Professional Documents

Culture Documents

Service Bulletin: Subject: Lube Oil and Vibration Analysis Programs

Service Bulletin: Subject: Lube Oil and Vibration Analysis Programs

Uploaded by

jussmeeeCopyright:

Available Formats

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Proven Method For Specifying Both Six Spectral Alarm Bands As Well As Narrowband Alarm EnvelopesDocument4 pagesProven Method For Specifying Both Six Spectral Alarm Bands As Well As Narrowband Alarm EnvelopesVILLANUEVA_DANIEL2064No ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Is My Machine OK?: A Field Guide to Assessing Process MachineryFrom EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryNo ratings yet

- Mathematics: Practice TestDocument8 pagesMathematics: Practice TestJeni100% (3)

- Gas Turbine ModelsDocument11 pagesGas Turbine ModelsEngr Mubeen100% (1)

- E 2412Document24 pagesE 2412Asep Thea100% (4)

- Integrating Vibration and Oil Analysis For Machine Condition MonitoringDocument10 pagesIntegrating Vibration and Oil Analysis For Machine Condition MonitoringAnda WahyudiNo ratings yet

- SKF - Tech Associates of CharlotteDocument57 pagesSKF - Tech Associates of Charlotteiatorres100% (5)

- Machine Condition Monitoring and Fault DiagnosticsDocument28 pagesMachine Condition Monitoring and Fault Diagnosticsزيد فؤاد اليافعيNo ratings yet

- WSN 91 2018 31 43Document13 pagesWSN 91 2018 31 43jerome okoyeNo ratings yet

- Vibration AnalysisDocument34 pagesVibration AnalysisImaduddin ShaNo ratings yet

- UCM Brochure 01272020Document4 pagesUCM Brochure 01272020Brian CareelNo ratings yet

- HP-DSA Aplication Note 243-1Document42 pagesHP-DSA Aplication Note 243-1Andres Felipe Loaiza PatiñoNo ratings yet

- Chapter 2 - Vibration Analysis Applications PDFDocument3 pagesChapter 2 - Vibration Analysis Applications PDFpanxo90007No ratings yet

- Oil Debris Analysis For Condition Monitoring of An IC EngineDocument3 pagesOil Debris Analysis For Condition Monitoring of An IC EngineJaime BerryNo ratings yet

- Designing of Indigenous Monitoring SystemDocument16 pagesDesigning of Indigenous Monitoring SystemNasir AbdullahNo ratings yet

- Lubricant Condition Monitoring: Why The Lubricants MonitoringDocument14 pagesLubricant Condition Monitoring: Why The Lubricants Monitoringrbdubey2020No ratings yet

- Vibration Analysis Applications: 2.1 Equipment and Processes Typical0 Monitored by Viiration AnalysisDocument3 pagesVibration Analysis Applications: 2.1 Equipment and Processes Typical0 Monitored by Viiration AnalysisVasile RaduNo ratings yet

- Assignment 2 CMDocument7 pagesAssignment 2 CMAhmad RazaNo ratings yet

- Fluidscan Handheld Lubricant Condition MonitorDocument11 pagesFluidscan Handheld Lubricant Condition MonitormancjaNo ratings yet

- Condition Monitoring and Assessment For Rotating MachineryDocument22 pagesCondition Monitoring and Assessment For Rotating MachineryMohamed KhaledNo ratings yet

- Vibration Analysis & Diagnostic StudiesDocument42 pagesVibration Analysis & Diagnostic Studiessoumya ranjan sahooNo ratings yet

- Libyan Academy of Graduate StudyDocument42 pagesLibyan Academy of Graduate StudysamobuNo ratings yet

- Machine Evaluator Series: Advanced Handheld Condition Monitoring InstrumentDocument12 pagesMachine Evaluator Series: Advanced Handheld Condition Monitoring InstrumentMohd Bahruddin Ab GhaparNo ratings yet

- Permanently Installed SensorsDocument2 pagesPermanently Installed SensorsrodrurenNo ratings yet

- On-Line and In-Line Wear Debris Detectors - What's Out ThereDocument15 pagesOn-Line and In-Line Wear Debris Detectors - What's Out ThereMahnooshNo ratings yet

- Vibration Analysis of Production Unit by Using Mechanical StethoscopeDocument67 pagesVibration Analysis of Production Unit by Using Mechanical Stethoscopek eswariNo ratings yet

- Vibration StandardDocument15 pagesVibration Standardelrajil100% (2)

- Vibration Analysis of Siemens v94 Gas TurbineDocument10 pagesVibration Analysis of Siemens v94 Gas TurbinepholippNo ratings yet

- Ijmet: International Journal of Mechanical Engineering and Technology (Ijmet)Document8 pagesIjmet: International Journal of Mechanical Engineering and Technology (Ijmet)IAEME PublicationNo ratings yet

- Dignostic Mode VibrationDocument1 pageDignostic Mode Vibrationphoneme79No ratings yet

