Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

15 viewsFPTM Operating Instructions

FPTM Operating Instructions

Uploaded by

anipo68The document provides operating instructions for a fire pump test meter. The instructions include closing the system valve, opening the bypass valve and throttle valve, purging air from the meter by opening vent valves, starting the fire pump and reading the flow in GPM, and adjusting the throttle valve to meet pump requirements before closing valves after the test.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- TRANSFORMER Inspection ChecklistDocument3 pagesTRANSFORMER Inspection ChecklistWisnu Hartono94% (17)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Iequipment (EDC) PDFDocument44 pagesIequipment (EDC) PDFAli mohammadNo ratings yet

- 2uz-Fe SfiDocument84 pages2uz-Fe SfiAe Manual100% (1)

- Basic Electrical SafetyDocument25 pagesBasic Electrical Safetyperezes100% (1)

- FPTM Installation Instructions - MetricDocument1 pageFPTM Installation Instructions - Metricanipo68No ratings yet

- Fire Pump Test Meter: Gerand EngineeringDocument5 pagesFire Pump Test Meter: Gerand EngineeringPIYARAT SUWANNAKHANo ratings yet

- Bendix - Master-Vac - Power Brake Service Manual - OCR - 8 PagesDocument8 pagesBendix - Master-Vac - Power Brake Service Manual - OCR - 8 Pagesgreg titanNo ratings yet

- Standing ValveDocument9 pagesStanding ValveRiswan Adhitya SaputraNo ratings yet

- BPH Barrel Pump 2021Document4 pagesBPH Barrel Pump 2021ANo ratings yet

- System - Rated - Plus - W - Sub - 150 Water Hammer PPPDocument2 pagesSystem - Rated - Plus - W - Sub - 150 Water Hammer PPPJeffry GabilanNo ratings yet

- Turbine Walkdown Checks PMIDocument15 pagesTurbine Walkdown Checks PMInikesh ranjanNo ratings yet

- Typical Chemical Injection-SystemDocument3 pagesTypical Chemical Injection-SystemAymen BabourNo ratings yet

- Foam System Line Proportioners: ApplicationDocument4 pagesFoam System Line Proportioners: ApplicationHarry NovaniNo ratings yet

- B B R R: Ird Ird Ain AinDocument8 pagesB B R R: Ird Ird Ain AinKamilNo ratings yet

- Paar-B: Potter Automatic Air ReleaseDocument3 pagesPaar-B: Potter Automatic Air ReleaseCesar GonzalesNo ratings yet

- Engineering & Installation ManualDocument61 pagesEngineering & Installation ManualThameem AnsariNo ratings yet

- Valves Deluge Valve Model h3-bkp-03-04-2018Document16 pagesValves Deluge Valve Model h3-bkp-03-04-2018Benny Kurniawan LimNo ratings yet

- Manifold Systems Catalog PDFDocument28 pagesManifold Systems Catalog PDFRam BabuNo ratings yet

- Brake Comp.Document47 pagesBrake Comp.Steven LincolnNo ratings yet

- Alarm Valve: Model-H (Ductile Iron)Document16 pagesAlarm Valve: Model-H (Ductile Iron)Karen IsananNo ratings yet

- VenturiDocument4 pagesVenturilipetrol007100% (1)

- Foam System Line Proportioners: ApplicationDocument4 pagesFoam System Line Proportioners: ApplicationMohammed SayedNo ratings yet

- Asco firePumpSensingLine RGDocument1 pageAsco firePumpSensingLine RGΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Inline Balance Pressure Foam Proportioner: HD Fire Protect Pvt. Ltd. Technical DataDocument10 pagesInline Balance Pressure Foam Proportioner: HD Fire Protect Pvt. Ltd. Technical Datadebu1985No ratings yet

- Man 80 eDocument17 pagesMan 80 eseanNo ratings yet

- Deluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataDocument16 pagesDeluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataNethajiNo ratings yet

- Deluge Valve Modelh5Document16 pagesDeluge Valve Modelh5Mariana HusainNo ratings yet

- Njwater RequirementDocument6 pagesNjwater RequirementSam ChoiNo ratings yet

- Valves Deluge Valve Model h3Document16 pagesValves Deluge Valve Model h3RaviNo ratings yet

