Professional Documents

Culture Documents

Explosion-Absorbing Panels and Wall Structures

Explosion-Absorbing Panels and Wall Structures

Uploaded by

ibrahim sugar0 ratings0% found this document useful (0 votes)

18 views5 pagesThis patent describes explosion-absorbing wall structures intended to reduce injuries from terrorist bombings. The walls consist of vertical metal pipes buried in the ground with horizontal pipes connecting them. Explosion-absorbing panels fill the spaces between the pipes. Unlike explosion-proof panels, these panels are designed to detach from the frame upon impact to absorb the shock of an explosion rather than remaining intact.

Original Description:

Original Title

Explosion-absorbing panels and wall structures

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes explosion-absorbing wall structures intended to reduce injuries from terrorist bombings. The walls consist of vertical metal pipes buried in the ground with horizontal pipes connecting them. Explosion-absorbing panels fill the spaces between the pipes. Unlike explosion-proof panels, these panels are designed to detach from the frame upon impact to absorb the shock of an explosion rather than remaining intact.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

18 views5 pagesExplosion-Absorbing Panels and Wall Structures

Explosion-Absorbing Panels and Wall Structures

Uploaded by

ibrahim sugarThis patent describes explosion-absorbing wall structures intended to reduce injuries from terrorist bombings. The walls consist of vertical metal pipes buried in the ground with horizontal pipes connecting them. Explosion-absorbing panels fill the spaces between the pipes. Unlike explosion-proof panels, these panels are designed to detach from the frame upon impact to absorb the shock of an explosion rather than remaining intact.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

USOO7380379B2

(12) United States Patent (10) Patent No.: US 7,380,379 B2

Venegas, Jr. (45) Date of Patent: Jun. 3, 2008

(54) EXPLOSION-ABSORBING PANELS AND Primary Examiner David Dunn

WALL STRUCTURES (74) Attorney, Agent, or Firm Gifford, Krass, Sprinkle,

Anderson & Citkowski, PC

(76) Inventor: Frank Venegas, Jr., 5682 Lake Ridge

Dr. Brighton, MI (US) 48116 (57) ABSTRACT

*) Notice: Subject to anyy disclaimer, the term of this This invention resides in explosion-resistant walls, panels

patent is extended or adjusted under 35 and partitions, particularly for use around buildings, works

U.S.C. 154(b) by 513 days. of art, public places, and so forth, and wherein, in certain

embodiments, may include textures and/or graphics to dis

(21) Appl. No.: 10/798,635 guise and/or beautify the structure. In terms of a typical

construction, the system includes a plurality of vertical

(22) Filed: Mar. 11, 2004 metal pipes, with a portion of each pipe being preferably

(65) Prior Publication Data

buried several feet below the ground surface, and a portion

of the pipe remains exposed above ground. Two or more

US 2007/O163189 A1 Jul. 19, 2007 horizontal metal pipes are interconnected to the vertical

metal pipes, creating apertures that are filled with explosion

(51) Int. Cl. absorbing panels. In contrast to “explosion-proof panels,

E04H 7/16 (2006.01) which require Sufficient strength to remain in tact in the

(52) U.S. Cl. ........................................... 52/222: 256/73 presence of a blast, the infill panels according to the inven

(58) Field of Classification Search .................. 256/73, tion Some form of attachment mechanism which "gives

256/24; 52/222, 741.3, 745.05, 1,98, 100 way’ in the presence of an explosion, thereby effectively

See application file for complete search history. absorbing the shock. In alternative embodiments, the infill

panels may be constructed of a fabric such Kevlar, or other

(56) References Cited material or mesh, which either deforms or breaks upon the

U.S. PATENT DOCUMENTS impact of a blast. Alternatively, a solid panel of metal or

even thick acrylic or other polymeric may be used, which

3,933,311 A 1/1976 Lemelson ................... 239,276 becomes detached from the frame structure upon impact, but

4,116,420 A 9/1978 Hazelett ...................... 256/24 does not get thrown in an uncontrolled manner. Rather,

4.225, 120 A * 9/1980 McLaughlin ................. 256/24 hinges or tethers keep the dislodged panels connected to the

4,269,004 A 5, 1981 Schiebroek frame structure. In the preferred embodiment, the pipes are

4,364,546 A * 12, 1982 Lyman et al. ................. 256/24 made of steel, and one or more of the pipes may be filled

4,502,812 A 3, 1985 Zucker

4,666,331 A 5/1987 Riley with a fortifying material. Such as cement. A cover may be

4,690,383 A * 9/1987 Batcheller .................... 256/24 provided to visually obscure the pipes. Such a cover may

4,769,191 A 9, 1988 Diana give the appearance of brick, cinder block, Stone or wood. In

4,818,137 A 4, 1989 GOrlov addition, the system may include a floral decorative element.

