Professional Documents

Culture Documents

HARPC Attachment 2.1 HACCP Flow Diagram - MALTRIN Musc 2017-18

HARPC Attachment 2.1 HACCP Flow Diagram - MALTRIN Musc 2017-18

Uploaded by

QA FP ParungCopyright:

Available Formats

You might also like

- Haccp PlanDocument21 pagesHaccp Planmizi1133% (3)

- Project Proposal MRF CttoDocument10 pagesProject Proposal MRF CttoLevi Manigo Buencamino100% (3)

- Metformin FormulationDocument6 pagesMetformin Formulationsujit50% (2)

- 0 0 25 Feb 2016 1108554031AnnexureManufacturing&EffluentTreatmentProcessDocument28 pages0 0 25 Feb 2016 1108554031AnnexureManufacturing&EffluentTreatmentProcessNeerav Indrajit GadhviNo ratings yet

- Mil PRF 7024Document10 pagesMil PRF 7024kidseismicNo ratings yet

- Procrastination Decision TreeDocument2 pagesProcrastination Decision Treeartus14100% (3)

- 5 Star Hotel - REQUIREMENTS PDFDocument28 pages5 Star Hotel - REQUIREMENTS PDFAnbu SelviNo ratings yet

- Lasers in EndoDocument144 pagesLasers in EndoPawan D Tekale100% (1)

- 8.2.2.1 Flow Chart - Fresh Blueberry - V07Document2 pages8.2.2.1 Flow Chart - Fresh Blueberry - V07ScribdTranslationsNo ratings yet

- Cane, Sugar and Ethanol: Innovation With IntegrityDocument16 pagesCane, Sugar and Ethanol: Innovation With IntegrityvjNo ratings yet

- Pulp & Paper - 378 - ITC - PSPD - Unit - Bhadrachalam - 0Document56 pagesPulp & Paper - 378 - ITC - PSPD - Unit - Bhadrachalam - 0Sanjeev Kumar100% (1)

- 02 LC of Double Cone Blender 02Document2 pages02 LC of Double Cone Blender 02Ravi Yadav0% (1)

- Ec, PH SaladDocument1 pageEc, PH SaladLim SoongNo ratings yet

- Hamilton WhitePaper Biopharm PATDocument20 pagesHamilton WhitePaper Biopharm PATjrosellogarciaNo ratings yet

- Daily Report - TC CDP Level 1: SubjectDocument4 pagesDaily Report - TC CDP Level 1: SubjectMuhammad IsroNo ratings yet

- APP - Analysis of Mycotoxins in Multi Grain and Corn Cereal - 013618 - 01Document5 pagesAPP - Analysis of Mycotoxins in Multi Grain and Corn Cereal - 013618 - 01carmenjimenezcejudoNo ratings yet

- CPV ProtocolDocument26 pagesCPV ProtocolPatricia Joyce Malabanan SunglaoNo ratings yet

- Approved Discharge Permit 2023 - QSJDMDocument2 pagesApproved Discharge Permit 2023 - QSJDMjeffrey gabrielNo ratings yet

- Pure Dent B700 Corn Starch HACCPDocument2 pagesPure Dent B700 Corn Starch HACCPElviraNo ratings yet

- HACCP Plan With Flow Chart-1Document23 pagesHACCP Plan With Flow Chart-1Anonymous aZA07k8TXfNo ratings yet

- Eco Titrator Oil PDFDocument5 pagesEco Titrator Oil PDFRobert SwaiNo ratings yet

- Capstone 3 - Easy DiscardDocument10 pagesCapstone 3 - Easy DiscardSmall Stone Big MangoNo ratings yet

- CCP MonitoringDocument5 pagesCCP Monitoringsajid waqasNo ratings yet

- Process Flow Diagram Hospital E.T.P: EP Bio CompositesDocument2 pagesProcess Flow Diagram Hospital E.T.P: EP Bio CompositesRohan Chaugule100% (1)

