Professional Documents

Culture Documents

Cookware Isn

Cookware Isn

Uploaded by

kedir yimerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cookware Isn

Cookware Isn

Uploaded by

kedir yimerCopyright:

Available Formats

Ethiopian Technical University

Faculty of Mechanical Technology,

Department of Manufacturing Technology

Course Title: Production Planning and

Control (MAT 615)

Individual Assignment for Manufacturing Technology MSc

Class of 2020/21 G.C

2nd Year Students –Section – I

ASSIGNMENT: One and Two

SUBMITTED BY:

No Name ID No

1 Kedir Yimer Ebrie MTR/615/13

SUBMITTED TO: Dr. Sujit Singh (PhD)

Jan 20, 2022

Advanced Forming Technology (MAT617)

Addis Ababa Ethiopia

Manufacturing Technology Dep’t Page 2

Advanced Forming Technology (MAT617)

INTRODUCTION

Cookwares and bakewares are food preparation equipment, such as cooking pots, pans,

baking sheets etc. used in kitchens. Cookware is used on a stove or range cooktop, while

bakeware is used in an oven. Some utensils are considered both cookware and bakeware.

There is a great variety of cookware and bakeware in shape, material, and inside surface.

Some materials conduct heat well; some retain heat well. Some surfaces are non-stick; some

require seasoning. Some pots and their lids have handles or knobs made of low thermal

conductance materials such as bakelite, plastic or wood, which make them easy to pick up

without oven gloves.

A good cooking pot design has an "overcook edge" which is what the lid lies on. The lid has

a dripping edge that prevents condensation fluid from dripping off when handling the lid

(taking it off and holding it 45°) or putting it down.

Producing of a cookingdish isn’t something typically build simply; it needs a well-equipped

metal shop to do the job and do it right. [Torbjörn Åhman] has just that, however, and set

about forging a stout-looking skillet from scratch.

The build starts with a round disc of steel serving as a blank for the project. The blank is spun

up and the outer perimeter ground down thinner with an angle grinder in what looks like a

moderately sketchy operation. A forge is then used to heat the blank so that it can be shaped

into a pan using a hammer. Slowly, as the metal is beaten one way and then to other, the

skillet begins to form. A belt sander takes off high points on the outside, and a torch is then

used to square up the base of the pan so it sits nicely. Finally a handle attached with some

stout rivets, and the newly formed piece of cookware gets a seasoning with sunflower oil.

The project shows just how many special skills are required to make even a simple cooking

dish by hand.

Manufacturing Technology Dep’t Page 3

Advanced Forming Technology (MAT617)

Various commercial baking pans

Types of Cookware materials

The size and shape of a cooking vessel is typically determined by how it will be used.

Intention, application, technique and configuration also have a bearing on whether a cooking

vessel is referred to as a pot or a pan. Generally within the classic batterie de cuisine a vessel

designated "pot" is round, has "ear" handles in diagonal opposition, with a relatively high

height to cooking surface ratio, and is intended for liquid cooking such as stewing, stocking,

brewing or boiling. Vessels with a long handle or ear handles, a relatively low height to

cooking surface ratio, used for frying, searing, reductions, braising and oven work take the

designation "pan". Additionally, while pots are round, pans may be round, oval, squared, or

irregularly shaped.

Metal

Metal pots are made from a narrow range of metals because pots and pans need to conduct

heat well, but also need to be chemically unreactive so that they do not alter the flavor of the

food. Most materials that are conductive enough to heat evenly are too reactive to use in food

preparation. In some cases (copper pots, for example), a pot may be made out of a more

reactive metal, and then tinned or clad with another.

Stainless steel

Fig: 7, Stainless steel

Stainless steel is an iron alloy containing a minimum of 11.5% chromium. Blends containing

18% chromium with either 8% nickel, called 18/8, or with 10% nickel, called 18/10, are

Manufacturing Technology Dep’t Page 4

Advanced Forming Technology (MAT617)

commonly used for kitchen cookware. Stainless steel's virtues are resistance to corrosion,

non-reactivity with either alkaline or acidic foods, and resistance to scratching and denting.