- CBM Tools For Equipment Failure PreventionDocument8 pagesCBM Tools For Equipment Failure PreventionNabil Al-KhirdajiNo ratings yet

- Vibration Analysis, Control and Optimum Accelerometer Placement For Successful Vibrations TestsDocument44 pagesVibration Analysis, Control and Optimum Accelerometer Placement For Successful Vibrations TestsVyankatesh AshtekarNo ratings yet

- Condition Monitoring by Vibration AnalysisDocument147 pagesCondition Monitoring by Vibration Analysisyanc100% (1)

- ST101 in A PDM ProgramDocument4 pagesST101 in A PDM Programho-faNo ratings yet

- Diesel Engine Fault Detection Using VibrDocument8 pagesDiesel Engine Fault Detection Using VibrRahmid Farezi 1707111363No ratings yet

- Phase 2 ReportDocument20 pagesPhase 2 ReportSusheel PoonjaNo ratings yet

- Good Vibes About Oil AnalysisDocument11 pagesGood Vibes About Oil AnalysisFerdian Farouq FNo ratings yet

- Vibration Workshop OptDocument84 pagesVibration Workshop OptOlusegun Olugbade100% (2)

- Predictive Maintenance: Condition Monitoring (Or, Colloquially, CM) Is The Process of Monitoring A Parameter ofDocument19 pagesPredictive Maintenance: Condition Monitoring (Or, Colloquially, CM) Is The Process of Monitoring A Parameter ofSaman MazharNo ratings yet

- Vibration Sensors Are Essential To Maintaining Machine HealthDocument3 pagesVibration Sensors Are Essential To Maintaining Machine HealthMarcelo TeixeiraNo ratings yet

- Evaluating Installation of Vibration Monitoring Equipment For Gas TurbinesDocument51 pagesEvaluating Installation of Vibration Monitoring Equipment For Gas TurbinesReshmi VinuNo ratings yet

- Online Condition Monitoring of Spur GearsDocument8 pagesOnline Condition Monitoring of Spur GearsjeyaselvanmNo ratings yet

- Making CBM Effective: A Guide To Condition-Based Monitoring Programs, and in Particular, Ultrasound DetectionDocument2 pagesMaking CBM Effective: A Guide To Condition-Based Monitoring Programs, and in Particular, Ultrasound DetectionLuisAlbarranNo ratings yet

- Thesis VADocument2 pagesThesis VAkrishnaNo ratings yet

- Vanaken AbsDocument5 pagesVanaken AbsGul sher BalochNo ratings yet

- Chapter 1Document34 pagesChapter 1Abdelrahman KassmNo ratings yet

- Machine Condition Monitoring Technical Library - N - Apr.2014 - NIDocument4 pagesMachine Condition Monitoring Technical Library - N - Apr.2014 - NIHmidaNo ratings yet

- Predictive Maintenance: What Is It, Tools, and Applications (Complete Guide 2021) - Infraspeak BlogDocument13 pagesPredictive Maintenance: What Is It, Tools, and Applications (Complete Guide 2021) - Infraspeak BlogShivaji ThubeNo ratings yet

- Condition Based MaintenaceDocument27 pagesCondition Based MaintenaceRitwik AravindNo ratings yet

- Bearing Condition Monitoring Using Vibration SignatureDocument7 pagesBearing Condition Monitoring Using Vibration SignaturemarnalaNo ratings yet

- Gas Turbine Blade Quality Inspection: Using NDT Resonant Acoustic MethodDocument20 pagesGas Turbine Blade Quality Inspection: Using NDT Resonant Acoustic MethodalirezaNo ratings yet

- Research Area 6Document14 pagesResearch Area 6OKIDI Thomas BecketNo ratings yet

- Converting Tribology Based Condition Monitoring Into Measurable Maintenance ResultsDocument12 pagesConverting Tribology Based Condition Monitoring Into Measurable Maintenance ResultsddadaraNo ratings yet

- Redictive Aintenance: Predictive Maintenance 99Document4 pagesRedictive Aintenance: Predictive Maintenance 99COE201No ratings yet

- Automation ProcessDocument3 pagesAutomation Processwwr.tonboomzNo ratings yet

- Monitoring Gear DrivesDocument4 pagesMonitoring Gear DrivesakhilsaNo ratings yet

- Freelander 2 ACDocument5 pagesFreelander 2 ACJim LiebNo ratings yet

- Vibration Based Condition Monitoring of Rotating MDocument18 pagesVibration Based Condition Monitoring of Rotating MNidhal Ben KhalifaNo ratings yet