- 928G Wheel Loader: - Implement Hydraulic System (Pilot Operated System)Document15 pages928G Wheel Loader: - Implement Hydraulic System (Pilot Operated System)puput utomoNo ratings yet

- Pumproom Layout Bldg. 8 & 9: Scale 1:30MDocument7 pagesPumproom Layout Bldg. 8 & 9: Scale 1:30MBrownstreet ArchitectsNo ratings yet

- zXQJunINI0EBhB SD-03-906 US 000Document4 pageszXQJunINI0EBhB SD-03-906 US 000udhayNo ratings yet

- Air Over BrakeDocument50 pagesAir Over Brakesidik purnomo100% (1)

- Flojet 4405 SN8386377Document4 pagesFlojet 4405 SN8386377Stathis MoumousisNo ratings yet

- Pre-Action Valve - WF-PAV250xx - v00Document2 pagesPre-Action Valve - WF-PAV250xx - v00genuNo ratings yet

- Wateer Hamer ArestoDocument2 pagesWateer Hamer Arestozaidabusamaha95No ratings yet

- Precision Plumbing Products: "Specify With Confidence - Install With Pride"Document2 pagesPrecision Plumbing Products: "Specify With Confidence - Install With Pride"Janavi RajaganapathyNo ratings yet

- WV-1 Install InstructionsDocument11 pagesWV-1 Install InstructionsmkaukolaNo ratings yet

- Automatic Dewatering SystemDocument2 pagesAutomatic Dewatering SystemRheoserve Industrial SolutionsNo ratings yet

- City Gas DirtibutionDocument32 pagesCity Gas DirtibutionGunjan Bhavsar100% (1)

- CGS PPTDocument32 pagesCGS PPTGunjan BhavsarNo ratings yet

- Valves Deluge Valve Model h3Document16 pagesValves Deluge Valve Model h3Pedro Caminos BolanosNo ratings yet

- Plumbing Lecture 11Document39 pagesPlumbing Lecture 11ahmedemadd19No ratings yet

- Different Types of Control Valves & Actuator SymbolsDocument8 pagesDifferent Types of Control Valves & Actuator SymbolsSangeeth SudhakaranNo ratings yet

- CT Hydraulic Syetem Schematics For PP and CCDocument12 pagesCT Hydraulic Syetem Schematics For PP and CCRolly Hillz SochimNo ratings yet

- 737 300/400/500 Boeing: ATA 36 PneumaticDocument51 pages737 300/400/500 Boeing: ATA 36 PneumaticmaryNo ratings yet

- Instrument Overview: For Yaman LNG On The Job TrainingDocument86 pagesInstrument Overview: For Yaman LNG On The Job TrainingQhismu AdjieNo ratings yet

- RP 546Document2 pagesRP 546Victor TobosqueNo ratings yet

- Inyector Venturi Netafim (Ingles)Document4 pagesInyector Venturi Netafim (Ingles)Alvaro Enrique Perdomo CharryNo ratings yet

- FT - 873905 - Proporcionador en Línea PDFDocument4 pagesFT - 873905 - Proporcionador en Línea PDFYacila AlvaradoNo ratings yet

- Hose Pressure Test Pump (Air-Powered) : Part No DC27530Document2 pagesHose Pressure Test Pump (Air-Powered) : Part No DC27530omernoumanNo ratings yet

- 05 VruDocument17 pages05 VruSergio RodriguezNo ratings yet

- Aro Pump Irits-0409-043Document60 pagesAro Pump Irits-0409-043Adolf MutangaduraNo ratings yet

- Instrument OverviewDocument86 pagesInstrument OverviewRoy PasmanNo ratings yet

- Installation of Injection Pump: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Injection Pump: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Accurate and Reliable Pressure Control: Qualitrol 070/351Document4 pagesAccurate and Reliable Pressure Control: Qualitrol 070/351setiyawanNo ratings yet

- Hyd - Ok & AtoxDocument59 pagesHyd - Ok & AtoxShaukat NadeemNo ratings yet

- TIB 031104 Hyd Sys PurgeDocument2 pagesTIB 031104 Hyd Sys Purgejesus_rs01No ratings yet

- Firefighting Catalog - ARGO 2017 DRAFTDocument2 pagesFirefighting Catalog - ARGO 2017 DRAFTBiljana GlisicNo ratings yet

