Professional Documents

Culture Documents

Factory Acceptance Test Procedure For DCS - Page 1

Factory Acceptance Test Procedure For DCS - Page 1

Uploaded by

kapsarcCopyright:

Available Formats

You might also like

- GCMS Reference Manual 28 May 2015Document445 pagesGCMS Reference Manual 28 May 2015Bom100% (2)

- Pre Qualified WPSDocument1 pagePre Qualified WPSkapsarcNo ratings yet

- Isolation Work Instruction TemplateDocument5 pagesIsolation Work Instruction TemplateppnNo ratings yet

- Heavy Duty Wheeled Vehicles Design, Theory, CalculationsDocument11 pagesHeavy Duty Wheeled Vehicles Design, Theory, CalculationszhenyupanNo ratings yet

- Mels Constuction Limitada: Commercial Management Mechanical Completion CertificateDocument1 pageMels Constuction Limitada: Commercial Management Mechanical Completion CertificateDeonNo ratings yet

- Test Procedure:: Functional Testing Guidance Pump PerformanceDocument10 pagesTest Procedure:: Functional Testing Guidance Pump PerformanceSagar Naduvinamani100% (1)

- Servicios en Red PDFDocument83 pagesServicios en Red PDF1312295841No ratings yet

- 935 Robert Bosch Interview Questions in C A Micro Controllers PDFDocument2 pages935 Robert Bosch Interview Questions in C A Micro Controllers PDFdhapra0% (1)

- Testing and Commissioning Procedure: 2017 EDITIONDocument26 pagesTesting and Commissioning Procedure: 2017 EDITIONvin ssNo ratings yet

- 5.3.2 Test ProcedureDocument6 pages5.3.2 Test ProcedureRija MobinNo ratings yet

- F P 22 02 - Instrument History CardDocument2 pagesF P 22 02 - Instrument History Cardshamir_ahmedabadNo ratings yet

- Mechanical Completion Check Sheet Electrical: Lighting & Power CircuitDocument2 pagesMechanical Completion Check Sheet Electrical: Lighting & Power CircuitYadira Centanaro GutierrezNo ratings yet

- PC - EXHAUST FANS ID #'SDocument3 pagesPC - EXHAUST FANS ID #'SAbdul Mohid SheikhNo ratings yet

- Factory Acceptance Test (FAT) of A PLC Panel - A Step-by-Step Basic GuideDocument13 pagesFactory Acceptance Test (FAT) of A PLC Panel - A Step-by-Step Basic Guidenzar HasanNo ratings yet

- 02-SOP No. ENG-GEN-002-01 Maintenance Request For Break Down or General ComplaintsDocument4 pages02-SOP No. ENG-GEN-002-01 Maintenance Request For Break Down or General ComplaintsAjlan KhanNo ratings yet

- Form No. 102 - Control ValveDocument2 pagesForm No. 102 - Control ValveVictor Nair100% (1)

- This Checklist Is To Be Used For The Commissioning of Plant or EquipmentDocument2 pagesThis Checklist Is To Be Used For The Commissioning of Plant or EquipmentAnonymous v6ybIxZFNo ratings yet

- Commissioning Plan TemplateDocument22 pagesCommissioning Plan Templaten.hartonoNo ratings yet

- Safety Understand The Requirement Calibration Documentation Calibration Procedure For Various InstrumentDocument6 pagesSafety Understand The Requirement Calibration Documentation Calibration Procedure For Various Instrumentkrishna kumarNo ratings yet

- C-54 NocDocument41 pagesC-54 NocRochdi SahliNo ratings yet

- J1525-HW1-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW1-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- En ACS580 Standard Control Program FW C A5Document440 pagesEn ACS580 Standard Control Program FW C A5joseNo ratings yet

- FDA Part11 Regulated Industries BR enDocument40 pagesFDA Part11 Regulated Industries BR enRuchirNo ratings yet

- Col Step7 v5.6 TrialDocument1 pageCol Step7 v5.6 TrialfasgafdgsfdgsfdgafdNo ratings yet

- Pre Commiss. Check List Chilled Water PumpsDocument3 pagesPre Commiss. Check List Chilled Water PumpsARUL SANKARAN100% (1)

- Attachment E - UPS Checklist PDFDocument1 pageAttachment E - UPS Checklist PDFnandaanujNo ratings yet

- Commissioning Requirements 03/02 01810 - 1 OF 20 D:/DOCS/DIV1/03-02/01810Document20 pagesCommissioning Requirements 03/02 01810 - 1 OF 20 D:/DOCS/DIV1/03-02/01810Venkataramanan SNo ratings yet

- Section 01 91 00 - General Commissioning Requirements Part 1 - GeneralDocument20 pagesSection 01 91 00 - General Commissioning Requirements Part 1 - GeneralJim WoodNo ratings yet