4,916,859 A 4, 1990 Butler For example, the infill panels may be die-cut or painted to

4,989,835 A 2, 1991 Hirsh look like foliage or the building or other environment the

5,026,203 A 6, 1991 Gorlov barrier is intended to protect.

5,123,773 A 6, 1992 Yodock

(Continued) 7 Claims, 1 Drawing Sheet

US 7,380,379 B2

Page 2

U.S. PATENT DOCUMENTS 6,062,765 A 5, 2000 Dotson

6,186.274 B1* 2/2001 Reynolds et al. ........... 182/138

5,152,508 A * 10, 1992 Fish ............................ 256/24 6,712,339 B1* 3/2004 Smith .......................... 256/10

5,213,312 A * 5/1993 MacDonald ... 256.26 2002fO184839 A1 12/2002 Emek

5,310,277 A 5, 1994 Uotila 2003/O127122 A1 7, 2003 Gower

5,402,988 A 4, 1995 Eisele ......................... 256/24 2003. O145534 A1 8/2003 Hojaji et al.

5,441,359 A 8/1995 Filippi 2003/0178614 A1* 9/2003 Venegas, Jr. ............... 256/651

5,628,495 A 5, 1997 Gandara ...................... 256/24 2003/0200716 A1 10, 2003 Manthel

5,651,635 A 7/1997 Nagle 2003/0210953 A1 11/2003 Williams et al.

5,746,538 A 5, 1998 Gunness 2003/0219308 A1 11/2003 Boulais et al.

5,961,099 A * 10/1999 Thommen, Jr. ............ 256,12.5

5,975,791 A 11/1999 McCulloch * cited by examiner

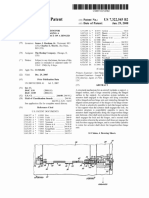

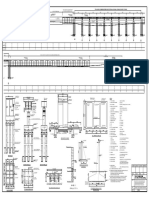

U.S. Patent Jun. 3, 2008 US 7,380,379 B2

102 102 102 102

504

202

104 2

104 104 104

Fig - 2 Fig - 3 Fig - 4 Fig - 5

US 7,380,379 B2

1. 2

EXPLOSION-ABSORBNG PANELS AND The window system is fitted with a blast energy absorbing

WALL STRUCTURES mechanism wherein the support members are formed with at

least one arm which at a mounted State of the Support frame,

FIELD OF THE INVENTION extends opposite a corresponding flange associated with the

frame, i.e. integral with the frame or otherwise articulated

This invention relates generally to shock- and explosion thereto. In accordance with an embodiment of the invention,

absorbing structures and, more particularly, to walls and the flange is a portion of the fixing members adapted for

panels for reducing injuries and casualties in the event of a engagement with a corresponding first arm of a Support

terrorist bombing or other threat. member. In accordance with a further embodiment of the

10 invention the flange is an extension of the frame adapted for

BACKGROUND OF THE INVENTION engagement with a corresponding second arm of a Support

member.

A dismantable protective window is disclosed in pub

Since the Sep. 11, 2001 attacks on the World Trade Center lished U.S. Patent Application No. 20020184839. By one

and Pentagon, there has been significant interest in provid particular embodiment of the invention, the Support mem

ing enhanced security around buildings and public places. 15

bers are bifurcated elements having a first arm and a second

One need is for barriers around buildings and other struc arm, which arms at a mounted State of the Support frame,

tures to prevent trucks and other vehicles, perhaps carrying extend opposite a corresponding portion of the fixing mem

explosives, or just intent upon inflicting damage, from bers and an extension flange of the frame. The arrangement

crashing into walls, and so forth. In addition to a need for is such that a shock wave striking the window pane gives

high-strength barriers of this kind, at the same time, Such rise to generation of forces acting in the plane of the window

structures should not be visually offensive, and indeed, it pane and orthogonally thereto, displacing the Support frame

would be beneficial if such barriers were aesthetically in an inward, radial direction, whereby the at least one arm

appealing, blending into the environment. of the Support members engage the corresponding flanges.

One solution is proposed in published U.S. Patent Appli

cation No. 2003/0127122, which teaches a flexible blast 25 SUMMARY OF THE INVENTION

curtain said to reduce casualties and property damage in the

event of a terrorist bombing by intercepting flying debris and This invention resides in explosion-resistant walls, panels

dissipating over pressure through deflection of the curtain. and partitions, particularly for use around buildings, works

The blast curtain may be attached directly to buildings or of art, public places, and so forth, and wherein, in certain

mounted on frames anchored in close proximity to build 30

embodiments, may include textures and/or graphics to dis

ings. The curtain provides complete visibility and easy guise and/or beautify the structure. In terms of a typical

pedestrian ingress and egress for the buildings. construction, the system includes a plurality of vertical

The curtain is in the form of a flexible barrier which is metal pipes, with a portion of each pipe being preferably

placed a distance out from the Surface to be protected. An buried several feet below the ground surface, and a portion

impacting missile stretches the barrier until it decelerates to of the pipe remains exposed above ground.

