Professional Documents

Culture Documents

5.05 - Page 52 of 155

5.05 - Page 52 of 155

Uploaded by

loukmanCopyright:

Available Formats

You might also like

- Still Steds Diesel Fork Truck Rx70 40 Rx70 45 Rx70 50 Rx70!50!600 Parts ManualDocument20 pagesStill Steds Diesel Fork Truck Rx70 40 Rx70 45 Rx70 50 Rx70!50!600 Parts Manualhannah100% (51)

- Vauxhall Workshop Manuals: Astra JDocument1 pageVauxhall Workshop Manuals: Astra JAhmed Almaghrby0% (1)

- Methodology For Installation of Paver Block WorkDocument3 pagesMethodology For Installation of Paver Block Workkunalji_jain50% (6)

- Install Guide - 5R55S & 5R55WDocument4 pagesInstall Guide - 5R55S & 5R55WLuis AlcalaNo ratings yet

- Concrete Pavement ConstructionDocument6 pagesConcrete Pavement ConstructionEngineeri TadiyosNo ratings yet

- Kerbstones Installation GuidelinesDocument4 pagesKerbstones Installation Guidelinespartha_svnitNo ratings yet

- 1limitation of MixingDocument4 pages1limitation of MixingJei EmNo ratings yet

- 609 - Curbing Concrete Medians (2012)Document6 pages609 - Curbing Concrete Medians (2012)Inapanuri Nageshwara RaoNo ratings yet

- Method Statement For Box CulvertDocument8 pagesMethod Statement For Box CulvertAlbertyNo ratings yet

- Spec 451 Reinforced Portland Cement Concrete PavementDocument6 pagesSpec 451 Reinforced Portland Cement Concrete PavementCharan ReddyNo ratings yet

- Paving Method StatementDocument10 pagesPaving Method StatementnewattelectricNo ratings yet

- Paving Method StatementDocument10 pagesPaving Method StatementDarshit VyasNo ratings yet

- Why Do Pavers CrackDocument12 pagesWhy Do Pavers CrackMoncea AndreeaNo ratings yet

- Assign of Construction TechnologyDocument7 pagesAssign of Construction TechnologyHaile Alex AbdisaNo ratings yet

- Methodolgy of Rigid Pavement: Friday, 13 July 2012Document19 pagesMethodolgy of Rigid Pavement: Friday, 13 July 2012Mac Lester MartinNo ratings yet

- 5.05 - Page 53 of 155Document1 page5.05 - Page 53 of 155loukmanNo ratings yet

- Guided By: Prepared By: Prof. Jain Sir Saurabh P. VDocument42 pagesGuided By: Prepared By: Prof. Jain Sir Saurabh P. VNagesh ChitariNo ratings yet

- Safe Work Method - ConcretingDocument11 pagesSafe Work Method - ConcretingJustin Ranjit100% (1)

- Div3 GC EJResponsibilitiesDocument2 pagesDiv3 GC EJResponsibilitiesamsteefenNo ratings yet

- Sika Grouting SystemsDocument7 pagesSika Grouting SystemsJossh TorresNo ratings yet

- Elements of Road: Highway Geometric Design: Cross Sectional Elements Width, Surface, CamberDocument45 pagesElements of Road: Highway Geometric Design: Cross Sectional Elements Width, Surface, Camberanarkali mominNo ratings yet

- QA/QC Procedure Installation of Perimeter FenceDocument3 pagesQA/QC Procedure Installation of Perimeter FencecandaceNo ratings yet

- Integral BridgesDocument12 pagesIntegral Bridgessoniafaisal100% (1)

- CONSTRUCTION METHODS RoadsDocument4 pagesCONSTRUCTION METHODS RoadsAngelicaNo ratings yet

- Vehicle Crossings DrawingsDocument13 pagesVehicle Crossings DrawingsfedajxzcfampflohwvNo ratings yet

- How Road Are Being ConstructedDocument4 pagesHow Road Are Being ConstructedDianaDion WintersPolNo ratings yet