- MNT-INTG-2007OP - Maintenance Welding InspectionDocument43 pagesMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanNo ratings yet

- Control Valve IPF Function Test1Document5 pagesControl Valve IPF Function Test1btjajadiNo ratings yet

- Loop Check and ValveDocument1 pageLoop Check and ValveMohd A IshakNo ratings yet

- Standard Operating Procedure: Qualification and Verification For Hvac System and AreasDocument64 pagesStandard Operating Procedure: Qualification and Verification For Hvac System and AreasMaryanthony NamyaloNo ratings yet

- Modbus IntroDocument10 pagesModbus IntroArmando GarciaNo ratings yet

- FAT Procedure (En)Document2 pagesFAT Procedure (En)wado11No ratings yet

- Sop For Strip CutterDocument4 pagesSop For Strip CutterMusyoka UrbanusNo ratings yet

- 6 Fire Protection SystemDocument1,320 pages6 Fire Protection SystemedmondevangelistacorpuzNo ratings yet

- Inspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyDocument4 pagesInspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyAhmad DagamsehNo ratings yet

- Work Method Statement Date of Revision 07 Sep 2015 Rev.01Document5 pagesWork Method Statement Date of Revision 07 Sep 2015 Rev.01Lanceal TanNo ratings yet

- Scope of FATDocument9 pagesScope of FATmahesh5277No ratings yet

- What Are The Different Types of Functional Testing?Document5 pagesWhat Are The Different Types of Functional Testing?khan 2003No ratings yet

- Commissioning Methodology For Boiler-1Document17 pagesCommissioning Methodology For Boiler-1Subhankar ChaudhuriNo ratings yet

- Quality Plan and Checklist (Electrical Condut & Raceways) - Sandvik G BlockDocument3 pagesQuality Plan and Checklist (Electrical Condut & Raceways) - Sandvik G BlockParasNo ratings yet

- Pre Commissioning ChecklistsDocument13 pagesPre Commissioning Checklistsmehul10941No ratings yet

- Pre and Post Shutdown Activity Forms and ChecklistsDocument44 pagesPre and Post Shutdown Activity Forms and ChecklistsDhanraj PatilNo ratings yet

- Unit 4 Use of Standard Operating ProceduresDocument13 pagesUnit 4 Use of Standard Operating ProceduresEileen LeeNo ratings yet

- Testing and Commissioning Procedure: 2012 EDITIONDocument104 pagesTesting and Commissioning Procedure: 2012 EDITIONAndres ZuñigaNo ratings yet

- MQP of PanelDocument1 pageMQP of Panelrahulchitrakoot123No ratings yet

- J1525-HW2-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW2-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- Department of Electrical EngineeringDocument39 pagesDepartment of Electrical EngineeringfdsafdsafasNo ratings yet

- Factory and Site Acceptance Testing Dave Lawrence TCT ConsultancyDocument17 pagesFactory and Site Acceptance Testing Dave Lawrence TCT ConsultancySuguna DeviNo ratings yet

- I-007 DP Transmitter Calibration CheckDocument1 pageI-007 DP Transmitter Calibration CheckAr RahmanNo ratings yet

- 250 00 Pipe Labeling ProcedureDocument11 pages250 00 Pipe Labeling ProcedureFrancis GarciaNo ratings yet

- S7-1500H Redundant SystemDocument52 pagesS7-1500H Redundant SystemThai Nguyen QuangNo ratings yet

- Essential Elements of A Successful Reliability ProgramDocument24 pagesEssential Elements of A Successful Reliability ProgramJesus R. AguileraNo ratings yet

- Quality Management: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 24 Slide 1Document55 pagesQuality Management: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 24 Slide 1faroakNo ratings yet

- Fitter CTS2.0 NSQF-4Document63 pagesFitter CTS2.0 NSQF-4Anil Fauzdar100% (1)

- 7 Equipment and CalibrationDocument20 pages7 Equipment and CalibrationsachinNo ratings yet

- Installation and Calibration of Instruments GuidanceDocument17 pagesInstallation and Calibration of Instruments GuidanceCarlos SalazarNo ratings yet

- Tightness Control SystemDocument4 pagesTightness Control SystemYetkin Erdoğan100% (1)

- Electrical Maintenance Standard Operative Procedure - Detailed ProceduresDocument1 pageElectrical Maintenance Standard Operative Procedure - Detailed ProceduresamlmrsscontrolNo ratings yet

- Antonio Regadio Regulatory Affairs (RMP) PAPPI 15th BiCon 11 Mar 2016Document52 pagesAntonio Regadio Regulatory Affairs (RMP) PAPPI 15th BiCon 11 Mar 2016Kim Cyrelle Samson Umbalin100% (2)