35

a stop or is deflected. The barrier material has a predeter Two or more horizontal metal pipes are interconnected to

mined tensile strength and stretch that makes it suitable for the vertical metal pipes, creating apertures that are filled

this application. The known strength and stretch, together with explosion-absorbing panels. In contrast to "explosion

with the speed, weight and size of the impacting missile, all proof panels, which require Sufficient strength to remain in

of which are given in test requirements, permit design tact in the presence of a blast, the infill panels according to

calculation to ascertain barrier deflection at impact. This 40 the invention some form of attachment mechanism which

deflection is a determinate of the minimum distance that this “gives way” in the presence of an explosion, thereby effec

barrier is to be spaced out from the frangible area to be tively absorbing the shock. In alternative embodiments, the

protected. infill panels may be constructed of a fabric such Kevlar, or

Published U.S. Patent Application No. 2003/0145534 other material or mesh, which either deforms or breaks upon

resides in a large, high-density foam glass tile which can be 45 the impact of a blast. Alternatively, a solid panel of metal or

used as a facade on both exterior and interior building walls. even thick acrylic or other polymeric may be used, which

The foam glass tile can also be used with other materials to becomes detached from the frame structure upon impact, but

form a panel or a composite. The invention may be used on does not get thrown in an uncontrolled manner. Rather,

the critical surfaces of buildings at high risk for terrorist hinges or tethers keep the dislodged panels connected to the

attacks, in combination with cement, Steel or other high frame structure.

50

strength building materials, and may also be used in Surfaces In the preferred embodiment, the pipes are made of steel,

of typical buildings. It purportedly has the advantage of and one or more of the pipes may be filled with a fortifying

absorbing a Substantial portion of a shock wave caused by an material. Such as cement. A cover may be provided to

explosion, while being more resistant to earthquakes. visually obscure the pipes. Such a cover may give the

According to published U.S. Patent Application No. 2003/ 55

appearance of brick, cinder block, Stone or wood. In addi

0200716, a wall is constructed from precast concrete blocks tion, the system may include a floral decorative element. For

stacked in tiers in which adjacent blocks are secured example, the infill panels may be die-cut or painted to look

together to increase the strength of the wall. Anchors are like foliage or the building or other environment the barrier

embedded in the tops of at least some of the blocks. The ends is intended to protect.

of the blocks have vertical grooves which form a vertical 60 BRIEF DESCRIPTION OF THE DRAWINGS

opening when the ends of two blocks abut. The blocks in the

tiers are offset so that the openings between blocks in one FIG. 1 illustrates the preferred embodiment of the present

tier are positioned above the anchors on the blocks on the

adjacent lower tier. The blocks in each tier are secured invention;

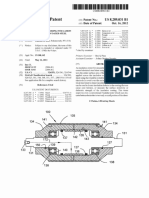

together by a tensioned cable extending through aligned FIG. 2 shows the way in which a panel may undergo

passages in the blocks. Locking members are placed in the 65 deformation in the presence of a blast;

openings to secure the ends of the abutting blocks to an FIG. 3 shows the way in which a panel may break in the

anchor in an adjacent lower block. presence of a blast;

US 7,380,379 B2

3 4

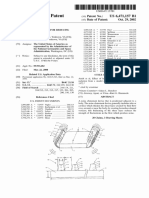

FIG. 4 shows an alternative embodiment including a hinge and absorb the blast. Although a certain level of

hinged panel; and maintenance would be required thereafter, this is certainly

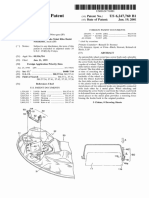

FIG. 5 shows yet a further alternative wherein a dislodged more acceptable than the alternative.

panel is retained with tethers. In a further preferred embodiment, a rigid panel 502 is

used, but instead of a hinge mechanism, tethers 504,506 are

DETAILED DESCRIPTION OF THE used to keep the panel 502 at least close to the barrier 102

INVENTION upon impact, in which case elements 508, 510 originally

holding the panel in place would become comprised or

FIG. 1 is a drawing of a preferred embodiment of the expelled. In a further alternative, the tethers 504, 506 may

invention, including a plurality of vertical tubular (i.e., Steel) 10 themselves be intended to break or rupture at a second,

members 102, interconnected by two or more horizontal higher level of shock, thereby resulting in further energy

members 104, 106, also preferably constructed of tubular absorption.

steel. The pipes may, or may not, be filled with other In terms of decorative features, the panels 202, 402, 504

strengthening materials, including cement. Preferably, the may either be solid, die-cut with a design, or clear in the case

vertical members are sunken several feet into the earth at a 15 of a rupturable safety glass or thick acrylic. If the panel or

distance "D' at least past the frost line, and surrounded and fabric is not transparent or semi-transparent, a design may be

filled in with cement or concrete. To further enhance secu die-cut or painted on the Surface, thereby resulting in an

rity, reinforcing elements or “re-rods’ may be used, as aesthetically pleasing, yet effective barrier system.

