Professional Documents

Culture Documents

POWERSIL 600 AB en 2019.12.05

POWERSIL 600 AB en 2019.12.05

Uploaded by

Aleksandar KaplijevCopyright:

Available Formats

You might also like

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- 202-Wacker Elastosil LR 3003-80 A-B Technical Data Sheet 03-23-2021Document4 pages202-Wacker Elastosil LR 3003-80 A-B Technical Data Sheet 03-23-2021ismail hakkıNo ratings yet

- Technical Data SheetDocument4 pagesTechnical Data SheetHardikNo ratings yet

- Elastosil M 4642 A/B: Room Temperature Curing Silicone Rubber (RTV-2)Document4 pagesElastosil M 4642 A/B: Room Temperature Curing Silicone Rubber (RTV-2)samsung A3No ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- TDS LSZH 4001Document2 pagesTDS LSZH 4001Rasel AhmedNo ratings yet

- Pghsim33 01NCDocument2 pagesPghsim33 01NCRanjan GnanaoliNo ratings yet

- Elastosil M 4641 A/B US: Room Temperature Curing Silicone Rubber (RTV-2)Document3 pagesElastosil M 4641 A/B US: Room Temperature Curing Silicone Rubber (RTV-2)MEHMET MERTNo ratings yet

- FR6082 DatasheetDocument3 pagesFR6082 DatasheetEric Baltus100% (1)

- Lexan Margard HLG5 2021Document3 pagesLexan Margard HLG5 2021Jessica RamosNo ratings yet

- Harna Sleeve 1625Document2 pagesHarna Sleeve 1625Deepu ChaturvediNo ratings yet

- SP MCBDocument2 pagesSP MCBRitesh AnandNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Tds A1105 en 2017pdfpdfDocument2 pagesTds A1105 en 2017pdfpdfagungNo ratings yet

- SP Max6 72c Com 1.5kv DC Ds en A4 544409 0Document2 pagesSP Max6 72c Com 1.5kv DC Ds en A4 544409 0bharat.aug86No ratings yet

- SP Max3 112c 415-430 Res DC 40years Warranty Ds en A4 544455Document2 pagesSP Max3 112c 415-430 Res DC 40years Warranty Ds en A4 544455Anselmo Aguado cortesNo ratings yet

- MKP 3366 y 2Document12 pagesMKP 3366 y 2Vincent Don KasambalaNo ratings yet

- 3M Scotchcast Electrical Insulating Resin 40 DatasheetDocument4 pages3M Scotchcast Electrical Insulating Resin 40 DatasheetEmeka IgweNo ratings yet

- Le6006 PDS Reg - World en V5 PDS World 25448 10048063Document3 pagesLe6006 PDS Reg - World en V5 PDS World 25448 10048063ShubhambaderiyaNo ratings yet

- Technical Data Sheet: Perspex CCDocument2 pagesTechnical Data Sheet: Perspex CCResist IkatNo ratings yet

- Pghsaw33 01BKDocument2 pagesPghsaw33 01BKRanjan GnanaoliNo ratings yet

- Cat, Painel Mono 3290-330Document2 pagesCat, Painel Mono 3290-330Andre Fanfa RibasNo ratings yet

- CAMPUS® Datasheet: CELANEX LW2333R - PBT - (GB+GF) 50 TiconaDocument2 pagesCAMPUS® Datasheet: CELANEX LW2333R - PBT - (GB+GF) 50 TiconaAngererNo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- Lexan Polycarbonate Embossed SheetDocument2 pagesLexan Polycarbonate Embossed SheetAmritraj CharlesNo ratings yet

- Technical Data Bulletin MC511AF: Typical PropertiesDocument2 pagesTechnical Data Bulletin MC511AF: Typical PropertiesRavi KumarNo ratings yet

- S SeriesDocument11 pagesS Series380665791408maksNo ratings yet

- CRCW-HP E3: Vishay DraloricDocument10 pagesCRCW-HP E3: Vishay DraloricMohendra PatiNo ratings yet

- 5SU93561KK10 Datasheet enDocument4 pages5SU93561KK10 Datasheet enpurwanto liemNo ratings yet

