Professional Documents

Culture Documents

Welding Procedure Specification KLPK 2

Welding Procedure Specification KLPK 2

Uploaded by

Zans 2001Copyright:

Available Formats

You might also like

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- Stress Analysis of ShaftDocument5 pagesStress Analysis of Shaftyashar2500100% (2)

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (3)

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNo ratings yet

- Shear Modulus at Room Temperature: Standard Test Method ForDocument5 pagesShear Modulus at Room Temperature: Standard Test Method ForROHITNo ratings yet

- BOMAG Original Cutting Tools PDFDocument36 pagesBOMAG Original Cutting Tools PDFchristophe laurensNo ratings yet

- Welding Procedure Specification PresentasiDocument3 pagesWelding Procedure Specification PresentasiHASIM HASIMNo ratings yet

- Welding Procedure Specification - Kel 3Document4 pagesWelding Procedure Specification - Kel 3Helmi KusumaNo ratings yet

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification SampleBrown's P LikoNo ratings yet

- Welding Procedure Specification Sample - New EditionDocument2 pagesWelding Procedure Specification Sample - New EditiondanteNo ratings yet

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Document2 pagesWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemNo ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNiel100% (1)

- Procedure Qualification Record (PQR) : JointDocument2 pagesProcedure Qualification Record (PQR) : JointBalkishan DyavanapellyNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- WPS Format For AWS D1.1 - WPS - SAWDocument1 pageWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- Main - Sample Welding Procedure Specification Wps FormDocument2 pagesMain - Sample Welding Procedure Specification Wps FormmuhammaddanishafandiNo ratings yet

- Document Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Document1 pageDocument Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Ed FangNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design PositionDocument9 pagesWelding Procedure Specification (WPS) : Joint Design PositionpetermanroelibraryNo ratings yet

- Je C 006 WPSDocument4 pagesJe C 006 WPScameron toolseeNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Wps Smaw3g Smaw B-U2 (Vacio)Document1 pageWps Smaw3g Smaw B-U2 (Vacio)Richard Gonzales CapchiNo ratings yet

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- Welding Procedure For Plate - WPSDocument1 pageWelding Procedure For Plate - WPSCristian ZidarescuNo ratings yet

- In Accordance To AWS D 1.1 - Structural Welding Code Steel, 2010 EditionDocument2 pagesIn Accordance To AWS D 1.1 - Structural Welding Code Steel, 2010 EditioncrysNo ratings yet

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipNo ratings yet

- GM TCL 1 2F - WebExampleDocument1 pageGM TCL 1 2F - WebExamplesuronocaturatmojoNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Computer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0Document1 pageComputer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0Erick GoyesNo ratings yet

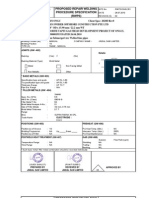

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet

- Base Metals Base Metal Thickness: Document IT-ME-XXX-XX/F-01 Rev. 0 DateDocument1 pageBase Metals Base Metal Thickness: Document IT-ME-XXX-XX/F-01 Rev. 0 Datehenry ayala100% (1)

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Wps (Gtaw & Smaw)Document3 pagesWps (Gtaw & Smaw)Ramadhan AdityaNo ratings yet

- Wps Blank Form 2sheetDocument4 pagesWps Blank Form 2sheetdidi sudiNo ratings yet

- Welding Procedure Specification (WPS) Yes Prequalified or Procedure Qualification Records (PQR) YesDocument2 pagesWelding Procedure Specification (WPS) Yes Prequalified or Procedure Qualification Records (PQR) YesRuben Purca0% (1)

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- MHC Conveying System Private Limited: JOINTS (QW-402)Document3 pagesMHC Conveying System Private Limited: JOINTS (QW-402)Lipika GayenNo ratings yet

- PQR WPSDocument2 pagesPQR WPSMiguel Alejandro SierraNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiNo ratings yet

- Je C 008 WPSDocument4 pagesJe C 008 WPScameron toolseeNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- d1 1 Wps 675 070 05 Digital FormDocument1 paged1 1 Wps 675 070 05 Digital FormGovind RaoNo ratings yet

- d1 1 Wps 675 070 05 Digital FormDocument1 paged1 1 Wps 675 070 05 Digital FormYeisson VillamizarNo ratings yet