shown in pending U.S. patent application Ser. No. 10/427, I claim:

059, the entire content of which is incorporated herein by 1. An energy-absorbing barrier system, comprising:

reference. The height of the structure, indicated by “H” may a plurality of spaced-apart vertical metal pipes, each

range from a few feet to much higher, in which case 3 or buried below a ground Surface, leaving a portion

more horizontal members would preferably be used. exposed above ground;

The horizontal members 104, 106 are preferably welded two or more spaced-apart horizontal metal pipes inter

to the vertical members utilizing a saddle-type weld for the 25

connected to the vertical metal pipes creating at least

greatest strength. This creates rectangular apertures founded one infill area;

by the welded tubular members, and these are filled with a material spanning the infill area which is operative to

panels 110, 112 according to the invention. However, rather absorb at least a portion of the impact of an explosive

than these panels being strong enough to actually resist the

shock due to an explosion or bombing, they are meant to 30

blast;

give way in one manner or another according to the inven a material spanning the infill area being fastened to the

tion. In FIG. 1, the panels are held in position with break horizontal or vertical pipes with mounts that break

away brackets or clamp 120, 130, which, upon a predeter away upon a predetermined force; and

mined force, break away, allowing the panel to become a material spanning the infill area is tethered to one or

dislodged from the frame structure. If the barrier of FIG. 1 35 more of the horizontal or vertical pipes to keep the

is sufficiently far away from humans or buildings or other material from uncontrolled travel upon impact.

items to be protected, no tethering to the frame structure 2. The energy-absorbing barrier system of claim 1,

would be required. However, since it is desirable to place the wherein one or more of the pipes are filled with cement.

structure of FIG. 1 close to buildings and pedestrian traffic, 3. The energy-absorbing barrier system of claim 1,

a different break-away mechanisms are preferably used. 40 wherein the metal pipes are steel.

For example as shown in FIG. 2, a fabric or material such 4. The energy-absorbing barrier system of claim 1, further

as Kevlar or other shock-absorbing material is stretched including a plastic cover over one or more of the pipes.

between the members, and this becomes deformed upon 5. The energy-absorbing barrier system of claim 1,

impact. The deformation may be temporary or, as shown in wherein the material spanning the infill area is a fabric that

FIG. 3, it may be permanent, resulting in a rupture in 45 deforms to absorb energy.

separate pieces 302,304 which would need to be replaced. 6. The energy-absorbing barrier system of claim 1,

In the preferred embodiment, a Solid, heavy rigid panel wherein the material spanning the infill area ruptures to

402 is used, which could be plate steel or the like. In the absorb energy.

alternative, a thick clear acrylic, or safety glass could 7. The energy-absorbing barrier system of claim 1,

alternatively be utilized. In Such a case, a panel would 50 wherein the material spanning the infill area is hinged to a

preferably be hinged at 404, such that upon a sufficiently horizontal pipe to Swing upon impact.

large blast, a bracket or retaining member 406 would

become comprised or expelled, allowing the panel 402 to k k k k k

You might also like

- FM Data Sheet 2-0Document115 pagesFM Data Sheet 2-0HESuarez82% (11)

- Bill of Quantity: S.N. Items of Work Qty. Unit Rate Amount (A) - Civil WorkDocument30 pagesBill of Quantity: S.N. Items of Work Qty. Unit Rate Amount (A) - Civil WorkRatnesh PatelNo ratings yet

- United States Patent (10) Patent No.: US 8,209,912 B2Document14 pagesUnited States Patent (10) Patent No.: US 8,209,912 B2pmurphNo ratings yet

- United States Patent (10) Patent No.: US 8,151,529 B2: Weidmann Et Al. (45) Date of Patent: Apr. 10, 2012Document9 pagesUnited States Patent (10) Patent No.: US 8,151,529 B2: Weidmann Et Al. (45) Date of Patent: Apr. 10, 2012Akshay GamreNo ratings yet

- United States Patent: (12) (10) Patent No.: US 8,122,648 B1Document17 pagesUnited States Patent: (12) (10) Patent No.: US 8,122,648 B1Jie99No ratings yet

- United States Patent (10) Patent No.: Us 7,799,187 B2: Dimilia Et Al. (45) Date of Patent: Sep. 21, 2010Document6 pagesUnited States Patent (10) Patent No.: Us 7,799,187 B2: Dimilia Et Al. (45) Date of Patent: Sep. 21, 2010turnipNo ratings yet

- Capacitive Discharge Plasma Ion SourceDocument37 pagesCapacitive Discharge Plasma Ion SourceVEDANAND BELUTNo ratings yet