- Annex C Metering Standards Procedures Opt PDFDocument218 pagesAnnex C Metering Standards Procedures Opt PDFhassanaagibNo ratings yet

- Telephone and Communication Systems CommissioningDocument1 pageTelephone and Communication Systems CommissioningHumaid Shaikh50% (2)

- Environmental Control System A Complete Guide - 2020 EditionFrom EverandEnvironmental Control System A Complete Guide - 2020 EditionNo ratings yet

- WQT - Aws D1.1Document3 pagesWQT - Aws D1.1kapsarc100% (1)

- Drum Screen - DesignDetailsDocument2 pagesDrum Screen - DesignDetailskapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 1Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 1kapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 2Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 2kapsarcNo ratings yet

- PN 16 Flange EN1092Document2 pagesPN 16 Flange EN1092kapsarcNo ratings yet

- Viking Material SpecsDocument12 pagesViking Material SpecskapsarcNo ratings yet

- One Week Look A Head PlanDocument1 pageOne Week Look A Head PlankapsarcNo ratings yet

- Drum Screen Installation - GearsDocument2 pagesDrum Screen Installation - GearskapsarcNo ratings yet

- Piping IsoDocument1 pagePiping IsokapsarcNo ratings yet

- Boehler 2507 P100 Rutile E2594 16 Covered ElectrodeDocument1 pageBoehler 2507 P100 Rutile E2594 16 Covered ElectrodekapsarcNo ratings yet

- Horizontal Slurry PumpDocument1 pageHorizontal Slurry PumpkapsarcNo ratings yet

- Slurry PumpDocument1 pageSlurry PumpkapsarcNo ratings yet

- Chemical Compositiopn of FCAW ElectrodesDocument1 pageChemical Compositiopn of FCAW ElectrodeskapsarcNo ratings yet

- Pump Back Pressure RegulatorDocument1 pagePump Back Pressure RegulatorkapsarcNo ratings yet

- Construction Progress Report - 2Document2 pagesConstruction Progress Report - 2kapsarcNo ratings yet

- Drive Unit For PumpDocument1 pageDrive Unit For PumpkapsarcNo ratings yet

- Construction Progress Report - 1Document2 pagesConstruction Progress Report - 1kapsarcNo ratings yet

- Instrumentation Control For Pumps - 1Document1 pageInstrumentation Control For Pumps - 1kapsarcNo ratings yet

- Double Suction ImpellerDocument1 pageDouble Suction ImpellerkapsarcNo ratings yet

- Vertical Dry Pit PumpDocument1 pageVertical Dry Pit PumpkapsarcNo ratings yet

- Integral Flange FactorDocument1 pageIntegral Flange FactorkapsarcNo ratings yet

- Delta Ferrite ContentDocument1 pageDelta Ferrite ContentkapsarcNo ratings yet

- Inspection For TanksDocument1 pageInspection For TankskapsarcNo ratings yet

- Forces On BoltsDocument1 pageForces On BoltskapsarcNo ratings yet

- RT Acceptance Criteria For Pressure VesselDocument1 pageRT Acceptance Criteria For Pressure VesselkapsarcNo ratings yet

- Flange ImperfectionDocument1 pageFlange ImperfectionkapsarcNo ratings yet

- Piping DWGDocument1 pagePiping DWGkapsarcNo ratings yet

- Weld Joint Location in Pressure VesselDocument1 pageWeld Joint Location in Pressure VesselkapsarcNo ratings yet

- Pump Alarm ControlDocument1 pagePump Alarm ControlkapsarcNo ratings yet

- 206L4 MM CH75 PDFDocument4 pages206L4 MM CH75 PDFRaisa RabeyaNo ratings yet

- 11th Computer Science Vol 1 Full Study Material English Medium PDFDocument83 pages11th Computer Science Vol 1 Full Study Material English Medium PDFM Mohamed MaahirNo ratings yet

- Ai in EduDocument14 pagesAi in EduKang YihyunNo ratings yet

- About Them Philanthropy: See AlsoDocument3 pagesAbout Them Philanthropy: See AlsojanelauraNo ratings yet

- Baker Bill Rosa 1973 Mexico PDFDocument21 pagesBaker Bill Rosa 1973 Mexico PDFthe missions networkNo ratings yet

- Unit 14 Marketing of Information Services: 14.0 ObjectivesDocument21 pagesUnit 14 Marketing of Information Services: 14.0 ObjectivesGirmaw TakiloNo ratings yet

- VALIX - Chapter 5Document28 pagesVALIX - Chapter 5glenn langcuyan100% (1)

- Dotnet - Interview Question and Answer'sDocument395 pagesDotnet - Interview Question and Answer'sPrashanth VamaniNo ratings yet

