity Management: Capacity Has A Cost, Whether It Is Used or NotDocument18 pagesCapacity Management: Capacity Has A Cost, Whether It Is Used or NotSubodh RanjanNo ratings yet

- Denison Mines PPT Vamshi-1Document10 pagesDenison Mines PPT Vamshi-1Thinkers ProNo ratings yet

- 102.COA PL I Solution CMA Special Examination 2021novemberDocument7 pages102.COA PL I Solution CMA Special Examination 2021novemberSky WalkerNo ratings yet

- EOQ Problem SolvingDocument4 pagesEOQ Problem Solvingmishal zikria100% (1)

- Phiếu Giao Bài Tập Số 3Document3 pagesPhiếu Giao Bài Tập Số 3Phạm Thị Thúy HằngNo ratings yet

- 11@ Costestimation Original at RevisedDocument15 pages11@ Costestimation Original at RevisedRajesh KtrNo ratings yet

- Acc116 G7Document6 pagesAcc116 G7ABDUL HAFIZ ABDULLAHNo ratings yet

- Coa B1Document39 pagesCoa B1imamulNo ratings yet

- HAslam - SolutionDocument12 pagesHAslam - SolutionSANA SAEEDNo ratings yet

- Pem M C07: Project Materials ManagementDocument276 pagesPem M C07: Project Materials ManagementKingSantoshNo ratings yet

- Activity 2 - Inventory ManagementDocument2 pagesActivity 2 - Inventory ManagementfayesandigNo ratings yet

- Cost SheetDocument20 pagesCost SheetKeshviNo ratings yet

- Midterm Question Strategic Management Accounting (11th Batch)Document5 pagesMidterm Question Strategic Management Accounting (11th Batch)Samir Raihan ChowdhuryNo ratings yet

- BookDocument7 pagesBookPrince Alexis GarciaNo ratings yet

- Cash 5,000 Accounts Receivable 1,500 Raw Materials Inventory 258 Finished Goods Inventory 1,462Document17 pagesCash 5,000 Accounts Receivable 1,500 Raw Materials Inventory 258 Finished Goods Inventory 1,462Lan Tran HoangNo ratings yet

- ACC416Document20 pagesACC416Anonymous N0mQBENo ratings yet

- Cost and Management Accounting 01 - Class NotesDocument114 pagesCost and Management Accounting 01 - Class NotessaurabhNo ratings yet

- Additional Exercises For Mid Term Test 1Document42 pagesAdditional Exercises For Mid Term Test 1Nguyen Hoang Tram AnhNo ratings yet

- ETIT Assignment (Mohit Kumar, Vidit Sharma)Document12 pagesETIT Assignment (Mohit Kumar, Vidit Sharma)Sarthak SharmaNo ratings yet

- Tanushreemini Project MB619Document12 pagesTanushreemini Project MB619tanushree singhNo ratings yet

- Costing 2 Material - 014417Document40 pagesCosting 2 Material - 014417sirjamtech36No ratings yet

- 2.2 PM - Activity Based Costing - 250622Document26 pages2.2 PM - Activity Based Costing - 250622abhijit tikekarNo ratings yet

- Summary, K EUR: Variable Production Cost Per Unit, EURDocument15 pagesSummary, K EUR: Variable Production Cost Per Unit, EURSiddharth Singh TomarNo ratings yet

- Combined Past Paper A2.2 PDFDocument123 pagesCombined Past Paper A2.2 PDFSinamenyeNo ratings yet

- Past Papers AllDocument223 pagesPast Papers AllHAGENIMANA JEAN CLAUDENo ratings yet

- Chapters 1 To 3 (Answers)Document8 pagesChapters 1 To 3 (Answers)Cho AndreaNo ratings yet

- Inventory ManagementDocument23 pagesInventory ManagementAiron Keith Along67% (3)

- Invtry MGMT by Suhas RaneDocument51 pagesInvtry MGMT by Suhas RanePruthviNo ratings yet

- Break Even Analysis in ExcelDocument21 pagesBreak Even Analysis in ExcelMarwan SaidNo ratings yet

- Quantitative Models For The Planning andDocument6 pagesQuantitative Models For The Planning andAngela Miles DizonNo ratings yet

- Overheads - IBADocument6 pagesOverheads - IBAZehra HussainNo ratings yet

- Activity Based CostingDocument17 pagesActivity Based CostingArpit GargNo ratings yet

- Acct602 Managerial AccountingDocument8 pagesAcct602 Managerial AccountingHaroon KhurshidNo ratings yet

- Economic Order Quantity (EOQ) Answer SampleDocument2 pagesEconomic Order Quantity (EOQ) Answer SampleAditya JandialNo ratings yet

- Presented by Bhavishya Gupta Section "A" ROLL No.-M08032Document12 pagesPresented by Bhavishya Gupta Section "A" ROLL No.-M08032Deepakgupta0001No ratings yet

- Costing Concepts (Cost Accounting) Workbook - Zaheer-SwatiDocument6 pagesCosting Concepts (Cost Accounting) Workbook - Zaheer-SwatiAhmedNo ratings yet

- Chapter9 WCInventoryARAPDocument33 pagesChapter9 WCInventoryARAPrbaambaNo ratings yet

- Title01 - Job Costing and Batch CostingDocument72 pagesTitle01 - Job Costing and Batch CostingPoonamNo ratings yet

- Costing Past Exams and RTP Questions CompilerDocument305 pagesCosting Past Exams and RTP Questions Compilergaxovi4187No ratings yet

