Professional Documents

Culture Documents

06 - Thruster Compl. - en

06 - Thruster Compl. - en

Uploaded by

Andi KastrawanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06 - Thruster Compl. - en

06 - Thruster Compl. - en

Uploaded by

Andi KastrawanCopyright:

Available Formats

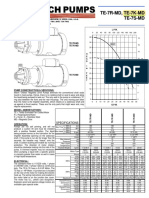

Thrustors

RÖMER Fördertechnik GmbH • Nielandstraße 53 • D-58300 Wetter / Ruhr • Germany

Tel.: 0049 - (0) 23 35 / 80 29 - 0 • Fax: 0049 - (0) 23 35 / 80 29 - 29

eMail: info@roemer-foerdertechnik.de • www.roemer-foerdertechnik.de

Thrustor acc. to DIN 15430 RÖMER

Type RBL Fördertechnik GmbH

Description and Data Page 1 of 1 Nielandstraße 53 · 58300 Wetter/Ruhr

Technical Description

Kolbenstangenkopf Dichtung

piston rod head Wiper

Staubschutzhaube Ölschraube

dust cover Oil plug

Kolbenstange Gehäuse

piston rod Housing

Zylinder Leitring

cylinder Guide ring

Kolben Zwischenflansch

piston intermediate flange

Flügelrad Deckel

impeller wheel Terminal box cover

Rotorwelle Rotor

rotor shaft rotor

Elektromotor Klemmenkastendichtung

electric motor Terminal box gasket

Fußgabel Kugellager

lug Ball bearing

Figure 1: Electrohydraulic Thrusters according to DIN 15 430 in principle.

Electro hydraulic thrusters are compact closed systems, consisting of an electric motor and a hydraulic

unit. In the switched-on state the electric motor in the lower part of the housing drives the impeller wheel

of the hydraulic unit lying above. The produced hydraulic pressure delivers the working fluid under the

piston that pushes the piston rod to the stroke end. In the switched-off state or by power cut the pump

stops operating, the oil pressure falls very quickly and the piston rod returns to its start position.

A fast return of the piston rod can be reached when inserting a re-setting spring (similar to a brake spring)

internally or against an external load or using a fast switching when normal piston lowering time is too

long.

The hydraulic unit is in a closed housing together with the tank. The oil can be checked and refilled from an

external oil filler inlet. The thrusters are supplied ready for assembling, colour coated and filled with oil. They

have to be fixed with bolts in the bores of the lug and of the piston rod head.

The piston stroke is either determined by a limit stop positioned within the thruster housing or outside of the

unit.

Tel.: 0049 - (0) 23 35 / 80 29 – 0 eMail: info@roemer-foerdertechnik.de

Modifications reserved - 100330

Fax: 0049 - (0) 23 35 / 80 29 – 29 Internet: www.roemer-foerdertechnik.de

Thrustor acc. to DIN 15430 RÖMER

Type RBL Fördertechnik GmbH

Description and Data Page 2 of 2 Nielandstraße 53 · 58300 Wetter/Ruhr

Application of Thrustors

o as brake lifter to release and apply to all types of brakes, for example on cranes, conveyors,

excavators, roller adjusting devices, stranding machines and transport systems,

o to operate pressure rollers, blocking devices and distributions guides on rolling mill trains, etc.

o to connect mechanical couplings,

o for valve and flap controls, etc.

Characteristics of RBL-Thrustors

o lifting forces from 230 to 6300 N.

o piston strokes of 50 mm and 60 mm for standard units, longer strokes up to 300 mm on demand

o short piston stroke and short lowering times

o robust construction, therefore particularly suitable for heavy duty and rough operation

o optional motor rotation direction because the impeller pump delivers oil in each direction

o designed for continuous operation (100% on-time) and high switching rate

o no excessive load of the electric motor in case of overload and stroke limitation

o not sensitive to voltage fluctuations

o all units can be supplied with protection class IP 65 and tropicalized. Units meeting the

requirements of protection class IP 56 are available on request

o piston descend and lifting time are adjustable by mounting a descend or ascend (lifting) control valve

o additional adjusting or brakeing springs can be fitted to all units

o with a normal oil filling the thrusters can be operated at ambient temperatures from –25° C to

+ 60° C. With a special oil filling and a heater down to –30° C

o additional damping springs are necessary on all units used for adjustable brake controls

