Professional Documents

Culture Documents

Standard Specification For Casting Dimensions, Tolerance by MicroMelt

Standard Specification For Casting Dimensions, Tolerance by MicroMelt

Uploaded by

Raviteja KarukolaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Specification For Casting Dimensions, Tolerance by MicroMelt

Standard Specification For Casting Dimensions, Tolerance by MicroMelt

Uploaded by

Raviteja KarukolaCopyright:

Available Formats

8/10/2021 Standard Specification for Casting Dimensions, Tolerance by MicroMelt

Tolerance level is something that calculates and figures out the exact and correct values for which an investment cast according to the given specification,

reaches a maximum point without getting damaged by any means. The tolerance can be specified in many dimensions and in many suitable industrial ways, by

which a buyer can deduce and co relate according to the required specification and be assured about the maximum ratings or tolerance accordingly.

We are Micro Melt Pvt. Ltd, an ISO certified 9001:2008 company dealing and manufacturing quality investment casting and metallic shaped instruments

according to the given specifications. We have a set of lists, from which a person or a company can correlate the charts so as to match their requirements. The

levels and different specified tolerances and its variants are listed below as follows:

SURFACE FINISH CONCENTRICITY

As-cast finishes will vary with alloy specified but generally fall within The larger the outside diameter becomes, the closer to concentric an inside

the range quoted. For a ground finish an allowance of 0.010 in. diameter can be cast.

(0.25mm) should be made. Mechanical correction can normally be made where wall thickness is thin

enough to allow plastic deformation.

C.I.A. value

Metal Micro-inches Eccentricity (mm)

O.D.(mm) I.D. (mm)

As-cast Machined

As-cast Corrected

Stainless Steels 90-126 60-125 18.75 6.25 ±0.100 ±0.100

Cobalt Chrome Alloys 80-100 50-100 25.00 12.50 ±0.125 ±0.125

Carbon Steels 90-125 60-125 37.50 18.45 ±0.200 ±0.200

50.00 25.00 ±0.250 ±0.200

GENERAL TOLERANCES

ROUNDNESS

Shape and alloy selected will influence accuracies achieved but values

given are normally accepted through out the investment casting For solid bars roundness is affected by solidification stresses and tolerance

industry. required increases nearly in proportion to diameter, inline with usual 'Lost

Wax' tolerances.

Dimension Tolerance Values shown are for as-cost roundness on inside and outside diameters of

tubes of varying sizes. Wall thickness is important and tighten tolerance can

Upto 25 mm ±0.25mm be obtained by mechanical correction if desired.

Above 25 mm ±0.25mm/25mm

O.D. (mm) Tolerance (mm) I.D. (mm) Tolerance (mm)

Closer tolerance may be held on selected dimensions following design

evaluation. 12.50 ±0.25 upto 6.25 ±0.30

STRAIGHTNESS 25.00 ±0.50 6.25-12.50 ±0.40

There are practical limits to straightness which can be achieved but 12.50-

37.50 ±0.60 ±0.50

mechanical straightning can reduce variations. 25.00

Casting Length As-cost Corrected ±0.50

above

50.00 ±0.75

25 mm ±0.50 mm ±0.25 mm 25.00

(per 25 mm)

50-100 mm ±0.75 mm ±0.50 mm

100-150 mm ±1.00 mm ±0.50 mm MINIMUM SECTION THICKNESS

150 mm ±1.50 mm ±0.62 mm Wall thickness will depend upon area of casting and alloy selected. The

following values are of guide from general experience.

FLATNESS

Material Minimun wall thickness obtainable

Flatness is also affected by dimensions of investment casting. 18/8 stainless steels 1.62 mm

Addition of ribs will minimize bowing, twisting and distortion and

25/12 stainless steels 1.50 mm

https://www.micromelt.com/tolerance.htm 1/2

8/10/2021 Standard Specification for Casting Dimensions, Tolerance by MicroMelt

mechanical straightning will reduce variations where necessary. Carbon steels 2.25 mm

Cobalt-Chrome alloy 1.12 mm

Casting Length As-Cast Corrected

25 mm ±0.20 mm ±0.10 mm PARALLEL SECTIONS

50 mm ±0.37 mm ±0.15 mm Parallelism can be maintain by adding fire-bars to minimize distorsions.

Values shown are typical tolerances for various gap-widths between parallel

75 mm ±0.50 mm ±0.20 mm sections per inch cost.