Stainless steel's drawbacks for cooking use are that it is a relatively poor heat conductor and

its non-magnetic property, although recent developments have allowed the production of

magnetic 18/10 alloys, which thereby provides compatibility with induction cooktops, which

require magnetic cookware.[citation needed]

Since the material does not adequately spread the heat itself, stainless steel cookware is

generally made as a cladding of stainless steel on both sides of an aluminum or copper core to

conduct the heat across all sides, thereby reducing "hot spots", or with a disk of copper or

aluminum on just the base to conduct the heat across the base, with possible "hot spots" at the

sides. In so-called "tri-ply" cookware, the central aluminum layer is obviously non-magnetic,

and the interior 18/10 layer need not be magnetic, but the exterior layer at the base must be

magnetic to be compatible with induction cooktops. Stainless steel does not require seasoning

to protect the surface from rust, but may be seasoned to provide a non-stick surface.

Carbon steel

Fig: 8, Carbon steel

Carbon-steel cookware can be rolled or hammered into relatively thin sheets of dense

material, which provides robust strength and improved heat distribution. Carbon steel

accommodates high, dry heat for such operations as dry searing. Carbon steel does not

conduct heat efficiently, but this may be an advantage for larger vessels, such as woks and

paella pans, where one portion of the pan is intentionally kept at a different temperature than

the rest. Like cast iron, carbon steel must be seasoned before use, usually by rubbing a fat or

oil on the cooking surface and heating the cookware on the stovetop or in the oven. With

proper use and care, seasoning oils polymerize on carbon steel to form a low track surface,

well-suited to browning, maillard reactions and easy release of fried foods. Carbon steel will

Manufacturing Technology Dep’t Page 5

Advanced Forming Technology (MAT617)

easily rust if not seasoned and should be stored seasoned to avoid rusting. Carbon steel is

traditionally used for crêpe and fry pans, as well as woks.

Clad aluminium or copper

Cladding is a technique for fabricating pans with a layer of efficient heat conducting material,

such as copper or aluminum, covered on the cooking surface by a non-reactive material such

as stainless steel, and often covered on the exterior aspect of the pan ("dual-clad") as well.

Some pans feature a copper or aluminum interface layer that extends over the entire pan

rather than just a heat-distributing disk on the base. Generally, the thicker the interface layer,

especially in the base of the pan, the more improved the heat distribution. Claims of thermal

efficiency improvements are, however, controversial, owing in particular to the limiting and

heat-banking effect of stainless steel on thermal flows.

Aluminum is typically clad on both the inside and the exterior pan surfaces, providing both a

stainless cooking surface and a stainless surface to contact the cooktop. Copper of various

thicknesses is often clad on its interior surface only, leaving the more attractive copper

exposed on the outside of the pan (see Copper above).

Some cookware use a dual-clad process, with a thin stainless layer on the cooking surface, a

thick core of aluminum to provide structure and improved heat diffusion, and a foil layer of

copper on the exterior to provide the "look" of a copper pot at a lower price.[16]

Coatings

Enamel

Enameled cast iron cooking vessels are made of cast iron covered with a porcelain surface.

This creates a piece that has the heat distribution and retention properties of cast iron

combined with a non-reactive, low-stick surface.

The enamel over steel technique creates a piece that has the heat distribution of carbon steel

and a non-reactive, low-stick surface. Such pots are much lighter than most other pots of

similar size, are cheaper to make than stainless steel pots, and do not have the rust and

reactivity issues of cast iron or carbon steel.[citation needed] Enamel over steel is ideal for large

stockpots and for other large pans used mostly for water-based cooking. Because of its light

weight and easy cleanup, enamel over steel is also popular for cookware used while camping.

Seasoning

Manufacturing Technology Dep’t Page 6

Advanced Forming Technology (MAT617)

Fig: 9. Cast-iron skillets, before seasoning (left) and after several years of use (right)

Fig: Commercial waffle iron requiring seasoning

Seasoning is the process of treating the surface of a cooking vessel with a dry, hard, smooth,

hydrophobic coating formed from polymerized fat or oil. When seasoned surfaces are used

for cookery in conjunction with oil or fat a stick-resistant effect is produced.