- United States Patent (10) Patent No.: US 6,282,863 B1: Christian Et Al. (45) Date of Patent: Sep. 4, 2001Document20 pagesUnited States Patent (10) Patent No.: US 6,282,863 B1: Christian Et Al. (45) Date of Patent: Sep. 4, 2001Munir KadernaniNo ratings yet

- Superalloy Mortartube Us7963202Document10 pagesSuperalloy Mortartube Us7963202Adnan ColoNo ratings yet

- United States Patent (10) Patent No.: US 7.587,842 B2: Tajiri Et Al. (45) Date of Patent: Sep. 15, 2009Document11 pagesUnited States Patent (10) Patent No.: US 7.587,842 B2: Tajiri Et Al. (45) Date of Patent: Sep. 15, 2009emre yıldırımNo ratings yet

- Reducing The Core-End Heating in Large Power GeneratorsDocument12 pagesReducing The Core-End Heating in Large Power GeneratorsMichal KowalczykNo ratings yet

- United States Patent: (75) Inventors: Jeffrey H. Wood, Eureka, MO (US)Document14 pagesUnited States Patent: (75) Inventors: Jeffrey H. Wood, Eureka, MO (US)Clóvis FerreiraNo ratings yet

- CC Relief DoorDocument7 pagesCC Relief DoorHim SatiNo ratings yet

- Structral Design For Solar Cana SDocument15 pagesStructral Design For Solar Cana SAliyana ShresthaNo ratings yet

- United States Patent: (12) (10) Patent No.: US 8,075,651 B2Document11 pagesUnited States Patent: (12) (10) Patent No.: US 8,075,651 B2maaathanNo ratings yet

- US8398905Document9 pagesUS8398905Ator VastatinNo ratings yet

- United States Patent (10) Patent No.: US 7,490,539 B2: Ma (45) Date of Patent: Feb. 17, 2009Document18 pagesUnited States Patent (10) Patent No.: US 7,490,539 B2: Ma (45) Date of Patent: Feb. 17, 2009Mary HullNo ratings yet

- United States Patent (10) Patent No.: US 8.263,231 B2Document13 pagesUnited States Patent (10) Patent No.: US 8.263,231 B2Alexander Franco CastrillonNo ratings yet

- US8069593Document9 pagesUS8069593PUVAN TSTNo ratings yet

- US7229140Document11 pagesUS7229140Baiuliang BaiuliangNo ratings yet

- United States Patent: GuirgisDocument11 pagesUnited States Patent: Guirgisamd mhmNo ratings yet

- United States Patent: Price (45) Date of Patent: Apr. 22, 2008Document11 pagesUnited States Patent: Price (45) Date of Patent: Apr. 22, 2008Aslam KhanNo ratings yet

- US7094341Document31 pagesUS7094341Diego RossoNo ratings yet

- Us 8172076Document6 pagesUs 8172076AdailsonNo ratings yet

- United States Patent: (10) Patent N0.: (45) Date of PatentDocument7 pagesUnited States Patent: (10) Patent N0.: (45) Date of PatentShameekaNo ratings yet

- United States Patent (10) Patent No.: US 8,102,071 B2Document52 pagesUnited States Patent (10) Patent No.: US 8,102,071 B2Marlon MataNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,322,545 B2Document13 pagesUnited States Patent: (12) (10) Patent No.: US 7,322,545 B2rakkaNo ratings yet

- United States Patent (10) Patent No.: US 7.498,471 B2: Schultz Et Al. (45) Date of Patent: Mar. 3, 2009Document7 pagesUnited States Patent (10) Patent No.: US 7.498,471 B2: Schultz Et Al. (45) Date of Patent: Mar. 3, 2009m yusuf syafzaNo ratings yet

- A New Apparatus For Surface Insulation Test On Crgo SheetsDocument13 pagesA New Apparatus For Surface Insulation Test On Crgo SheetsipraoNo ratings yet

- United States Patent (10) Patent No.: US 7,207,268 B2: Brunst (45) Date of Patent: Apr. 24, 2007Document8 pagesUnited States Patent (10) Patent No.: US 7,207,268 B2: Brunst (45) Date of Patent: Apr. 24, 2007Quý Đình Mai MaiNo ratings yet

- United States Patent (10) Patent No.: US 7.562,614 B2: Polston (45) Date of Patent: Jul. 21, 2009Document22 pagesUnited States Patent (10) Patent No.: US 7.562,614 B2: Polston (45) Date of Patent: Jul. 21, 2009Слэйтер Строительная компанияNo ratings yet

- US6485553Document5 pagesUS6485553Marm246247 AlloyNo ratings yet

- United States Patent (10) Patent No.: US 6,439,110 B1: Lin (45) Date of Patent: Aug. 27, 2002Document5 pagesUnited States Patent (10) Patent No.: US 6,439,110 B1: Lin (45) Date of Patent: Aug. 27, 2002BobNo ratings yet