100 mm ±0.62 mm ±0.25mm

Tolerance(mm)

Gap (mm) Corrected

CAST HOLES As-cast

6.25 ±0.075 ±0.075

Depth (D) and Diameter(d) of hole must allow for adequate

penetration of investment material. Values given show usual limits for 12.50 ±0.125 ±0.100

cast holes but pre-formed ceramic cores allow this restrictions tobe

exceeded, although usually at increased cost. 18.65 ±0.150 ±0.100

25.00 ±0.175 ±0.125

Through holes

Diameter (d) mm Maximum Depth (D) mm OTHER FEATURES :

3.17-6.35 D upto 1.5 d

Angles : Angular tolerance to ±1/2° (Closer by mechanical corrections).

6.35-12.70 D upto 3.0 d Symbols : Latters, Numbers, etc., can be reproduce in relief or inset.

12.70 D upto 5.0 d Serrations, Splines and Gear Teeth may be cast in certain instances subject

to prior agreement.

Blind Holes

Diameter (d) mm Maximum Depth (D) mm

4.76-12.70 D upto 1.5d

12.70 D upto 2.0 d

https://www.micromelt.com/tolerance.htm 2/2

You might also like

- Helmut Zander, Anthroposophie in DeutschlandDocument14 pagesHelmut Zander, Anthroposophie in DeutschlandBibliorare100% (1)

- Datasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Document5 pagesDatasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Raja Sekaran SajjaNo ratings yet

- Catalogue Silicon Steel CoresDocument35 pagesCatalogue Silicon Steel CoresraushankNo ratings yet

- Critical Seal Design Tolerance Charts: Recommended Shaft and Bore TolerancesDocument3 pagesCritical Seal Design Tolerance Charts: Recommended Shaft and Bore TolerancesRameshNo ratings yet

- Forging BasicsDocument9 pagesForging BasicsAl EnggNo ratings yet

- Tolerances To en 10051Document2 pagesTolerances To en 10051Joan ReigNo ratings yet

- Investment Casting TolerancesDocument1 pageInvestment Casting TolerancesPardeep SharmaNo ratings yet

- Shaft Seals With A Type 5 Stop: Seal Design DescriptionDocument5 pagesShaft Seals With A Type 5 Stop: Seal Design DescriptionJoni HartonoNo ratings yet

- Bearing and Sealing Components: For Mechanical EngineeringDocument24 pagesBearing and Sealing Components: For Mechanical EngineeringramakantinamdarNo ratings yet

- Metal-Coated - Galvsteel: Data SheetDocument2 pagesMetal-Coated - Galvsteel: Data SheetjcvalenciaNo ratings yet

- 1) Thickness Tolerance (IS: 852-1985) : A) Hot Rolled SectionsDocument2 pages1) Thickness Tolerance (IS: 852-1985) : A) Hot Rolled Sectionsketan mehtaNo ratings yet

- Casting TolerancesDocument2 pagesCasting TolerancesAnonymous shUWODvoNo ratings yet

- Beryllium Copper (C17200) DatasheetDocument2 pagesBeryllium Copper (C17200) Datasheetjr_satishNo ratings yet

- Esteves Group Bunching Dies 2018 04 EU EN PDFDocument2 pagesEsteves Group Bunching Dies 2018 04 EU EN PDFYayan RnsNo ratings yet

- Grades and Tolerances of Bearing BallsDocument1 pageGrades and Tolerances of Bearing BallsAjay BorawakeNo ratings yet

- FJ Product Data Standard Shaft Seal VCW 064526200 1714 08122015Document5 pagesFJ Product Data Standard Shaft Seal VCW 064526200 1714 08122015Mochamad CholiqNo ratings yet

- Seamless Circular Tubes of Non-Alloy Steels With Special Quality RequirementsDocument2 pagesSeamless Circular Tubes of Non-Alloy Steels With Special Quality RequirementsWiryanto DewobrotoNo ratings yet

- MicrometroDocument1 pageMicrometroEnriqueVeNo ratings yet

- Property ModificationDocument4 pagesProperty ModificationAldrin BernardoNo ratings yet

- Yellow: LM6 (EN 1706 AC-44100) Aluminium Casting AlloyDocument3 pagesYellow: LM6 (EN 1706 AC-44100) Aluminium Casting AlloySohail ShaikhNo ratings yet

- Supertec Galvanized Steel SpecsDocument6 pagesSupertec Galvanized Steel Specszineil BlackwoodNo ratings yet

- Glass Specifications ClicktouchDocument7 pagesGlass Specifications ClicktouchAldrian BarbasanNo ratings yet

- Lypds Adk-2022-2 FaDocument2 pagesLypds Adk-2022-2 Famicko kennoviyanaNo ratings yet

