Professional Documents

Culture Documents

JB Pumping Pty LTD

JB Pumping Pty LTD

Uploaded by

JB PumpingOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JB Pumping Pty LTD

JB Pumping Pty LTD

Uploaded by

JB PumpingCopyright:

Available Formats

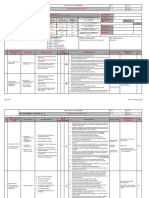

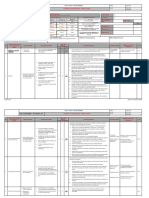

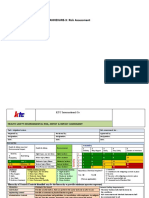

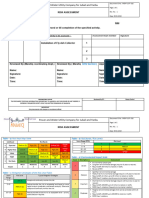

HEALTH SAFETY AND ENVIRONMENT Author: Approved:

Issued: Rev. Date:

RISK ASSESSMENT: ACT/HSE/RA 001 Use of Mobile Concrete Pump

Revision: 0

RISK SCORE CALCULATOR Project Name: xxx

Use the Risk Score Calculator to Determine the Level of Risk of each Hazard

What is the LIKELIHOOD of an occurrence? Hierarchy of Controls RA Ref No.: xxx

What w ould be the

CONSEQUENCE Frequent/Almost certain (5) Rarely (1) Can the hazard be Elim inated or removed

Continuous or will happen

Often (4) Likely (3) Possible (2) Less than once every 5 RA compilation

of an occurrence be? 6 to 12 times a year 1 to 5 times a year Once every 5 years from the w ork place? Review date:

frequently years Date:

Catastrophic (5) Can the product or process be substituted for Date:

High 25 High 20 High 15 Medium 10 Medium 5

Multiple Fatalities a less hazardous alternative?

Serious (4) Can the hazard be engineered aw ay w ith

High 20 High 16 High 12 Medium 8 Low 4 Compiled by:

Class 1 single fatality guards or barriers?

Moderate (3)

Can Adm inistration Controls be adopted

Class2 (AWI or LTI) or Class 1 High 15 High 12 Medium 9 Medium 6 Low 3 Reviewed by:

Permanently disabling effects

I.e. procedures, job rotation etc.

Minor (2)

Medical attention needed, no work Medium 10 Medium 8 Medium 6 Low 4 Low 2 Can Personal Protective Equipm ent & Approved by:

restrictions. MTI Clothing be w orn to safe guard against

Insignificant (1) hazards?

FAI

Medium 10 Medium 4 Low 3 Low 2 Low 1

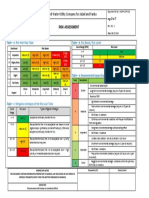

Overall Task Details Relevant Applicable MAS: Text Additional Training required: NOC’s Required for task:

010407 – Traffic controls

Concrete Pours using mobile pump within site boundary

Specific Task Step Initial Risk

Additional Control

No (In sequence of Hazard Details Consequence/Risk Rating Control Measures Residual Risks RR

Measures

works) P S RR

i. All mobile concrete pumps to be Third Party Certificated by a DM

Unauthorized operation of the mobile

Concrete Pump approved inspector, documentation available on arrival to site;

pump resulting in incident;

checks on arrival to Documentation

Use of mobile 12 ii. Operators to have in-date Third Party certificate by approved body, Pump quarantined until

1 site Failure due to use of un-certificated 3 4 unavailable for Low

concrete pump HIGH available for review on arrival to site; evidence provided

pump; review

PRIOR TO SITE iii. Pump load indicator to be installed and functioning correctly;

ACCESS iv. Visual inspection of pump undertaken by competent person;

Collision with plant or vehicles and i. Worker pedestrian routes to be designed and implemented with clear

live traffic; signage to provide segregation;

Access of mobile pump

Workers struck by plant, very high Workers not

and delivery trucks to Plant and workers in ii. Instruction to workers at induction on use of access routes around the