(e.g. when the lifting motor speed is to be reduced to approx. 20% of the rated speed)

o every unit can be installed vertically, in-between or horizontally and is largely maintenance-free

Tel.: 0049 - (0) 23 35 / 80 29 – 0 eMail: info@roemer-foerdertechnik.de

Modifications reserved - 100330

Fax: 0049 - (0) 23 35 / 80 29 – 29 Internet: www.roemer-foerdertechnik.de

Thrustor acc. to DIN 15430 RÖMER

Type RBL Fördertechnik GmbH

Description and Data Page 3 of 3 Nielandstraße 53 · 58300 Wetter/Ruhr

Electrical Equipment

Motor: Two-pole, three-phase, cage motors are fitted in all thrusters. The insulation

class of all motors supplied is F - VDE 0530 – the temperature limit of the motor

is therefore 150° C.

Protection class DIN 40050: IP 65 acc. to EN60529, DIN VDE 0470 T1. Standard thrusters are suitable for

use in the tropics.

Voltage/Frequency: The standard thruster is designed for three-phase current 230/400 Volt, 50 Hz or

for 500 Volt, 50 Hz. Units for all other three-phase voltages and frequencies are

also available. Nine pole, special design terminal boards can be supplied too. All

motor terminal boxes are fitted with an IPON M25x1.5 watertight cable entry.

Operating mode: All thrusters are approved for 100% on-time operation (hydraulic operating mode

S1 – VDE 0530) at ambient temperatures of up to 50°C.

Switching rate: All thrusters are designed for up to 2000 switching operations per hour under

normal conditions.

Rapid lowering circuit: If the normal piston descend (lowering) time is insufficient, it can be reduced by

three capacitors in parallel circuit. Using this capacitor arrangement the slow

down time of the electric motor is reduced with switch-off and so the oil pressure

decreases rapidly. In this case, the thruster must be controlled by a separate

relay.

Limit switch: All thrusters can be delivered with limit switches on request.

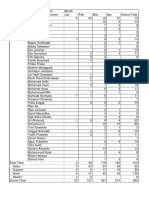

Table 1: Technical Data

Force Stroke Brake Frequency Power Voltage Current max. weight

Type Spring Consum. Operating

Force

1) 2) 3) 4)

N mm N Hz W V A per/h kg

RBL 230 - 50 220 50 180 50 165 400 0.49 2000 10

RBL 300 - 50 300 50 270 50 200 400 0.44 2000 14

RBL 500 - 60 500 60 460 50 210 400 0.47 2000 21

RBL 500 - 120 500 120 50 210 400 0.47 1200 26

RBL 800 - 60 800 60 750 50 330 400 1.35 2000 24

RBL 800 - 120 800 120 50 330 400 1.35 1200 27

RBL 1250 - 60 1250 60 1200 50 330 400 1.37 2000 39

RBL 1250 - 120 1250 120 50 330 400 1.37 1200 39

RBL 2000 - 60 2000 60 1900 50 450 400 1.38 2000 39

RBL 2000 - 120 2000 120 50 450 400 1.38 1200 39

RBL 3000 - 60 3000 60 2700 50 550 400 1.39 1500 40

RBL 3000 - 120 3000 120 50 550 400 1.39 900 40

RBL 6300 - 120 6300 120 50 1100 400 2.28 630

All technical data are mean values related to +20°C operating temperature of thrustor.

1) Values at end position of piston still achieved at ambient temperature between -25°C and +50°C and a voltage drop up to

5%.

2) Values of braking force apply to 1/3 of the related stroke.

3) Values at retracted piston rod. During lifting operation the specified values will increase. At –25°C operating temperature the

current consumption is approx. 1,5 times higher than the consumption at +20°C.

4) Permitted for continuous operation S1 and intermittent duty S3-60% ED up to 50°C ambient temperature.