- Power Mar Bus BarDocument16 pagesPower Mar Bus BarKatty CachagoNo ratings yet

- 37 Styrolux656CDocument4 pages37 Styrolux656Cyassineamn115No ratings yet

- TP Wanhua Clarnate A1227 Vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNo ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- PA12 SLS Black - CRP TechnologyDocument3 pagesPA12 SLS Black - CRP TechnologyalkhalidibaiderNo ratings yet

- Datasheet SaphirAS 2016 EN v1Document2 pagesDatasheet SaphirAS 2016 EN v1André CardosoNo ratings yet

- Sabic - Sabic® Hdpe CC453 PDFDocument4 pagesSabic - Sabic® Hdpe CC453 PDFquangga10091986No ratings yet

- Hypertrans Iec 60296 2012 (Latest 2017)Document3 pagesHypertrans Iec 60296 2012 (Latest 2017)Mohd Izzat Abd GhaniNo ratings yet

- Lanxess Durethan B 30 S 000000 Astm enDocument2 pagesLanxess Durethan B 30 S 000000 Astm enJoan GnanaoliNo ratings yet

- GL XX Univolt N 61 BDocument2 pagesGL XX Univolt N 61 Bvj singhNo ratings yet

- Metal Detectable PE1000 Data SheetDocument2 pagesMetal Detectable PE1000 Data SheetPrashant MalikNo ratings yet

- Ultraform N2320 003 BK120 Q600Document2 pagesUltraform N2320 003 BK120 Q600JoelNo ratings yet

- Controlled Volatility RTV Ablative Silicone: Description ApplicationDocument3 pagesControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUINo ratings yet

- XB7NA42: Product Data SheetDocument5 pagesXB7NA42: Product Data SheetElvirModricNo ratings yet

- Desmopan 6064A - en - 81165785 05123103 20014072Document2 pagesDesmopan 6064A - en - 81165785 05123103 20014072shahin_723No ratings yet

- Technical Data Sheet: Typical PropertiesDocument2 pagesTechnical Data Sheet: Typical PropertiesahmedNo ratings yet

- 2024 03 06 TDS Elastollan1185ADocument4 pages2024 03 06 TDS Elastollan1185AChaker AbdellatifNo ratings yet

- PC 8B35 Ge Lexan PCDocument3 pagesPC 8B35 Ge Lexan PCbalu gunaNo ratings yet

- SABIC® HDPE - C0549 - GlobalDocument2 pagesSABIC® HDPE - C0549 - Globaltechnical kmiNo ratings yet

- SP Max3 128c 470-485 Com DC 40years Warranty Ds en A4 544457Document2 pagesSP Max3 128c 470-485 Com DC 40years Warranty Ds en A4 544457ibrahimaNo ratings yet

- Datasheet - CoronaShield C - 215.51 - EN - GLDocument3 pagesDatasheet - CoronaShield C - 215.51 - EN - GLLECTORNo ratings yet

- Sc. Cl. - 004 - MSE0615AEOXS-1000V - R. 0-4Document1 pageSc. Cl. - 004 - MSE0615AEOXS-1000V - R. 0-4Nader AhmedNo ratings yet

- 03 KÖHL ModuPro ModuCon ENDocument12 pages03 KÖHL ModuPro ModuCon ENGustavoGamezNo ratings yet

- Miniature Circuit Breaker: Quick Selection GuideDocument8 pagesMiniature Circuit Breaker: Quick Selection GuideYass CosmeticsNo ratings yet

- Product Data Sheet: Domae MCB - Miniature Circuit-Breaker - 1P - 6A - C Curve - 6000ADocument34 pagesProduct Data Sheet: Domae MCB - Miniature Circuit-Breaker - 1P - 6A - C Curve - 6000ATarique ImamNo ratings yet

- Lexan™ Exell D STP - Sheet DatasheetDocument2 pagesLexan™ Exell D STP - Sheet DatasheetAmritraj CharlesNo ratings yet

- ELASTOSIL R 40275 S en 2019.11.05Document3 pagesELASTOSIL R 40275 S en 2019.11.05Jorge MendezNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- SK485LC: Acera Mark 8Document16 pagesSK485LC: Acera Mark 8Ruben Perez MuñozNo ratings yet

- Quality Organizer - SqiDocument7 pagesQuality Organizer - SqierkaNo ratings yet

- Mobile SIM PolicyDocument2 pagesMobile SIM PolicyAnila Waheed100% (1)