- 3 - SVM Process Flow Chart HACCPDocument3 pages3 - SVM Process Flow Chart HACCPc.ramNo ratings yet

- Sensory and Product PromotionDocument5 pagesSensory and Product PromotionRenmar BaccayNo ratings yet

- Bottled Water Report (Jan-Mar 2018)Document24 pagesBottled Water Report (Jan-Mar 2018)AZEEM CHEEMANo ratings yet

- Purified Water Installation QualificationDocument112 pagesPurified Water Installation Qualificationankur_haldarNo ratings yet

- 01 LC Vibratory Sifter 01Document2 pages01 LC Vibratory Sifter 01Ravi YadavNo ratings yet

- Trifold BesarDocument2 pagesTrifold Besarglobalsutama.admNo ratings yet

- KAPA LibQuant Illumina TDS KR0405 v7.16 A41Document12 pagesKAPA LibQuant Illumina TDS KR0405 v7.16 A41Daliléia SantanaNo ratings yet

- UPPC Liner RoHS 2024 1Document8 pagesUPPC Liner RoHS 2024 1Daizy AyrosoNo ratings yet

- Review HACPDocument1 pageReview HACPSmsajid WaqasNo ratings yet

- Achievement Chart Prepare and Produce Pastry Products Date Started: Target Date To FininshedDocument1 pageAchievement Chart Prepare and Produce Pastry Products Date Started: Target Date To FininshedCrystal Maiden ArcabalNo ratings yet

- 380 FDDocument25 pages380 FDvanessa valerieNo ratings yet

- 16 Pages 2022 (2571)Document16 pages16 Pages 2022 (2571)The ProfessionalNo ratings yet

- Installation Qualification For Purified Water Generation SystemDocument56 pagesInstallation Qualification For Purified Water Generation SystemMohamad IsmailNo ratings yet

- Presentation of DTL BHPDocument26 pagesPresentation of DTL BHPAmarNo ratings yet

- Design Qualification Pretreatment & Purified Water Generation System - Pharmaceutical GuidanceDocument54 pagesDesign Qualification Pretreatment & Purified Water Generation System - Pharmaceutical GuidanceMohamad IsmailNo ratings yet

- Global Supply Chain Management: Prepared By: Magdalena B. DascoDocument41 pagesGlobal Supply Chain Management: Prepared By: Magdalena B. DascoMhagz MaggieNo ratings yet

- 20191022151611direktori Teknologi Komersil UPMDocument58 pages20191022151611direktori Teknologi Komersil UPMMuhd Khairul AmriNo ratings yet

- SOP Transfer Material (Draft by Tiara)Document8 pagesSOP Transfer Material (Draft by Tiara)Anonymous beoDDMtxNo ratings yet

- Material Preparation and Handling: FORM B. Flow DiagramDocument4 pagesMaterial Preparation and Handling: FORM B. Flow DiagramNadila ApriliyanNo ratings yet

- InstructionsforUsingBrukerBacterialTestStandardforMALDI TOF MSDocument12 pagesInstructionsforUsingBrukerBacterialTestStandardforMALDI TOF MSElena IftimiNo ratings yet

- Indentification&Tracability ProcedureDocument3 pagesIndentification&Tracability ProcedureSaad ZiaNo ratings yet

- Surface Activity of Surfactin Under Extreme Conditions (H, Temperature and Ionic Strength) - A Prospection For Microbial Enhanced Oil RecoveryDocument28 pagesSurface Activity of Surfactin Under Extreme Conditions (H, Temperature and Ionic Strength) - A Prospection For Microbial Enhanced Oil RecoveryGambas OrakNo ratings yet

- 03 LC of Semi Auto Cap Filling Machine 03Document2 pages03 LC of Semi Auto Cap Filling Machine 03Ravi YadavNo ratings yet