- Bladder Tank DesignDocument6 pagesBladder Tank DesignDo BuiNo ratings yet

- CAL Manual BookDocument25 pagesCAL Manual Bookanipo68No ratings yet

- CEN Manual BookDocument13 pagesCEN Manual Bookanipo68No ratings yet

- Technical Data: Deluge Foam/Water System Supplied by Bladder TankDocument9 pagesTechnical Data: Deluge Foam/Water System Supplied by Bladder Tankanipo68No ratings yet

- Fire Pump Test Meter: Gerand EngineeringDocument1 pageFire Pump Test Meter: Gerand Engineeringanipo68No ratings yet

- FPTM Installation Instructions - MetricDocument1 pageFPTM Installation Instructions - Metricanipo68No ratings yet

- 3VM12254GE420AA0 Datasheet enDocument5 pages3VM12254GE420AA0 Datasheet enkrishnenduNo ratings yet

- PC 500Document7 pagesPC 500eduardo reyes gallardoNo ratings yet

- Switch Board Installation Guide Revision 1.2 Playstation Mainboard (Pu-20)Document11 pagesSwitch Board Installation Guide Revision 1.2 Playstation Mainboard (Pu-20)Leonardo Monroy SandovalNo ratings yet

- APC Easy Rack Brochure ENDocument9 pagesAPC Easy Rack Brochure ENAsad NizamNo ratings yet

- MP250 ManualDocument13 pagesMP250 ManualfquenNo ratings yet

- Sungrow - Smart Communication Box (COM100D) - Datasheet - V10 - ENDocument1 pageSungrow - Smart Communication Box (COM100D) - Datasheet - V10 - ENAizat AlongNo ratings yet

- Power 6393: Power 6393, Modular Power SupplyDocument2 pagesPower 6393: Power 6393, Modular Power Supplyghhg ioii100% (1)

- Signaling Units Ø 70: Harmony XVB Modular Tower LightsDocument24 pagesSignaling Units Ø 70: Harmony XVB Modular Tower LightsEdgar VillamizarNo ratings yet

- KeiDocument7 pagesKeimazumdar_satyajitNo ratings yet

- Integrated Science Research Notes On Electronic Safety DevicesDocument4 pagesIntegrated Science Research Notes On Electronic Safety DevicesAmisha RamkumarNo ratings yet

- Tool Story (2003) SYF Gold Award 2005.mp4Document25 pagesTool Story (2003) SYF Gold Award 2005.mp4Jelyn OkekeNo ratings yet

- Sirena SiemensDocument4 pagesSirena SiemensAlfredo BauNo ratings yet

- Siemens: 3. Contact Resistance Measurement - (U) - (Acceptable Valus +/ 58 of MegDocument1 pageSiemens: 3. Contact Resistance Measurement - (U) - (Acceptable Valus +/ 58 of MegDeepak VermaNo ratings yet

- Handy Pricelist - 290212 PDFDocument261 pagesHandy Pricelist - 290212 PDFRwanita Anggar DewiNo ratings yet

- Form Service Activity 2020 DraegerDocument57 pagesForm Service Activity 2020 DraegerRenaoval AchillesNo ratings yet

- Fedhii Bittaa Meeshaa EMG Bara 2013Document11 pagesFedhii Bittaa Meeshaa EMG Bara 2013Jamal100% (1)

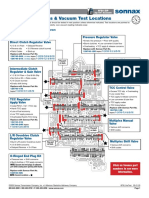

- Critical Wear Areas & Vacuum Test Locations: Upper Valve Body - 6F50 ShownDocument4 pagesCritical Wear Areas & Vacuum Test Locations: Upper Valve Body - 6F50 ShownautomaticosbrasilNo ratings yet

- Sensor Calibration SIBDocument8 pagesSensor Calibration SIBcristianNo ratings yet

- 1st Lab ManualDocument4 pages1st Lab Manualjanlerenz acantoNo ratings yet

- Motor Type HMK - Dimensions and Technical DataDocument2 pagesMotor Type HMK - Dimensions and Technical DataSamuel Lopez BenitesNo ratings yet

- BURKERT Inf Tecnica 8690Document6 pagesBURKERT Inf Tecnica 8690luisNo ratings yet