- GPSMAP 10x2-12x2 Keyed Install EN-USDocument6 pagesGPSMAP 10x2-12x2 Keyed Install EN-USSarath PavithranNo ratings yet

- Defining The Product-Based Non-Conformance ClassificationDocument14 pagesDefining The Product-Based Non-Conformance Classificationmyie83100% (1)

- UNIT 5 MCQsDocument12 pagesUNIT 5 MCQsssssmailnatNo ratings yet

- Hotel TV Setting GuideDocument10 pagesHotel TV Setting Guidenaing layNo ratings yet

- Generic Two Degree of FreedomlinearandfuzzyDocument24 pagesGeneric Two Degree of FreedomlinearandfuzzyMohamed AbdouNo ratings yet

- Simple Chat Room AbstractDocument2 pagesSimple Chat Room Abstractvipin rawatNo ratings yet

- MPT BBU ComparisonDocument7 pagesMPT BBU ComparisonRandy Alonzo BondocNo ratings yet

- Introduction To Generative AI - Quiz - Google Cloud Skills BoostDocument1 pageIntroduction To Generative AI - Quiz - Google Cloud Skills BoostErvinNo ratings yet

- Critical SkillsDocument5 pagesCritical SkillsJosiah MwashitaNo ratings yet

- App 2019 Combined PDFDocument257 pagesApp 2019 Combined PDFGlenn LapizNo ratings yet

- An Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemDocument5 pagesAn Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemIJSTENo ratings yet

- Failure Analysis of Engineering Structures Methodology and Case HistoriesDocument206 pagesFailure Analysis of Engineering Structures Methodology and Case Historiesdennis_dizon_6100% (4)

- Q-000 - CPI (Checklist - SMO CS WUR MD C1668423)Document27 pagesQ-000 - CPI (Checklist - SMO CS WUR MD C1668423)Erick Savrinaldo100% (2)

- PPLADocument55 pagesPPLAdreamafonNo ratings yet

- Data Sheet: NPN 4 GHZ Wideband TransistorDocument10 pagesData Sheet: NPN 4 GHZ Wideband TransistorMassimo MaestraleNo ratings yet

- Diamond Shape Layouts 20641Document17 pagesDiamond Shape Layouts 20641Aleja SaavedraNo ratings yet

- Cybersecurity Lab MaualDocument66 pagesCybersecurity Lab MaualJatin PrajapatNo ratings yet

- Digital Subscriber Line Access Multiplexer: DslamDocument14 pagesDigital Subscriber Line Access Multiplexer: DslamwasiullahNo ratings yet

- Voice Bots: AdvantagesDocument3 pagesVoice Bots: AdvantagesMainak SarkarNo ratings yet

- Instagram User AnalyticsDocument6 pagesInstagram User AnalyticsRahul ShirudeNo ratings yet

- Melissa Esenam Klu CVDocument1 pageMelissa Esenam Klu CVmelissa.esenamNo ratings yet

- Elic & Coll Input OutputDocument1 pageElic & Coll Input OutputdeshpandedhaneshNo ratings yet

- 01 TM51101EN03GLA3 UMTS Overview PDFDocument42 pages01 TM51101EN03GLA3 UMTS Overview PDFPraveen KumarNo ratings yet

- Axelspace: Coding Assignment For: Embedded Systems Software EngineerDocument4 pagesAxelspace: Coding Assignment For: Embedded Systems Software EngineerkennethNo ratings yet

- Basics of Profibus Profibus in Practice v111Document44 pagesBasics of Profibus Profibus in Practice v111chandakbera100% (1)

- Fit Gap AnalysisDocument3 pagesFit Gap AnalysiszazoNo ratings yet

- OOADS Notes-) BTIT604-Object Oriented Analysis and DesignDocument82 pagesOOADS Notes-) BTIT604-Object Oriented Analysis and DesignDisha SorathiyaNo ratings yet

POWERSIL 600 AB en 2019.12.05

POWERSIL 600 AB en 2019.12.05

Uploaded by

Aleksandar KaplijevOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

POWERSIL 600 AB en 2019.12.05

POWERSIL 600 AB en 2019.12.05

Uploaded by

Aleksandar KaplijevCopyright:

Available Formats

CREATING TOMORROW'S SOLUTIONS

POWERSIL® 600 A/B

Room Temperature Curing Silicone Rubber (RTV-2)

POWERSIL® 600 A/B is a pourable, addition-curing, two-component silicone rubber that cures at room temperature to

form soft products with high mechanical strength.