- CAC Boomerang Flight ManualDocument103 pagesCAC Boomerang Flight ManualAnonymous KeGjwtNo ratings yet

- Swot AnalysisDocument7 pagesSwot AnalysisAlyssa Harriet MartinezNo ratings yet

- Letter of Indemnity For Maturity - Survival ClaimDocument2 pagesLetter of Indemnity For Maturity - Survival Claimsajeer n FORWARDNo ratings yet

- Nursing Excellence StandardsDocument58 pagesNursing Excellence StandardsJyoti100% (1)

- Global SecurityDocument1 pageGlobal SecurityNeil MNNo ratings yet

- World History 2147, Shayaan.Document15 pagesWorld History 2147, Shayaan.Ifrah DarNo ratings yet

- 3 - Minipack 48-800 Rectifier ModuleDocument18 pages3 - Minipack 48-800 Rectifier ModuleEdwin David ColqueNo ratings yet

- Topic 19 - Manufactures - and - IndustriesDocument1 pageTopic 19 - Manufactures - and - IndustriesMATIAS XAVIER LUNA PARRANo ratings yet

- AAPG Memoir 71.reservoir Characterization-Recent Advances PDFDocument388 pagesAAPG Memoir 71.reservoir Characterization-Recent Advances PDFCarolina Castaño Uribe100% (1)

- Lab Policies KOH Prep For Fungal Elements Affiliate Lab 8649 4Document3 pagesLab Policies KOH Prep For Fungal Elements Affiliate Lab 8649 4Geby JeonNo ratings yet

- Land Development Banks PDFDocument9 pagesLand Development Banks PDFTapesh AwasthiNo ratings yet

- Unit-Iii Electronic Payment SystemDocument30 pagesUnit-Iii Electronic Payment SystemPreet SinghNo ratings yet

- Hazare Et Al-2015-Systems EngineeringDocument17 pagesHazare Et Al-2015-Systems EngineeringJúlio CortêsNo ratings yet

- Review Aruna 3Document7 pagesReview Aruna 3Angel Francisco Zacarias MartinezNo ratings yet

- APFBC JFMC EDC Operational Manual (Assam)Document119 pagesAPFBC JFMC EDC Operational Manual (Assam)poNo ratings yet

- Research Paper On Emotional StabilityDocument8 pagesResearch Paper On Emotional Stabilityegw48xp5100% (1)

- Waiting at The TableDocument20 pagesWaiting at The TableHelene Forte100% (1)

- Thermaline Heat Shield PDSDocument4 pagesThermaline Heat Shield PDSfrosted296No ratings yet

Factory Acceptance Test Procedure For DCS - Page 1

Factory Acceptance Test Procedure For DCS - Page 1

Uploaded by

kapsarcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Factory Acceptance Test Procedure For DCS - Page 1

Factory Acceptance Test Procedure For DCS - Page 1

Uploaded by

kapsarcCopyright:

Available Formats

R E PLA CE ME N T O F S W C P L A NT-1 D RU M S C R E E N

S YST E M 72 00 0 43 00 0

( 7 NOS ) & LC P I N P LA NT- 2, JU B AI L

FAC TO RY A CC E P TA NC E T E ST P RO CE D U R E PA G E 7 O F 4 5

I NS -A B -DS - 219 RE V: 0

3. TEST METHODOLOGY

3.1. General Principles

This specification aims to ensure that the testing is performed consistently and accurately and

that all results are recorded.

Testing will continue, and faults corrected at the end of a test or series of tests as deemed

appropriate by ABB. Testing will only be interrupted for corrections to be carried out if further

testing is prevented until this has been completed.

Testing will be deemed to be completed once all the tests and any PQs raised as a result of

these tests have been signed off.

Refer to the typical Testing flow chart identified in section 3.2.

a) All hardware modules will be subject to formal configuration management control once

they have been incorporated into the system build.

b) The Query / Change Procedure will be used to manage queries raised from each stage of

testing.

c) A competent person independent of hardware and application program design,

development and production shall perform functional testing. Signatures will be

required at the appropriate sections of each test record.

d) Items that cannot be tested at any test stage(s) shall be recorded as a PQ.

e) Note that where target (client) hardware is not available for module & integrated or

factory acceptance testing, the test environment will be described and agreed with the

client. Additional site installation testing stages may be necessary to validate all

aspects of the integration of the target (client) hardware on site.

f) Full documentation of the test requirements and results are recorded and stored, so

that comprehensive records exist for the whole system, giving confidence that all

aspects of the system functionality has been satisfactorily tested.

g) Where testing has previously taken place, then reasonable credit for this may be taken

during subsequent test stages.

h) In all test stages, test coverage as identified within the respective tests will be the aim.