Some form of post-manufacturing treatment or end-user seasoning is mandatory on cast-iron

cookware, which rusts rapidly when heated in the presence of available oxygen, notably from

water, even small quantities such as drippings from dry meat. Food tends to stick to

unseasoned iron and carbon steel cookware, both of which are seasoned for this reason as

well.

Other cookware surfaces such as stainless steel or cast aluminium do not require as much

protection from corrosion but seasoning is still very often employed by professional chefs to

avoid sticking.

Seasoning of other cookware surfaces is generally discouraged. Non-stick enamels often

crack under heat stress, and non-stick polymers (such as Teflon) degrade at high heat so

neither type of surface should be seasoned.

The raw materials for cookware

Over the ages, humankind has used many different materials for cookware. Each

material has different requirements and properties. Apart from clay vessels, copper kettles or

uncoated aluminium cookware, above all cast steel pots and pans have been used in more

recent human history. Ever higher requirements relating to cooking and cleaning triggered the

Manufacturing Technology Dep’t Page 7

Advanced Forming Technology (MAT617)

development of stainless steel, aluminium and cast aluminium cookware as well as non-stick

coatings. Today, BERNDES focuses on cookware made of stainless steel, aluminium and

cast aluminium.

Stainless steel

The starting point for stainless steel products is a stainless steel blank (flat disc). This is

greased, placed in a hydraulic drawing press and shaped over a so-called deep-drawing die.

Next, the edge of the raw body is punched so that the finished cookware has a clean pouring

edge. For better heat conduction, stainless steel bodies are fitted with a capsule base.

Aluminium is integrated in the capsule base to optimise the absorption and transfer of heat.

Aluminium

A circular aluminium disc (blank) is used for the pan or frying pan. BERNDES uses

discs between 3 and 5 mm thick. We use two different production methods and exclusively

process aluminium alloys approved for contact with food.

Deep-drawing

Similar to stainless steel processing, the aluminium blank is greased and placed into a

hydraulic drawing press where it is shaped over a deep-drawing die. Depending on the

product size and blank thickness, a weight of up to 200 tons is applied for this forming

process. The advantage of deep-drawn parts is an even thickness of base and walls. This

ensures good heat conductivity.

Manufacturing Technology Dep’t Page 8

Advanced Forming Technology (MAT617)

Forging

Each pan starts its journey as a flat, circular steel disc. The disc is pressed between a larger

outer ring and a smaller inner die. This process raises the side walls and gives the steel a

basic and rough pan shape.

Following the press, the blank is placed in the forge and heated to a glowing red. Blacksmiths

continue to shape the sidewalls with precise and rhythmic blows on the anvil.

When the side walls are of even height and pitch the pan returns to the press where the base is

flattened under fifteen tons of pressure. Fine adjustments are made with a lever and hammer

blows.

Manufacturing Technology Dep’t Page 9

Advanced Forming Technology (MAT617)

Manufacturing Technology Dep’t Page 10

Advanced Forming Technology (MAT617)

Fig: Forging process of cooking dish

Assembly

Once the pan base has cooled, it is passed along to clean-up and assembly. The sharp edges

of each pan are taken down with grinders and smoothed to an even radius.

Handles are shaped on the anvil and hammered to match the curvature of the pan's sidewall.

Holes are drilled and the handles are riveted in place.

Manufacturing Technology Dep’t Page 11

Advanced Forming Technology (MAT617)

Fig: Assembling Process of the cooking dish

Clean Up & Seasoning

After the pan is fully assembled, it is placed in the sand blasting cabinet. Aluminum-oxide

combined with high-pressure air blasts the surface of the metal removing mill scale and

surface imperfections. A wire-brush then polishes the surface, restoring the surface to an even

and smooth finish. At this stage the steel is very reactive to moisture and oxygen. Left in this

state the steel will begin to rust. To create a protective barrier the pans are placed in a kiln

and baked at high temps for forty minutes.

Manufacturing Technology Dep’t Page 12

Advanced Forming Technology (MAT617)

Under this high temperature, the steel reacts and builds a layer of iron-oxide on its surface.