Tel.: 0049 - (0) 23 35 / 80 29 – 0 eMail: info@roemer-foerdertechnik.de

Modifications reserved - 100330

Fax: 0049 - (0) 23 35 / 80 29 – 29 Internet: www.roemer-foerdertechnik.de

Thrustor acc. to DIN 15430 RÖMER

Type RBL Fördertechnik GmbH

Description and Data Page 4 of 4 Nielandstraße 53 · 58300 Wetter/Ruhr

b3 b3

h5

d2

s

h6

H S

h1

Hubventil

H Ascent Valve

h3

Senkventil

S

b1 Descent Valve

h2

d1

b2

d-Feder

d-spring

b4

R Q

b5

T

b6

U

d2

V

h6

h1

ungespannt gespannt

(Gerät gelüftet) (Gerät in

Bremsposition)

decompressed compressed

(thrustor (thrustor in

releasing brake) brake position)

Figure 2: Electrohydraulic Thrustor size 230-50 to 800-120

Table 2 : Dimensions of Thrustors size 230-50 to 800-120

1) 2)

Type b1 b2 b3 b4 b5 b6 d1 d2 h1 h2 h3 h5 h6 Q R S T U V

RBL 230 - 50 40 80 20 160 80 200 16 12 286 20 16 12 26 85 55 75 100 20 15

RBL 300 - 50 40 80 25 160 80 197 16 16 370 18 16 15 34 85 55 75 100 20 15

RBL 500 - 60 60 120 30 195 97 254 20 20 435 23 22 18 36 85 55 75 100 20 15

RBL 500 -120 60 120 30 195 97 254 20 20 515 23 22 18 36

RBL 800 - 60 60 120 30 195 97 254 20 20 450 23 22 18 36 85 55 75 100 20 15

RBL 800 -120 60 120 30 195 97 254 20 20 530 23 22 18 36

1) Tolerance +0,15 / +0,25

2) Tolerance: +0,1

Tel.: 0049 - (0) 23 35 / 80 29 – 0 eMail: info@roemer-foerdertechnik.de

Modifications reserved - 100330

Fax: 0049 - (0) 23 35 / 80 29 – 29 Internet: www.roemer-foerdertechnik.de

Thrustor acc. to DIN 15430 RÖMER

Type RBL Fördertechnik GmbH

Description and Data Page 5 of 5 Nielandstraße 53 · 58300 Wetter/Ruhr

b3 b3

h5

d2

s

h6

h4

( Ed 1250,

h1

H S Ed 2000 )

Hubventil

H Ascent Valve

h2

Senkventil h3

S Descent Valve

b1

d1

b2

d-Feder

b4 d-spring

R Q

b5

b6

T

U

d2

V

h6

h1

ungespannt gespannt

(Gerät gelüftet) (Gerät in

Bremsposition)

decompressed compressed

(thrustor (thrustor in

releasing brake) brake position)

Figure 3: Electro Hydraulic Thrusters size 1250-60 to 6300-120

Table 3 : Dimensions of Thrustors size 1250-60 to 6300-120

1) 2)

Type b1 b2 b3 b4 b5 b6 d1 d2 h1 h2 h3 h4 h5 h6 Q R S T U V

RBL 1250 - 60 40 90 40 240 112 260 25 25 645 35 25 130 25 38 130 80 120 147 35 20

RBL 1250 -120 40 90 40 240 112 260 25 25 705 35 25 130 25 38

RBL 2000 - 60 40 90 40 240 112 260 25 25 645 35 25 130 25 38 130 80 120 147 35 20

RBL 2000 -120 40 90 40 240 112 260 25 25 705 35 25 130 25 38

RBL 3000 - 60 40 90 40 240 112 260 25 25 645 35 25 130 25 38 130 80 120 147 35 20

RBL 3000 -120 40 90 40 240 112 260 25 25 705 35 25 130 25 38

1) Tolerance: +0,15 / +0,25

2) Tolerance: +0,1

Tel.: 0049 - (0) 23 35 / 80 29 – 0 eMail: info@roemer-foerdertechnik.de

Modifications reserved - 100330

Fax: 0049 - (0) 23 35 / 80 29 – 29 Internet: www.roemer-foerdertechnik.de

Thrustor acc. to DIN 15430 RÖMER

Type RBL Fördertechnik GmbH

Description and Data Page 6 of 6 Nielandstraße 53 · 58300 Wetter/Ruhr

b4 d-Feder

b3 b3 d-spring

R Q

h5

d2

s

h6

T

U

d2

V

h6

h1

S

ungespannt gespannt

(Gerät gelüftet) (Gerät in

h1

Bremsposition)

decompressed compressed

(thrustor (thrustor in

Ex releasing brake) brake position)

h2

h3

b1

d1

b5

b2 Kabeleinführung wahlweise: b6

rechts, links oder unten -

Standardausführung ist "rechts"

wiring fitting by choice:

right, left or below -

standard is "right"