- Grade of Concrete Permissible Stress in Compression Bending DirectDocument37 pagesGrade of Concrete Permissible Stress in Compression Bending DirectKasiNo ratings yet

- 0607 Carcoseal Un Data SheetDocument2 pages0607 Carcoseal Un Data SheetMarco FranceseNo ratings yet

- Outside Micrometers: Series 102Document2 pagesOutside Micrometers: Series 102PeepeepoopoomanNo ratings yet

- Cromax 280X: Hard Chrome BarDocument4 pagesCromax 280X: Hard Chrome BarpeterNo ratings yet

- Hydro-Catalogue-08 09 2020Document74 pagesHydro-Catalogue-08 09 2020Prince MiwaNo ratings yet

- Meltio Mild Steel ER70S - Material - DatasheetDocument2 pagesMeltio Mild Steel ER70S - Material - DatasheetJakNo ratings yet

- H - Class Fibre Glass SleevesDocument1 pageH - Class Fibre Glass SleevesHARSHNo ratings yet

- TIE44 Processing of ZerodurDocument11 pagesTIE44 Processing of Zerodur侯涛No ratings yet

- Celsius SHS: Celsius Structural Hollow SectionsDocument13 pagesCelsius SHS: Celsius Structural Hollow SectionsDuarte CardosoNo ratings yet

- GALVSTEEL® G300 SteelDocument2 pagesGALVSTEEL® G300 SteelTulus Ztx ZaputroNo ratings yet

- Din 10060 - 2005Document5 pagesDin 10060 - 2005krkmurthyNo ratings yet

- Tata Steel - C75S - Data Sheet ENDocument2 pagesTata Steel - C75S - Data Sheet ENАндрей МеньшовNo ratings yet

- Standard Tolerance Guide Sheet: Rubber MouldingDocument1 pageStandard Tolerance Guide Sheet: Rubber MouldingMarcos Antonio RossiNo ratings yet

- Ch-24 Limit, Tolerance - FitsDocument62 pagesCh-24 Limit, Tolerance - FitsAdhanom G.No ratings yet

- Data Sheet 2351 COR-TEN® A, Hot Rolled 2017-04-19 PDFDocument2 pagesData Sheet 2351 COR-TEN® A, Hot Rolled 2017-04-19 PDFCristian RamirezNo ratings yet

- COR-TEN A, Hot Rolled: General Product DescriptionDocument2 pagesCOR-TEN A, Hot Rolled: General Product DescriptionCristian RamirezNo ratings yet

- Machining Processes Used To Produce Round ShapesDocument47 pagesMachining Processes Used To Produce Round Shapes2arunagiriNo ratings yet

- HysonCells Overview2012Document76 pagesHysonCells Overview2012paulogmello0% (1)

- The Accuracy Under VDG - Merkblatt P690: Length Tolerances (In MM)Document2 pagesThe Accuracy Under VDG - Merkblatt P690: Length Tolerances (In MM)MichaelNo ratings yet

- Specifications: Dimensional TolerancesDocument1 pageSpecifications: Dimensional TolerancesIvar KuusikNo ratings yet

- CZLLCW511L TN enDocument4 pagesCZLLCW511L TN endrgilleNo ratings yet

- AS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsDocument2 pagesAS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsAdamNo ratings yet

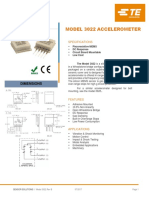

- Model 3022 Accelerometer: DimensionsDocument3 pagesModel 3022 Accelerometer: DimensionsRahulNo ratings yet

- M25 Mix Design 100 Recycled AggregateDocument9 pagesM25 Mix Design 100 Recycled AggregateRakesh ReddyNo ratings yet

- 6082 Extruded ENDocument3 pages6082 Extruded ENKeyur LadaniNo ratings yet

- H Beam STDDocument2 pagesH Beam STDPamungkasNo ratings yet

- Essar Steel Rockstar 400Document2 pagesEssar Steel Rockstar 400HimanshuNarayanSinghNo ratings yet

- Technical Aluminium Alloys LM20 09 05 22Document3 pagesTechnical Aluminium Alloys LM20 09 05 22baskaran.marieNo ratings yet

- NOTA Offers Natural Diamond and Synthetic Monocrystalline Diamond DiesDocument5 pagesNOTA Offers Natural Diamond and Synthetic Monocrystalline Diamond DiesTrajkoNo ratings yet

- NIC Components NRM SeriesDocument1 pageNIC Components NRM SeriesNICCompNo ratings yet

- Z ZhaoDocument15 pagesZ Zhaoxaen.ali3No ratings yet

- General Tolerances DIN ISO 2768Document4 pagesGeneral Tolerances DIN ISO 2768Ecaterina RusuNo ratings yet