This reaction produces the familiar blue-ish black tones of the final product. While the pans

are still hot, coconut oil is applied and allowed to pull into the pores of the metal as it cools.

Fig: Cleaning up and seasoning of cooking dish

Manufacturing Technology Dep’t Page 13

Advanced Forming Technology (MAT617)

COOKWARE TO AVOID

TEFLON

PFOA (Perfluorooctanoic acid) is the compound that is used to manufacture non-stick

coatings. It is linked to thyroid damage and is a likely human carcinogen. PFOA’s build up in

your body and are difficult to eliminate once they are absorbed.

High-temperature cooking with Teflon cookware can induce a “Teflon flu” in which

you experience flu-like symptoms several hours after inhaling toxic Teflon fumes – yuck.

ALUMINUM

There are 2 types of aluminum cookware: non-anodized aluminum and anodized

aluminum. Anodized aluminum has been sealed with a coating to make it denser, harder,

non-reactive and non-stick. Most cookware today is made of anodized aluminum. The

problem with the newer anodized pots and pans, is that they have a non-stick coating applied

to them, which has it’s own health dangers.

Old aluminum pots and pans are often made of non-anodized aluminum. These can

leach aluminum particles into the food. They react with acidic foods that are cooked in them

and give them an unpleasant taste. Non-anodized aluminum pots are usually heavy, with an

appearance of having been pressed from a single piece of thick metal. The inside and outside

are the same color.

Hard anodized aluminum is said to be a safe cookware, and it can be, if it is not

scratched at all. Once it has become scratched, it can leak aluminum into your food. Also, if a

non-stick coating is applied, you will be exposed to those chemicals as well. We all know

how easy it is to accidentally scratch a pot or pan, so why even bother investing in aluminum

cookware then?

COPPER

Copper responds to heat very quickly. It heats well and evenly, then loses heat rapidly

when the temperature is turned down. It is more reactive than cast-iron or aluminum and is

often sold “tinned”, or mixed with another metal such as stainless steel to prevent copper

Manufacturing Technology Dep’t Page 14

Advanced Forming Technology (MAT617)

leaching into food. Large amounts of copper ingestion can cause nausea, vomiting, and

diarrhea.

Coatings on copper cookware can break down over time, exposing the copper to food.

Old copper cookware often has tin or nickel coatings and should not be used for cooking.

Copper is often used as a base to help stainless steel cookware conduct heat better, and

as long as the copper is not coming in contact with the food, it is safe.

Manufacturing Technology Dep’t Page 15

You might also like

- Business Plan Example Ammo ManufacturerDocument78 pagesBusiness Plan Example Ammo ManufacturerChris Leidlein60% (5)

- New Larousse Encyclopedia of MythologyDocument479 pagesNew Larousse Encyclopedia of MythologyCat Net99% (73)

- Group 8Document24 pagesGroup 8Derek Tate0% (1)

- Metal PackagingDocument34 pagesMetal PackagingAmyHuiNo ratings yet

- White and Blue Paper SteelDocument1 pageWhite and Blue Paper SteelCristian BujorNo ratings yet

- Heat Treating The Kitchen SinkDocument1 pageHeat Treating The Kitchen Sinkmp87_ingNo ratings yet

- Tayobong MSE 123 Final Output Instructions Due June 7Document2 pagesTayobong MSE 123 Final Output Instructions Due June 7Utak Ma3No ratings yet

- Agglomerating ProcessesDocument32 pagesAgglomerating Processesbuenaventura.jojieNo ratings yet

- Entrepreneurial Skill Development: A Case Study of The Design and Construction of Charcoal Baking OvenDocument4 pagesEntrepreneurial Skill Development: A Case Study of The Design and Construction of Charcoal Baking OvenInnovative Research PublicationsNo ratings yet

- A Simplified Guide To Heat Treating Tool SteelsDocument3 pagesA Simplified Guide To Heat Treating Tool SteelsАнна КокоеваNo ratings yet

- Induction CookingDocument9 pagesInduction Cookingtechzones100% (1)