Figure 4: Electro Hydraulic Thrusters size 230-50 to 6300-120 explosion insulated

Table 4 : Dimensions of Thrustors size 230-50 to 6300-120 explosion insulated

1) 2)

Type b1 b2 b3 b4 b5 b6 d1 d2 h1 h2 h3 h5 h6 Q R S T U V

RBL 300 - 50 40 80 25 15 80 270 16 16 410 18 16 15 34 85 55 75 98 20 15

RBL 500 - 60 60 120 30 18 95 285 24 20 490 23 20 18 36 85 55 75 100 22 15

RBL 500 -120 60 120 30 18 95 285 24 20 570 23 20 18 36

RBL 800 - 60 60 120 30 18 95 285 24 20 490 23 20 18 36 85 55 75 100 22 15

RBL 800 -120 60 120 30 18 95 285 24 20 570 23 20 18 36

RBL 1250 - 60 40 90 40 25 112 324 25 25 690 35 25 25 38 130 80 120 147 35 20

RBL 1250 -120 40 90 40 25 112 324 25 25 750 35 25 25 38

RBL 2000 - 60 40 90 40 25 112 324 25 25 690 35 25 25 38 130 80 120 147 35 20

RBL 2000 -120 40 90 40 25 112 324 25 25 750 35 25 25 38

RBL 3000 - 60 40 90 40 25 112 324 25 25 690 35 25 25 38 130 80 120 147 35 20

RBL 3000 -120 40 90 40 25 112 324 25 25 750 35 25 25 38

1) Tolerance: +0,15 / +0,25

2) Tolerance: +0,1

Tel.: 0049 - (0) 23 35 / 80 29 – 0 eMail: info@roemer-foerdertechnik.de

Modifications reserved - 100330

Fax: 0049 - (0) 23 35 / 80 29 – 29 Internet: www.roemer-foerdertechnik.de

You might also like

- Ljungström Air Preheater Operation & Maintenance Manual: Ind Barath Energies LTDDocument35 pagesLjungström Air Preheater Operation & Maintenance Manual: Ind Barath Energies LTDSunil K67% (3)

- MAN B&W 6S50MC - Components DescriptionDocument182 pagesMAN B&W 6S50MC - Components DescriptionHải Nguyễn Văn67% (3)

- 2020.8.5 Manual Book For Auto Steel Cage Welding Machine Operation ManualDocument21 pages2020.8.5 Manual Book For Auto Steel Cage Welding Machine Operation Manualarifhannasy3100% (1)

- Bonny 13Document756 pagesBonny 13Oscar CorderoNo ratings yet

- 100vjr User ManualDocument92 pages100vjr User Manualruizinho 1No ratings yet

- Assignment 1Document2 pagesAssignment 1Sourav kumar MeenaNo ratings yet

- BWA-Engl AC-motorsDocument17 pagesBWA-Engl AC-motorsG GhjNo ratings yet

- Supplies & Solutions: For Every IndustryDocument2 pagesSupplies & Solutions: For Every IndustryranjithNo ratings yet

- 15T2 Engineering Data - 2Document2 pages15T2 Engineering Data - 2Dedi MulyanaNo ratings yet

- Soot Blower-MergedDocument20 pagesSoot Blower-MergedRahul S. ChandrawarNo ratings yet

- Sootblower SystemDocument5 pagesSootblower SystemRahulNo ratings yet

- 376 IBS V09-120327 Electro-Hydraulic-Thruster DIN15430 enDocument8 pages376 IBS V09-120327 Electro-Hydraulic-Thruster DIN15430 enrajeevkumarrajeevNo ratings yet

- The Marine Engine.: 81-300 KW (110 - 408 HP) at 1500-2600 RPMDocument4 pagesThe Marine Engine.: 81-300 KW (110 - 408 HP) at 1500-2600 RPMSiding BarroNo ratings yet

- Bombas de Tinta - 1Document3 pagesBombas de Tinta - 1leandrouniaNo ratings yet

- CRN32-14 A-F-G-V-HQQV 3x400/690 50 HZ: Grundfos Pump 96122405Document14 pagesCRN32-14 A-F-G-V-HQQV 3x400/690 50 HZ: Grundfos Pump 96122405Hamed YazidiNo ratings yet