- Us7390970 PDFDocument9 pagesUs7390970 PDFabiliovieiraNo ratings yet

- United States Patent (10) Patent No.: US 9,038,332 B1Document17 pagesUnited States Patent (10) Patent No.: US 9,038,332 B1ibrahim sugarNo ratings yet

- United States Patent: (10) Patent No.: US 6,974,554 B2Document8 pagesUnited States Patent: (10) Patent No.: US 6,974,554 B2Vansala GanesanNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7.225,900 B2Document8 pagesUnited States Patent: (12) (10) Patent No.: US 7.225,900 B2flavioNo ratings yet

- United States Patent (10) Patent No.: US 6,471,157 B1: Streett Et Al. (45) Date of Patent: Oct. 29, 2002Document8 pagesUnited States Patent (10) Patent No.: US 6,471,157 B1: Streett Et Al. (45) Date of Patent: Oct. 29, 2002155No ratings yet

- N, N 3 Gé28 G 3 Z2%at: (12) United States Patent (10) Patent No.: US 6,877,682 B2Document14 pagesN, N 3 Gé28 G 3 Z2%at: (12) United States Patent (10) Patent No.: US 6,877,682 B2tmNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument22 pagesUnited States Patent: (10) Patent No.: (45) Date of Patent63No ratings yet

- Laminated ManufactureDocument9 pagesLaminated Manufactureconfused597No ratings yet

- United States Patent (19) : Aerospatiale, FranceDocument7 pagesUnited States Patent (19) : Aerospatiale, Franceingeniomeca8800No ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument11 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentMANo ratings yet

- Us 6651961Document13 pagesUs 6651961Huy Nguyễn Võ XuânNo ratings yet

- United States Patent (10) Patent No.: US 7,759,419 B2: Stoffer Et Al. (45) Date of Patent: Jul. 20, 2010Document24 pagesUnited States Patent (10) Patent No.: US 7,759,419 B2: Stoffer Et Al. (45) Date of Patent: Jul. 20, 2010Alexander Franco CastrillonNo ratings yet

- United States Patent (10) Patent No.: US 8,821,069 B2Document13 pagesUnited States Patent (10) Patent No.: US 8,821,069 B2AnonyNo ratings yet

- United States Patent (10) Patent No.: US 6,921,304 B2: Hewitt (45) Date of Patent: Jul. 26, 2005Document17 pagesUnited States Patent (10) Patent No.: US 6,921,304 B2: Hewitt (45) Date of Patent: Jul. 26, 2005shruti kapseNo ratings yet

- United States Patent (10) Patent No.: US 7.467,604 B1: Werner Et Al. (45) Date of Patent: Dec. 23, 2008Document22 pagesUnited States Patent (10) Patent No.: US 7.467,604 B1: Werner Et Al. (45) Date of Patent: Dec. 23, 2008BobNo ratings yet

- Cleaning and Polishing CompoundDocument9 pagesCleaning and Polishing CompoundcuibaprauNo ratings yet

- United States Patent (10) Patent No.: US 7,311,236 B2: Smith Et Al. (45) Date of Patent: Dec. 25, 2007Document14 pagesUnited States Patent (10) Patent No.: US 7,311,236 B2: Smith Et Al. (45) Date of Patent: Dec. 25, 2007chicken curryNo ratings yet

- United States Patent: Bhattacharya Et Al. Dec. 17, 2013Document25 pagesUnited States Patent: Bhattacharya Et Al. Dec. 17, 2013Blue StarNo ratings yet

- US6247760Document12 pagesUS6247760aungkyawzoreNo ratings yet

- United States Patent (10) Patent No.: US 7.282,100 B1: Schouest Et Al. (45) Date of Patent: Oct. 16, 2007Document15 pagesUnited States Patent (10) Patent No.: US 7.282,100 B1: Schouest Et Al. (45) Date of Patent: Oct. 16, 2007opik24No ratings yet

- Google Patent IIDocument8 pagesGoogle Patent IIRezky PrasetyajiNo ratings yet

- United States Patent (10) Patent No.: US 8.468,753 B2Document29 pagesUnited States Patent (10) Patent No.: US 8.468,753 B2Dhrubajyoti BoraNo ratings yet

- United States Patent (10) Patent No.: US 6,382,646 B1: Shaw (45) Date of Patent: May 7, 2002Document10 pagesUnited States Patent (10) Patent No.: US 6,382,646 B1: Shaw (45) Date of Patent: May 7, 2002Eric Manuel Mercedes AbreuNo ratings yet

- United States Patent (10) Patent No.: US 7.624,666 B1: O'Neill Et Al. (45) Date of Patent: Dec. 1, 2009Document9 pagesUnited States Patent (10) Patent No.: US 7.624,666 B1: O'Neill Et Al. (45) Date of Patent: Dec. 1, 2009Turk SoloNo ratings yet