- PIA - Contabilidad AdministraivaDocument24 pagesPIA - Contabilidad AdministraivaleslieNo ratings yet

- PIA Contabilidad AdministraivaDocument20 pagesPIA Contabilidad AdministraivaleslieNo ratings yet

- Assignment1 10%Document3 pagesAssignment1 10%Felicia ChinNo ratings yet

- Assignment Managerial FinanceDocument6 pagesAssignment Managerial Financegagansingla328No ratings yet

- Group 2: Wilkins, A Zurn Company: Aggregate Production PlanningDocument10 pagesGroup 2: Wilkins, A Zurn Company: Aggregate Production PlanningSiddhant SinghNo ratings yet

- Total Annual Overhead CostsDocument3 pagesTotal Annual Overhead CostsJEYASHREE ESTEBANNo ratings yet

- Man TparDocument10 pagesMan TparFrederick GbliNo ratings yet

- Revision Notes & Question May 2024 - CA Aman AgarwalDocument159 pagesRevision Notes & Question May 2024 - CA Aman Agarwalmayankpantgg.14No ratings yet

- FM Chapter 17Document9 pagesFM Chapter 17Nguyễn Hoàng Anh ThưNo ratings yet

- Arnold Palmer HospitalDocument2 pagesArnold Palmer HospitalHimanshu SharmaNo ratings yet

- Process Stragey at Wheeled CoachDocument1 pageProcess Stragey at Wheeled CoachHimanshu SharmaNo ratings yet

- Exercises On Inventory ManagementDocument3 pagesExercises On Inventory ManagementHimanshu SharmaNo ratings yet

- Exercises On Line BalancingDocument3 pagesExercises On Line BalancingHimanshu SharmaNo ratings yet

- Class Schedule - AccutDocument2 pagesClass Schedule - AccutZhenhua RuiNo ratings yet

- Applied Research Methods: Dr. Sahar AwanDocument20 pagesApplied Research Methods: Dr. Sahar AwanNajia SiddiquiNo ratings yet

- Campaign Quotation 3Document1 pageCampaign Quotation 3Kelvin ChumaNo ratings yet

- MGA3033 Course Outline OBE 1092013Document9 pagesMGA3033 Course Outline OBE 1092013Nur FahanaNo ratings yet

- GSTR-1 07AUYPS5769G2ZJ March 2018-19Document41 pagesGSTR-1 07AUYPS5769G2ZJ March 2018-19Sachin SharmaNo ratings yet

- Internship Report On Bank AlfalahDocument33 pagesInternship Report On Bank AlfalahUmar Din WazirNo ratings yet

- VP Finance Controller CFO in Cincinnati OH Resume Jerome StanislawDocument2 pagesVP Finance Controller CFO in Cincinnati OH Resume Jerome StanislawJeromeStanislawNo ratings yet

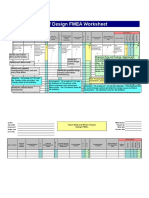

- Example of Design FMEA WorksheetDocument5 pagesExample of Design FMEA Worksheetரஞ்சன் ஞானயோளிNo ratings yet

- Invoice OD110947400306001000Document1 pageInvoice OD110947400306001000Vivek BajajNo ratings yet

- Investment - Code - La UnionDocument9 pagesInvestment - Code - La UnionAlbino T AbellaNo ratings yet

- Chapter 2 HomeworkDocument2 pagesChapter 2 Homeworkkabi7725No ratings yet

- The Monopolistic and Restrictive Trade Practices Act HandoutDocument7 pagesThe Monopolistic and Restrictive Trade Practices Act HandoutSyed AsadNo ratings yet

- Lauranne Shipping 03Document2 pagesLauranne Shipping 03Laurentiu Matei100% (1)

- Document Checklist For USA - KIECDocument5 pagesDocument Checklist For USA - KIECNirav ThakkarNo ratings yet

- BIM Data Quality Control Report: The Great Lakes Region 5 Standard ForDocument3 pagesBIM Data Quality Control Report: The Great Lakes Region 5 Standard ForAR-Jay ARNo ratings yet

- Modern Architecture Magazine TemplateDocument12 pagesModern Architecture Magazine TemplateBreanna CIel E. CabahitNo ratings yet

- Project Assistant Job DescriptionDocument7 pagesProject Assistant Job DescriptionProjectmanagement101No ratings yet

- SAD Problems For AssignmentDocument2 pagesSAD Problems For AssignmentPhạmHoàngĐạiNo ratings yet

- Presentation On Key Performance Indicators (KPI) and CAMEL Analysis of andDocument44 pagesPresentation On Key Performance Indicators (KPI) and CAMEL Analysis of andPravin MehtaNo ratings yet

- Oracle® Fusion Middleware Installing and Configuring Oracle Data IntegratorDocument110 pagesOracle® Fusion Middleware Installing and Configuring Oracle Data Integratortranhieu5959No ratings yet

- CH 6Document51 pagesCH 6Ella ApeloNo ratings yet

- Rais 13 SMCH 03Document51 pagesRais 13 SMCH 03Endah FitriaNo ratings yet

- Breakeven and Leverage AnalysisDocument17 pagesBreakeven and Leverage AnalysisSohan KhatriNo ratings yet

- IBPS Specialist Officer Recruitment Notification 2016Document8 pagesIBPS Specialist Officer Recruitment Notification 2016TushitaNo ratings yet

- Consumer Behaviour Towards Chocolates 1Document52 pagesConsumer Behaviour Towards Chocolates 1Ashu SinghNo ratings yet