- Bonny 13 EspañolDocument284 pagesBonny 13 EspañolOscar CorderoNo ratings yet

- Motor Protection: A. Motor Cooling MethodsDocument5 pagesMotor Protection: A. Motor Cooling MethodsamrezzatNo ratings yet

- Actuator DRD DREDocument35 pagesActuator DRD DRESandi AslanNo ratings yet

- Grundfos - TP 25 50 2 A O A GQQEDocument11 pagesGrundfos - TP 25 50 2 A O A GQQEJovisa MaricNo ratings yet

- Grundfos - NB 50 250 254 A F2 A E BAQEDocument13 pagesGrundfos - NB 50 250 254 A F2 A E BAQEHoria AliNo ratings yet

- Sew Brake MotorsDocument6 pagesSew Brake MotorsMohd Baharuddin Mohd Abu100% (1)

- 256 Copeland Scroll Motor Technical Information PDFDocument11 pages256 Copeland Scroll Motor Technical Information PDFDianichtrNo ratings yet

- Fludex (Flender)Document50 pagesFludex (Flender)Waris La Joi Wakatobi100% (1)

- Grundfos - CM10 3 A R G V AQQVDocument12 pagesGrundfos - CM10 3 A R G V AQQVD Manmath RaoNo ratings yet

- TE-MO07-65 (York MiniSplit Confort)Document17 pagesTE-MO07-65 (York MiniSplit Confort)LuisMarceloNadirRNo ratings yet

- Minerbolter Class NotesDocument10 pagesMinerbolter Class NotesSivalya SivaramanNo ratings yet

- Grundfos - CM1 5 A R I E AQQEDocument13 pagesGrundfos - CM1 5 A R I E AQQEVimal KalariaNo ratings yet

- Datasheetcr 3210 AfaehqqeDocument7 pagesDatasheetcr 3210 Afaehqqedtt000001No ratings yet

- Grundfos Pompa PDFDocument9 pagesGrundfos Pompa PDFAnastasia Lova DiantoroNo ratings yet

- NK 50250235 Aa2f2aesbaqerw1Document6 pagesNK 50250235 Aa2f2aesbaqerw1rifanderiNo ratings yet

- Grundfos MTS Screw Spindle PumpDocument68 pagesGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- Fludex Md10 1 Flender Standard Couplings en 0909Document51 pagesFludex Md10 1 Flender Standard Couplings en 0909Diego SilvaNo ratings yet

- ALLWEILER-Pump GK 796451 CWH 250-500 GB PDFDocument8 pagesALLWEILER-Pump GK 796451 CWH 250-500 GB PDFGeorge_Wabag_2014100% (1)

- RXVRXHDCYPDocument31 pagesRXVRXHDCYPFARIDNo ratings yet

- 04 Synchronous MotorsDocument2 pages04 Synchronous MotorsgancanNo ratings yet

- Grundfos - TP 150 220 4 A F A BAQEDocument12 pagesGrundfos - TP 150 220 4 A F A BAQEYoesoef HasyimNo ratings yet

- Project: Reference Number: 98479659 (Without Lloyd's Client: Client Number: - ContactDocument7 pagesProject: Reference Number: 98479659 (Without Lloyd's Client: Client Number: - Contactjavahz74No ratings yet

- Grundfos - NK 125 315 317 A2 F A E BAQEDocument14 pagesGrundfos - NK 125 315 317 A2 F A E BAQEMaryasa RobedNo ratings yet

- Grundfos - CM10 2 A R A E AQQEDocument11 pagesGrundfos - CM10 2 A R A E AQQEmanusnair247No ratings yet

- Workshop Small NewDocument36 pagesWorkshop Small Newesteban marinkovicNo ratings yet

- Alternator GEDocument4 pagesAlternator GEELYOU89100% (2)

- Manual March Te-7k-MdDocument2 pagesManual March Te-7k-MdjoseNo ratings yet

- Opearion Manual For Co Gas Boosting Station (Tata Kpo)Document68 pagesOpearion Manual For Co Gas Boosting Station (Tata Kpo)Sebanti BanerjeeNo ratings yet