- Bridge Technical Note 2018 - 011 Approach Slabs Jan 2018Document2 pagesBridge Technical Note 2018 - 011 Approach Slabs Jan 2018Jing CaoNo ratings yet

- Construction and Materials Manual: 4.16.1 Slip-Form MethodDocument2 pagesConstruction and Materials Manual: 4.16.1 Slip-Form MethodSherif M. GebNo ratings yet

- PQC - Road ConcreteDocument10 pagesPQC - Road Concretemangeshshinde124100% (1)

- M.E. Laws, Contracts and Ethics PresentationDocument28 pagesM.E. Laws, Contracts and Ethics PresentationLeo Paulo Del Rosario0% (1)

- CBRI - Waffle Unit & JoistDocument11 pagesCBRI - Waffle Unit & JoistAnkita Ghodke100% (2)

- Mechanically Stabilized EmbankmentsDocument6 pagesMechanically Stabilized EmbankmentsScribdmarificNo ratings yet

- Planning and Site Preparation For ConcreteDocument1 pagePlanning and Site Preparation For ConcreteKimo KenoNo ratings yet

- RIGID PAVEMENT AssignmentDocument16 pagesRIGID PAVEMENT AssignmentSsekajjigo Dungu MuwongeNo ratings yet

- Final Report: Industrial Training (Construction of Flyover)Document16 pagesFinal Report: Industrial Training (Construction of Flyover)Abhishek kumar100% (1)

- Review of Related LiteratureDocument12 pagesReview of Related LiteratureJohn Clyde Agayao100% (1)

- Slope ProtectionDocument3 pagesSlope Protectionshima2727No ratings yet

- Joints in Concrete Pavement Technical PaperDocument22 pagesJoints in Concrete Pavement Technical Paperphyo_thar_1100% (1)

- Grouting Systems - 620Document6 pagesGrouting Systems - 620arunkumarNo ratings yet

- Box Culvert, VUP & Minor BridgeDocument22 pagesBox Culvert, VUP & Minor BridgeĐărsĥąna RanasingheNo ratings yet

- Trench Install Guide1Document4 pagesTrench Install Guide1Fatholla Salehi100% (1)

- EdgeDocument4 pagesEdgeHazmi Bcool100% (1)

- Construction Procedures of Slip-Form PavementDocument5 pagesConstruction Procedures of Slip-Form PavementSerdarNo ratings yet

- Method Statement For EmbankmentDocument5 pagesMethod Statement For EmbankmentAlbertyNo ratings yet

- Site ReportDocument40 pagesSite ReportCaleb KhisaNo ratings yet

- Method Statement - Chasing Work On Block Wall For PVC Conduits PDFDocument2 pagesMethod Statement - Chasing Work On Block Wall For PVC Conduits PDFPrimo MartinezNo ratings yet

- Method Statement - Chasing Work On Block Wall For PVC Conduits PDFDocument2 pagesMethod Statement - Chasing Work On Block Wall For PVC Conduits PDFPrimo MartinezNo ratings yet

- Item 103 and Item 506Document42 pagesItem 103 and Item 506Wilbert Carlo RachoNo ratings yet

- REPORTDocument20 pagesREPORTkishen972No ratings yet

- Structural Design of Railways and PavementsDocument57 pagesStructural Design of Railways and PavementsJannila PaulinoNo ratings yet

- Ministry of Higher SalihDocument29 pagesMinistry of Higher SalihSalih MohayaddinNo ratings yet

- Gang Mounted Needle Vibrator Fix Form Paver - NCCDocument2 pagesGang Mounted Needle Vibrator Fix Form Paver - NCCKawrw DgedeaNo ratings yet

- Design of Surfaces & Guide Ways: PavementDocument20 pagesDesign of Surfaces & Guide Ways: PavementSam BarotillaNo ratings yet

- March 1986 No. 870Document2 pagesMarch 1986 No. 870Dyeri FloresNo ratings yet

- Real Final Year ProjectDocument18 pagesReal Final Year ProjectJaffar Manzoor 39No ratings yet