- 041-Transmissão F4a4 MitsubishiDocument2 pages041-Transmissão F4a4 MitsubishiDanilo A. MarquesNo ratings yet

- Compair Dryer - Commissioning ReportDocument3 pagesCompair Dryer - Commissioning Reportandy habibiNo ratings yet

- Colposcope Model 955 Led: Owner'S ManualDocument16 pagesColposcope Model 955 Led: Owner'S ManualmihaelaputinaNo ratings yet

- Physics Worksheet Topic: Temperature: Encircle The Correct OptionDocument4 pagesPhysics Worksheet Topic: Temperature: Encircle The Correct OptionSaneea ZahraNo ratings yet

- PSP552W, Papaso, RBS6601 DUW30 RRUS2100 Encl - ShoppingDocument2 pagesPSP552W, Papaso, RBS6601 DUW30 RRUS2100 Encl - ShoppingFred AksoNo ratings yet

- sl35 Installation InstructionsDocument2 pagessl35 Installation InstructionsHenry CanalesNo ratings yet

FPTM Operating Instructions

FPTM Operating Instructions

Uploaded by

anipo680 ratings0% found this document useful (0 votes)

15 views1 pageThe document provides operating instructions for a fire pump test meter. The instructions include closing the system valve, opening the bypass valve and throttle valve, purging air from the meter by opening vent valves, starting the fire pump and reading the flow in GPM, and adjusting the throttle valve to meet pump requirements before closing valves after the test.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides operating instructions for a fire pump test meter. The instructions include closing the system valve, opening the bypass valve and throttle valve, purging air from the meter by opening vent valves, starting the fire pump and reading the flow in GPM, and adjusting the throttle valve to meet pump requirements before closing valves after the test.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

15 views1 pageFPTM Operating Instructions

FPTM Operating Instructions

Uploaded by

anipo68The document provides operating instructions for a fire pump test meter. The instructions include closing the system valve, opening the bypass valve and throttle valve, purging air from the meter by opening vent valves, starting the fire pump and reading the flow in GPM, and adjusting the throttle valve to meet pump requirements before closing valves after the test.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

GERAND ENGINEERING CO.

2300 EDGEWOOD AVE S, MINNEAPOLIS, MN 55426 952.374.1320 WWW.GERAND.COM

Fire Pump Test Meter Operating Instructions

BRASS VENT VALVES

METER

PLASTIC VENT HOSE

CONNECTING HOSE

VENTURI

VENTURI SHUT-OFF VALVE

Attached to the meter with a brass chain is an oblong metal tag with the suggested piping diagram of the

system on one side, and the following operating instructions on the reverse side:

1. Close system OSY valve “A”

2. Open by-pass valve and “B” butterfly throttle valve

3. Purge meter, located on venturi, as follows:

a) Open station shut-off valves on venturi, and vent valves attached to meter.

When a steady stream of water without air bubbles passes through the clear plastic hoses,

the meter is purged of air.

b) Close the vent valves after purging.

4. Start the fire pump, and read meter in GPM.

5. Refer to pump GPM requirement and adjust throttle valve to meet the requirement.

6.After the test, open valve “A” and close the by-pass and “B” valves.

*SPECIFY RAISED OR FLAT FACE

GERAND GPM METER - VENTURI PACKAGE

“B” - Butterfly Throttle Valve OSY or Indicating

Butterfly Bypass Valve Flow SUGGESTED

TO RESERVOIR Air Vent PIPING

OR WASTE

DIAGRAM

(2) (5)

Optional to

Pump Inlet Min. Straight Pipe Diameters same line size as Venturi

OSY Valve “A” OSY Valve

Flow

Supply from

City Main or

Reservoir To System

FIRE PUMP

You might also like

- TRANSFORMER Inspection ChecklistDocument3 pagesTRANSFORMER Inspection ChecklistWisnu Hartono94% (17)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Iequipment (EDC) PDFDocument44 pagesIequipment (EDC) PDFAli mohammadNo ratings yet

- 2uz-Fe SfiDocument84 pages2uz-Fe SfiAe Manual100% (1)

- Basic Electrical SafetyDocument25 pagesBasic Electrical Safetyperezes100% (1)

- FPTM Installation Instructions - MetricDocument1 pageFPTM Installation Instructions - Metricanipo68No ratings yet