Properties

• castable RTV-2

• ready-to-use, two component system

• very easy to process due to its low viscosity

• excellent dielectric properties

• best suitable for outdoor applications (UV & weathering resistance, excellent hydrophobic properties)

Special features

• Excellent pouring properties

• Resistant to tracking and erosion

POWERSIL® 600 A/B | Most recent change: 05.12.2019 1/4

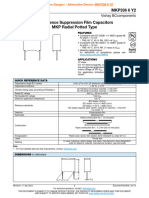

Technical data

Properties Uncured

Property Condition Value Method

Pot Life 23 °C 70 min -

Mix ratio - 9:1 A:B

Viscosity, dynamic of mix (10

- 10000 mPa·s DIN EN ISO 3219

s⁻¹)

Color - Light gray -

These figures are only intended as a guide and should not be used in preparing specifications.

Properties Cured

Cure conditions: 10 min / 100 °C in press

Property Condition Value Method

Arc resistance - > 300 s IEC 61621

Tracking resistance - 1A 3.5 IEC 60587

Dielectric strength - 23 kV/mm IEC 60243-1

Dissipation factor 50 Hz 3 x 10⁻⁴ IEC 62631-2-1

Permittivity 50 Hz 2.9 IEC 62631-2-1

Volume resistivity - 10¹⁵ Ohmcm IEC 62631-3-1

Elongation at break - 500 % ISO 37 type 1

Tensile strength - 8.0 N/mm² ISO 37 type 1

Hardness Shore A - 30 ISO 7619-1

Density 23 °C 1.13 g/cm³ DIN EN ISO 1183-1 A

Flammability - FV 0 IEC 60695-11-10

Tear strength - 22 N/mm ASTM D 624 B

These figures are only intended as a guide and should not be used in preparing specifications.

All the information provided is in accordance with the present state of our knowledge. Nonetheless, we disclaim any warranty or liability whatsoever and reserve the right, at any

time, to effect technical alterations. The information provided, as well as the product's fitness for an intended application, should be checked by the buyer in preliminary trials.

Contractual terms and conditions always take precedence. This disclaimer of warranty and liability also applies particularly in foreign countries with respect to third parties' rights.

Applications

POWERSIL® 600 A/B | Most recent change: 05.12.2019 2/4

• Cable Accessories

• Insulators

• Arresters

Application details

• cable accessories

• insulators

• prototyping

Processing

Components A and B are delivered ready to use in drums of 20 and 200 litres capacity. They can be pumped by means of

standard metering equipment from these drums and mixing in a static mixer straight into the mold. The mixing ratio is 9 : 1.

The extreme low viscosity and resulting high volumetric flow rate ensure consistent, void-free production at room

temperature. Curing at room temperature results in very little inner mould pressure. Therefore POWERSIL® 600 A/B is

suitable for the production of products with complex installation parts.

At room temperature, mixtures of A and B components have a pot life of at least 70 minutes.

POWERSIL® 600 A/B is also recommended for prototyping of products since no expensive machinery is needed for its

processing.

Detailed information on processing of POWERSIL® 600 A/B is given in brochure “Processing RTV-2 Silicone Rubbers”.

Packaging and storage

Storage

The 'Best use before end' date of each batch is shown on the product label. Storage beyond the date specified on the

label does not necessarily mean that the product is no longer usable. In this case however, the properties required for the

intended use must be checked for quality assurance reasons.

Safety notes

Comprehensive instructions are given in the corresponding Material Safety Data Sheets. They are available on request from

WACKER subsidiaries or may be printed via WACKER web site http://www.wacker.com.