- US6699426Document16 pagesUS6699426Muhammed BALIKÇINo ratings yet

- United States Patent: Gaydos Et AlDocument8 pagesUnited States Patent: Gaydos Et AlHugo Mauricio Echeverry HerreraNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 6,344,071 B1Document20 pagesUnited States Patent: (12) (10) Patent N0.: US 6,344,071 B143No ratings yet

- United States Patent: Ker Et Al. (45) Date of Patent: Jul. 4, 2006Document28 pagesUnited States Patent: Ker Et Al. (45) Date of Patent: Jul. 4, 2006aminiel kivuyoNo ratings yet

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Study of The Influence Factors For Ballistic PerfoDocument11 pagesStudy of The Influence Factors For Ballistic Perfoibrahim sugarNo ratings yet

- CA2921663A1Document27 pagesCA2921663A1ibrahim sugarNo ratings yet

- H WIN Authorized Dealer AgreementDocument5 pagesH WIN Authorized Dealer Agreementibrahim sugarNo ratings yet

- Experimental and Numerical Study On DynamicDocument20 pagesExperimental and Numerical Study On Dynamicibrahim sugarNo ratings yet

- 7 62x51mmDocument11 pages7 62x51mmibrahim sugarNo ratings yet

- Erratum To Numerical Simulation of Armored VehicleDocument2 pagesErratum To Numerical Simulation of Armored Vehicleibrahim sugarNo ratings yet

- Ballistic Protection Against Armour Piercing Projectiles Using Titanium Base ArmourDocument17 pagesBallistic Protection Against Armour Piercing Projectiles Using Titanium Base Armouribrahim sugarNo ratings yet

- Fragmentation of Armor Piercing Steel ProjectilesDocument6 pagesFragmentation of Armor Piercing Steel Projectilesibrahim sugarNo ratings yet

- PU UltrasonıkDocument20 pagesPU Ultrasonıkibrahim sugarNo ratings yet

- Reinforcement of Elastomers 2016Document9 pagesReinforcement of Elastomers 2016ibrahim sugarNo ratings yet

- Concept of A Gun Barrel Based On The LayerDocument11 pagesConcept of A Gun Barrel Based On The Layeribrahim sugarNo ratings yet

- Investigation of Dynamic Response of A Mannequin in A Vehicle Exposed ToDocument10 pagesInvestigation of Dynamic Response of A Mannequin in A Vehicle Exposed Toibrahim sugarNo ratings yet

- Fatigue Crack Propagation For A Through Thickness Crack: A Crack Propagation Law Considering Cyclic Plasticity Near The Crack TipDocument10 pagesFatigue Crack Propagation For A Through Thickness Crack: A Crack Propagation Law Considering Cyclic Plasticity Near The Crack Tipibrahim sugarNo ratings yet

- The Art of Armor DevelopmentDocument8 pagesThe Art of Armor Developmentibrahim sugarNo ratings yet

- Finite Element and Experimental Analyses of An Armoured VehicleDocument7 pagesFinite Element and Experimental Analyses of An Armoured Vehicleibrahim sugarNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2010/0326336A1Document8 pagesPatent Application Publication (10) Pub. No.: US 2010/0326336A1ibrahim sugarNo ratings yet

- United States Patent (19) 11 Patent Number: 6,112,635: Cohen (45) Date of Patent: Sep. 5, 2000Document12 pagesUnited States Patent (19) 11 Patent Number: 6,112,635: Cohen (45) Date of Patent: Sep. 5, 2000ibrahim sugarNo ratings yet

- Experimental and Numerical Investigation of Kevlar and UHMWPEDocument9 pagesExperimental and Numerical Investigation of Kevlar and UHMWPEibrahim sugarNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2009/0211225A1Document14 pagesPatent Application Publication (10) Pub. No.: US 2009/0211225A1ibrahim sugarNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2016/0102949 A1Document11 pagesPatent Application Publication (10) Pub. No.: US 2016/0102949 A1ibrahim sugarNo ratings yet

- United States Patent (10) Patent No.: US 9.261,334 B1Document10 pagesUnited States Patent (10) Patent No.: US 9.261,334 B1ibrahim sugarNo ratings yet

- United States Patent (10) Patent No.: US 8,580,387 B1Document9 pagesUnited States Patent (10) Patent No.: US 8,580,387 B1ibrahim sugarNo ratings yet

- United States Patent (10) Patent No.: US 9,038,332 B1Document17 pagesUnited States Patent (10) Patent No.: US 9,038,332 B1ibrahim sugarNo ratings yet

- Paul BourkeDocument290 pagesPaul Bourkeibrahim sugarNo ratings yet

- Fragment Simulating Projectile Penetration Into LaDocument10 pagesFragment Simulating Projectile Penetration Into Laibrahim sugarNo ratings yet