- Fire Pump Test Meter: Gerand EngineeringDocument5 pagesFire Pump Test Meter: Gerand EngineeringPIYARAT SUWANNAKHANo ratings yet

- Bendix - Master-Vac - Power Brake Service Manual - OCR - 8 PagesDocument8 pagesBendix - Master-Vac - Power Brake Service Manual - OCR - 8 Pagesgreg titanNo ratings yet

- Standing ValveDocument9 pagesStanding ValveRiswan Adhitya SaputraNo ratings yet

- BPH Barrel Pump 2021Document4 pagesBPH Barrel Pump 2021ANo ratings yet

- System - Rated - Plus - W - Sub - 150 Water Hammer PPPDocument2 pagesSystem - Rated - Plus - W - Sub - 150 Water Hammer PPPJeffry GabilanNo ratings yet

- Turbine Walkdown Checks PMIDocument15 pagesTurbine Walkdown Checks PMInikesh ranjanNo ratings yet

- Typical Chemical Injection-SystemDocument3 pagesTypical Chemical Injection-SystemAymen BabourNo ratings yet

- Foam System Line Proportioners: ApplicationDocument4 pagesFoam System Line Proportioners: ApplicationHarry NovaniNo ratings yet

- B B R R: Ird Ird Ain AinDocument8 pagesB B R R: Ird Ird Ain AinKamilNo ratings yet

- Paar-B: Potter Automatic Air ReleaseDocument3 pagesPaar-B: Potter Automatic Air ReleaseCesar GonzalesNo ratings yet

- Engineering & Installation ManualDocument61 pagesEngineering & Installation ManualThameem AnsariNo ratings yet

- Valves Deluge Valve Model h3-bkp-03-04-2018Document16 pagesValves Deluge Valve Model h3-bkp-03-04-2018Benny Kurniawan LimNo ratings yet

- Manifold Systems Catalog PDFDocument28 pagesManifold Systems Catalog PDFRam BabuNo ratings yet

- Brake Comp.Document47 pagesBrake Comp.Steven LincolnNo ratings yet

- Alarm Valve: Model-H (Ductile Iron)Document16 pagesAlarm Valve: Model-H (Ductile Iron)Karen IsananNo ratings yet

- VenturiDocument4 pagesVenturilipetrol007100% (1)

- Foam System Line Proportioners: ApplicationDocument4 pagesFoam System Line Proportioners: ApplicationMohammed SayedNo ratings yet

- Asco firePumpSensingLine RGDocument1 pageAsco firePumpSensingLine RGΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Inline Balance Pressure Foam Proportioner: HD Fire Protect Pvt. Ltd. Technical DataDocument10 pagesInline Balance Pressure Foam Proportioner: HD Fire Protect Pvt. Ltd. Technical Datadebu1985No ratings yet

- Man 80 eDocument17 pagesMan 80 eseanNo ratings yet

- Deluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataDocument16 pagesDeluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataNethajiNo ratings yet

- Deluge Valve Modelh5Document16 pagesDeluge Valve Modelh5Mariana HusainNo ratings yet

- Njwater RequirementDocument6 pagesNjwater RequirementSam ChoiNo ratings yet

- Valves Deluge Valve Model h3Document16 pagesValves Deluge Valve Model h3RaviNo ratings yet

- 928G Wheel Loader: - Implement Hydraulic System (Pilot Operated System)Document15 pages928G Wheel Loader: - Implement Hydraulic System (Pilot Operated System)puput utomoNo ratings yet

- Pumproom Layout Bldg. 8 & 9: Scale 1:30MDocument7 pagesPumproom Layout Bldg. 8 & 9: Scale 1:30MBrownstreet ArchitectsNo ratings yet

- zXQJunINI0EBhB SD-03-906 US 000Document4 pageszXQJunINI0EBhB SD-03-906 US 000udhayNo ratings yet

- Air Over BrakeDocument50 pagesAir Over Brakesidik purnomo100% (1)

- Flojet 4405 SN8386377Document4 pagesFlojet 4405 SN8386377Stathis MoumousisNo ratings yet

- Pre-Action Valve - WF-PAV250xx - v00Document2 pagesPre-Action Valve - WF-PAV250xx - v00genuNo ratings yet