QR Code POWERSIL® 600 A/B

POWERSIL® 600 A/B | Most recent change: 05.12.2019 3/4

For technical, quality or product safety questions, please contact:

Wacker Chemie AG, Hanns-Seidel-Platz 4, 81737 Munich, Germany

info@wacker.com, www.wacker.com

The data presented in this medium are in accordance with the present state of our knowledge but do not absolve the user from carefully checking all supplies immediately on

receipt. We reserve the right to alter product constants within the scope of technical progress or new developments. The recommendations made in this medium should be

checked by preliminary trials because of conditions during processing over which we have no control, especially where other companies’ raw materials are also being used. The

information provided by us does not absolve the user from the obligation of investigating the possibility of infringement of third parties’ rights and, if necessary, clarifying the

position. Recommendations for use do not constitute a warranty, either express or implied, of the fitness or suitability of the product for a particular purpose.

POWERSIL® 600 A/B | Most recent change: 05.12.2019 4/4

You might also like

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- 202-Wacker Elastosil LR 3003-80 A-B Technical Data Sheet 03-23-2021Document4 pages202-Wacker Elastosil LR 3003-80 A-B Technical Data Sheet 03-23-2021ismail hakkıNo ratings yet

- Technical Data SheetDocument4 pagesTechnical Data SheetHardikNo ratings yet

- Elastosil M 4642 A/B: Room Temperature Curing Silicone Rubber (RTV-2)Document4 pagesElastosil M 4642 A/B: Room Temperature Curing Silicone Rubber (RTV-2)samsung A3No ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- TDS LSZH 4001Document2 pagesTDS LSZH 4001Rasel AhmedNo ratings yet

- Pghsim33 01NCDocument2 pagesPghsim33 01NCRanjan GnanaoliNo ratings yet

- Elastosil M 4641 A/B US: Room Temperature Curing Silicone Rubber (RTV-2)Document3 pagesElastosil M 4641 A/B US: Room Temperature Curing Silicone Rubber (RTV-2)MEHMET MERTNo ratings yet

- FR6082 DatasheetDocument3 pagesFR6082 DatasheetEric Baltus100% (1)

- Lexan Margard HLG5 2021Document3 pagesLexan Margard HLG5 2021Jessica RamosNo ratings yet

- Harna Sleeve 1625Document2 pagesHarna Sleeve 1625Deepu ChaturvediNo ratings yet

- SP MCBDocument2 pagesSP MCBRitesh AnandNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Tds A1105 en 2017pdfpdfDocument2 pagesTds A1105 en 2017pdfpdfagungNo ratings yet

- SP Max6 72c Com 1.5kv DC Ds en A4 544409 0Document2 pagesSP Max6 72c Com 1.5kv DC Ds en A4 544409 0bharat.aug86No ratings yet

- SP Max3 112c 415-430 Res DC 40years Warranty Ds en A4 544455Document2 pagesSP Max3 112c 415-430 Res DC 40years Warranty Ds en A4 544455Anselmo Aguado cortesNo ratings yet

- MKP 3366 y 2Document12 pagesMKP 3366 y 2Vincent Don KasambalaNo ratings yet

- 3M Scotchcast Electrical Insulating Resin 40 DatasheetDocument4 pages3M Scotchcast Electrical Insulating Resin 40 DatasheetEmeka IgweNo ratings yet

- Le6006 PDS Reg - World en V5 PDS World 25448 10048063Document3 pagesLe6006 PDS Reg - World en V5 PDS World 25448 10048063ShubhambaderiyaNo ratings yet

- Technical Data Sheet: Perspex CCDocument2 pagesTechnical Data Sheet: Perspex CCResist IkatNo ratings yet

- Pghsaw33 01BKDocument2 pagesPghsaw33 01BKRanjan GnanaoliNo ratings yet

- Cat, Painel Mono 3290-330Document2 pagesCat, Painel Mono 3290-330Andre Fanfa RibasNo ratings yet

- CAMPUS® Datasheet: CELANEX LW2333R - PBT - (GB+GF) 50 TiconaDocument2 pagesCAMPUS® Datasheet: CELANEX LW2333R - PBT - (GB+GF) 50 TiconaAngererNo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- Lexan Polycarbonate Embossed SheetDocument2 pagesLexan Polycarbonate Embossed SheetAmritraj CharlesNo ratings yet

- Technical Data Bulletin MC511AF: Typical PropertiesDocument2 pagesTechnical Data Bulletin MC511AF: Typical PropertiesRavi KumarNo ratings yet

- S SeriesDocument11 pagesS Series380665791408maksNo ratings yet

- CRCW-HP E3: Vishay DraloricDocument10 pagesCRCW-HP E3: Vishay DraloricMohendra PatiNo ratings yet