- ASTM A370 Standard Specimen: A. Plat Type and Sheet TypeDocument8 pagesASTM A370 Standard Specimen: A. Plat Type and Sheet TypeAGnes Stephani MuntheNo ratings yet

- Mechanical Limit, Tolerance & FitsDocument104 pagesMechanical Limit, Tolerance & FitssrinivasNo ratings yet

- Durability: Hot Dip Galvanised Steel Sheet & CoilDocument8 pagesDurability: Hot Dip Galvanised Steel Sheet & CoilDin TcmNo ratings yet

- En10140 250700Document6 pagesEn10140 250700ersin esenNo ratings yet

- Catálogo Bombas K3V y K5VDocument15 pagesCatálogo Bombas K3V y K5VRamón Rivera100% (2)

- Appositives and AdjectiveDocument2 pagesAppositives and AdjectiveRinda RiztyaNo ratings yet

- Mick Thomson's Guitars and GearDocument10 pagesMick Thomson's Guitars and GearAleksandar LjubinkovicNo ratings yet

- 11th English BE Confident 5 Test Questions With Answer PDF DownloadDocument57 pages11th English BE Confident 5 Test Questions With Answer PDF Downloadbsai2749No ratings yet

- Staff Data Format-AUCDocument1 pageStaff Data Format-AUCSenthil KumarNo ratings yet

- Brkarc-2350 - 2014Document128 pagesBrkarc-2350 - 2014Sarah AnandNo ratings yet

- SAP Kernel 720Document24 pagesSAP Kernel 720rajaraobhmNo ratings yet

- Al Boury Oil FieldDocument11 pagesAl Boury Oil FieldSherif MohammedNo ratings yet

- Front Wheel Assy. DrumDocument2 pagesFront Wheel Assy. DrumSoroj BiswasNo ratings yet

- Bill of QuantityDocument6 pagesBill of QuantityKhairoden SangcopanNo ratings yet

- InfoDocument2 pagesInfofukinbobNo ratings yet

- Commercial Negotiations NotesDocument14 pagesCommercial Negotiations NotesJoan Foster100% (1)

- 6501i-8001i Manual de Servicio r5Document1,126 pages6501i-8001i Manual de Servicio r5marco102167% (3)

- Jetblue Airways: A New BeginningDocument25 pagesJetblue Airways: A New BeginningHesty Tri BudihartiNo ratings yet

- Corrosion Detection Midterm LessonDocument52 pagesCorrosion Detection Midterm LessonVv ZoidNo ratings yet

- Spare Parts Catalogue: AXLE 26.18 - (CM8118) REF: 133821Document8 pagesSpare Parts Catalogue: AXLE 26.18 - (CM8118) REF: 133821Paulinho InformáticaNo ratings yet

- Lean StartupDocument10 pagesLean StartupAlfredo Romero GNo ratings yet

- Chebyshev Filter: Linear Analog Electronic FiltersDocument10 pagesChebyshev Filter: Linear Analog Electronic FiltersSri Jai PriyaNo ratings yet

- The Spirit of Jugaad / Bricolage For Enhanced Corporate EntrepreneurshipDocument20 pagesThe Spirit of Jugaad / Bricolage For Enhanced Corporate EntrepreneurshippanditpreachesNo ratings yet

- Earth Dams Foundation & Earth Material InvestigationDocument111 pagesEarth Dams Foundation & Earth Material Investigationmustafurade1No ratings yet

- Worksheet in Deloittes System Design DocumentDocument32 pagesWorksheet in Deloittes System Design Documentascentcommerce100% (1)

- Flow of Communication: Emergency Response For Oil SpillageDocument5 pagesFlow of Communication: Emergency Response For Oil Spillagenarm nNo ratings yet

- 2127 - Mahatma Gandhi Missions College of Engineering, Hingoli RD, NandedDocument8 pages2127 - Mahatma Gandhi Missions College of Engineering, Hingoli RD, NandedAjit DeshmukhNo ratings yet

- Bread Board - Transformer - PCB - Soldering - LectureDocument31 pagesBread Board - Transformer - PCB - Soldering - Lectureananyautkarsh140904No ratings yet

- Iso 7966 1993Document11 pagesIso 7966 1993Sci KelayNo ratings yet

- Brac Bank LimitedDocument1 pageBrac Bank LimitedMd Mojibar RahmanNo ratings yet

- Application Form For Initial Review: Section A - Basic InformationDocument33 pagesApplication Form For Initial Review: Section A - Basic Informationsaptarshi DasNo ratings yet