- Wateer Hamer ArestoDocument2 pagesWateer Hamer Arestozaidabusamaha95No ratings yet

- Precision Plumbing Products: "Specify With Confidence - Install With Pride"Document2 pagesPrecision Plumbing Products: "Specify With Confidence - Install With Pride"Janavi RajaganapathyNo ratings yet

- WV-1 Install InstructionsDocument11 pagesWV-1 Install InstructionsmkaukolaNo ratings yet

- Automatic Dewatering SystemDocument2 pagesAutomatic Dewatering SystemRheoserve Industrial SolutionsNo ratings yet

- City Gas DirtibutionDocument32 pagesCity Gas DirtibutionGunjan Bhavsar100% (1)

- CGS PPTDocument32 pagesCGS PPTGunjan BhavsarNo ratings yet

- Valves Deluge Valve Model h3Document16 pagesValves Deluge Valve Model h3Pedro Caminos BolanosNo ratings yet

- Plumbing Lecture 11Document39 pagesPlumbing Lecture 11ahmedemadd19No ratings yet

- Different Types of Control Valves & Actuator SymbolsDocument8 pagesDifferent Types of Control Valves & Actuator SymbolsSangeeth SudhakaranNo ratings yet

- CT Hydraulic Syetem Schematics For PP and CCDocument12 pagesCT Hydraulic Syetem Schematics For PP and CCRolly Hillz SochimNo ratings yet

- 737 300/400/500 Boeing: ATA 36 PneumaticDocument51 pages737 300/400/500 Boeing: ATA 36 PneumaticmaryNo ratings yet

- Instrument Overview: For Yaman LNG On The Job TrainingDocument86 pagesInstrument Overview: For Yaman LNG On The Job TrainingQhismu AdjieNo ratings yet

- RP 546Document2 pagesRP 546Victor TobosqueNo ratings yet

- Inyector Venturi Netafim (Ingles)Document4 pagesInyector Venturi Netafim (Ingles)Alvaro Enrique Perdomo CharryNo ratings yet

- FT - 873905 - Proporcionador en Línea PDFDocument4 pagesFT - 873905 - Proporcionador en Línea PDFYacila AlvaradoNo ratings yet

- Hose Pressure Test Pump (Air-Powered) : Part No DC27530Document2 pagesHose Pressure Test Pump (Air-Powered) : Part No DC27530omernoumanNo ratings yet

- 05 VruDocument17 pages05 VruSergio RodriguezNo ratings yet

- Aro Pump Irits-0409-043Document60 pagesAro Pump Irits-0409-043Adolf MutangaduraNo ratings yet

- Instrument OverviewDocument86 pagesInstrument OverviewRoy PasmanNo ratings yet

- Installation of Injection Pump: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Injection Pump: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Accurate and Reliable Pressure Control: Qualitrol 070/351Document4 pagesAccurate and Reliable Pressure Control: Qualitrol 070/351setiyawanNo ratings yet

- Hyd - Ok & AtoxDocument59 pagesHyd - Ok & AtoxShaukat NadeemNo ratings yet

- TIB 031104 Hyd Sys PurgeDocument2 pagesTIB 031104 Hyd Sys Purgejesus_rs01No ratings yet

- Firefighting Catalog - ARGO 2017 DRAFTDocument2 pagesFirefighting Catalog - ARGO 2017 DRAFTBiljana GlisicNo ratings yet

- Bladder Tank DesignDocument6 pagesBladder Tank DesignDo BuiNo ratings yet

- CAL Manual BookDocument25 pagesCAL Manual Bookanipo68No ratings yet

- CEN Manual BookDocument13 pagesCEN Manual Bookanipo68No ratings yet

- Technical Data: Deluge Foam/Water System Supplied by Bladder TankDocument9 pagesTechnical Data: Deluge Foam/Water System Supplied by Bladder Tankanipo68No ratings yet

- Fire Pump Test Meter: Gerand EngineeringDocument1 pageFire Pump Test Meter: Gerand Engineeringanipo68No ratings yet

- FPTM Installation Instructions - MetricDocument1 pageFPTM Installation Instructions - Metricanipo68No ratings yet

- 3VM12254GE420AA0 Datasheet enDocument5 pages3VM12254GE420AA0 Datasheet enkrishnenduNo ratings yet