- Projectile PDFDocument6 pagesProjectile PDFSlim ShaddysNo ratings yet

- HARDNESSDocument42 pagesHARDNESSNicole Andrei BaldozaNo ratings yet

- Daniel MeeksDocument2 pagesDaniel MeeksDaniel Aaron MeeksNo ratings yet

- Certificado TipoDocument168 pagesCertificado TipoAndresLopezMllanNo ratings yet

- LN2 Fill Process For Dewars SOPDocument3 pagesLN2 Fill Process For Dewars SOPLokesh RavichandranNo ratings yet

- Gear BoxDocument14 pagesGear Boxarackalfrancis0% (1)

- STATIC REPORT-STATIC EQUILIBRIUM FinalDocument12 pagesSTATIC REPORT-STATIC EQUILIBRIUM FinalAbbyNo ratings yet

- 4.4 HeatDocument7 pages4.4 HeatvelavanNo ratings yet

- Physics Formulas: G G (1-d) RDocument6 pagesPhysics Formulas: G G (1-d) Ronewing949100% (1)

- Hot Water Family Brochure UEENOJDocument16 pagesHot Water Family Brochure UEENOJRuben David Ibañez RetamalNo ratings yet

- Engine Oil Pump and Asociated UnitsDocument19 pagesEngine Oil Pump and Asociated Unitsanon_828948057No ratings yet

- Selecting Reaction Type Hydraulic Turbines and Pump Turbines - USACEDocument161 pagesSelecting Reaction Type Hydraulic Turbines and Pump Turbines - USACEnjsmith5No ratings yet

- Greenheck RSF RSFPDocument4 pagesGreenheck RSF RSFPSAJADNo ratings yet

- Plant Utility Audit ReportDocument4 pagesPlant Utility Audit Reportkishore1214No ratings yet

- Ipr RegDocument34 pagesIpr RegNicolae PopNo ratings yet

- Diltancy AngleDocument7 pagesDiltancy AngleGopal PNo ratings yet

- Working Principle of A D.C Motor or How A D.C Motor RotatesDocument3 pagesWorking Principle of A D.C Motor or How A D.C Motor RotatesXahid HasanNo ratings yet

- Dve.023.001 Ball Bearing Components PDFDocument32 pagesDve.023.001 Ball Bearing Components PDFlucian lunaNo ratings yet

- Big Idea 13 Forces and Change in MotionDocument7 pagesBig Idea 13 Forces and Change in Motionapi-291011460No ratings yet

- Iso 25239-2-2011 PDFDocument12 pagesIso 25239-2-2011 PDFJorgeNo ratings yet

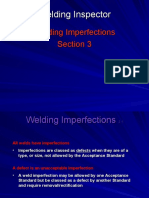

- 3 Welding ImperfectionsDocument44 pages3 Welding ImperfectionsAdhanom G.No ratings yet

- Kisssoft Specifications: GearsDocument12 pagesKisssoft Specifications: GearslicobarrosNo ratings yet

- High VoltageDocument79 pagesHigh Voltagefauzan220No ratings yet

- 海信单元机样册Hisense Single Split - Hi-Smart U series - Catalogue - 20220715-TDocument12 pages海信单元机样册Hisense Single Split - Hi-Smart U series - Catalogue - 20220715-Tchuquynh12a3dqhNo ratings yet

- Q Paper MSE-II TOM-IDocument1 pageQ Paper MSE-II TOM-ISurjit Kumar GandhiNo ratings yet

- Summative - Consumer Chemistry 9 - 1.1Document2 pagesSummative - Consumer Chemistry 9 - 1.1Gabriela FernandezNo ratings yet

- Parker PV270 46 PDFDocument44 pagesParker PV270 46 PDFAlan100% (1)

Welding Procedure Specification KLPK 2

Welding Procedure Specification KLPK 2

Uploaded by

Zans 2001Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification KLPK 2

Welding Procedure Specification KLPK 2

Uploaded by

Zans 2001Copyright:

Available Formats

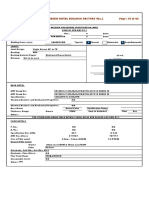

Welding Procedure Specification (WPS)

Code: AWS D1.1

Company name: UNY Identification #: 1

Addres : KLPK 2 SMAW –

Welding Process: Process Type: Position :

SMAW Manual 1G Is WPS Prequalified?