- Bi/Multiply-Metal: Click To Edit Master Subtitle Style How Relevant Is To IndiaDocument59 pagesBi/Multiply-Metal: Click To Edit Master Subtitle Style How Relevant Is To Indiakr_ananthNo ratings yet

- The Best Solution For Glass Ceramic Cooktop Panels: Frequently Asked QuestionsDocument20 pagesThe Best Solution For Glass Ceramic Cooktop Panels: Frequently Asked QuestionsSuci Mandasari 1611110571No ratings yet

- Ceramic EngineeringDocument8 pagesCeramic EngineeringahumairNo ratings yet

- A Guide To The Language of SteelDocument7 pagesA Guide To The Language of SteelIwona AnkaNo ratings yet

- Present Trend On Refractory Uses For Reheating Furnaces: G. D. SinghDocument6 pagesPresent Trend On Refractory Uses For Reheating Furnaces: G. D. SinghmmkattaNo ratings yet

- Processes, Uses, Properties, MethodsDocument93 pagesProcesses, Uses, Properties, MethodsMicho CalimaNo ratings yet

- Material Science and Engineering Heat TRDocument18 pagesMaterial Science and Engineering Heat TRSamit NagNo ratings yet

- Meet Your Metal v4Document17 pagesMeet Your Metal v4João ArthurNo ratings yet

- Furnace MaintenanceDocument3 pagesFurnace MaintenanceTravis WoodNo ratings yet

- Container - Steel Packaging - Tinplate Production Process - SMDI - Steel Market Development InstituteDocument2 pagesContainer - Steel Packaging - Tinplate Production Process - SMDI - Steel Market Development InstituteProf C.S.PurushothamanNo ratings yet

- Deepesh Heat TreatmentDocument26 pagesDeepesh Heat TreatmentVaidNo ratings yet

- Secondary Steel Making and Steel CastingDocument16 pagesSecondary Steel Making and Steel Castingritoce8668No ratings yet

- Chemistry Group 5 (Glass and Ceramics)Document18 pagesChemistry Group 5 (Glass and Ceramics)Muhammad FaizanNo ratings yet

- Casting MergedDocument218 pagesCasting Mergedsrujan baluNo ratings yet

- Melting and Casting: Dr.S.N.AlamDocument218 pagesMelting and Casting: Dr.S.N.Alamsrujan baluNo ratings yet

- Ceramic: From Wikipedia, The Free EncyclopediaDocument6 pagesCeramic: From Wikipedia, The Free EncyclopediabekkuNo ratings yet

- Stainless Steel 2008Document25 pagesStainless Steel 2008hawktripNo ratings yet

- Beverage ContainersDocument14 pagesBeverage Containersadilneu0% (1)

- Characteristics of St.37 Steel Materials With Temperature and Time On Heat Treatment Test Using FurnaceDocument5 pagesCharacteristics of St.37 Steel Materials With Temperature and Time On Heat Treatment Test Using FurnaceInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Food Packaging Technology Unit 2 Part CDocument20 pagesFood Packaging Technology Unit 2 Part CAkash DuttaNo ratings yet

- Alsheet: Hot-Dip Aluminum-Coated Steel SheetsDocument12 pagesAlsheet: Hot-Dip Aluminum-Coated Steel SheetshadiNo ratings yet

- All About CanningDocument12 pagesAll About CanningGayathri Fernando100% (1)

- Manufacturing of Glass 1Document21 pagesManufacturing of Glass 1MonishNo ratings yet

- MMEN 120 - Surface HardeningDocument19 pagesMMEN 120 - Surface HardeningnattydreadfathelahNo ratings yet

- Cost Reduction in Heat Treatment With Protective CoatingsDocument7 pagesCost Reduction in Heat Treatment With Protective CoatingsAnand KesarkarNo ratings yet

- Lecturas PNF Mecánica.Document4 pagesLecturas PNF Mecánica.thedios100No ratings yet

- Report Heat Treatment Eng Lab 3Document7 pagesReport Heat Treatment Eng Lab 3khalifawhan43% (7)

- Lesson - 11 Metal ContainersDocument21 pagesLesson - 11 Metal ContainersRishquez DCVNo ratings yet