- SB 21-0-105Document5 pagesSB 21-0-105jussmeeeNo ratings yet

- SB3 0 120Document2 pagesSB3 0 120jussmeeeNo ratings yet

- SB 3-1-103Document19 pagesSB 3-1-103jussmeeeNo ratings yet

- Service BulletinDocument9 pagesService BulletinjussmeeeNo ratings yet

- SB3 1 101Document3 pagesSB3 1 101jussmeeeNo ratings yet

- SB3 1 100Document10 pagesSB3 1 100jussmeeeNo ratings yet

- SB 7-4-102Document2 pagesSB 7-4-102jussmeeeNo ratings yet

- SB3 1 102Document6 pagesSB3 1 102jussmeeeNo ratings yet

- SB 7-4-104Document8 pagesSB 7-4-104jussmeeeNo ratings yet

- SB3 0 115 - NCDocument4 pagesSB3 0 115 - NCjussmeeeNo ratings yet

- SB3 3-111Document4 pagesSB3 3-111jussmeeeNo ratings yet

- Solar SB 14-039Document3 pagesSolar SB 14-039jussmeeeNo ratings yet

- Solar SB 15-007Document3 pagesSolar SB 15-007jussmeeeNo ratings yet

- SB 7-1-106Document2 pagesSB 7-1-106jussmeeeNo ratings yet

- Solar SB 16-002Document3 pagesSolar SB 16-002jussmeeeNo ratings yet

- SB 7-4-101Document2 pagesSB 7-4-101jussmeeeNo ratings yet

- Solar SB 19-0-100Document3 pagesSolar SB 19-0-100jussmeeeNo ratings yet

- Solar SB 15-015Document2 pagesSolar SB 15-015jussmeeeNo ratings yet

- SB 7-1-107Document8 pagesSB 7-1-107jussmeeeNo ratings yet

- Solar SB 15-010Document5 pagesSolar SB 15-010jussmeeeNo ratings yet

- Solar SB 14-035Document3 pagesSolar SB 14-035jussmeeeNo ratings yet

- Solar SB 14-044Document3 pagesSolar SB 14-044jussmeeeNo ratings yet

- Solar SB 14-043Document14 pagesSolar SB 14-043jussmeeeNo ratings yet

- Solar SB 14-032Document6 pagesSolar SB 14-032jussmeeeNo ratings yet

- Solar SB 14-038Document2 pagesSolar SB 14-038jussmeeeNo ratings yet

- Service BulletinDocument20 pagesService BulletinjussmeeeNo ratings yet

- Service Bulletin: Service Bulletin NUMBER: 22.0/101 Caterpillar: Confidential Green Page 1 of 3Document3 pagesService Bulletin: Service Bulletin NUMBER: 22.0/101 Caterpillar: Confidential Green Page 1 of 3jussmeeeNo ratings yet

- Solar SB 21-0-109Document3 pagesSolar SB 21-0-109jussmeeeNo ratings yet

- 22 0 100 - NCDocument7 pages22 0 100 - NCjussmeeeNo ratings yet

- Service Bulletin: Subject: Turbine Package Electrical System Test KitDocument4 pagesService Bulletin: Subject: Turbine Package Electrical System Test KitjussmeeeNo ratings yet

- Listening 5Document5 pagesListening 5Trung Nguyên PhanNo ratings yet

- Final Draft en Iso Fdis 15548-2 - 2007Document39 pagesFinal Draft en Iso Fdis 15548-2 - 2007gorkembaytenNo ratings yet

- Electrical MeasurementsDocument236 pagesElectrical Measurementsrajkumar100% (2)

- No - Ntnu Inspera 2190000Document75 pagesNo - Ntnu Inspera 2190000okifabianNo ratings yet

- CFD BasicsDocument63 pagesCFD BasicssivivargheseNo ratings yet

- How Good Are 2D Transistors? An Application-Specific Benchmarking StudyDocument8 pagesHow Good Are 2D Transistors? An Application-Specific Benchmarking StudyOmar HMNo ratings yet

- Salami Catalog vdm8 PDFDocument38 pagesSalami Catalog vdm8 PDFHeather Murphy0% (1)

- PDF Download For JEE Advanced Previous Year Questions With Solutions On GravitationDocument7 pagesPDF Download For JEE Advanced Previous Year Questions With Solutions On GravitationGeetha NNo ratings yet

- Model F156 EC Extended Coverage Pendent Sprinkler Model F156 EC Recessed Extended Coverage Sprinkler With Model F1, F2 & FP EscutcheonDocument4 pagesModel F156 EC Extended Coverage Pendent Sprinkler Model F156 EC Recessed Extended Coverage Sprinkler With Model F1, F2 & FP EscutcheonJonathan Uribe0% (1)

- Astm C131-06 PDFDocument4 pagesAstm C131-06 PDFAshraf Tomizeh100% (1)

- The First Law of Thermodynamics An IntroductionDocument6 pagesThe First Law of Thermodynamics An IntroductionNarayanan SubramanianNo ratings yet

- Instant Download Test Bank For Options Futures and Other Derivatives 8th Edition by Hull PDF FullDocument32 pagesInstant Download Test Bank For Options Futures and Other Derivatives 8th Edition by Hull PDF Fulloweltyswiller.28sh100% (17)

- SAMPLE Examination in Teaching Mathematics in The Primary GradesDocument3 pagesSAMPLE Examination in Teaching Mathematics in The Primary GradesWindel Q. BojosNo ratings yet