- CPV Report: Documentation Template & Evaluation InstrumentDocument8 pagesCPV Report: Documentation Template & Evaluation InstrumentKonisbell Alcántara UreñaNo ratings yet

- Archean EIADocument57 pagesArchean EIARavi PanaraNo ratings yet

- Abbott Brahms Sepsis Procalcitonin SellsheetDocument2 pagesAbbott Brahms Sepsis Procalcitonin SellsheetLau GómezNo ratings yet

- GLT - QA.PR.01 - Hygiene KPI Procedure - Ver 0 - 08 Feb 10Document14 pagesGLT - QA.PR.01 - Hygiene KPI Procedure - Ver 0 - 08 Feb 10RiyanNo ratings yet

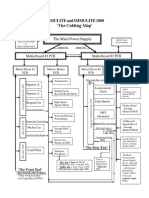

- 'The Cabling Map' - IMM1 1KDocument1 page'The Cabling Map' - IMM1 1KMarcel SalasNo ratings yet

- Courseform 43Document2 pagesCourseform 43Elizabeth OjumoolaNo ratings yet

- Commercial Facility For CBD ProductsDocument6 pagesCommercial Facility For CBD ProductsUmair ShekhaniNo ratings yet

- Presentation For Surabaya Green and CleanDocument14 pagesPresentation For Surabaya Green and CleanPerdana KusumaNo ratings yet

- PakScan P3 Modbus ManualDocument96 pagesPakScan P3 Modbus ManualJirahudys Caroline King HarrysNo ratings yet

- AppBull Chlo1 08-11Document2 pagesAppBull Chlo1 08-11Darshan PatelNo ratings yet

- BMR - Metro - 0.5 % - IP - 100 ML - 4800 LDocument32 pagesBMR - Metro - 0.5 % - IP - 100 ML - 4800 LJayDwarkadhish.15No ratings yet

- 40319NexION2200ICP MSPlant BasedFoodsAppNoteDocument9 pages40319NexION2200ICP MSPlant BasedFoodsAppNoteMohammed NahelNo ratings yet

- APN 2.11.01 Tomato - KetchupDocument2 pagesAPN 2.11.01 Tomato - KetchupHouari Brahim100% (1)

- GPS x2023Document5 pagesGPS x2023Mahfoud-Rock HeronNo ratings yet

- 4.peptide Optimizer and MH QQQ AcqDocument46 pages4.peptide Optimizer and MH QQQ AcqNguyen TriNo ratings yet

- Supply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Document24 pagesSupply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Saif Ahmed Nabil100% (1)

- Advances in Dairy ProductsFrom EverandAdvances in Dairy ProductsFrancesco ContoNo ratings yet

- Gender Based Violence: A Paradoxical Analysis: Mohd ShakilDocument8 pagesGender Based Violence: A Paradoxical Analysis: Mohd ShakilMohd ShakilNo ratings yet

- Measuring Food Safety Indicators To Achieve Sustainable Development GoalsDocument64 pagesMeasuring Food Safety Indicators To Achieve Sustainable Development Goalsmnegm2890No ratings yet

- The Slight Edge SummaryDocument7 pagesThe Slight Edge SummaryJonathan Cragle100% (2)

- Clinical Case Reports - 2016 - Ronco - A Novel Suturing Approach For Tissue Displacement Within Minimally InvasiveDocument7 pagesClinical Case Reports - 2016 - Ronco - A Novel Suturing Approach For Tissue Displacement Within Minimally InvasiveÄpriolia SuNo ratings yet

- MBRDocument16 pagesMBRDhananjay Khadse100% (3)

- An Insight Into The Quality Assurance of Ayurvedic, Siddha and Unani DrugsDocument10 pagesAn Insight Into The Quality Assurance of Ayurvedic, Siddha and Unani DrugsHomoeopathic PulseNo ratings yet

- Caneiro 2021 Fear To SafetyDocument12 pagesCaneiro 2021 Fear To SafetyIan JuanicoNo ratings yet