- Assignment Metal FormingDocument10 pagesAssignment Metal FormingpuneetNo ratings yet

- Can I Use Galvanized Sheet Metal For Kitchen TabletopDocument2 pagesCan I Use Galvanized Sheet Metal For Kitchen TabletopmarketingNo ratings yet

- Steel Terms and DefinitionsDocument42 pagesSteel Terms and DefinitionsIwona AnkaNo ratings yet

- Project On Boiler, Metallurgy, Materials & Heat TreatmentDocument34 pagesProject On Boiler, Metallurgy, Materials & Heat Treatmentmohitamitabh20100% (3)

- Hardening Is Usually Done To: Heat Treatment of AlloysDocument8 pagesHardening Is Usually Done To: Heat Treatment of AlloysMadhavanIceNo ratings yet

- EMM2312 - Surface HardeningDocument19 pagesEMM2312 - Surface Hardeningjohnnjoro100No ratings yet

- Please Read: A Personal Appeal From Wikipedia Programmer Brandon HarrisDocument7 pagesPlease Read: A Personal Appeal From Wikipedia Programmer Brandon HarriskrishsinoriNo ratings yet

- Metal ContainersDocument50 pagesMetal Containerssalmanamjad995No ratings yet

- Keywords: Fuel Efficient, High Temperature, Simple Machine, Low Cost, Rocket Stove, EtcDocument1 pageKeywords: Fuel Efficient, High Temperature, Simple Machine, Low Cost, Rocket Stove, EtcWilliam J ThompsonNo ratings yet

- Light Weight Non-Metals To Replace Steel: A Term Paper OnDocument15 pagesLight Weight Non-Metals To Replace Steel: A Term Paper OnJatinderjot SinghNo ratings yet

- Crucible FurnacesDocument10 pagesCrucible FurnacesZara SaeedNo ratings yet

- Nickel Alloys For Sulfuric Acid ProductionDocument5 pagesNickel Alloys For Sulfuric Acid ProductionHeanjiaAlloysNo ratings yet

- Rice Cooker Lid (Forging Process)Document12 pagesRice Cooker Lid (Forging Process)AzfarFaizNo ratings yet

- Billets ProcessDocument5 pagesBillets ProcessWewey NuestroNo ratings yet

- BCMDocument9 pagesBCMSahar ZehraNo ratings yet

- Advantages and Disadvantages of Stainless Steel CookwareDocument15 pagesAdvantages and Disadvantages of Stainless Steel CookwareFaIz FauziNo ratings yet

- 304L WeldingDocument6 pages304L Weldingeedbdmdud100% (1)

- Foundry CruciblesDocument8 pagesFoundry Cruciblesagusdn21100% (2)

- Report On Jindal Steel WorksDocument13 pagesReport On Jindal Steel WorksAmit DubeyNo ratings yet

- Materials and Methods in Building Construction-Iv: Presented By: Puneet B Rani P Ratan R Ritika B Sachin CDocument25 pagesMaterials and Methods in Building Construction-Iv: Presented By: Puneet B Rani P Ratan R Ritika B Sachin CNidhi MehtaNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- LG-02 Machine Design - Direct StressDocument6 pagesLG-02 Machine Design - Direct Stresskedir yimerNo ratings yet

- LG-01 Machine Design - IntroDocument15 pagesLG-01 Machine Design - Introkedir yimerNo ratings yet

- Modern Door and Window PreparationDocument55 pagesModern Door and Window Preparationkedir yimerNo ratings yet

- Ethiopian Technical University: Technology Research Methodology (MAT-510)Document5 pagesEthiopian Technical University: Technology Research Methodology (MAT-510)kedir yimerNo ratings yet

- Government Polytechnic, Panchkula: Branch: Mechanical Engineering Subject: Machine Design Semester: 5ThDocument42 pagesGovernment Polytechnic, Panchkula: Branch: Mechanical Engineering Subject: Machine Design Semester: 5Thkedir yimerNo ratings yet

- Med Chem IV Sem Pre RuhsDocument1 pageMed Chem IV Sem Pre Ruhsabhay sharmaNo ratings yet