2 risk of fatality; project; complying with Regular topic in TBT’s Low

work areas same working area;

flagmen

Uncontrolled pump and truck iii. Flagmen to be used to control Pump and delivery truck movements;

reversing;

iv. The Logistics plan shall clearly illustrate pump access and egress points;

Overturning due to incorrect siting or i. Ensure pump is set up/rigged out correctly, is on firm level ground as per

incorrect pump outrigger extension; siting plan with outriggers fully extended; Unable to fully Operation revised, pump

Working in proximity Collision of jib with overhead ii. Solid barriers should be situated, where practicable, to protect pump from

Siting and setting up of 12 extend outriggers moved to new area;

3 to existing structures services; 3 4 traffic routes around working radius of cab; Low

concrete pump High due to restrictions

and services; Pump never used without full

iii. Consideration given to overhead services and existing structures when in area

Blocking access routes with pump; outrigger extension

siting pump;

Jib striking stationary structures;

i. Pumping Plan to be completed prior to any pour taking place by

Temporary Works Coordinator;

ii. Method statements and risk assessments to be submitted and adhered to; Machine

Operator competency; Incident due to use of defective breakdown Machine isolated and

Pumping concrete hoses / equipment; iii. Pump load indicator to be functioning correctly, and not to be overridden quarantined until repaired.

20

4 Pump planning; 4 5 under any circumstances; Low

Concrete spillage; HIGH

(Pump Operator) Spoil removed and treated as

iv. Operator to adhere to safe working load limits; Hydraulic fluid spill

hazardous waste

v. Daily inspections of hoses, pipes, connections etc. prior to use. Damaged

equipment immediately removed from service;

vi. Pump hopper guards to be in place at all times;

Page 1 of 2 HSEQ -Rev-01(Aug-2018)

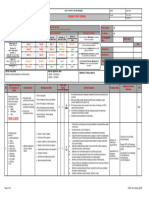

HEALTH SAFETY AND ENVIRONMENT Author: Approved:

Issued: Rev. Date:

RISK ASSESSMENT: ACT/HSE/RA 001 Use of Mobile Concrete Pump

Revision: 0

Specific Task Step Initial Risk

Additional Control

No (In sequence of Hazard Details Consequence/Risk Rating Control Measures Residual Risks RR

Measures

works) P S RR

vii. Plastic sheeting placed under hopper to contain spills;

Pumping operations Worker struck by delivery vehicle; i. No over-sailing of hose over live traffic routes without road closure;

around workers; Hose swinging / spinning ii. Supervision to undertake visual inspection of all pumping gear and

uncontrolled; equipment daily; Work stopped, area cleared

Workers in pump

Pump operator unable to see task – iii. Workers to wear correct PPE at all times, nitrile gloves, wellingtons, Incident – large and full investigation

operating radius;

Pumping operation 15 concrete spill undertaken

5 high level pumping; 3 5 glasses; Low

supervision Reversing concrete High

delivery vehicles; Over-sailing of material over live iv. Flagmen controlling delivery truck movements;

traffic routes; v. Spotters to direct pump operators at high level in clear view at all times;

Use of concrete – protective gear; vi. All concrete soaked workwear to be removed immediately;

Working on rebar – risk of injury; vii. Planks placed on rebar for worker access, clear access maintained;

Page 2 of 2 HSEQ -Rev-01(Aug-2018)

You might also like

- 2011 - PDA - How Risky Are Pinholes in Gloves - 2Document15 pages2011 - PDA - How Risky Are Pinholes in Gloves - 2Александр ЗикеевNo ratings yet

- Risk Assessment Guidance: Hazard Severity Likelihood of OccurrenceDocument10 pagesRisk Assessment Guidance: Hazard Severity Likelihood of OccurrenceSaleem AkhtarNo ratings yet

- Risk Assessment - HV 11kV Cable, Joint & TerminationDocument90 pagesRisk Assessment - HV 11kV Cable, Joint & TerminationJobish PK0% (2)