- Destefano OppoDocument14 pagesDestefano OppoNHUDL0% (1)

- 14 Nothing About Us Without UsDocument8 pages14 Nothing About Us Without UsPaul WaughNo ratings yet

- FMEADocument5 pagesFMEAmz007No ratings yet

- Renal Disease in PregnancyDocument28 pagesRenal Disease in PregnancysuperjaxxxonNo ratings yet

- Research MethodologyDocument4 pagesResearch MethodologyPayal PurohitNo ratings yet

- Anganwadi Workers - Midhun Varghese-2Document17 pagesAnganwadi Workers - Midhun Varghese-2FEBIN RAJUNo ratings yet

- Penders Health Promotion ModelDocument7 pagesPenders Health Promotion ModelANIME SOLONo ratings yet

- 1st Garging Garde 9 ScienceDocument10 pages1st Garging Garde 9 ScienceElaine Claire Gorospe PanchoNo ratings yet

- The Role of Physiotherapy in People Living With HivDocument9 pagesThe Role of Physiotherapy in People Living With HivKate HizonNo ratings yet

- Notes by DR Faiza Niaz Ahmad Key2plab2 PDFDocument35 pagesNotes by DR Faiza Niaz Ahmad Key2plab2 PDFBeaulahNo ratings yet

- Oats Dosa Recipe - How To Make Oats Dosa RecipeDocument18 pagesOats Dosa Recipe - How To Make Oats Dosa RecipeKiran KumarNo ratings yet

- A Comparison of Community-Based Resistance Exercise and Flexibility Exercise For SeniorsDocument5 pagesA Comparison of Community-Based Resistance Exercise and Flexibility Exercise For SeniorsAlejandraRiveraLondoñoNo ratings yet

- Hmis Poster LargeDocument1 pageHmis Poster Largevalentin-giuglea-343No ratings yet

- Caring For People With Challenging Behaviors, Second Edition ExcerptDocument6 pagesCaring For People With Challenging Behaviors, Second Edition ExcerptHealth Professions Press, an imprint of Paul H. Brookes Publishing Co., Inc.No ratings yet

- What Is Protected Health Information (PHI) ?Document1 pageWhat Is Protected Health Information (PHI) ?Muhammad Yasir KhanNo ratings yet

- Red Parachute Rocket: Wescom Signal and Rescue Germany GMBHDocument10 pagesRed Parachute Rocket: Wescom Signal and Rescue Germany GMBHRaflii Nur IlhamNo ratings yet

- Intrauterine Growth RestrictionDocument5 pagesIntrauterine Growth RestrictionColleen MercadoNo ratings yet

- Cross-Sectional Imaging of Intrahepatic Cholangiocarcinoma: Development, Growth, Spread, and PrognosisDocument12 pagesCross-Sectional Imaging of Intrahepatic Cholangiocarcinoma: Development, Growth, Spread, and PrognosisNikos SerifisNo ratings yet

HARPC Attachment 2.1 HACCP Flow Diagram - MALTRIN Musc 2017-18

HARPC Attachment 2.1 HACCP Flow Diagram - MALTRIN Musc 2017-18

Uploaded by

QA FP ParungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HARPC Attachment 2.1 HACCP Flow Diagram - MALTRIN Musc 2017-18

HARPC Attachment 2.1 HACCP Flow Diagram - MALTRIN Musc 2017-18

Uploaded by

QA FP ParungCopyright:

Available Formats

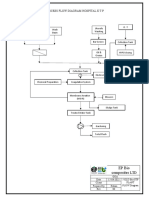

44-07-03-01 Attachment 2.