- Rolling Element Bearings Vibration AnalysisDocument10 pagesRolling Element Bearings Vibration Analysisi.kamalNo ratings yet

- Homework Packet - Unit 3 PDFDocument6 pagesHomework Packet - Unit 3 PDFPhoebe LinNo ratings yet

- Energy and Matter Study GuideDocument3 pagesEnergy and Matter Study GuideNorlijun HilutinNo ratings yet

- Diffusion Based Representation LearningDocument20 pagesDiffusion Based Representation Learningmarkus.aureliusNo ratings yet

- Tcu11 11prDocument3 pagesTcu11 11prPierre BerkshireNo ratings yet

- Dirac Delta FuctionDocument4 pagesDirac Delta Fuctionreky_georgeNo ratings yet

- ME463 Plate3 CapulDocument9 pagesME463 Plate3 CapulJuvy Lyka CapulNo ratings yet

- Math ReaderDocument563 pagesMath ReaderNeidyNo ratings yet

- C3 Integration - AreasDocument7 pagesC3 Integration - AreasAhmed MohamedNo ratings yet

- Crop Water ManagementDocument69 pagesCrop Water ManagementAyadiegwu PeterNo ratings yet

- IntroductionDocument17 pagesIntroductionRamish SaeedNo ratings yet

- DPWH - Cabangahan - Tago Road - Surigao Del Sur - BH LogDocument10 pagesDPWH - Cabangahan - Tago Road - Surigao Del Sur - BH LogNoeme QuinalaganNo ratings yet

- Quadri GageDocument2 pagesQuadri GageKeron TrotzNo ratings yet

- Problems Chapter 2Document26 pagesProblems Chapter 2Babar Ali100% (1)

- Raise Productivity With Tungsten Carbide InsertsDocument20 pagesRaise Productivity With Tungsten Carbide InsertsJackChanNo ratings yet

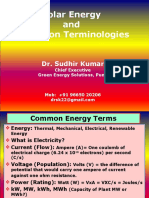

- Solar Energy and Radiation Terminologies: Dr. Sudhir KumarDocument24 pagesSolar Energy and Radiation Terminologies: Dr. Sudhir KumarAyman OsamaNo ratings yet

Service Bulletin: Subject: Lube Oil and Vibration Analysis Programs

Service Bulletin: Subject: Lube Oil and Vibration Analysis Programs

Uploaded by

jussmeeeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Bulletin: Subject: Lube Oil and Vibration Analysis Programs

Service Bulletin: Subject: Lube Oil and Vibration Analysis Programs

Uploaded by

jussmeeeCopyright:

Available Formats

SERVICE BULLETIN

NOTICE: The Type of Change and Recommended Compliance specified reflects Solar’s best judgment regarding the

Service Bulletin. All questions should be directed to your Solar Field Service Representative. Solar, Saturn,

Centaur, Taurus, Mercury, Mars, Titan, SoLoNOx, and Turbotronic are trademarks of Solar Turbines Incorporated.

Cat and Caterpillar are trademarks of Caterpillar Inc. Specifications subject to change without notice.

NUMBER: 1.0/110

ISSUED: January 1987

REVISED:

PRODUCT: All

MODEL(S): All

Specifics:

SUBJECT: LUBE OIL AND VIBRATION ANALYSIS PROGRAMS

Type of Change: Product Information

Recommended

Compliance: Information

Purpose:

To announce the availability of customized Lube Oil and Vibration Analysis Programs for machin-

ery condition monitoring.

GENERAL INFORMATION:

Many turbomachinery owners are seeking ways of reducing the cost of owning and operating their

machinery, while maximizing its useful life. Increasing interest has been shown in machinery health

and condition monitoring, with various types of lube oil analyses and vibration analyses being key

parts of these programs.

Several different types of oil and vibration analyses offer various means of detecting and diagnosing

of machine faults before they become critical. This provides more information on the true internal

condition of the machine, which in turn helps to achieve timely and accurate maintenance planning.

The goal is to reduce unscheduled downtime and maintenance, avoid component failures, and re-

duce long-term overhaul costs.

In addition to our Inspection Services Programs (designed for standby power generation applica-

tions), and our Contract Maintenance Programs (for continuous duty applications), Solar offers a

SERVICE BULLETIN Page 1 of 3

NUMBER: 1.0/110

variety of customized oil analysis and vibration analysis services. These are briefly described be-

low.

Spectrographic Oil Analysis

Spectrographic analysis of lube oil has been widely used for a number of years in machinery con-

dition monitoring. Oil samples are periodically taken from a machine in a prescribed manner, and

are sent to a laboratory for analysis. At the lab, a spectrometer is utilized to vaporize a portion of

the sample. The light emitted during this process is optically broken down to reveal the spectro-

graphic signature of selected chemical elements. A printout is made showing the quantity, in parts

per million, of each element present in the sample. Examination of these analyses provides valuable

information concerning the wear occurring within the machine and the condition of the oil itself.

Other tests are performed to determine the presence of water in the oil, fuel dilution, and such im-

portant physical properties as viscosity and acidity.