- TurboGen ConstructionDocument71 pagesTurboGen Constructiondevanand_sawantNo ratings yet

- Constructional Details of TransformerDocument16 pagesConstructional Details of TransformerAravind NNo ratings yet

- Generator DescriptionDocument6 pagesGenerator Descriptionjosenit1787No ratings yet

- Del 1 E 180-195-VD250 General DescriptionDocument8 pagesDel 1 E 180-195-VD250 General DescriptionManuel Morales TorresNo ratings yet

- Grundfos CM5-3Document13 pagesGrundfos CM5-3Kiyimba DanielNo ratings yet

- POMPA Grundfos CM 5-2Document2 pagesPOMPA Grundfos CM 5-2Deby Eka ChandraNo ratings yet

- Brush Dax Generadores Dax - 2 - PoleDocument4 pagesBrush Dax Generadores Dax - 2 - PoleHernan GirautNo ratings yet

- Bell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDocument20 pagesBell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDenis JimenezNo ratings yet

- Turbo GeneratorsDocument26 pagesTurbo Generatorsmani_sne100% (1)

- Electric Submersible PumpingDocument12 pagesElectric Submersible Pumpinglvargas3767No ratings yet

- 38CKC Product DataDocument26 pages38CKC Product DataCarlos Enrique Godoy Sifontes0% (1)

- Brosur Pompa KSB Type CLTDocument20 pagesBrosur Pompa KSB Type CLThenryhh111No ratings yet

- 4 Hermetic Chemical Pumps Single Stage Series CN CNF CNK PDFDocument16 pages4 Hermetic Chemical Pumps Single Stage Series CN CNF CNK PDFmiguel callataNo ratings yet

- Basics of Motors & Control PanelDocument59 pagesBasics of Motors & Control PanelPraveen BalakrishnanNo ratings yet

- Grundfos NK 100 400 415 Eup A2 F A e BaqeDocument14 pagesGrundfos NK 100 400 415 Eup A2 F A e BaqePedro Luis ParedesNo ratings yet

- Technical Manual en KYP TDDocument25 pagesTechnical Manual en KYP TDbeqsNo ratings yet

- Transformer ProtectionDocument139 pagesTransformer Protectionjoblogs432100% (5)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- CQE12R15R操作手册 英文 - 20180531 - 165303Document38 pagesCQE12R15R操作手册 英文 - 20180531 - 165303Andi Kastrawan100% (1)

- P.DC Pro 1-20, DCM1-5Document68 pagesP.DC Pro 1-20, DCM1-5Andi KastrawanNo ratings yet

- Mounting & Operating Manual - Thrustor Type RBLDocument13 pagesMounting & Operating Manual - Thrustor Type RBLAndi KastrawanNo ratings yet

- PrintDocument1 pagePrintAndi KastrawanNo ratings yet

- Fault Code: 1664 - SPN: 4796 - FMI: 31: ISX CM871Document4 pagesFault Code: 1664 - SPN: 4796 - FMI: 31: ISX CM871Andi KastrawanNo ratings yet

- Packing List To MDI Makassar - Warranty Claim Part (Lift Cylinder)Document2 pagesPacking List To MDI Makassar - Warranty Claim Part (Lift Cylinder)Andi KastrawanNo ratings yet

- Chain: Service & Inspection ManualDocument12 pagesChain: Service & Inspection ManualAndi KastrawanNo ratings yet

- Work Observation List Ytd - 20210503Document1 pageWork Observation List Ytd - 20210503Andi KastrawanNo ratings yet

- Empilhadeira Hyster 1698731 - (J006) - H-PM-US-EN - (10-2021)Document826 pagesEmpilhadeira Hyster 1698731 - (J006) - H-PM-US-EN - (10-2021)Antonio100% (1)

- PGDC (Ppe) Information BrochureDocument7 pagesPGDC (Ppe) Information BrochureKaviyarasan SNo ratings yet

- Design and Control of Online Battery Energy Storage System Using Programmable Logic ControllerDocument10 pagesDesign and Control of Online Battery Energy Storage System Using Programmable Logic ControllerErdi ÜnverdiNo ratings yet

- QA - LAS - 41 43 General Physics 1 Quarter 2 Week 1 Competency 1 Techie G. Vera CruzDocument22 pagesQA - LAS - 41 43 General Physics 1 Quarter 2 Week 1 Competency 1 Techie G. Vera CruzlaurenceNo ratings yet