Base Metal Part I (Material Spec., type or grade): Base Metal Part II (Material Spec., type

Supporrting PQRorNo.

grade):

(S):

Thicness*/Pipe Diameter: Filler Metals:

AWS Classification*/AWS Specification:

Groove or Fillet Range:

*If Prequalified, qualified range as shown in sketch

Joint Detail/Sketch:

Table 3.4 of AWS D1.1

T S E min

T=

RF ≥

the drawing

T≤

As specified in

T≤

T≤

G =

E= T≤

T≥

Joint Design Used (Design information for Prequalified WPS as shown in Sketch):

Root Opening G: Root Dace RF: Groove Angle: Radius (J-U):

Weld Type: Joint Type:

Backing Option: Backing Material: Back Gouging Method:

Identification

Electrical Characteristics : Shielding:

Current Type Polarity :

Transfer Mode :

Welding Procedure

Filler Wire

Current Travel

Weld Pass Filler Metal Metal Current Feed Remarks or

Process Type & Volts Speed

Layer(s) No. Classification Diameter Amps Speed Heat Input

Polarity (in/min)

mm(in) (in/min)

1 1

Layer 11 SMAW E6013 1.6 mm 95 DCEP - 380 200,79 9296

1 to 2 2 to 3

2 to n 3 to n

Technique:

Stringer or Weave Bead:

Initial/Interpass Cleaning:

Number Of Electrodes:

Electrode Spacing:

Heat Treatment:

Preheat Temp: Interpass Temp:

Postweld Heat Treatment: Time: n/a

Additional Notes:

Manufacturer/Contractor Authorized by:

Welding Engineer:

Name: Name:

Title: Title:

Date Date:

You might also like

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- Stress Analysis of ShaftDocument5 pagesStress Analysis of Shaftyashar2500100% (2)

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (3)

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNo ratings yet

- Shear Modulus at Room Temperature: Standard Test Method ForDocument5 pagesShear Modulus at Room Temperature: Standard Test Method ForROHITNo ratings yet

- BOMAG Original Cutting Tools PDFDocument36 pagesBOMAG Original Cutting Tools PDFchristophe laurensNo ratings yet

- Welding Procedure Specification PresentasiDocument3 pagesWelding Procedure Specification PresentasiHASIM HASIMNo ratings yet

- Welding Procedure Specification - Kel 3Document4 pagesWelding Procedure Specification - Kel 3Helmi KusumaNo ratings yet

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification SampleBrown's P LikoNo ratings yet

- Welding Procedure Specification Sample - New EditionDocument2 pagesWelding Procedure Specification Sample - New EditiondanteNo ratings yet

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Document2 pagesWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemNo ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNiel100% (1)

- Procedure Qualification Record (PQR) : JointDocument2 pagesProcedure Qualification Record (PQR) : JointBalkishan DyavanapellyNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- WPS Format For AWS D1.1 - WPS - SAWDocument1 pageWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- Main - Sample Welding Procedure Specification Wps FormDocument2 pagesMain - Sample Welding Procedure Specification Wps FormmuhammaddanishafandiNo ratings yet

- Document Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Document1 pageDocument Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Ed FangNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design PositionDocument9 pagesWelding Procedure Specification (WPS) : Joint Design PositionpetermanroelibraryNo ratings yet

- Je C 006 WPSDocument4 pagesJe C 006 WPScameron toolseeNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Wps Smaw3g Smaw B-U2 (Vacio)Document1 pageWps Smaw3g Smaw B-U2 (Vacio)Richard Gonzales CapchiNo ratings yet

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- Welding Procedure For Plate - WPSDocument1 pageWelding Procedure For Plate - WPSCristian ZidarescuNo ratings yet

- In Accordance To AWS D 1.1 - Structural Welding Code Steel, 2010 EditionDocument2 pagesIn Accordance To AWS D 1.1 - Structural Welding Code Steel, 2010 EditioncrysNo ratings yet

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipNo ratings yet

- GM TCL 1 2F - WebExampleDocument1 pageGM TCL 1 2F - WebExamplesuronocaturatmojoNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Computer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0Document1 pageComputer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0Erick GoyesNo ratings yet

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet

- Base Metals Base Metal Thickness: Document IT-ME-XXX-XX/F-01 Rev. 0 DateDocument1 pageBase Metals Base Metal Thickness: Document IT-ME-XXX-XX/F-01 Rev. 0 Datehenry ayala100% (1)

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Wps (Gtaw & Smaw)Document3 pagesWps (Gtaw & Smaw)Ramadhan AdityaNo ratings yet

- Wps Blank Form 2sheetDocument4 pagesWps Blank Form 2sheetdidi sudiNo ratings yet