- 5SU93561KK10 Datasheet enDocument4 pages5SU93561KK10 Datasheet enpurwanto liemNo ratings yet

- Power Mar Bus BarDocument16 pagesPower Mar Bus BarKatty CachagoNo ratings yet

- 37 Styrolux656CDocument4 pages37 Styrolux656Cyassineamn115No ratings yet

- TP Wanhua Clarnate A1227 Vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNo ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- PA12 SLS Black - CRP TechnologyDocument3 pagesPA12 SLS Black - CRP TechnologyalkhalidibaiderNo ratings yet

- Datasheet SaphirAS 2016 EN v1Document2 pagesDatasheet SaphirAS 2016 EN v1André CardosoNo ratings yet

- Sabic - Sabic® Hdpe CC453 PDFDocument4 pagesSabic - Sabic® Hdpe CC453 PDFquangga10091986No ratings yet

- Hypertrans Iec 60296 2012 (Latest 2017)Document3 pagesHypertrans Iec 60296 2012 (Latest 2017)Mohd Izzat Abd GhaniNo ratings yet

- Lanxess Durethan B 30 S 000000 Astm enDocument2 pagesLanxess Durethan B 30 S 000000 Astm enJoan GnanaoliNo ratings yet

- GL XX Univolt N 61 BDocument2 pagesGL XX Univolt N 61 Bvj singhNo ratings yet

- Metal Detectable PE1000 Data SheetDocument2 pagesMetal Detectable PE1000 Data SheetPrashant MalikNo ratings yet

- Ultraform N2320 003 BK120 Q600Document2 pagesUltraform N2320 003 BK120 Q600JoelNo ratings yet

- Controlled Volatility RTV Ablative Silicone: Description ApplicationDocument3 pagesControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUINo ratings yet

- XB7NA42: Product Data SheetDocument5 pagesXB7NA42: Product Data SheetElvirModricNo ratings yet

- Desmopan 6064A - en - 81165785 05123103 20014072Document2 pagesDesmopan 6064A - en - 81165785 05123103 20014072shahin_723No ratings yet

- Technical Data Sheet: Typical PropertiesDocument2 pagesTechnical Data Sheet: Typical PropertiesahmedNo ratings yet

- 2024 03 06 TDS Elastollan1185ADocument4 pages2024 03 06 TDS Elastollan1185AChaker AbdellatifNo ratings yet

- PC 8B35 Ge Lexan PCDocument3 pagesPC 8B35 Ge Lexan PCbalu gunaNo ratings yet

- SABIC® HDPE - C0549 - GlobalDocument2 pagesSABIC® HDPE - C0549 - Globaltechnical kmiNo ratings yet

- SP Max3 128c 470-485 Com DC 40years Warranty Ds en A4 544457Document2 pagesSP Max3 128c 470-485 Com DC 40years Warranty Ds en A4 544457ibrahimaNo ratings yet

- Datasheet - CoronaShield C - 215.51 - EN - GLDocument3 pagesDatasheet - CoronaShield C - 215.51 - EN - GLLECTORNo ratings yet

- Sc. Cl. - 004 - MSE0615AEOXS-1000V - R. 0-4Document1 pageSc. Cl. - 004 - MSE0615AEOXS-1000V - R. 0-4Nader AhmedNo ratings yet

- 03 KÖHL ModuPro ModuCon ENDocument12 pages03 KÖHL ModuPro ModuCon ENGustavoGamezNo ratings yet

- Miniature Circuit Breaker: Quick Selection GuideDocument8 pagesMiniature Circuit Breaker: Quick Selection GuideYass CosmeticsNo ratings yet

- Product Data Sheet: Domae MCB - Miniature Circuit-Breaker - 1P - 6A - C Curve - 6000ADocument34 pagesProduct Data Sheet: Domae MCB - Miniature Circuit-Breaker - 1P - 6A - C Curve - 6000ATarique ImamNo ratings yet

- Lexan™ Exell D STP - Sheet DatasheetDocument2 pagesLexan™ Exell D STP - Sheet DatasheetAmritraj CharlesNo ratings yet