- Crossection of A RoadDocument27 pagesCrossection of A RoadFatima KamranNo ratings yet

- Section 606 Bridge Restoration and Waterproofing With Concrete OverlaysDocument12 pagesSection 606 Bridge Restoration and Waterproofing With Concrete OverlaysSuranga ManuNo ratings yet

- 2287 Technical SpecificationDocument9 pages2287 Technical SpecificationBasava NNo ratings yet

- Method of Statement For Concreting and Safety MeasuresDocument5 pagesMethod of Statement For Concreting and Safety MeasuresDivya ShahNo ratings yet

- Block Masonary Work: Method StatementDocument5 pagesBlock Masonary Work: Method StatementAneel KumarNo ratings yet

- Epoxy Grout Handbook - MasterFlowDocument17 pagesEpoxy Grout Handbook - MasterFlowaruncg2No ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- $RHOY5V6Document1 page$RHOY5V6loukmanNo ratings yet

- $RMJOFAWDocument1 page$RMJOFAWloukmanNo ratings yet

- $RUBCKHZDocument2 pages$RUBCKHZloukmanNo ratings yet

- Al JazeeraDocument1 pageAl JazeeraloukmanNo ratings yet

- 5.05 - Page 53 of 155Document1 page5.05 - Page 53 of 155loukmanNo ratings yet

- 5.04 - Page 45 of 155Document1 page5.04 - Page 45 of 155loukmanNo ratings yet

- MNL-117 3rd Edition XVDocument1 pageMNL-117 3rd Edition XVloukmanNo ratings yet

- 3Document1 page3loukmanNo ratings yet

- Standard Commentary: 1.2.2 Documented ProceduresDocument1 pageStandard Commentary: 1.2.2 Documented ProceduresloukmanNo ratings yet

- Definitions: MNL-117 3rd Edition XiDocument1 pageDefinitions: MNL-117 3rd Edition XiloukmanNo ratings yet

- Table of Contents: 3rd EditionDocument1 pageTable of Contents: 3rd EditionloukmanNo ratings yet

- Pip Ars13120pre Engineered Metal Building SpecificationDocument26 pagesPip Ars13120pre Engineered Metal Building SpecificationloukmanNo ratings yet

- Process Industry Practices Structural: PIP STF05530 Grating Fabrication DetailsDocument13 pagesProcess Industry Practices Structural: PIP STF05530 Grating Fabrication DetailsloukmanNo ratings yet

- Ausa C 150h x4 Parts ManualDocument10 pagesAusa C 150h x4 Parts Manualmichael100% (61)

- 4 Consideration of Alternatives: 4.1 GeneralDocument15 pages4 Consideration of Alternatives: 4.1 GeneralHrithik IGNo ratings yet

- GUJ Directory of Institution - College 06012019074800483PMDocument434 pagesGUJ Directory of Institution - College 06012019074800483PMFalgunNo ratings yet

- 02-09-2022 Lista Unificada Completa MonoDocument26 pages02-09-2022 Lista Unificada Completa MonoCarlos Jose MorenoNo ratings yet

- Structure RFI Status Summary For The Month of December-2021Document11 pagesStructure RFI Status Summary For The Month of December-2021Thakur Ravi ChauhanNo ratings yet

- Volvo 740 Owner's ManualDocument141 pagesVolvo 740 Owner's ManualAziz AzizNo ratings yet

- Passenger Ropeway Checklists 2008 11 1Document19 pagesPassenger Ropeway Checklists 2008 11 1Borislav VulićNo ratings yet

- Compatibilite BMW CR Max v3Document287 pagesCompatibilite BMW CR Max v3Bruno MarquesNo ratings yet

- mcrp4-11-3f - Convoy Operations PDFDocument74 pagesmcrp4-11-3f - Convoy Operations PDFdwightNo ratings yet

- Dynapac - Ca25pd-D Tier 3 Rev.1Document220 pagesDynapac - Ca25pd-D Tier 3 Rev.1Maycon Harrison100% (2)

- TenderAwardedDetailsReport AndhraDocument5,631 pagesTenderAwardedDetailsReport AndhraSarang Mohide0% (1)