The key to spectrographic analysis lies in the determination of changes in the signature over a

period of time. Each individual machine will have its own signature, and broad classes of machine

types display different patterns in the levels of selected wear elements. In addition to providing a

printed report of the laboratory analysis, Solar offers the advantages of data interpretation and trend

analysis based on in-depth knowledge of our machinery, gained through many years of experience.

A spectrographic oil analysis program is a valuable and cost effective tool for machinery condition

monitoring, especially when used in conjunction with other techniques such as vibration analysis.

Ferrographic Oil Analysis

Ferrography is a technology used to analyze wear particles found in lubricating oil, as opposed to

analysis of the oil itself. A laboratory device uses a strong magnetic field to produce a "ferrogram",

a special glass slide. A bichromatic microscope is then used to examine the particles deposited on

the slide. These particles (both ferrous and non-ferrous) are photographed and visually classified

according to their number, size, shape, and distribution. Analysis of the results can provide valuable

information as to the wear mechanisms present in the machine, and can be used to detect abnormal

wear rates.

Examples of the types of particles include normal wear and cutting wear particles, fatigue chunks,

microscopic spheres caused by roller bearing fatigue, and non-metallic polymers.

Ferrographic analysis has proven to be a useful diagnostic tool, especially when other techniques

(spectrographic analysis, vibration analysis) indicate a potential problem.

Vibration Analysis

In addition to permanently installed hardware which allows for on-line Vibration Monitoring and

microprocessor-based Condition Monitoring, Solar offers a variety of vibration analysis services.

Page 2 of 3 SERVICE BULLETIN

NUMBER: 1.0/110

These range from periodic surveys using a simple hand-held device to highly sophisticated real-

time spectrum analysis. Vibration analysis has proven to be one of the most valuable techniques

for detecting, diagnosing, and correcting a number of machine faults in the field. Examples include

imbalance, misalignment, gear and bearing defects, impending oil pump failures, oil whirl, and

others.

While the use of hand-held vibration transducers and simple instrumentation allows the detection of

many adverse conditions, a significantly increased capability is afforded by our Spectral Analysis

program. Under this program, each machine is first prepared in a way that allows specially selected

vibration transducers to be hard-mounted at key locations on the machine. During each periodic

survey, the transducers are attached to the machine, and their signals are processed using a real-

time analyzer. A series of vibration plots are produced. Analysis of these plots allows sophisticated

examination of the machine’s vibration profile.

Besides gathering the vibration data, Solar offers the benefits of years of experience by providing in-

depth interpretation and trending of the data, as well as appropriate recommendations for follow-up

action.

The specific type and frequency of vibration surveys recommended depends on many factors, in-

cluding the site conditions, operational tempo, and others. Our Customer Services staff can assist

in evaluating these factors to design a customized, cost-effective program for vibration analysis.

ACTION REQUIRED:

It is recommended that your current maintenance and machinery condition monitoring program

be examined. Consideration should be given to incorporating oil and vibration analysis into your

program on a regular, periodic basis. Solar’s District Service Manager or Customer Services Sales

Representative in your area can assist you by providing additional information, and in the develop-

ment of a program designed to meet your unique operating requirements.

SERVICE BULLETIN Page 3 of 3

NUMBER: 1.0/110

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Proven Method For Specifying Both Six Spectral Alarm Bands As Well As Narrowband Alarm EnvelopesDocument4 pagesProven Method For Specifying Both Six Spectral Alarm Bands As Well As Narrowband Alarm EnvelopesVILLANUEVA_DANIEL2064No ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Is My Machine OK?: A Field Guide to Assessing Process MachineryFrom EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryNo ratings yet

- Mathematics: Practice TestDocument8 pagesMathematics: Practice TestJeni100% (3)

- Gas Turbine ModelsDocument11 pagesGas Turbine ModelsEngr Mubeen100% (1)

- E 2412Document24 pagesE 2412Asep Thea100% (4)

- Integrating Vibration and Oil Analysis For Machine Condition MonitoringDocument10 pagesIntegrating Vibration and Oil Analysis For Machine Condition MonitoringAnda WahyudiNo ratings yet

- SKF - Tech Associates of CharlotteDocument57 pagesSKF - Tech Associates of Charlotteiatorres100% (5)

- Machine Condition Monitoring and Fault DiagnosticsDocument28 pagesMachine Condition Monitoring and Fault Diagnosticsزيد فؤاد اليافعيNo ratings yet

- WSN 91 2018 31 43Document13 pagesWSN 91 2018 31 43jerome okoyeNo ratings yet

- Vibration AnalysisDocument34 pagesVibration AnalysisImaduddin ShaNo ratings yet

- UCM Brochure 01272020Document4 pagesUCM Brochure 01272020Brian CareelNo ratings yet

- HP-DSA Aplication Note 243-1Document42 pagesHP-DSA Aplication Note 243-1Andres Felipe Loaiza PatiñoNo ratings yet

