Professional Documents

Culture Documents

3.3 Area Measurement

3.3 Area Measurement

Uploaded by

nate anantathatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.3 Area Measurement

3.3 Area Measurement

Uploaded by

nate anantathatCopyright:

Available Formats

ges,apermanentmagnetisbroughtintodirect

contactwiththecoatedsurface. Theforcenecessarytopull

themapreted asthecoatingthicknessvalueonasc age, wear, or

as well as the measured thickness value obtained, and the

higRHGEWRHRgrngkWMEgm:emhgl:wmelksdmflG,N: method used to verify gage accuracy. If the same gage, refer-

ewkqghj linear in nature. Any adjustment of these gages will ence standard, and method of verification are used throughout

limit the DFT range for which the gage will provide accurate a job, they need to be recorded only once. The stated value of

readings; therefore adjustment of the gage is not the standard and the measured value must be recorded each

recom-mended. Furthermore, the application of a single “corr time accuracy is verified. linear in nature. Any adjustment of

these gages will limit the DFT range for which the gage will

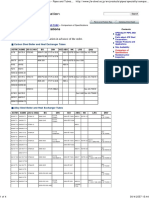

3.3 Area Measurement: The average of five spot provide accurate readings; therefore adjustment of the gage

measurements obtained over each 100 ft2 (~10 m2) of coated is not recom-mended. Furthermore, the application of a single

surface.

“correction value” representing the full range o

4. Description of Gages 5.5 If the gage fails the post-measurement accuracy

verification check, all measurements acquired since the

4.1 Gage Types: The gage type is determined by the

last accuracy verification check are suspect. In the event of

operating principal employed in measuring the thickness and

physical damage, wear, or high usage, or after an established

is not determined by the mode of data readout, i.e. digital or

calibration interval, the gage shall be rechecked for accuracy

analog.

of measuremage, wear, or high usage, or recalibrated

(usually by the gage manufacturer).

4.1.1 Type 1 – Magnetic Pull-Off Gages: In magnetic

pull-off gages, a permanent magnet is brought into direct

5.6 Type 1 gages have nonlinear scales and any adjusting

contact with the coated surface. The force necessary to pull

feature is linear in nature. Any adjustment of these gages will

the magnet from the surface is measured and interpreted

limit the DFT range for which the gage will provide accurate

as the coating thickness value on a scale or display on the

readings; therefore adjustment of the gage is not recom-

gage. Less force is required to remove the magnet from a thick

mended. Furthermore, the application of a single “correction

coating. The scale is nonlinear.

value” representing the full range of the gage to compensate

for a gage that is not measuring accurately is not appropriate,

4.1.2 Type 2 – Electronic Gages: An electronic gage

uses electronic circuitry to convert a reference signal into since the correction will also be non-linear.4 linear in

coating thickness. nature. Any adjustment of these gages will limit the

DFT range for which the gage will provide accurate

5. Calibration and Verification of Accuracy readings; therefore adjustment of the gage is not

recom-mended. Furthermore, the application of a

5.1 ASTM D 7091 describes three operational steps single “correction value” representing the full

necessary to ensure accurate coating thickness measurement: range o6. Measurement Procedure - Type 1 Gages

calibration, verification and adjustment of coating thickness

measuring gages, as well as proper methods for obtaining

6.1 Type 1 gage accuracy is verified using smooth test

coating thickness measurements on both ferrous and non-

blocks. In order to compensate for any effect of the substrate

ferrous metal substrates. These steps shall be completed

itself and surface roughness, obtain measurements from the

before taking coating thickness measurements to determine

bare, prepared substrate at a minimum of ten (10) locations

conformance to a specified coating thickness range.

(arbitrarily spaced) and calculate the average value. This value

represents the effect of the substrate/surface roughness on a

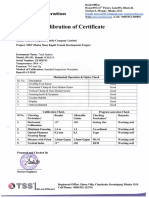

5.2 Gages shall be calibrated by the manufacturer or

coating thickness gage. This average value is the base metal

a qualified laboratory. A Certificate of Calibration or other

reading (BMR). The gage shall not be adjusted to read zero on

documentation showing traceability to a national metrology

the prepared, bare substrate.

institution is required. There is no standard time interval for

re-calibration, nor is one absolutely required. Calibration inter-

6.2 Measure the DFT of the dry coating at the number of

vals are usually established based upon experience and the

spots specified in Section 8.

work environment. A one-year calibration intervalployed in

measuring the thickness and is not determined by the mode

6.3 Subtract the BMR fro linear in nature. Any adjustment

of data readout, i.e. digital or analog. is a typical starting

of these gages will limit the DFT range for which the gage will

point suggested by gage manufacturers.

provide accurate readings; therefore adjustment of the gage

is not recom-mended. Furthermore, the application of a singm

5.3 To guard against measuring with an inaccurate gage,

the gage reading to obtain the thickness of the coating.

gage accuracy shall be verified at a minimum of the begin- 4

A correction curve can be prepared by plotting the actual gage

ning and end of each work shift according to the procedures readings against the stated values on the calibration test blocks.