- Les Jeux Sont Faits - Jean-Paul SartreDocument140 pagesLes Jeux Sont Faits - Jean-Paul SartreSarah WangNo ratings yet

- Rashad Al-Khunaizi C.V.: SummaryDocument2 pagesRashad Al-Khunaizi C.V.: Summaryapi-537994696No ratings yet

- BS en 14067-6-2010 - (2016-12-22 - 07-29-34 Am)Document128 pagesBS en 14067-6-2010 - (2016-12-22 - 07-29-34 Am)Julio Andrés Casal RamosNo ratings yet

- For A Greater Frankford 1912Document84 pagesFor A Greater Frankford 1912Richard Castor100% (1)

- Effects of Different Methods of Stockpiling Aggregates Interim ReportDocument58 pagesEffects of Different Methods of Stockpiling Aggregates Interim ReportJulio César Párraga CurielNo ratings yet

- Central Luzon Link Expressway CLLEX Phase 1Document19 pagesCentral Luzon Link Expressway CLLEX Phase 1Angel YuNo ratings yet

- Yaris en Owners Manual 2004Document257 pagesYaris en Owners Manual 2004Marco OchoaNo ratings yet

- Inverted T-WALL ®: A New Solution From The Neel CompanyDocument3 pagesInverted T-WALL ®: A New Solution From The Neel CompanysamNo ratings yet

- Corona EnginesDocument1 pageCorona EnginesShamim OmulangiraNo ratings yet

- TN1 Unit 5 AssessmentDocument6 pagesTN1 Unit 5 AssessmentJhon VallejoNo ratings yet

- Automoviles Electricos: International Energy AgencyDocument3 pagesAutomoviles Electricos: International Energy AgencyEDGAR SOLISNo ratings yet

- Highway Geometric Alignment and Design LectureDocument98 pagesHighway Geometric Alignment and Design LectureMatthew MazivanhangaNo ratings yet

- GS2668 e 3268RT - Parts 2011 - 84121Document238 pagesGS2668 e 3268RT - Parts 2011 - 84121walmadasanNo ratings yet

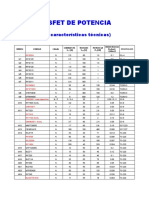

- Mosfet de PotenciaDocument7 pagesMosfet de Potenciaalb_fedeNo ratings yet

- 900 SsDocument234 pages900 SsAlberto PHNo ratings yet

- Construction Equipments - Rollers: Presented byDocument20 pagesConstruction Equipments - Rollers: Presented byAditi BazajNo ratings yet

5.05 - Page 52 of 155

5.05 - Page 52 of 155

Uploaded by

loukmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5.05 - Page 52 of 155

5.05 - Page 52 of 155

Uploaded by

loukmanCopyright:

Available Formats

K. Vibrators shall not rest on new pavement or side forms.

Power to vibrators shall be

connected so that vibration ceases when forward or backward motion of the machine is stopped.

L. When concrete is being placed adjacent to an existing pavement, the part of the

equipment supported on the existing pavement shall be fitted with protective pads on crawler

tracks or rubber-tired wheels with the bearing surface offset to run a sufficient distance from the

pavement edge to avoid breaking or cracking the edge.

M. Concrete placed at existing ramp termini, truck weigh stations, ramps, connectors with

steep grades and high rates of superelevation, in short sections of city streets, on sharp curves,

in short lengths or in widths other than multiples of traffic lanes shall be spread and shaped by

suitable powered finishing machines, supplement by handwork as necessary. Consolidation of

concrete so placed shall be completed using high frequency internal vibrators and within 15

minutes of placement. Vibration of concrete shall be carried out with care and the Contractor

shall ensure adequate consolidation adjacent to forms and uniform consolidation across the full

paving width. Use of vibrators for shifting masses or piles of concrete is not permitted. Methods

of spreading, shaping and compaction that result in segregation, voids or rock pockets shall be

discontinued. The Contractor shall adopt methods which will produce a dense and homogeneous

pavement.