- 7SJ41 Definite-Time Overcurrent Protection Relay Instruction ManualDocument15 pages7SJ41 Definite-Time Overcurrent Protection Relay Instruction Manualtien taiNo ratings yet

- 7408 3bd Specimen Question Paper Set 2 Paper 3bd Turning Points v1.1Document9 pages7408 3bd Specimen Question Paper Set 2 Paper 3bd Turning Points v1.1Cadet SikanderNo ratings yet

- En 600ugStepUpSine 1Document35 pagesEn 600ugStepUpSine 1cristian mauricio calderon escobarNo ratings yet

- SCH 3250 Atomic Structures BondingDocument3 pagesSCH 3250 Atomic Structures BondingPst Kaka ClaranceNo ratings yet

- NSPR Ipp Ac 001Document1 pageNSPR Ipp Ac 001rutujaNo ratings yet

- Canadian Solar-Datasheet-HiKu6 CS6W-MS v1.4 enDocument2 pagesCanadian Solar-Datasheet-HiKu6 CS6W-MS v1.4 enLuiz HenriqueNo ratings yet

- RW LO 2 Prepare Tools and EquipmentDocument7 pagesRW LO 2 Prepare Tools and EquipmentJoy BuycoNo ratings yet

- Spare Part StockDocument20 pagesSpare Part StockNORAINI BINTI NORDIN MoeNo ratings yet

- Datasheet QSB6.7 C220 30 特性曲线Document2 pagesDatasheet QSB6.7 C220 30 特性曲线Zhao Xingyin100% (1)

- Feasibility Study of ..Document108 pagesFeasibility Study of ..mohanadNo ratings yet

- Application of Piezoelectric Transducer in Energy Harvesting in PavementDocument8 pagesApplication of Piezoelectric Transducer in Energy Harvesting in PavementvisionNo ratings yet

- Process Industry Practices ElectricalDocument21 pagesProcess Industry Practices Electricalmariannel perezNo ratings yet

- (Draft - Jurnal) KONTROL YAW DAN ROLLING LAYAR PADA KAPAL MODEL KATAMARAN - Mohammad - Kamil - Firdaus - 1741170060Document8 pages(Draft - Jurnal) KONTROL YAW DAN ROLLING LAYAR PADA KAPAL MODEL KATAMARAN - Mohammad - Kamil - Firdaus - 1741170060Anwar CoreNo ratings yet

- Pump Catalog: Product Quality, Reliability and Support You ExpectDocument24 pagesPump Catalog: Product Quality, Reliability and Support You ExpectCharles Onyechere100% (1)

- Operation and Maintenance Manual For PowerKit M33 Series Diesel EngineDocument225 pagesOperation and Maintenance Manual For PowerKit M33 Series Diesel EngineNguyễn Văn Toán100% (2)

- 1 - HV Bushing - GOM - Technical Guide - ABBDocument12 pages1 - HV Bushing - GOM - Technical Guide - ABBTrần Minh TríNo ratings yet

- Challenge of Fault Location On Long Submarine Power CablesDocument6 pagesChallenge of Fault Location On Long Submarine Power CablesMarcelo Gomes PlanteirNo ratings yet

- Cummins 1 - of - 3Document100 pagesCummins 1 - of - 3totok100% (1)

- Belts Right-HandDocument2 pagesBelts Right-HandValentinNo ratings yet

- CHP 2... Safety in Pressure System (Controllable Units)Document56 pagesCHP 2... Safety in Pressure System (Controllable Units)kira ENTERTAINMENT100% (2)

- Slide GP EV - SEMINARDocument57 pagesSlide GP EV - SEMINARPeng Keong LeongNo ratings yet

- NORGREN Pressure SensorDocument3 pagesNORGREN Pressure SensorWily WayerNo ratings yet

- Electrical Power Transmission 7Document4 pagesElectrical Power Transmission 7FaisalSoNo ratings yet

- Ee413 Ehv and Uhv Ac Transmission Unit 4 MECHANICAL DESIGN OF LINES AND GROUNDINGDocument27 pagesEe413 Ehv and Uhv Ac Transmission Unit 4 MECHANICAL DESIGN OF LINES AND GROUNDINGDr G VijayakumarNo ratings yet