1 - HARPC FLOW DIAGRAM

PROCESS: MALTRIN® Products LOCATION: Muscatine, IA DATE: May 15, 2017 Page 1 of 1

Hazard Analysis Risk-Based Preventative Controls (HARPC) Program

Flow Diagram

MALTRIN® Maltodextrin and Corn Syrup Solids

Raw Starch

Cooker

Conversion

Polish

Evaporator Feed

Spray Dryer

Sanitation PC #2

Vibratory Screener CCP #1

Biological PC #3

Processing PC #1

Metal Detector CCP #2

Final Product Approval

MALTRIN® Maltodextrin and Corn Syrup Solids are each mixtures of glucose polymers produced by the controlled de-polymerization of #2 yellow dent corn starch

grown in the United States by the use of acid and/or enzymes to convert liquid starch to targeted dextrose equivalence (DE). These are generally low pH products of low

water activity that promote stability of the products both analytically and microbiologically. Maltodextrin and Corn Syrup Solids are preferably packaged in Kraft multi

walled bags (in both 50 pound and 25 kg sizes), but are also available in other packaging such as Super Sack tote bags, upon specified agreements made between GPC

and individual customers. MALTRIN® products should be stored under ambient conditions; protected from excessive heat and excessive humidity for extended

periods of time. Under good storage conditions, the shelf life is expected to be two years. MALTRIN® products will remain stable, but may pick up moisture if stored

in excessive humidity, so reevaluation for moisture is recommended after one year to confirm the product still meets desired specifications. Maltodextrin and Corn

Syrup Solids are used in dried food, beverage preparations, and nutritional products as well as used as an excipient to the pharmaceutical industry.

You might also like

- Haccp PlanDocument21 pagesHaccp Planmizi1133% (3)

- Project Proposal MRF CttoDocument10 pagesProject Proposal MRF CttoLevi Manigo Buencamino100% (3)

- Metformin FormulationDocument6 pagesMetformin Formulationsujit50% (2)

- 0 0 25 Feb 2016 1108554031AnnexureManufacturing&EffluentTreatmentProcessDocument28 pages0 0 25 Feb 2016 1108554031AnnexureManufacturing&EffluentTreatmentProcessNeerav Indrajit GadhviNo ratings yet

- Mil PRF 7024Document10 pagesMil PRF 7024kidseismicNo ratings yet

- Procrastination Decision TreeDocument2 pagesProcrastination Decision Treeartus14100% (3)

- 5 Star Hotel - REQUIREMENTS PDFDocument28 pages5 Star Hotel - REQUIREMENTS PDFAnbu SelviNo ratings yet

- Lasers in EndoDocument144 pagesLasers in EndoPawan D Tekale100% (1)

- 8.2.2.1 Flow Chart - Fresh Blueberry - V07Document2 pages8.2.2.1 Flow Chart - Fresh Blueberry - V07ScribdTranslationsNo ratings yet

- Cane, Sugar and Ethanol: Innovation With IntegrityDocument16 pagesCane, Sugar and Ethanol: Innovation With IntegrityvjNo ratings yet

- Pulp & Paper - 378 - ITC - PSPD - Unit - Bhadrachalam - 0Document56 pagesPulp & Paper - 378 - ITC - PSPD - Unit - Bhadrachalam - 0Sanjeev Kumar100% (1)

- 02 LC of Double Cone Blender 02Document2 pages02 LC of Double Cone Blender 02Ravi Yadav0% (1)

- Ec, PH SaladDocument1 pageEc, PH SaladLim SoongNo ratings yet

- Hamilton WhitePaper Biopharm PATDocument20 pagesHamilton WhitePaper Biopharm PATjrosellogarciaNo ratings yet

- Daily Report - TC CDP Level 1: SubjectDocument4 pagesDaily Report - TC CDP Level 1: SubjectMuhammad IsroNo ratings yet

- APP - Analysis of Mycotoxins in Multi Grain and Corn Cereal - 013618 - 01Document5 pagesAPP - Analysis of Mycotoxins in Multi Grain and Corn Cereal - 013618 - 01carmenjimenezcejudoNo ratings yet