5.05.9 SLIP-FORM CONSTRUCTION

A. Slip-form pavers shall be equipped with travelling side forms of sufficient dimensions,

shape and strength to support the concrete laterally for a sufficient length of time to produce a

pavement of the required cross section. Slip-form paving equipment shall spread, consolidate and

screed freshly placed concrete in order that a minimum of handwork shall be required to produce

a dense homogeneous pavement.

B. No abrupt changes in longitudinal alignment of the pavement shall be permitted. The

horizontal deviation shall not exceed 30 mm from the alignment shown on the Drawings.

C. Concrete shall be effectively compacted over the full paving width by high frequency

internal vibrators. Vibrators shall be mounted with their axes parallel or normal to pavement

alignment. When vibrators are mounted with their axes parallel with the pavement alignment,

they shall be spaced at intervals not exceeding 750 mm measured centre to centre. When

vibrators are mounted with their axes normal to pavement alignment, they shall be spaced so that

lateral clearance between individual vibrating units does not exceed 150 mm.

D. The vibration rate of each vibrating unit shall be not less than 5,000 cycles/minute. The

amplitude of vibration shall be sufficient to be perceptible on the surface of concrete along the

entire length of vibrating units and for a distance up to 0.5 metres therefrom. The Contractor

shall furnish a tachometer or other suitable device for measuring and indicating frequency of

vibration.

E. When concrete is being placed adjacent to an existing pavement, the part of the

equipment supported on existing pavement shall be fitted with protective pads on crawler tracks

or rubber-tired wheels with the bearing surface offset to run a sufficient distance from the

pavement edge to avoid breaking or cracking such edge.

(Consultant) CONCRETE PAVEMENT

5.05 - Page 52 of 155

You might also like

- Still Steds Diesel Fork Truck Rx70 40 Rx70 45 Rx70 50 Rx70!50!600 Parts ManualDocument20 pagesStill Steds Diesel Fork Truck Rx70 40 Rx70 45 Rx70 50 Rx70!50!600 Parts Manualhannah100% (51)

- Vauxhall Workshop Manuals: Astra JDocument1 pageVauxhall Workshop Manuals: Astra JAhmed Almaghrby0% (1)

- Methodology For Installation of Paver Block WorkDocument3 pagesMethodology For Installation of Paver Block Workkunalji_jain50% (6)

- Install Guide - 5R55S & 5R55WDocument4 pagesInstall Guide - 5R55S & 5R55WLuis AlcalaNo ratings yet

- Concrete Pavement ConstructionDocument6 pagesConcrete Pavement ConstructionEngineeri TadiyosNo ratings yet

- Kerbstones Installation GuidelinesDocument4 pagesKerbstones Installation Guidelinespartha_svnitNo ratings yet

- 1limitation of MixingDocument4 pages1limitation of MixingJei EmNo ratings yet

- 609 - Curbing Concrete Medians (2012)Document6 pages609 - Curbing Concrete Medians (2012)Inapanuri Nageshwara RaoNo ratings yet

- Method Statement For Box CulvertDocument8 pagesMethod Statement For Box CulvertAlbertyNo ratings yet

- Spec 451 Reinforced Portland Cement Concrete PavementDocument6 pagesSpec 451 Reinforced Portland Cement Concrete PavementCharan ReddyNo ratings yet

- Paving Method StatementDocument10 pagesPaving Method StatementnewattelectricNo ratings yet

- Paving Method StatementDocument10 pagesPaving Method StatementDarshit VyasNo ratings yet

- Why Do Pavers CrackDocument12 pagesWhy Do Pavers CrackMoncea AndreeaNo ratings yet

- Assign of Construction TechnologyDocument7 pagesAssign of Construction TechnologyHaile Alex AbdisaNo ratings yet

- Methodolgy of Rigid Pavement: Friday, 13 July 2012Document19 pagesMethodolgy of Rigid Pavement: Friday, 13 July 2012Mac Lester MartinNo ratings yet