If it is not possible to achieve this test coverage, the reasons will be documented in the

test records.

i) Initial Quality Control Checks: The documents controlling the design of hardware and

application program modules (e.g. PQs) will be reviewed as part of the project quality

procedures. When these checks have been successfully completed, the Lead Engineer will

review and determine if the relevant hardware setup and application program is ready to

be released for test. Provided that it is appropriate, the Hardware and Software

Production Logs will be updated with the new module status recorded as “Authorised for

Test”.

j) Control of Hardware Setup And Application Program Released for Test: Hardware setup

and application program will always be tested against the current released and reviewed

reference documents. Where the changes require a significant re-test of the module, a PQ

will be raised and testing will be halted on that module until the updates have been

STATUS SECURITY LEVEL DOCUMENT ID. REV. LANG. PAGE

In Review Internal INS-AB-DS-219 0 en 7/45

© Copyright 2020 ABB. All rights reserved.

REPL AC EM ENT O F SW C P L AN T-1 DR UM S CREEN

SYSTEM 72 00 043 00 0

( 7 N O S) & LC P IN PL A NT- 2, J U BAIL

FACTORY ACCEPTAN CE T EST PR OC ED URE PAG E 8 O F 45

I NS- AB -D S- 219 RE V: 0

completed. The testing of changes specified on PQs will be achieved by repeating, as

necessary, all or part of the test that generated the PQ.

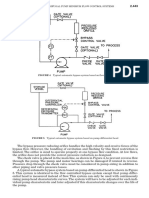

3.2. Typical Testing Flowchart

Start

Pre-Test Meeting

Agree scope

Note exceptions

Test Stage

Test the application

software & hardware

Post-Test Meeting

Agree categorisation of

faults

Incorporate exceptions System passed back to

and re-submit for limited Test Status Fail correct and re-submit

Testing

Pass

Post-Test Meeting

Agree remedial work

Remedial Work

Implement remedial

actions

Remedial Fail

Retest

Pass

No Exceptions Yes Test Complete

Cleared

Figure 1 – Typical Testing Flowchart

STATUS SECURITY LEVEL DOCUMENT ID. REV. LANG. PAGE

In Review Internal INS-AB-DS-219 0 en 8/45

© Copyright 2020 ABB. All rights reserved.

You might also like

- GCMS Reference Manual 28 May 2015Document445 pagesGCMS Reference Manual 28 May 2015Bom100% (2)

- Pre Qualified WPSDocument1 pagePre Qualified WPSkapsarcNo ratings yet

- Isolation Work Instruction TemplateDocument5 pagesIsolation Work Instruction TemplateppnNo ratings yet

- Heavy Duty Wheeled Vehicles Design, Theory, CalculationsDocument11 pagesHeavy Duty Wheeled Vehicles Design, Theory, CalculationszhenyupanNo ratings yet

- Mels Constuction Limitada: Commercial Management Mechanical Completion CertificateDocument1 pageMels Constuction Limitada: Commercial Management Mechanical Completion CertificateDeonNo ratings yet

- Test Procedure:: Functional Testing Guidance Pump PerformanceDocument10 pagesTest Procedure:: Functional Testing Guidance Pump PerformanceSagar Naduvinamani100% (1)

- Servicios en Red PDFDocument83 pagesServicios en Red PDF1312295841No ratings yet

- 935 Robert Bosch Interview Questions in C A Micro Controllers PDFDocument2 pages935 Robert Bosch Interview Questions in C A Micro Controllers PDFdhapra0% (1)

- Testing and Commissioning Procedure: 2017 EDITIONDocument26 pagesTesting and Commissioning Procedure: 2017 EDITIONvin ssNo ratings yet

- 5.3.2 Test ProcedureDocument6 pages5.3.2 Test ProcedureRija MobinNo ratings yet

- F P 22 02 - Instrument History CardDocument2 pagesF P 22 02 - Instrument History Cardshamir_ahmedabadNo ratings yet

- Mechanical Completion Check Sheet Electrical: Lighting & Power CircuitDocument2 pagesMechanical Completion Check Sheet Electrical: Lighting & Power CircuitYadira Centanaro GutierrezNo ratings yet

- PC - EXHAUST FANS ID #'SDocument3 pagesPC - EXHAUST FANS ID #'SAbdul Mohid SheikhNo ratings yet

- Factory Acceptance Test (FAT) of A PLC Panel - A Step-by-Step Basic GuideDocument13 pagesFactory Acceptance Test (FAT) of A PLC Panel - A Step-by-Step Basic Guidenzar HasanNo ratings yet