- Risk AssessmentDocument13 pagesRisk AssessmentDisha Shah100% (3)

- Risk Assessment: Act/Hse/Ra 001: Use of Suspended Access Cradles and Platforms (Temporary Works)Document2 pagesRisk Assessment: Act/Hse/Ra 001: Use of Suspended Access Cradles and Platforms (Temporary Works)Saravana0% (1)

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument6 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardPearl TeresaNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument3 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Confined Space WorkingDocument1 pageRisk Assessment: Act/Hse/Ra 001: Confined Space WorkingbrandedwahidNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardPRASAD6219No ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardAffin RoyNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardSaravanaNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument3 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- 13initialprojectsiteofficeset Upriskassessmenttemplates 200616093558Document6 pages13initialprojectsiteofficeset Upriskassessmenttemplates 200616093558test fypNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Lifting Operations With Mobile CraneDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Lifting Operations With Mobile CraneKhalid KhalidNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Lifting Operations With Tower CraneDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Lifting Operations With Tower CraneM ShahzadNo ratings yet

- 17trafficoperations Workingonliveroadsriskassessmenttemplates 230419084508 3275aa2bDocument2 pages17trafficoperations Workingonliveroadsriskassessmenttemplates 230419084508 3275aa2bM ShahzadNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Laying Blockwork With Access ScaffoldingDocument3 pagesRisk Assessment: Act/Hse/Ra 001: Laying Blockwork With Access ScaffoldingEdwin MofokengNo ratings yet

- ScaffoldingDocument2 pagesScaffoldingLheo PaduaNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Sheet Piling Operations (Temporary Works)Document2 pagesRisk Assessment: Act/Hse/Ra 001: Sheet Piling Operations (Temporary Works)M ShahzadNo ratings yet

- 31.0.9 ALR - Loading & Off-Loading TruckDocument5 pages31.0.9 ALR - Loading & Off-Loading TruckGerrit100% (1)

- 31.0.11 ALR - Temporary Electrical InstallationDocument3 pages31.0.11 ALR - Temporary Electrical InstallationGerritNo ratings yet

- 31.0.12 ALR - Traffic Control by FlagmanDocument3 pages31.0.12 ALR - Traffic Control by FlagmanGerrit100% (1)

- 31.0.10 LLA - Manual HandlingDocument4 pages31.0.10 LLA - Manual HandlingGerrit100% (1)

- 1 - R.A. - 003 - CompactionDocument2 pages1 - R.A. - 003 - CompactionmahmoudabidaliNo ratings yet

- Risk Assessment For Structural Concretes Works at Birkat Al Awamer Logistic ParkDocument22 pagesRisk Assessment For Structural Concretes Works at Birkat Al Awamer Logistic ParkAshir RIZNo ratings yet

- Risk Assessment Guidance: Hazard Severity (A) Likelihood of Occurrence (B)Document3 pagesRisk Assessment Guidance: Hazard Severity (A) Likelihood of Occurrence (B)Ahmad Syauqi SuhairiNo ratings yet

- Rev-01-Mariner WorkDocument40 pagesRev-01-Mariner Workrohit kumarNo ratings yet

- Jsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.Document67 pagesJsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.jafar mohdNo ratings yet

- Context - General Risk AssessmentDocument14 pagesContext - General Risk AssessmentAngeloNo ratings yet

- Site Mobilization Risk Assessment at Birkat Al Awamer Logistic ParkDocument26 pagesSite Mobilization Risk Assessment at Birkat Al Awamer Logistic ParkAshir RIZNo ratings yet

- Risk Assessment P3 Permanent Power Provision at IthraDocument2 pagesRisk Assessment P3 Permanent Power Provision at Ithraghazi4uNo ratings yet

- Risk Assessment Fitout SalonDocument19 pagesRisk Assessment Fitout SalonVision ConceptNo ratings yet

- Risk Assessment For Runway Beams 1Document10 pagesRisk Assessment For Runway Beams 1Subbu AbuNo ratings yet