- CPV ProtocolDocument26 pagesCPV ProtocolPatricia Joyce Malabanan SunglaoNo ratings yet

- Approved Discharge Permit 2023 - QSJDMDocument2 pagesApproved Discharge Permit 2023 - QSJDMjeffrey gabrielNo ratings yet

- Pure Dent B700 Corn Starch HACCPDocument2 pagesPure Dent B700 Corn Starch HACCPElviraNo ratings yet

- HACCP Plan With Flow Chart-1Document23 pagesHACCP Plan With Flow Chart-1Anonymous aZA07k8TXfNo ratings yet

- Eco Titrator Oil PDFDocument5 pagesEco Titrator Oil PDFRobert SwaiNo ratings yet

- Capstone 3 - Easy DiscardDocument10 pagesCapstone 3 - Easy DiscardSmall Stone Big MangoNo ratings yet

- CCP MonitoringDocument5 pagesCCP Monitoringsajid waqasNo ratings yet

- Process Flow Diagram Hospital E.T.P: EP Bio CompositesDocument2 pagesProcess Flow Diagram Hospital E.T.P: EP Bio CompositesRohan Chaugule100% (1)

- 3 - SVM Process Flow Chart HACCPDocument3 pages3 - SVM Process Flow Chart HACCPc.ramNo ratings yet

- Sensory and Product PromotionDocument5 pagesSensory and Product PromotionRenmar BaccayNo ratings yet

- Bottled Water Report (Jan-Mar 2018)Document24 pagesBottled Water Report (Jan-Mar 2018)AZEEM CHEEMANo ratings yet

- Purified Water Installation QualificationDocument112 pagesPurified Water Installation Qualificationankur_haldarNo ratings yet

- 01 LC Vibratory Sifter 01Document2 pages01 LC Vibratory Sifter 01Ravi YadavNo ratings yet

- Trifold BesarDocument2 pagesTrifold Besarglobalsutama.admNo ratings yet

- KAPA LibQuant Illumina TDS KR0405 v7.16 A41Document12 pagesKAPA LibQuant Illumina TDS KR0405 v7.16 A41Daliléia SantanaNo ratings yet

- UPPC Liner RoHS 2024 1Document8 pagesUPPC Liner RoHS 2024 1Daizy AyrosoNo ratings yet

- Review HACPDocument1 pageReview HACPSmsajid WaqasNo ratings yet

- Achievement Chart Prepare and Produce Pastry Products Date Started: Target Date To FininshedDocument1 pageAchievement Chart Prepare and Produce Pastry Products Date Started: Target Date To FininshedCrystal Maiden ArcabalNo ratings yet

- 380 FDDocument25 pages380 FDvanessa valerieNo ratings yet

- 16 Pages 2022 (2571)Document16 pages16 Pages 2022 (2571)The ProfessionalNo ratings yet

- Installation Qualification For Purified Water Generation SystemDocument56 pagesInstallation Qualification For Purified Water Generation SystemMohamad IsmailNo ratings yet

- Presentation of DTL BHPDocument26 pagesPresentation of DTL BHPAmarNo ratings yet

- Design Qualification Pretreatment & Purified Water Generation System - Pharmaceutical GuidanceDocument54 pagesDesign Qualification Pretreatment & Purified Water Generation System - Pharmaceutical GuidanceMohamad IsmailNo ratings yet

- Global Supply Chain Management: Prepared By: Magdalena B. DascoDocument41 pagesGlobal Supply Chain Management: Prepared By: Magdalena B. DascoMhagz MaggieNo ratings yet

- 20191022151611direktori Teknologi Komersil UPMDocument58 pages20191022151611direktori Teknologi Komersil UPMMuhd Khairul AmriNo ratings yet

- SOP Transfer Material (Draft by Tiara)Document8 pagesSOP Transfer Material (Draft by Tiara)Anonymous beoDDMtxNo ratings yet