- 02-SOP No. ENG-GEN-002-01 Maintenance Request For Break Down or General ComplaintsDocument4 pages02-SOP No. ENG-GEN-002-01 Maintenance Request For Break Down or General ComplaintsAjlan KhanNo ratings yet

- Form No. 102 - Control ValveDocument2 pagesForm No. 102 - Control ValveVictor Nair100% (1)

- This Checklist Is To Be Used For The Commissioning of Plant or EquipmentDocument2 pagesThis Checklist Is To Be Used For The Commissioning of Plant or EquipmentAnonymous v6ybIxZFNo ratings yet

- Commissioning Plan TemplateDocument22 pagesCommissioning Plan Templaten.hartonoNo ratings yet

- Safety Understand The Requirement Calibration Documentation Calibration Procedure For Various InstrumentDocument6 pagesSafety Understand The Requirement Calibration Documentation Calibration Procedure For Various Instrumentkrishna kumarNo ratings yet

- C-54 NocDocument41 pagesC-54 NocRochdi SahliNo ratings yet

- J1525-HW1-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW1-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- En ACS580 Standard Control Program FW C A5Document440 pagesEn ACS580 Standard Control Program FW C A5joseNo ratings yet

- FDA Part11 Regulated Industries BR enDocument40 pagesFDA Part11 Regulated Industries BR enRuchirNo ratings yet

- Col Step7 v5.6 TrialDocument1 pageCol Step7 v5.6 TrialfasgafdgsfdgsfdgafdNo ratings yet

- Pre Commiss. Check List Chilled Water PumpsDocument3 pagesPre Commiss. Check List Chilled Water PumpsARUL SANKARAN100% (1)

- Attachment E - UPS Checklist PDFDocument1 pageAttachment E - UPS Checklist PDFnandaanujNo ratings yet

- Commissioning Requirements 03/02 01810 - 1 OF 20 D:/DOCS/DIV1/03-02/01810Document20 pagesCommissioning Requirements 03/02 01810 - 1 OF 20 D:/DOCS/DIV1/03-02/01810Venkataramanan SNo ratings yet

- Section 01 91 00 - General Commissioning Requirements Part 1 - GeneralDocument20 pagesSection 01 91 00 - General Commissioning Requirements Part 1 - GeneralJim WoodNo ratings yet

- MNT-INTG-2007OP - Maintenance Welding InspectionDocument43 pagesMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanNo ratings yet

- Control Valve IPF Function Test1Document5 pagesControl Valve IPF Function Test1btjajadiNo ratings yet

- Loop Check and ValveDocument1 pageLoop Check and ValveMohd A IshakNo ratings yet

- Standard Operating Procedure: Qualification and Verification For Hvac System and AreasDocument64 pagesStandard Operating Procedure: Qualification and Verification For Hvac System and AreasMaryanthony NamyaloNo ratings yet

- Modbus IntroDocument10 pagesModbus IntroArmando GarciaNo ratings yet

- FAT Procedure (En)Document2 pagesFAT Procedure (En)wado11No ratings yet

- Sop For Strip CutterDocument4 pagesSop For Strip CutterMusyoka UrbanusNo ratings yet

- 6 Fire Protection SystemDocument1,320 pages6 Fire Protection SystemedmondevangelistacorpuzNo ratings yet

- Inspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyDocument4 pagesInspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyAhmad DagamsehNo ratings yet

- Work Method Statement Date of Revision 07 Sep 2015 Rev.01Document5 pagesWork Method Statement Date of Revision 07 Sep 2015 Rev.01Lanceal TanNo ratings yet

- Scope of FATDocument9 pagesScope of FATmahesh5277No ratings yet

- What Are The Different Types of Functional Testing?Document5 pagesWhat Are The Different Types of Functional Testing?khan 2003No ratings yet

- Commissioning Methodology For Boiler-1Document17 pagesCommissioning Methodology For Boiler-1Subhankar ChaudhuriNo ratings yet

- Quality Plan and Checklist (Electrical Condut & Raceways) - Sandvik G BlockDocument3 pagesQuality Plan and Checklist (Electrical Condut & Raceways) - Sandvik G BlockParasNo ratings yet

- Pre Commissioning ChecklistsDocument13 pagesPre Commissioning Checklistsmehul10941No ratings yet

- Pre and Post Shutdown Activity Forms and ChecklistsDocument44 pagesPre and Post Shutdown Activity Forms and ChecklistsDhanraj PatilNo ratings yet

- Unit 4 Use of Standard Operating ProceduresDocument13 pagesUnit 4 Use of Standard Operating ProceduresEileen LeeNo ratings yet

- Testing and Commissioning Procedure: 2012 EDITIONDocument104 pagesTesting and Commissioning Procedure: 2012 EDITIONAndres ZuñigaNo ratings yet