- PC 500Document7 pagesPC 500eduardo reyes gallardoNo ratings yet

- Switch Board Installation Guide Revision 1.2 Playstation Mainboard (Pu-20)Document11 pagesSwitch Board Installation Guide Revision 1.2 Playstation Mainboard (Pu-20)Leonardo Monroy SandovalNo ratings yet

- APC Easy Rack Brochure ENDocument9 pagesAPC Easy Rack Brochure ENAsad NizamNo ratings yet

- MP250 ManualDocument13 pagesMP250 ManualfquenNo ratings yet

- Sungrow - Smart Communication Box (COM100D) - Datasheet - V10 - ENDocument1 pageSungrow - Smart Communication Box (COM100D) - Datasheet - V10 - ENAizat AlongNo ratings yet

- Power 6393: Power 6393, Modular Power SupplyDocument2 pagesPower 6393: Power 6393, Modular Power Supplyghhg ioii100% (1)

- Signaling Units Ø 70: Harmony XVB Modular Tower LightsDocument24 pagesSignaling Units Ø 70: Harmony XVB Modular Tower LightsEdgar VillamizarNo ratings yet

- KeiDocument7 pagesKeimazumdar_satyajitNo ratings yet

- Integrated Science Research Notes On Electronic Safety DevicesDocument4 pagesIntegrated Science Research Notes On Electronic Safety DevicesAmisha RamkumarNo ratings yet

- Tool Story (2003) SYF Gold Award 2005.mp4Document25 pagesTool Story (2003) SYF Gold Award 2005.mp4Jelyn OkekeNo ratings yet

- Sirena SiemensDocument4 pagesSirena SiemensAlfredo BauNo ratings yet

- Siemens: 3. Contact Resistance Measurement - (U) - (Acceptable Valus +/ 58 of MegDocument1 pageSiemens: 3. Contact Resistance Measurement - (U) - (Acceptable Valus +/ 58 of MegDeepak VermaNo ratings yet

- Handy Pricelist - 290212 PDFDocument261 pagesHandy Pricelist - 290212 PDFRwanita Anggar DewiNo ratings yet

- Form Service Activity 2020 DraegerDocument57 pagesForm Service Activity 2020 DraegerRenaoval AchillesNo ratings yet

- Fedhii Bittaa Meeshaa EMG Bara 2013Document11 pagesFedhii Bittaa Meeshaa EMG Bara 2013Jamal100% (1)

- Critical Wear Areas & Vacuum Test Locations: Upper Valve Body - 6F50 ShownDocument4 pagesCritical Wear Areas & Vacuum Test Locations: Upper Valve Body - 6F50 ShownautomaticosbrasilNo ratings yet

- Sensor Calibration SIBDocument8 pagesSensor Calibration SIBcristianNo ratings yet

- 1st Lab ManualDocument4 pages1st Lab Manualjanlerenz acantoNo ratings yet

- Motor Type HMK - Dimensions and Technical DataDocument2 pagesMotor Type HMK - Dimensions and Technical DataSamuel Lopez BenitesNo ratings yet

- BURKERT Inf Tecnica 8690Document6 pagesBURKERT Inf Tecnica 8690luisNo ratings yet

- 041-Transmissão F4a4 MitsubishiDocument2 pages041-Transmissão F4a4 MitsubishiDanilo A. MarquesNo ratings yet

- Compair Dryer - Commissioning ReportDocument3 pagesCompair Dryer - Commissioning Reportandy habibiNo ratings yet

- Colposcope Model 955 Led: Owner'S ManualDocument16 pagesColposcope Model 955 Led: Owner'S ManualmihaelaputinaNo ratings yet

- Physics Worksheet Topic: Temperature: Encircle The Correct OptionDocument4 pagesPhysics Worksheet Topic: Temperature: Encircle The Correct OptionSaneea ZahraNo ratings yet

- PSP552W, Papaso, RBS6601 DUW30 RRUS2100 Encl - ShoppingDocument2 pagesPSP552W, Papaso, RBS6601 DUW30 RRUS2100 Encl - ShoppingFred AksoNo ratings yet

- sl35 Installation InstructionsDocument2 pagessl35 Installation InstructionsHenry CanalesNo ratings yet