- Material Preparation and Handling: FORM B. Flow DiagramDocument4 pagesMaterial Preparation and Handling: FORM B. Flow DiagramNadila ApriliyanNo ratings yet

- InstructionsforUsingBrukerBacterialTestStandardforMALDI TOF MSDocument12 pagesInstructionsforUsingBrukerBacterialTestStandardforMALDI TOF MSElena IftimiNo ratings yet

- Indentification&Tracability ProcedureDocument3 pagesIndentification&Tracability ProcedureSaad ZiaNo ratings yet

- Surface Activity of Surfactin Under Extreme Conditions (H, Temperature and Ionic Strength) - A Prospection For Microbial Enhanced Oil RecoveryDocument28 pagesSurface Activity of Surfactin Under Extreme Conditions (H, Temperature and Ionic Strength) - A Prospection For Microbial Enhanced Oil RecoveryGambas OrakNo ratings yet

- 03 LC of Semi Auto Cap Filling Machine 03Document2 pages03 LC of Semi Auto Cap Filling Machine 03Ravi YadavNo ratings yet

- CPV Report: Documentation Template & Evaluation InstrumentDocument8 pagesCPV Report: Documentation Template & Evaluation InstrumentKonisbell Alcántara UreñaNo ratings yet

- Archean EIADocument57 pagesArchean EIARavi PanaraNo ratings yet

- Abbott Brahms Sepsis Procalcitonin SellsheetDocument2 pagesAbbott Brahms Sepsis Procalcitonin SellsheetLau GómezNo ratings yet

- GLT - QA.PR.01 - Hygiene KPI Procedure - Ver 0 - 08 Feb 10Document14 pagesGLT - QA.PR.01 - Hygiene KPI Procedure - Ver 0 - 08 Feb 10RiyanNo ratings yet

- 'The Cabling Map' - IMM1 1KDocument1 page'The Cabling Map' - IMM1 1KMarcel SalasNo ratings yet

- Courseform 43Document2 pagesCourseform 43Elizabeth OjumoolaNo ratings yet

- Commercial Facility For CBD ProductsDocument6 pagesCommercial Facility For CBD ProductsUmair ShekhaniNo ratings yet

- Presentation For Surabaya Green and CleanDocument14 pagesPresentation For Surabaya Green and CleanPerdana KusumaNo ratings yet

- PakScan P3 Modbus ManualDocument96 pagesPakScan P3 Modbus ManualJirahudys Caroline King HarrysNo ratings yet

- AppBull Chlo1 08-11Document2 pagesAppBull Chlo1 08-11Darshan PatelNo ratings yet

- BMR - Metro - 0.5 % - IP - 100 ML - 4800 LDocument32 pagesBMR - Metro - 0.5 % - IP - 100 ML - 4800 LJayDwarkadhish.15No ratings yet

- 40319NexION2200ICP MSPlant BasedFoodsAppNoteDocument9 pages40319NexION2200ICP MSPlant BasedFoodsAppNoteMohammed NahelNo ratings yet

- APN 2.11.01 Tomato - KetchupDocument2 pagesAPN 2.11.01 Tomato - KetchupHouari Brahim100% (1)

- GPS x2023Document5 pagesGPS x2023Mahfoud-Rock HeronNo ratings yet

- 4.peptide Optimizer and MH QQQ AcqDocument46 pages4.peptide Optimizer and MH QQQ AcqNguyen TriNo ratings yet

- Supply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Document24 pagesSupply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Saif Ahmed Nabil100% (1)

- Advances in Dairy ProductsFrom EverandAdvances in Dairy ProductsFrancesco ContoNo ratings yet

- Gender Based Violence: A Paradoxical Analysis: Mohd ShakilDocument8 pagesGender Based Violence: A Paradoxical Analysis: Mohd ShakilMohd ShakilNo ratings yet

- Measuring Food Safety Indicators To Achieve Sustainable Development GoalsDocument64 pagesMeasuring Food Safety Indicators To Achieve Sustainable Development Goalsmnegm2890No ratings yet