- MQP of PanelDocument1 pageMQP of Panelrahulchitrakoot123No ratings yet

- J1525-HW2-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW2-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- Department of Electrical EngineeringDocument39 pagesDepartment of Electrical EngineeringfdsafdsafasNo ratings yet

- Factory and Site Acceptance Testing Dave Lawrence TCT ConsultancyDocument17 pagesFactory and Site Acceptance Testing Dave Lawrence TCT ConsultancySuguna DeviNo ratings yet

- I-007 DP Transmitter Calibration CheckDocument1 pageI-007 DP Transmitter Calibration CheckAr RahmanNo ratings yet

- 250 00 Pipe Labeling ProcedureDocument11 pages250 00 Pipe Labeling ProcedureFrancis GarciaNo ratings yet

- S7-1500H Redundant SystemDocument52 pagesS7-1500H Redundant SystemThai Nguyen QuangNo ratings yet

- Essential Elements of A Successful Reliability ProgramDocument24 pagesEssential Elements of A Successful Reliability ProgramJesus R. AguileraNo ratings yet

- Quality Management: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 24 Slide 1Document55 pagesQuality Management: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 24 Slide 1faroakNo ratings yet

- Fitter CTS2.0 NSQF-4Document63 pagesFitter CTS2.0 NSQF-4Anil Fauzdar100% (1)

- 7 Equipment and CalibrationDocument20 pages7 Equipment and CalibrationsachinNo ratings yet

- Installation and Calibration of Instruments GuidanceDocument17 pagesInstallation and Calibration of Instruments GuidanceCarlos SalazarNo ratings yet

- Tightness Control SystemDocument4 pagesTightness Control SystemYetkin Erdoğan100% (1)

- Electrical Maintenance Standard Operative Procedure - Detailed ProceduresDocument1 pageElectrical Maintenance Standard Operative Procedure - Detailed ProceduresamlmrsscontrolNo ratings yet

- Antonio Regadio Regulatory Affairs (RMP) PAPPI 15th BiCon 11 Mar 2016Document52 pagesAntonio Regadio Regulatory Affairs (RMP) PAPPI 15th BiCon 11 Mar 2016Kim Cyrelle Samson Umbalin100% (2)

- Annex C Metering Standards Procedures Opt PDFDocument218 pagesAnnex C Metering Standards Procedures Opt PDFhassanaagibNo ratings yet

- Telephone and Communication Systems CommissioningDocument1 pageTelephone and Communication Systems CommissioningHumaid Shaikh50% (2)

- Environmental Control System A Complete Guide - 2020 EditionFrom EverandEnvironmental Control System A Complete Guide - 2020 EditionNo ratings yet

- WQT - Aws D1.1Document3 pagesWQT - Aws D1.1kapsarc100% (1)

- Drum Screen - DesignDetailsDocument2 pagesDrum Screen - DesignDetailskapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 1Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 1kapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 2Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 2kapsarcNo ratings yet

- PN 16 Flange EN1092Document2 pagesPN 16 Flange EN1092kapsarcNo ratings yet

- Viking Material SpecsDocument12 pagesViking Material SpecskapsarcNo ratings yet

- One Week Look A Head PlanDocument1 pageOne Week Look A Head PlankapsarcNo ratings yet

- Drum Screen Installation - GearsDocument2 pagesDrum Screen Installation - GearskapsarcNo ratings yet

- Piping IsoDocument1 pagePiping IsokapsarcNo ratings yet

- Boehler 2507 P100 Rutile E2594 16 Covered ElectrodeDocument1 pageBoehler 2507 P100 Rutile E2594 16 Covered ElectrodekapsarcNo ratings yet

- Horizontal Slurry PumpDocument1 pageHorizontal Slurry PumpkapsarcNo ratings yet

- Slurry PumpDocument1 pageSlurry PumpkapsarcNo ratings yet

- Chemical Compositiopn of FCAW ElectrodesDocument1 pageChemical Compositiopn of FCAW ElectrodeskapsarcNo ratings yet

- Pump Back Pressure RegulatorDocument1 pagePump Back Pressure RegulatorkapsarcNo ratings yet

- Construction Progress Report - 2Document2 pagesConstruction Progress Report - 2kapsarcNo ratings yet

- Drive Unit For PumpDocument1 pageDrive Unit For PumpkapsarcNo ratings yet

- Construction Progress Report - 1Document2 pagesConstruction Progress Report - 1kapsarcNo ratings yet

- Instrumentation Control For Pumps - 1Document1 pageInstrumentation Control For Pumps - 1kapsarcNo ratings yet

- Double Suction ImpellerDocument1 pageDouble Suction ImpellerkapsarcNo ratings yet