- 5.05 - Page 53 of 155Document1 page5.05 - Page 53 of 155loukmanNo ratings yet

- Guided By: Prepared By: Prof. Jain Sir Saurabh P. VDocument42 pagesGuided By: Prepared By: Prof. Jain Sir Saurabh P. VNagesh ChitariNo ratings yet

- Safe Work Method - ConcretingDocument11 pagesSafe Work Method - ConcretingJustin Ranjit100% (1)

- Div3 GC EJResponsibilitiesDocument2 pagesDiv3 GC EJResponsibilitiesamsteefenNo ratings yet

- Sika Grouting SystemsDocument7 pagesSika Grouting SystemsJossh TorresNo ratings yet

- Elements of Road: Highway Geometric Design: Cross Sectional Elements Width, Surface, CamberDocument45 pagesElements of Road: Highway Geometric Design: Cross Sectional Elements Width, Surface, Camberanarkali mominNo ratings yet

- QA/QC Procedure Installation of Perimeter FenceDocument3 pagesQA/QC Procedure Installation of Perimeter FencecandaceNo ratings yet

- Integral BridgesDocument12 pagesIntegral Bridgessoniafaisal100% (1)

- CONSTRUCTION METHODS RoadsDocument4 pagesCONSTRUCTION METHODS RoadsAngelicaNo ratings yet

- Vehicle Crossings DrawingsDocument13 pagesVehicle Crossings DrawingsfedajxzcfampflohwvNo ratings yet

- How Road Are Being ConstructedDocument4 pagesHow Road Are Being ConstructedDianaDion WintersPolNo ratings yet

- Bridge Technical Note 2018 - 011 Approach Slabs Jan 2018Document2 pagesBridge Technical Note 2018 - 011 Approach Slabs Jan 2018Jing CaoNo ratings yet

- Construction and Materials Manual: 4.16.1 Slip-Form MethodDocument2 pagesConstruction and Materials Manual: 4.16.1 Slip-Form MethodSherif M. GebNo ratings yet

- PQC - Road ConcreteDocument10 pagesPQC - Road Concretemangeshshinde124100% (1)

- M.E. Laws, Contracts and Ethics PresentationDocument28 pagesM.E. Laws, Contracts and Ethics PresentationLeo Paulo Del Rosario0% (1)

- CBRI - Waffle Unit & JoistDocument11 pagesCBRI - Waffle Unit & JoistAnkita Ghodke100% (2)

- Mechanically Stabilized EmbankmentsDocument6 pagesMechanically Stabilized EmbankmentsScribdmarificNo ratings yet

- Planning and Site Preparation For ConcreteDocument1 pagePlanning and Site Preparation For ConcreteKimo KenoNo ratings yet

- RIGID PAVEMENT AssignmentDocument16 pagesRIGID PAVEMENT AssignmentSsekajjigo Dungu MuwongeNo ratings yet

- Final Report: Industrial Training (Construction of Flyover)Document16 pagesFinal Report: Industrial Training (Construction of Flyover)Abhishek kumar100% (1)

- Review of Related LiteratureDocument12 pagesReview of Related LiteratureJohn Clyde Agayao100% (1)

- Slope ProtectionDocument3 pagesSlope Protectionshima2727No ratings yet

- Joints in Concrete Pavement Technical PaperDocument22 pagesJoints in Concrete Pavement Technical Paperphyo_thar_1100% (1)

- Grouting Systems - 620Document6 pagesGrouting Systems - 620arunkumarNo ratings yet

- Box Culvert, VUP & Minor BridgeDocument22 pagesBox Culvert, VUP & Minor BridgeĐărsĥąna RanasingheNo ratings yet

- Trench Install Guide1Document4 pagesTrench Install Guide1Fatholla Salehi100% (1)

- EdgeDocument4 pagesEdgeHazmi Bcool100% (1)

- Construction Procedures of Slip-Form PavementDocument5 pagesConstruction Procedures of Slip-Form PavementSerdarNo ratings yet

- Method Statement For EmbankmentDocument5 pagesMethod Statement For EmbankmentAlbertyNo ratings yet