- Chapter 2 - Vibration Analysis Applications PDFDocument3 pagesChapter 2 - Vibration Analysis Applications PDFpanxo90007No ratings yet

- Oil Debris Analysis For Condition Monitoring of An IC EngineDocument3 pagesOil Debris Analysis For Condition Monitoring of An IC EngineJaime BerryNo ratings yet

- Designing of Indigenous Monitoring SystemDocument16 pagesDesigning of Indigenous Monitoring SystemNasir AbdullahNo ratings yet

- Lubricant Condition Monitoring: Why The Lubricants MonitoringDocument14 pagesLubricant Condition Monitoring: Why The Lubricants Monitoringrbdubey2020No ratings yet

- Vibration Analysis Applications: 2.1 Equipment and Processes Typical0 Monitored by Viiration AnalysisDocument3 pagesVibration Analysis Applications: 2.1 Equipment and Processes Typical0 Monitored by Viiration AnalysisVasile RaduNo ratings yet

- Assignment 2 CMDocument7 pagesAssignment 2 CMAhmad RazaNo ratings yet

- Fluidscan Handheld Lubricant Condition MonitorDocument11 pagesFluidscan Handheld Lubricant Condition MonitormancjaNo ratings yet

- Condition Monitoring and Assessment For Rotating MachineryDocument22 pagesCondition Monitoring and Assessment For Rotating MachineryMohamed KhaledNo ratings yet

- Vibration Analysis & Diagnostic StudiesDocument42 pagesVibration Analysis & Diagnostic Studiessoumya ranjan sahooNo ratings yet

- Libyan Academy of Graduate StudyDocument42 pagesLibyan Academy of Graduate StudysamobuNo ratings yet

- Machine Evaluator Series: Advanced Handheld Condition Monitoring InstrumentDocument12 pagesMachine Evaluator Series: Advanced Handheld Condition Monitoring InstrumentMohd Bahruddin Ab GhaparNo ratings yet

- Permanently Installed SensorsDocument2 pagesPermanently Installed SensorsrodrurenNo ratings yet

- On-Line and In-Line Wear Debris Detectors - What's Out ThereDocument15 pagesOn-Line and In-Line Wear Debris Detectors - What's Out ThereMahnooshNo ratings yet

- Vibration Analysis of Production Unit by Using Mechanical StethoscopeDocument67 pagesVibration Analysis of Production Unit by Using Mechanical Stethoscopek eswariNo ratings yet

- Vibration StandardDocument15 pagesVibration Standardelrajil100% (2)

- Vibration Analysis of Siemens v94 Gas TurbineDocument10 pagesVibration Analysis of Siemens v94 Gas TurbinepholippNo ratings yet

- Ijmet: International Journal of Mechanical Engineering and Technology (Ijmet)Document8 pagesIjmet: International Journal of Mechanical Engineering and Technology (Ijmet)IAEME PublicationNo ratings yet

- Dignostic Mode VibrationDocument1 pageDignostic Mode Vibrationphoneme79No ratings yet

- CBM Tools For Equipment Failure PreventionDocument8 pagesCBM Tools For Equipment Failure PreventionNabil Al-KhirdajiNo ratings yet

- Vibration Analysis, Control and Optimum Accelerometer Placement For Successful Vibrations TestsDocument44 pagesVibration Analysis, Control and Optimum Accelerometer Placement For Successful Vibrations TestsVyankatesh AshtekarNo ratings yet

- Condition Monitoring by Vibration AnalysisDocument147 pagesCondition Monitoring by Vibration Analysisyanc100% (1)

- ST101 in A PDM ProgramDocument4 pagesST101 in A PDM Programho-faNo ratings yet

- Diesel Engine Fault Detection Using VibrDocument8 pagesDiesel Engine Fault Detection Using VibrRahmid Farezi 1707111363No ratings yet

- Phase 2 ReportDocument20 pagesPhase 2 ReportSusheel PoonjaNo ratings yet

- Good Vibes About Oil AnalysisDocument11 pagesGood Vibes About Oil AnalysisFerdian Farouq FNo ratings yet

- Vibration Workshop OptDocument84 pagesVibration Workshop OptOlusegun Olugbade100% (2)

- Predictive Maintenance: Condition Monitoring (Or, Colloquially, CM) Is The Process of Monitoring A Parameter ofDocument19 pagesPredictive Maintenance: Condition Monitoring (Or, Colloquially, CM) Is The Process of Monitoring A Parameter ofSaman MazharNo ratings yet

- Vibration Sensors Are Essential To Maintaining Machine HealthDocument3 pagesVibration Sensors Are Essential To Maintaining Machine HealthMarcelo TeixeiraNo ratings yet

- Evaluating Installation of Vibration Monitoring Equipment For Gas TurbinesDocument51 pagesEvaluating Installation of Vibration Monitoring Equipment For Gas TurbinesReshmi VinuNo ratings yet

- Online Condition Monitoring of Spur GearsDocument8 pagesOnline Condition Monitoring of Spur GearsjeyaselvanmNo ratings yet