- Vertical Dry Pit PumpDocument1 pageVertical Dry Pit PumpkapsarcNo ratings yet

- Integral Flange FactorDocument1 pageIntegral Flange FactorkapsarcNo ratings yet

- Delta Ferrite ContentDocument1 pageDelta Ferrite ContentkapsarcNo ratings yet

- Inspection For TanksDocument1 pageInspection For TankskapsarcNo ratings yet

- Forces On BoltsDocument1 pageForces On BoltskapsarcNo ratings yet

- RT Acceptance Criteria For Pressure VesselDocument1 pageRT Acceptance Criteria For Pressure VesselkapsarcNo ratings yet

- Flange ImperfectionDocument1 pageFlange ImperfectionkapsarcNo ratings yet

- Piping DWGDocument1 pagePiping DWGkapsarcNo ratings yet

- Weld Joint Location in Pressure VesselDocument1 pageWeld Joint Location in Pressure VesselkapsarcNo ratings yet

- Pump Alarm ControlDocument1 pagePump Alarm ControlkapsarcNo ratings yet

- 206L4 MM CH75 PDFDocument4 pages206L4 MM CH75 PDFRaisa RabeyaNo ratings yet

- 11th Computer Science Vol 1 Full Study Material English Medium PDFDocument83 pages11th Computer Science Vol 1 Full Study Material English Medium PDFM Mohamed MaahirNo ratings yet

- Ai in EduDocument14 pagesAi in EduKang YihyunNo ratings yet

- About Them Philanthropy: See AlsoDocument3 pagesAbout Them Philanthropy: See AlsojanelauraNo ratings yet

- Baker Bill Rosa 1973 Mexico PDFDocument21 pagesBaker Bill Rosa 1973 Mexico PDFthe missions networkNo ratings yet

- Unit 14 Marketing of Information Services: 14.0 ObjectivesDocument21 pagesUnit 14 Marketing of Information Services: 14.0 ObjectivesGirmaw TakiloNo ratings yet

- VALIX - Chapter 5Document28 pagesVALIX - Chapter 5glenn langcuyan100% (1)

- Dotnet - Interview Question and Answer'sDocument395 pagesDotnet - Interview Question and Answer'sPrashanth VamaniNo ratings yet

- CAC Boomerang Flight ManualDocument103 pagesCAC Boomerang Flight ManualAnonymous KeGjwtNo ratings yet

- Swot AnalysisDocument7 pagesSwot AnalysisAlyssa Harriet MartinezNo ratings yet

- Letter of Indemnity For Maturity - Survival ClaimDocument2 pagesLetter of Indemnity For Maturity - Survival Claimsajeer n FORWARDNo ratings yet

- Nursing Excellence StandardsDocument58 pagesNursing Excellence StandardsJyoti100% (1)

- Global SecurityDocument1 pageGlobal SecurityNeil MNNo ratings yet

- World History 2147, Shayaan.Document15 pagesWorld History 2147, Shayaan.Ifrah DarNo ratings yet

- 3 - Minipack 48-800 Rectifier ModuleDocument18 pages3 - Minipack 48-800 Rectifier ModuleEdwin David ColqueNo ratings yet

- Topic 19 - Manufactures - and - IndustriesDocument1 pageTopic 19 - Manufactures - and - IndustriesMATIAS XAVIER LUNA PARRANo ratings yet

- AAPG Memoir 71.reservoir Characterization-Recent Advances PDFDocument388 pagesAAPG Memoir 71.reservoir Characterization-Recent Advances PDFCarolina Castaño Uribe100% (1)

- Lab Policies KOH Prep For Fungal Elements Affiliate Lab 8649 4Document3 pagesLab Policies KOH Prep For Fungal Elements Affiliate Lab 8649 4Geby JeonNo ratings yet

- Land Development Banks PDFDocument9 pagesLand Development Banks PDFTapesh AwasthiNo ratings yet

- Unit-Iii Electronic Payment SystemDocument30 pagesUnit-Iii Electronic Payment SystemPreet SinghNo ratings yet

- Hazare Et Al-2015-Systems EngineeringDocument17 pagesHazare Et Al-2015-Systems EngineeringJúlio CortêsNo ratings yet

- Review Aruna 3Document7 pagesReview Aruna 3Angel Francisco Zacarias MartinezNo ratings yet

- APFBC JFMC EDC Operational Manual (Assam)Document119 pagesAPFBC JFMC EDC Operational Manual (Assam)poNo ratings yet

- Research Paper On Emotional StabilityDocument8 pagesResearch Paper On Emotional Stabilityegw48xp5100% (1)

- Waiting at The TableDocument20 pagesWaiting at The TableHelene Forte100% (1)

- Thermaline Heat Shield PDSDocument4 pagesThermaline Heat Shield PDSfrosted296No ratings yet