- Site ReportDocument40 pagesSite ReportCaleb KhisaNo ratings yet

- Method Statement - Chasing Work On Block Wall For PVC Conduits PDFDocument2 pagesMethod Statement - Chasing Work On Block Wall For PVC Conduits PDFPrimo MartinezNo ratings yet

- Method Statement - Chasing Work On Block Wall For PVC Conduits PDFDocument2 pagesMethod Statement - Chasing Work On Block Wall For PVC Conduits PDFPrimo MartinezNo ratings yet

- Item 103 and Item 506Document42 pagesItem 103 and Item 506Wilbert Carlo RachoNo ratings yet

- REPORTDocument20 pagesREPORTkishen972No ratings yet

- Structural Design of Railways and PavementsDocument57 pagesStructural Design of Railways and PavementsJannila PaulinoNo ratings yet

- Ministry of Higher SalihDocument29 pagesMinistry of Higher SalihSalih MohayaddinNo ratings yet

- Gang Mounted Needle Vibrator Fix Form Paver - NCCDocument2 pagesGang Mounted Needle Vibrator Fix Form Paver - NCCKawrw DgedeaNo ratings yet

- Design of Surfaces & Guide Ways: PavementDocument20 pagesDesign of Surfaces & Guide Ways: PavementSam BarotillaNo ratings yet

- March 1986 No. 870Document2 pagesMarch 1986 No. 870Dyeri FloresNo ratings yet

- Real Final Year ProjectDocument18 pagesReal Final Year ProjectJaffar Manzoor 39No ratings yet

- Crossection of A RoadDocument27 pagesCrossection of A RoadFatima KamranNo ratings yet

- Section 606 Bridge Restoration and Waterproofing With Concrete OverlaysDocument12 pagesSection 606 Bridge Restoration and Waterproofing With Concrete OverlaysSuranga ManuNo ratings yet

- 2287 Technical SpecificationDocument9 pages2287 Technical SpecificationBasava NNo ratings yet

- Method of Statement For Concreting and Safety MeasuresDocument5 pagesMethod of Statement For Concreting and Safety MeasuresDivya ShahNo ratings yet

- Block Masonary Work: Method StatementDocument5 pagesBlock Masonary Work: Method StatementAneel KumarNo ratings yet

- Epoxy Grout Handbook - MasterFlowDocument17 pagesEpoxy Grout Handbook - MasterFlowaruncg2No ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- $RHOY5V6Document1 page$RHOY5V6loukmanNo ratings yet

- $RMJOFAWDocument1 page$RMJOFAWloukmanNo ratings yet

- $RUBCKHZDocument2 pages$RUBCKHZloukmanNo ratings yet

- Al JazeeraDocument1 pageAl JazeeraloukmanNo ratings yet

- 5.05 - Page 53 of 155Document1 page5.05 - Page 53 of 155loukmanNo ratings yet

- 5.04 - Page 45 of 155Document1 page5.04 - Page 45 of 155loukmanNo ratings yet

- MNL-117 3rd Edition XVDocument1 pageMNL-117 3rd Edition XVloukmanNo ratings yet

- 3Document1 page3loukmanNo ratings yet

- Standard Commentary: 1.2.2 Documented ProceduresDocument1 pageStandard Commentary: 1.2.2 Documented ProceduresloukmanNo ratings yet

- Definitions: MNL-117 3rd Edition XiDocument1 pageDefinitions: MNL-117 3rd Edition XiloukmanNo ratings yet

- Table of Contents: 3rd EditionDocument1 pageTable of Contents: 3rd EditionloukmanNo ratings yet

- Pip Ars13120pre Engineered Metal Building SpecificationDocument26 pagesPip Ars13120pre Engineered Metal Building SpecificationloukmanNo ratings yet

- Process Industry Practices Structural: PIP STF05530 Grating Fabrication DetailsDocument13 pagesProcess Industry Practices Structural: PIP STF05530 Grating Fabrication DetailsloukmanNo ratings yet

- Ausa C 150h x4 Parts ManualDocument10 pagesAusa C 150h x4 Parts Manualmichael100% (61)