- ELASTOSIL R 40275 S en 2019.11.05Document3 pagesELASTOSIL R 40275 S en 2019.11.05Jorge MendezNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- SK485LC: Acera Mark 8Document16 pagesSK485LC: Acera Mark 8Ruben Perez MuñozNo ratings yet

- Quality Organizer - SqiDocument7 pagesQuality Organizer - SqierkaNo ratings yet

- Mobile SIM PolicyDocument2 pagesMobile SIM PolicyAnila Waheed100% (1)

- GPSMAP 10x2-12x2 Keyed Install EN-USDocument6 pagesGPSMAP 10x2-12x2 Keyed Install EN-USSarath PavithranNo ratings yet

- Defining The Product-Based Non-Conformance ClassificationDocument14 pagesDefining The Product-Based Non-Conformance Classificationmyie83100% (1)

- UNIT 5 MCQsDocument12 pagesUNIT 5 MCQsssssmailnatNo ratings yet

- Hotel TV Setting GuideDocument10 pagesHotel TV Setting Guidenaing layNo ratings yet

- Generic Two Degree of FreedomlinearandfuzzyDocument24 pagesGeneric Two Degree of FreedomlinearandfuzzyMohamed AbdouNo ratings yet

- Simple Chat Room AbstractDocument2 pagesSimple Chat Room Abstractvipin rawatNo ratings yet

- MPT BBU ComparisonDocument7 pagesMPT BBU ComparisonRandy Alonzo BondocNo ratings yet

- Introduction To Generative AI - Quiz - Google Cloud Skills BoostDocument1 pageIntroduction To Generative AI - Quiz - Google Cloud Skills BoostErvinNo ratings yet

- Critical SkillsDocument5 pagesCritical SkillsJosiah MwashitaNo ratings yet

- App 2019 Combined PDFDocument257 pagesApp 2019 Combined PDFGlenn LapizNo ratings yet

- An Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemDocument5 pagesAn Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemIJSTENo ratings yet

- Failure Analysis of Engineering Structures Methodology and Case HistoriesDocument206 pagesFailure Analysis of Engineering Structures Methodology and Case Historiesdennis_dizon_6100% (4)

- Q-000 - CPI (Checklist - SMO CS WUR MD C1668423)Document27 pagesQ-000 - CPI (Checklist - SMO CS WUR MD C1668423)Erick Savrinaldo100% (2)

- PPLADocument55 pagesPPLAdreamafonNo ratings yet

- Data Sheet: NPN 4 GHZ Wideband TransistorDocument10 pagesData Sheet: NPN 4 GHZ Wideband TransistorMassimo MaestraleNo ratings yet

- Diamond Shape Layouts 20641Document17 pagesDiamond Shape Layouts 20641Aleja SaavedraNo ratings yet

- Cybersecurity Lab MaualDocument66 pagesCybersecurity Lab MaualJatin PrajapatNo ratings yet

- Digital Subscriber Line Access Multiplexer: DslamDocument14 pagesDigital Subscriber Line Access Multiplexer: DslamwasiullahNo ratings yet

- Voice Bots: AdvantagesDocument3 pagesVoice Bots: AdvantagesMainak SarkarNo ratings yet

- Instagram User AnalyticsDocument6 pagesInstagram User AnalyticsRahul ShirudeNo ratings yet

- Melissa Esenam Klu CVDocument1 pageMelissa Esenam Klu CVmelissa.esenamNo ratings yet

- Elic & Coll Input OutputDocument1 pageElic & Coll Input OutputdeshpandedhaneshNo ratings yet

- 01 TM51101EN03GLA3 UMTS Overview PDFDocument42 pages01 TM51101EN03GLA3 UMTS Overview PDFPraveen KumarNo ratings yet

- Axelspace: Coding Assignment For: Embedded Systems Software EngineerDocument4 pagesAxelspace: Coding Assignment For: Embedded Systems Software EngineerkennethNo ratings yet

- Basics of Profibus Profibus in Practice v111Document44 pagesBasics of Profibus Profibus in Practice v111chandakbera100% (1)

- Fit Gap AnalysisDocument3 pagesFit Gap AnalysiszazoNo ratings yet

- OOADS Notes-) BTIT604-Object Oriented Analysis and DesignDocument82 pagesOOADS Notes-) BTIT604-Object Oriented Analysis and DesignDisha SorathiyaNo ratings yet