- Generic RA FSDocument5 pagesGeneric RA FSStephenNo ratings yet

- SF 011 Hazard Risk AseessmentDocument3 pagesSF 011 Hazard Risk AseessmentShahid RazaNo ratings yet

- Sample of JHA - Roofing Top Installation Rev 2Document5 pagesSample of JHA - Roofing Top Installation Rev 2vajiravel407No ratings yet

- RA Excessive Noise .Vibration.Document11 pagesRA Excessive Noise .Vibration.Ndifor Dinho0% (1)

- Baseline Risk Assessment1 PDFDocument25 pagesBaseline Risk Assessment1 PDFRico100% (2)

- Risk Assement UpdatedDocument10 pagesRisk Assement Updatedashwin0% (1)

- Blank Risk Assessment TemplateDocument4 pagesBlank Risk Assessment TemplateMNo ratings yet

- EFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & ShampooDocument4 pagesEFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & Shampoomohammed ayazNo ratings yet

- SFSDFDocument6 pagesSFSDFali shahNo ratings yet

- Bubas RA 2013Document4 pagesBubas RA 2013vilashni prasadNo ratings yet

- Hazard Identification and Risk Assessment FormDocument4 pagesHazard Identification and Risk Assessment FormAli Al-GhamghamNo ratings yet

- Welcome To TÜV Rheinland Vietnam: Risk AssessmentDocument50 pagesWelcome To TÜV Rheinland Vietnam: Risk AssessmentTruong Quang HuyNo ratings yet

- Risk Assessment ContDocument4 pagesRisk Assessment Contdevnraj 09No ratings yet

- Safety at OffshoreDocument51 pagesSafety at OffshoreRavi Kant TripathiNo ratings yet

- Installation of CollectorsDocument20 pagesInstallation of CollectorsShah MuzzamilNo ratings yet

- Ra Concrete Chipping 7514Document5 pagesRa Concrete Chipping 7514Charles DoriaNo ratings yet

- Risk Assessment Concrete Cutting - 01Document1 pageRisk Assessment Concrete Cutting - 01kapsarcNo ratings yet

- Chemical Risk Assessment FormDocument7 pagesChemical Risk Assessment FormCamilo piconNo ratings yet

- Risk Assesment Fab - Rev-07Document71 pagesRisk Assesment Fab - Rev-07Nikhil PuthiryNo ratings yet

- Risk Assesment Generic Tender Despatch Electrical DepotDocument10 pagesRisk Assesment Generic Tender Despatch Electrical DepotanishavanloggerenbergNo ratings yet

- International Building Systems Factory Co. LTDDocument6 pagesInternational Building Systems Factory Co. LTDMohammad Imtiaz AliNo ratings yet

- Risk Assessment 004 NGSCHDocument2 pagesRisk Assessment 004 NGSCHsheraaz87100% (1)

- Instructions For Using OHS Risk Assessment Template: Only Complete The Unshaded Cells All Others Are Locked 1. 2Document4 pagesInstructions For Using OHS Risk Assessment Template: Only Complete The Unshaded Cells All Others Are Locked 1. 2Abdelrahman N. Ali100% (1)

- Ra-035c - Sheet Installation - Side Wall Rev.01Document6 pagesRa-035c - Sheet Installation - Side Wall Rev.01amrismail2012No ratings yet

- Cafe Risk Assessment XDocument6 pagesCafe Risk Assessment Xpaul bladesNo ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- PHED 10032 Individual, Dual, and Combative SportsDocument52 pagesPHED 10032 Individual, Dual, and Combative SportsMicmic CalivaNo ratings yet

- SOST - Laboratory Course Unit 2-1Document4 pagesSOST - Laboratory Course Unit 2-1kocarillo6481valNo ratings yet

- Sapolsky The Troublewith TestosteroneDocument7 pagesSapolsky The Troublewith Testosteronetheoantichi864100% (1)