- 4 Consideration of Alternatives: 4.1 GeneralDocument15 pages4 Consideration of Alternatives: 4.1 GeneralHrithik IGNo ratings yet

- GUJ Directory of Institution - College 06012019074800483PMDocument434 pagesGUJ Directory of Institution - College 06012019074800483PMFalgunNo ratings yet

- 02-09-2022 Lista Unificada Completa MonoDocument26 pages02-09-2022 Lista Unificada Completa MonoCarlos Jose MorenoNo ratings yet

- Structure RFI Status Summary For The Month of December-2021Document11 pagesStructure RFI Status Summary For The Month of December-2021Thakur Ravi ChauhanNo ratings yet

- Volvo 740 Owner's ManualDocument141 pagesVolvo 740 Owner's ManualAziz AzizNo ratings yet

- Passenger Ropeway Checklists 2008 11 1Document19 pagesPassenger Ropeway Checklists 2008 11 1Borislav VulićNo ratings yet

- Compatibilite BMW CR Max v3Document287 pagesCompatibilite BMW CR Max v3Bruno MarquesNo ratings yet

- mcrp4-11-3f - Convoy Operations PDFDocument74 pagesmcrp4-11-3f - Convoy Operations PDFdwightNo ratings yet

- Dynapac - Ca25pd-D Tier 3 Rev.1Document220 pagesDynapac - Ca25pd-D Tier 3 Rev.1Maycon Harrison100% (2)

- TenderAwardedDetailsReport AndhraDocument5,631 pagesTenderAwardedDetailsReport AndhraSarang Mohide0% (1)

- Les Jeux Sont Faits - Jean-Paul SartreDocument140 pagesLes Jeux Sont Faits - Jean-Paul SartreSarah WangNo ratings yet

- Rashad Al-Khunaizi C.V.: SummaryDocument2 pagesRashad Al-Khunaizi C.V.: Summaryapi-537994696No ratings yet

- BS en 14067-6-2010 - (2016-12-22 - 07-29-34 Am)Document128 pagesBS en 14067-6-2010 - (2016-12-22 - 07-29-34 Am)Julio Andrés Casal RamosNo ratings yet

- For A Greater Frankford 1912Document84 pagesFor A Greater Frankford 1912Richard Castor100% (1)

- Effects of Different Methods of Stockpiling Aggregates Interim ReportDocument58 pagesEffects of Different Methods of Stockpiling Aggregates Interim ReportJulio César Párraga CurielNo ratings yet

- Central Luzon Link Expressway CLLEX Phase 1Document19 pagesCentral Luzon Link Expressway CLLEX Phase 1Angel YuNo ratings yet

- Yaris en Owners Manual 2004Document257 pagesYaris en Owners Manual 2004Marco OchoaNo ratings yet

- Inverted T-WALL ®: A New Solution From The Neel CompanyDocument3 pagesInverted T-WALL ®: A New Solution From The Neel CompanysamNo ratings yet

- Corona EnginesDocument1 pageCorona EnginesShamim OmulangiraNo ratings yet

- TN1 Unit 5 AssessmentDocument6 pagesTN1 Unit 5 AssessmentJhon VallejoNo ratings yet

- Automoviles Electricos: International Energy AgencyDocument3 pagesAutomoviles Electricos: International Energy AgencyEDGAR SOLISNo ratings yet

- Highway Geometric Alignment and Design LectureDocument98 pagesHighway Geometric Alignment and Design LectureMatthew MazivanhangaNo ratings yet

- GS2668 e 3268RT - Parts 2011 - 84121Document238 pagesGS2668 e 3268RT - Parts 2011 - 84121walmadasanNo ratings yet

- Mosfet de PotenciaDocument7 pagesMosfet de Potenciaalb_fedeNo ratings yet

- 900 SsDocument234 pages900 SsAlberto PHNo ratings yet

- Construction Equipments - Rollers: Presented byDocument20 pagesConstruction Equipments - Rollers: Presented byAditi BazajNo ratings yet