- Welding Procedure Specification (WPS) Yes Prequalified or Procedure Qualification Records (PQR) YesDocument2 pagesWelding Procedure Specification (WPS) Yes Prequalified or Procedure Qualification Records (PQR) YesRuben Purca0% (1)

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- MHC Conveying System Private Limited: JOINTS (QW-402)Document3 pagesMHC Conveying System Private Limited: JOINTS (QW-402)Lipika GayenNo ratings yet

- PQR WPSDocument2 pagesPQR WPSMiguel Alejandro SierraNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiNo ratings yet

- Je C 008 WPSDocument4 pagesJe C 008 WPScameron toolseeNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- d1 1 Wps 675 070 05 Digital FormDocument1 paged1 1 Wps 675 070 05 Digital FormGovind RaoNo ratings yet

- d1 1 Wps 675 070 05 Digital FormDocument1 paged1 1 Wps 675 070 05 Digital FormYeisson VillamizarNo ratings yet

- Projectile PDFDocument6 pagesProjectile PDFSlim ShaddysNo ratings yet

- HARDNESSDocument42 pagesHARDNESSNicole Andrei BaldozaNo ratings yet

- Daniel MeeksDocument2 pagesDaniel MeeksDaniel Aaron MeeksNo ratings yet

- Certificado TipoDocument168 pagesCertificado TipoAndresLopezMllanNo ratings yet

- LN2 Fill Process For Dewars SOPDocument3 pagesLN2 Fill Process For Dewars SOPLokesh RavichandranNo ratings yet

- Gear BoxDocument14 pagesGear Boxarackalfrancis0% (1)

- STATIC REPORT-STATIC EQUILIBRIUM FinalDocument12 pagesSTATIC REPORT-STATIC EQUILIBRIUM FinalAbbyNo ratings yet

- 4.4 HeatDocument7 pages4.4 HeatvelavanNo ratings yet

- Physics Formulas: G G (1-d) RDocument6 pagesPhysics Formulas: G G (1-d) Ronewing949100% (1)

- Hot Water Family Brochure UEENOJDocument16 pagesHot Water Family Brochure UEENOJRuben David Ibañez RetamalNo ratings yet

- Engine Oil Pump and Asociated UnitsDocument19 pagesEngine Oil Pump and Asociated Unitsanon_828948057No ratings yet

- Selecting Reaction Type Hydraulic Turbines and Pump Turbines - USACEDocument161 pagesSelecting Reaction Type Hydraulic Turbines and Pump Turbines - USACEnjsmith5No ratings yet

- Greenheck RSF RSFPDocument4 pagesGreenheck RSF RSFPSAJADNo ratings yet

- Plant Utility Audit ReportDocument4 pagesPlant Utility Audit Reportkishore1214No ratings yet

- Ipr RegDocument34 pagesIpr RegNicolae PopNo ratings yet

- Diltancy AngleDocument7 pagesDiltancy AngleGopal PNo ratings yet

- Working Principle of A D.C Motor or How A D.C Motor RotatesDocument3 pagesWorking Principle of A D.C Motor or How A D.C Motor RotatesXahid HasanNo ratings yet

- Dve.023.001 Ball Bearing Components PDFDocument32 pagesDve.023.001 Ball Bearing Components PDFlucian lunaNo ratings yet

- Big Idea 13 Forces and Change in MotionDocument7 pagesBig Idea 13 Forces and Change in Motionapi-291011460No ratings yet

- Iso 25239-2-2011 PDFDocument12 pagesIso 25239-2-2011 PDFJorgeNo ratings yet

- 3 Welding ImperfectionsDocument44 pages3 Welding ImperfectionsAdhanom G.No ratings yet

- Kisssoft Specifications: GearsDocument12 pagesKisssoft Specifications: GearslicobarrosNo ratings yet

- High VoltageDocument79 pagesHigh Voltagefauzan220No ratings yet

- 海信单元机样册Hisense Single Split - Hi-Smart U series - Catalogue - 20220715-TDocument12 pages海信单元机样册Hisense Single Split - Hi-Smart U series - Catalogue - 20220715-Tchuquynh12a3dqhNo ratings yet

- Q Paper MSE-II TOM-IDocument1 pageQ Paper MSE-II TOM-ISurjit Kumar GandhiNo ratings yet

- Summative - Consumer Chemistry 9 - 1.1Document2 pagesSummative - Consumer Chemistry 9 - 1.1Gabriela FernandezNo ratings yet

- Parker PV270 46 PDFDocument44 pagesParker PV270 46 PDFAlan100% (1)