- Making CBM Effective: A Guide To Condition-Based Monitoring Programs, and in Particular, Ultrasound DetectionDocument2 pagesMaking CBM Effective: A Guide To Condition-Based Monitoring Programs, and in Particular, Ultrasound DetectionLuisAlbarranNo ratings yet

- Thesis VADocument2 pagesThesis VAkrishnaNo ratings yet

- Vanaken AbsDocument5 pagesVanaken AbsGul sher BalochNo ratings yet

- Chapter 1Document34 pagesChapter 1Abdelrahman KassmNo ratings yet

- Machine Condition Monitoring Technical Library - N - Apr.2014 - NIDocument4 pagesMachine Condition Monitoring Technical Library - N - Apr.2014 - NIHmidaNo ratings yet

- Predictive Maintenance: What Is It, Tools, and Applications (Complete Guide 2021) - Infraspeak BlogDocument13 pagesPredictive Maintenance: What Is It, Tools, and Applications (Complete Guide 2021) - Infraspeak BlogShivaji ThubeNo ratings yet

- Condition Based MaintenaceDocument27 pagesCondition Based MaintenaceRitwik AravindNo ratings yet

- Bearing Condition Monitoring Using Vibration SignatureDocument7 pagesBearing Condition Monitoring Using Vibration SignaturemarnalaNo ratings yet

- Gas Turbine Blade Quality Inspection: Using NDT Resonant Acoustic MethodDocument20 pagesGas Turbine Blade Quality Inspection: Using NDT Resonant Acoustic MethodalirezaNo ratings yet

- Research Area 6Document14 pagesResearch Area 6OKIDI Thomas BecketNo ratings yet

- Converting Tribology Based Condition Monitoring Into Measurable Maintenance ResultsDocument12 pagesConverting Tribology Based Condition Monitoring Into Measurable Maintenance ResultsddadaraNo ratings yet

- Redictive Aintenance: Predictive Maintenance 99Document4 pagesRedictive Aintenance: Predictive Maintenance 99COE201No ratings yet

- Automation ProcessDocument3 pagesAutomation Processwwr.tonboomzNo ratings yet

- Monitoring Gear DrivesDocument4 pagesMonitoring Gear DrivesakhilsaNo ratings yet

- Freelander 2 ACDocument5 pagesFreelander 2 ACJim LiebNo ratings yet

- Vibration Based Condition Monitoring of Rotating MDocument18 pagesVibration Based Condition Monitoring of Rotating MNidhal Ben KhalifaNo ratings yet

- SB 21-0-105Document5 pagesSB 21-0-105jussmeeeNo ratings yet

- SB3 0 120Document2 pagesSB3 0 120jussmeeeNo ratings yet

- SB 3-1-103Document19 pagesSB 3-1-103jussmeeeNo ratings yet

- Service BulletinDocument9 pagesService BulletinjussmeeeNo ratings yet

- SB3 1 101Document3 pagesSB3 1 101jussmeeeNo ratings yet

- SB3 1 100Document10 pagesSB3 1 100jussmeeeNo ratings yet

- SB 7-4-102Document2 pagesSB 7-4-102jussmeeeNo ratings yet

- SB3 1 102Document6 pagesSB3 1 102jussmeeeNo ratings yet

- SB 7-4-104Document8 pagesSB 7-4-104jussmeeeNo ratings yet

- SB3 0 115 - NCDocument4 pagesSB3 0 115 - NCjussmeeeNo ratings yet

- SB3 3-111Document4 pagesSB3 3-111jussmeeeNo ratings yet

- Solar SB 14-039Document3 pagesSolar SB 14-039jussmeeeNo ratings yet

- Solar SB 15-007Document3 pagesSolar SB 15-007jussmeeeNo ratings yet

- SB 7-1-106Document2 pagesSB 7-1-106jussmeeeNo ratings yet

- Solar SB 16-002Document3 pagesSolar SB 16-002jussmeeeNo ratings yet

- SB 7-4-101Document2 pagesSB 7-4-101jussmeeeNo ratings yet

- Solar SB 19-0-100Document3 pagesSolar SB 19-0-100jussmeeeNo ratings yet

- Solar SB 15-015Document2 pagesSolar SB 15-015jussmeeeNo ratings yet

- SB 7-1-107Document8 pagesSB 7-1-107jussmeeeNo ratings yet

- Solar SB 15-010Document5 pagesSolar SB 15-010jussmeeeNo ratings yet

- Solar SB 14-035Document3 pagesSolar SB 14-035jussmeeeNo ratings yet

- Solar SB 14-044Document3 pagesSolar SB 14-044jussmeeeNo ratings yet

- Solar SB 14-043Document14 pagesSolar SB 14-043jussmeeeNo ratings yet

- Solar SB 14-032Document6 pagesSolar SB 14-032jussmeeeNo ratings yet

- Solar SB 14-038Document2 pagesSolar SB 14-038jussmeeeNo ratings yet

- Service BulletinDocument20 pagesService BulletinjussmeeeNo ratings yet

- Service Bulletin: Service Bulletin NUMBER: 22.0/101 Caterpillar: Confidential Green Page 1 of 3Document3 pagesService Bulletin: Service Bulletin NUMBER: 22.0/101 Caterpillar: Confidential Green Page 1 of 3jussmeeeNo ratings yet