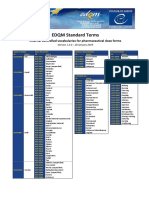

- Standard Terms Internal Vocabularies For Pharmaceutical Dose FormsDocument7 pagesStandard Terms Internal Vocabularies For Pharmaceutical Dose FormsJose De La Cruz De La ONo ratings yet

- Knowledge L3/E Comprehension L4/D Application L5/C Analysis L6/B Synthesis L7/A Evaluation L8/ADocument2 pagesKnowledge L3/E Comprehension L4/D Application L5/C Analysis L6/B Synthesis L7/A Evaluation L8/AWaltWritmanNo ratings yet

- Etrodeifio (dgd#sd6: Sodrod"Document29 pagesEtrodeifio (dgd#sd6: Sodrod"darkcopycat69No ratings yet

- Dufaycolor Book: Dufay-Chromex LimitedDocument60 pagesDufaycolor Book: Dufay-Chromex LimitedSergey PopovNo ratings yet

- Afghan Girl: in Search of TheDocument2 pagesAfghan Girl: in Search of TheSon PhamNo ratings yet

- SxzsaDocument15 pagesSxzsabadmash1988No ratings yet

- Corrosion Prevention and ControlDocument19 pagesCorrosion Prevention and ControlJosa FatyNo ratings yet

- India Political MapDocument1 pageIndia Political MapMediaWatch News100% (2)

- The Self As A Social Construct: The Self in The Western and Oriental Thought IndividualismDocument5 pagesThe Self As A Social Construct: The Self in The Western and Oriental Thought IndividualismStef FieNo ratings yet

- NutriSmart - Food Products Recommendation SystemDocument3 pagesNutriSmart - Food Products Recommendation SystemAnonymous izrFWiQNo ratings yet

- Inorganic Chemistry 1 - Alkali Metals RevisioDocument7 pagesInorganic Chemistry 1 - Alkali Metals RevisioAshleyn Mary SandersNo ratings yet

- Pengembangan Prosedur Dan Penataan Dinas JagaDocument11 pagesPengembangan Prosedur Dan Penataan Dinas JaganoviNo ratings yet

- Carter Procession Closure MapDocument1 pageCarter Procession Closure Mapcookiespiffey21No ratings yet

- Accelerated MotionDocument205 pagesAccelerated MotionphysicspalanichamyNo ratings yet

- ScribdDocument66 pagesScribdyeyeu5No ratings yet

- SENEPOL1Document36 pagesSENEPOL1JuanNo ratings yet

- Cape Sewing - Industrial Sewing TechnologyDocument33 pagesCape Sewing - Industrial Sewing TechnologyMonika GadgilNo ratings yet

- Pow Const of Drainage Canal - StationDocument16 pagesPow Const of Drainage Canal - StationDA 3No ratings yet

- Adamson M. An Archaeological Analysis of Gender Roles in Ancient Nonliterate Cultures in Eurasia - Diss. 2005Document228 pagesAdamson M. An Archaeological Analysis of Gender Roles in Ancient Nonliterate Cultures in Eurasia - Diss. 2005serge57100% (1)

- LCM105 LCM115 PDFDocument3 pagesLCM105 LCM115 PDFCABean1No ratings yet

- Antiragging Committee - Jan-20Document1 pageAntiragging Committee - Jan-20TRH RECRUITMENTNo ratings yet

- Summer Training Project ReportDocument94 pagesSummer Training Project Reportumeshpastor100% (1)

- Syllabi Econ 1CDocument2 pagesSyllabi Econ 1Challel jhon butacNo ratings yet

- Welcome To Good Shepherd Chapel: Thirty-Third Sunday in Ordinary TimeDocument4 pagesWelcome To Good Shepherd Chapel: Thirty-Third Sunday in Ordinary Timesaintmichaelpar7090No ratings yet

- Statements of Financial Position As at 31 December 2009 and 2010Document3 pagesStatements of Financial Position As at 31 December 2009 and 2010mohitgaba19No ratings yet

- 06380492Document18 pages06380492Imam Adhita ViryaNo ratings yet

- PeriodontitisDocument14 pagesPeriodontitisDanni MontielNo ratings yet