- United States Patent (19) : Tasdemiroglu 11 Patent Number: 4,664,967 (45) Date of Patent: May 12, 1987Document6 pagesUnited States Patent (19) : Tasdemiroglu 11 Patent Number: 4,664,967 (45) Date of Patent: May 12, 1987ibrahim sugarNo ratings yet

- Materials: Blast Resistance of 240 MM Building Wall Coated With Polyurea ElastomerDocument12 pagesMaterials: Blast Resistance of 240 MM Building Wall Coated With Polyurea Elastomeribrahim sugarNo ratings yet

- Ballistic Composites - Protecting The Protectors: George MarshDocument4 pagesBallistic Composites - Protecting The Protectors: George Marshibrahim sugarNo ratings yet

- Ballistic Testing of Thyssenkrupp Steel Europe Armor Steel in Accordance With U.S. Military Armor SpecificationsDocument11 pagesBallistic Testing of Thyssenkrupp Steel Europe Armor Steel in Accordance With U.S. Military Armor Specificationsibrahim sugarNo ratings yet

- Armor Ceramic: For Ballistic ProtectionDocument10 pagesArmor Ceramic: For Ballistic Protectionibrahim sugarNo ratings yet

- AWWA D100 Guide Specification PDFDocument8 pagesAWWA D100 Guide Specification PDFDaniel Marín100% (1)

- The UmbrellaDocument6 pagesThe UmbrellaTila FitrianiNo ratings yet

- JARWAHI NALLA KATNI 25112020-Layout1Document1 pageJARWAHI NALLA KATNI 25112020-Layout1Satendra TiwariNo ratings yet

- Godrej Meadows BrochureDocument42 pagesGodrej Meadows BrochurePrashant Joshi100% (1)

- Engineer Wise Daily Work Done QtyDocument125 pagesEngineer Wise Daily Work Done Qtyuday kumarNo ratings yet

- Weathershield Quote - Rev 08-23Document11 pagesWeathershield Quote - Rev 08-23lemasteryoNo ratings yet

- Goa As Per G+4Document53 pagesGoa As Per G+4sameershedgeNo ratings yet

- CHP 4Document24 pagesCHP 4M.IDREES KhanNo ratings yet

- 2Document1 page2Manupriya KapleshNo ratings yet

- Theory of Structures ReviewerDocument13 pagesTheory of Structures Reviewerjohn kyle bartolayNo ratings yet

- Villa 4 PDFDocument20 pagesVilla 4 PDFBookun SkyyNo ratings yet

- 708 WF Ire Jan 06.01.23 WebsiteDocument24 pages708 WF Ire Jan 06.01.23 WebsitetedNo ratings yet

- Mantri Centrium PDFDocument68 pagesMantri Centrium PDFsheenamNo ratings yet

- Ductile Detailing & Its Important CLPIU EduDocument73 pagesDuctile Detailing & Its Important CLPIU EduSankalp LamaNo ratings yet

- Construction Estimating Using ExcelDocument19 pagesConstruction Estimating Using ExcelEl Patron 167% (6)

- 10 Well-Designed Social Housing Projects From Around The WorldDocument9 pages10 Well-Designed Social Housing Projects From Around The WorldMiguel R MoNo ratings yet

- 6 Requirements of Good Quality BricksDocument1 page6 Requirements of Good Quality BricksRamaprasad VarmaNo ratings yet

- Efficient Utilisation of Optimal Network ArchesDocument6 pagesEfficient Utilisation of Optimal Network ArchesDave ThompsonNo ratings yet

- 2019 Droplight Pricelist Sept 2019Document14 pages2019 Droplight Pricelist Sept 2019ALvin SaLvaNo ratings yet

- L02 R02D01 Fos 00 XX DWG Ar 62005Document1 pageL02 R02D01 Fos 00 XX DWG Ar 62005Osama KheadryNo ratings yet

- A Taxonomy of Architectural Tectonics: June 2017Document9 pagesA Taxonomy of Architectural Tectonics: June 2017Beby OktavianiNo ratings yet

- ANNEX - A & B of IS 456-2000Document14 pagesANNEX - A & B of IS 456-2000Abrar AhmadNo ratings yet

- TOGAF 9 Template - Architecture RoadmapDocument7 pagesTOGAF 9 Template - Architecture Roadmapnahendhran1812No ratings yet

- Moses P. Perley HouseDocument2 pagesMoses P. Perley HouseRemi DrigoNo ratings yet

- IRS Concrete Bridge Code - CS 9 PDFDocument3 pagesIRS Concrete Bridge Code - CS 9 PDFfaumijkNo ratings yet

- Primary SchoolDocument57 pagesPrimary SchoolMUUTHUKRISHNAN100% (1)

- Emailing Jade E BROCHURE CompressedDocument10 pagesEmailing Jade E BROCHURE CompressedManish AhujaNo ratings yet

- White Book C05 S03 Specialist Partitions FireWallDocument11 pagesWhite Book C05 S03 Specialist Partitions FireWallpictura sticlaNo ratings yet