- 207 CFM MCQDocument45 pages207 CFM MCQAbhinav JoshiNo ratings yet

- Red Orchid - Best PracticesDocument80 pagesRed Orchid - Best PracticeslabiaernestoNo ratings yet

- Phenytoin Infusion Revisited: Stability and AdministrationDocument4 pagesPhenytoin Infusion Revisited: Stability and AdministrationRieka NurulNo ratings yet

- Laudit, Arnel Z.Document30 pagesLaudit, Arnel Z.Japs De la CruzNo ratings yet

- Livro 1 - 003 - Abortion Leading Cause of Death in 2018 With 41 Million KilledDocument3 pagesLivro 1 - 003 - Abortion Leading Cause of Death in 2018 With 41 Million KilledLeonardo OliveiraNo ratings yet

- نسخة Assignment of PsychologyDocument3 pagesنسخة Assignment of Psychologyموم الحربيNo ratings yet

- Trauma and Play Therapy Helping Children Heal (Paris Goodyear-Brown) (Z-Library)Document251 pagesTrauma and Play Therapy Helping Children Heal (Paris Goodyear-Brown) (Z-Library)Alice GavrilaNo ratings yet

- Initial Dose: 50 MG Orally Once A Day Maintenan Ce Dose: 50 To 200 MG Orally Once A DayDocument2 pagesInitial Dose: 50 MG Orally Once A Day Maintenan Ce Dose: 50 To 200 MG Orally Once A Dayunkown userNo ratings yet

- Position PaperDocument2 pagesPosition PaperEivrahm Soralc100% (1)

- PIP PCCCV001 Control Valves Selection CriteriaDocument29 pagesPIP PCCCV001 Control Valves Selection CriteriaMehdi orojluNo ratings yet

- Isolation and Molecular Characterization of Salmonella Enterica, Escherichia Coli O157-H7 and Shigella Spp. From Meat and Dairy Products in EgyptDocument6 pagesIsolation and Molecular Characterization of Salmonella Enterica, Escherichia Coli O157-H7 and Shigella Spp. From Meat and Dairy Products in EgyptAffan GaffarNo ratings yet

- Intro To Social WorkDocument35 pagesIntro To Social WorkJane April CalanaoNo ratings yet

- 346 RLSLDocument19 pages346 RLSLparlindunganNo ratings yet

- Degree of Axis Correction in Valgus High Tibial OsteotomyDocument9 pagesDegree of Axis Correction in Valgus High Tibial Osteotomy洪侊增No ratings yet

- Sodio OralDocument6 pagesSodio OralBoris QuelcaNo ratings yet

- Drugs AbuseDocument20 pagesDrugs AbuseKrishnaNo ratings yet

- Kenya-Kilifi County Teenage Pregnancy ReportDocument36 pagesKenya-Kilifi County Teenage Pregnancy Reportchrismwas47No ratings yet

- Background of The StudyDocument3 pagesBackground of The StudyFranchesca ValerioNo ratings yet

- Blood Circulatory SystemDocument5 pagesBlood Circulatory SystemAathifa ThowfeekNo ratings yet

- Draft 5letter RubioDocument2 pagesDraft 5letter Rubioapi-376280075No ratings yet

- NEJMoa 2028436Document12 pagesNEJMoa 2028436arman ahdokhshNo ratings yet

- Covid-19 Mobile Disinfection Chamber Appears in VietnamDocument9 pagesCovid-19 Mobile Disinfection Chamber Appears in Vietnamrajesh_rbpNo ratings yet

- Red EyeDocument6 pagesRed EyeafatNo ratings yet

- Dream NumerologyDocument63 pagesDream NumerologySanjoy RoyNo ratings yet

- Covid-19 Vaccine Trial Protocols ReleasedDocument2 pagesCovid-19 Vaccine Trial Protocols ReleasedChafik MegherbiNo ratings yet

- Portable 7D HIFU User Manual-2023Document18 pagesPortable 7D HIFU User Manual-2023Oswaldo UlacioNo ratings yet