- Solar SB 21-0-109Document3 pagesSolar SB 21-0-109jussmeeeNo ratings yet

- 22 0 100 - NCDocument7 pages22 0 100 - NCjussmeeeNo ratings yet

- Service Bulletin: Subject: Turbine Package Electrical System Test KitDocument4 pagesService Bulletin: Subject: Turbine Package Electrical System Test KitjussmeeeNo ratings yet

- Listening 5Document5 pagesListening 5Trung Nguyên PhanNo ratings yet

- Final Draft en Iso Fdis 15548-2 - 2007Document39 pagesFinal Draft en Iso Fdis 15548-2 - 2007gorkembaytenNo ratings yet

- Electrical MeasurementsDocument236 pagesElectrical Measurementsrajkumar100% (2)

- No - Ntnu Inspera 2190000Document75 pagesNo - Ntnu Inspera 2190000okifabianNo ratings yet

- CFD BasicsDocument63 pagesCFD BasicssivivargheseNo ratings yet

- How Good Are 2D Transistors? An Application-Specific Benchmarking StudyDocument8 pagesHow Good Are 2D Transistors? An Application-Specific Benchmarking StudyOmar HMNo ratings yet

- Salami Catalog vdm8 PDFDocument38 pagesSalami Catalog vdm8 PDFHeather Murphy0% (1)

- PDF Download For JEE Advanced Previous Year Questions With Solutions On GravitationDocument7 pagesPDF Download For JEE Advanced Previous Year Questions With Solutions On GravitationGeetha NNo ratings yet

- Model F156 EC Extended Coverage Pendent Sprinkler Model F156 EC Recessed Extended Coverage Sprinkler With Model F1, F2 & FP EscutcheonDocument4 pagesModel F156 EC Extended Coverage Pendent Sprinkler Model F156 EC Recessed Extended Coverage Sprinkler With Model F1, F2 & FP EscutcheonJonathan Uribe0% (1)

- Astm C131-06 PDFDocument4 pagesAstm C131-06 PDFAshraf Tomizeh100% (1)

- The First Law of Thermodynamics An IntroductionDocument6 pagesThe First Law of Thermodynamics An IntroductionNarayanan SubramanianNo ratings yet

- Instant Download Test Bank For Options Futures and Other Derivatives 8th Edition by Hull PDF FullDocument32 pagesInstant Download Test Bank For Options Futures and Other Derivatives 8th Edition by Hull PDF Fulloweltyswiller.28sh100% (17)

- SAMPLE Examination in Teaching Mathematics in The Primary GradesDocument3 pagesSAMPLE Examination in Teaching Mathematics in The Primary GradesWindel Q. BojosNo ratings yet

- Rolling Element Bearings Vibration AnalysisDocument10 pagesRolling Element Bearings Vibration Analysisi.kamalNo ratings yet

- Homework Packet - Unit 3 PDFDocument6 pagesHomework Packet - Unit 3 PDFPhoebe LinNo ratings yet

- Energy and Matter Study GuideDocument3 pagesEnergy and Matter Study GuideNorlijun HilutinNo ratings yet

- Diffusion Based Representation LearningDocument20 pagesDiffusion Based Representation Learningmarkus.aureliusNo ratings yet

- Tcu11 11prDocument3 pagesTcu11 11prPierre BerkshireNo ratings yet

- Dirac Delta FuctionDocument4 pagesDirac Delta Fuctionreky_georgeNo ratings yet

- ME463 Plate3 CapulDocument9 pagesME463 Plate3 CapulJuvy Lyka CapulNo ratings yet

- Math ReaderDocument563 pagesMath ReaderNeidyNo ratings yet

- C3 Integration - AreasDocument7 pagesC3 Integration - AreasAhmed MohamedNo ratings yet

- Crop Water ManagementDocument69 pagesCrop Water ManagementAyadiegwu PeterNo ratings yet

- IntroductionDocument17 pagesIntroductionRamish SaeedNo ratings yet

- DPWH - Cabangahan - Tago Road - Surigao Del Sur - BH LogDocument10 pagesDPWH - Cabangahan - Tago Road - Surigao Del Sur - BH LogNoeme QuinalaganNo ratings yet

- Quadri GageDocument2 pagesQuadri GageKeron TrotzNo ratings yet

- Problems Chapter 2Document26 pagesProblems Chapter 2Babar Ali100% (1)

- Raise Productivity With Tungsten Carbide InsertsDocument20 pagesRaise Productivity With Tungsten Carbide InsertsJackChanNo ratings yet

- Solar Energy and Radiation Terminologies: Dr. Sudhir KumarDocument24 pagesSolar Energy and Radiation Terminologies: Dr. Sudhir KumarAyman OsamaNo ratings yet