- The Slight Edge SummaryDocument7 pagesThe Slight Edge SummaryJonathan Cragle100% (2)

- Clinical Case Reports - 2016 - Ronco - A Novel Suturing Approach For Tissue Displacement Within Minimally InvasiveDocument7 pagesClinical Case Reports - 2016 - Ronco - A Novel Suturing Approach For Tissue Displacement Within Minimally InvasiveÄpriolia SuNo ratings yet

- MBRDocument16 pagesMBRDhananjay Khadse100% (3)

- An Insight Into The Quality Assurance of Ayurvedic, Siddha and Unani DrugsDocument10 pagesAn Insight Into The Quality Assurance of Ayurvedic, Siddha and Unani DrugsHomoeopathic PulseNo ratings yet

- Caneiro 2021 Fear To SafetyDocument12 pagesCaneiro 2021 Fear To SafetyIan JuanicoNo ratings yet

- Destefano OppoDocument14 pagesDestefano OppoNHUDL0% (1)

- 14 Nothing About Us Without UsDocument8 pages14 Nothing About Us Without UsPaul WaughNo ratings yet

- FMEADocument5 pagesFMEAmz007No ratings yet

- Renal Disease in PregnancyDocument28 pagesRenal Disease in PregnancysuperjaxxxonNo ratings yet

- Research MethodologyDocument4 pagesResearch MethodologyPayal PurohitNo ratings yet

- Anganwadi Workers - Midhun Varghese-2Document17 pagesAnganwadi Workers - Midhun Varghese-2FEBIN RAJUNo ratings yet

- Penders Health Promotion ModelDocument7 pagesPenders Health Promotion ModelANIME SOLONo ratings yet

- 1st Garging Garde 9 ScienceDocument10 pages1st Garging Garde 9 ScienceElaine Claire Gorospe PanchoNo ratings yet

- The Role of Physiotherapy in People Living With HivDocument9 pagesThe Role of Physiotherapy in People Living With HivKate HizonNo ratings yet

- Notes by DR Faiza Niaz Ahmad Key2plab2 PDFDocument35 pagesNotes by DR Faiza Niaz Ahmad Key2plab2 PDFBeaulahNo ratings yet

- Oats Dosa Recipe - How To Make Oats Dosa RecipeDocument18 pagesOats Dosa Recipe - How To Make Oats Dosa RecipeKiran KumarNo ratings yet

- A Comparison of Community-Based Resistance Exercise and Flexibility Exercise For SeniorsDocument5 pagesA Comparison of Community-Based Resistance Exercise and Flexibility Exercise For SeniorsAlejandraRiveraLondoñoNo ratings yet

- Hmis Poster LargeDocument1 pageHmis Poster Largevalentin-giuglea-343No ratings yet

- Caring For People With Challenging Behaviors, Second Edition ExcerptDocument6 pagesCaring For People With Challenging Behaviors, Second Edition ExcerptHealth Professions Press, an imprint of Paul H. Brookes Publishing Co., Inc.No ratings yet

- What Is Protected Health Information (PHI) ?Document1 pageWhat Is Protected Health Information (PHI) ?Muhammad Yasir KhanNo ratings yet

- Red Parachute Rocket: Wescom Signal and Rescue Germany GMBHDocument10 pagesRed Parachute Rocket: Wescom Signal and Rescue Germany GMBHRaflii Nur IlhamNo ratings yet

- Intrauterine Growth RestrictionDocument5 pagesIntrauterine Growth RestrictionColleen MercadoNo ratings yet

- Cross-Sectional Imaging of Intrahepatic Cholangiocarcinoma: Development, Growth, Spread, and PrognosisDocument12 pagesCross-Sectional Imaging of Intrahepatic Cholangiocarcinoma: Development, Growth, Spread, and PrognosisNikos SerifisNo ratings yet