7.Subsequent

MEASUREMENT PROCEDURE

coating thickness measurements - TYPE

can be2“corrected”

GAGESby

described in ASTM D 7091. The user is advised to verify gage plotting the measurements along the correction curve. The correc-

accuracy during measurement acquisition (e.g., hourly) when tion7.1

curve maymanufacturers

The or may not cover the

of full

Typerange

2 of(electronic)

the gage, but gages

should

a large number of measurements are being obtained. If the cover the intended range of use. The Base Metal Readings (BMR)

prescribe different methods of adjustment to measure dry film

gage is dropped or suspected of giving erroneous readings described in 6.1 may also need to be plotted on the correction curve.

thickness over abrasive blast cleaned surfaces. Adjust the

during the work shift, its accuracy shall be rechecked. gage according to the manufacturers instructions using one of

2 the methods described in ASTM D 7091 or Appendix 8 of this

5.4 Record the serial number of the gage, the reference

standard.

standard used, the stated thickness of the reference standard

You might also like

- Astm G171 PDFDocument7 pagesAstm G171 PDFGAVILANES MARTINEZ GEISSON ANIBAL0% (1)

- ASTM B 487 Yr 87 R 13 PDFDocument4 pagesASTM B 487 Yr 87 R 13 PDFnedim cılız100% (1)

- SSPC-PA 2 Procedure For Determining Conformance To Dry Coating Thickness RequirementsDocument11 pagesSSPC-PA 2 Procedure For Determining Conformance To Dry Coating Thickness RequirementsDavid Aliaga Sayas100% (1)

- SSPC-PA 2 (2004) - Measurement of DFT With Magnetic Gages PDFDocument11 pagesSSPC-PA 2 (2004) - Measurement of DFT With Magnetic Gages PDFkhuramilyas100% (1)

- Astm D1186-01 PDFDocument5 pagesAstm D1186-01 PDFCalidad - TGINo ratings yet

- ASTM D646-13 GrammatureDocument2 pagesASTM D646-13 GrammatureAgeng Wahyu PatrianitaNo ratings yet

- Camphor Lab ReportDocument11 pagesCamphor Lab ReportNikita Ivanov100% (1)

- An Overview of The Intelligent Packaging Technologies in The FoodDocument11 pagesAn Overview of The Intelligent Packaging Technologies in The FoodAncuţa-IonelaPartinNo ratings yet

- Description of Gages: 3.3 Area MeasurementDocument1 pageDescription of Gages: 3.3 Area Measurementnate anantathatNo ratings yet

- Description of Gages: 3.3 Area MeasurementDocument1 pageDescription of Gages: 3.3 Area Measurementnate anantathatNo ratings yet

- SPCPA2Document1 pageSPCPA2Rajesh RajeshNo ratings yet

- Ployed in Measuring The Thidescription of Gages: 3.3 Area MeasurementDocument1 pagePloyed in Measuring The Thidescription of Gages: 3.3 Area Measurementnate anantathatNo ratings yet

- Measurement Procedure - Type 1 GagesDocument1 pageMeasurement Procedure - Type 1 Gagesnate anantathatNo ratings yet

- SSPC PA2 Measurement of Dry Coating Thickness With Magnetic GagesDocument11 pagesSSPC PA2 Measurement of Dry Coating Thickness With Magnetic Gageslonglong3003No ratings yet

- Guia para La Medición de Espesores SSPC - PA2Document11 pagesGuia para La Medición de Espesores SSPC - PA2robertabarreiroNo ratings yet

- Paint Application Specification No. 2: SSPC: The Society For Protective CoatingsDocument12 pagesPaint Application Specification No. 2: SSPC: The Society For Protective CoatingsEdgar Sanchez ChamizoNo ratings yet

- SSPC Pa2Document11 pagesSSPC Pa2Nageswara Rao BavisettyNo ratings yet

- SSPC-PA 2. Measurement of DFT With Mag. Gauges.Document7 pagesSSPC-PA 2. Measurement of DFT With Mag. Gauges.banglvhNo ratings yet

- ASTM E384 (2022) - Part5Document1 pageASTM E384 (2022) - Part5david4231993No ratings yet

- ASTM D7091-05 DFT of Non Magnetic Coatings To Ferrous MetalsDocument7 pagesASTM D7091-05 DFT of Non Magnetic Coatings To Ferrous MetalsChris Parkinson100% (1)

- 001-SSPC Pa 02 2004 Measurement of Dry Coating Thickness With Magnetic GagesDocument11 pages001-SSPC Pa 02 2004 Measurement of Dry Coating Thickness With Magnetic GagesIka Sundari SunNo ratings yet

- Measuring Core Thickness of Textured Geomembrane: Standard Test Method ForDocument3 pagesMeasuring Core Thickness of Textured Geomembrane: Standard Test Method ForIsrael Aaron Gonzalez VegaNo ratings yet

- SSPC - Pa 2Document11 pagesSSPC - Pa 2marciobispoalmeidaNo ratings yet

- SSPC Pa 2 2004 PDFDocument11 pagesSSPC Pa 2 2004 PDFrams789100% (1)

- Recubrimientos - SSPC-PA 2-2012Document11 pagesRecubrimientos - SSPC-PA 2-2012ALEXIS MARTINEZNo ratings yet

- MT Comparsion of RCCM & ASMEDocument5 pagesMT Comparsion of RCCM & ASMEsafeer ahmadNo ratings yet

- Astm AnodizingDocument4 pagesAstm AnodizingStephany RojasNo ratings yet

- G171.1207962-1 - Standard Test Scratch HardnessDocument7 pagesG171.1207962-1 - Standard Test Scratch HardnessVictor Manuel Florez FrancoNo ratings yet

- SSPC Pa2Document12 pagesSSPC Pa2Robinson Cesar De la VegaNo ratings yet

- SSPC Pa2Document6 pagesSSPC Pa2Dang Thanh TuanNo ratings yet

- DFT StandardsDocument42 pagesDFT StandardsDandy Adrianto100% (2)

- D1400 PDFDocument2 pagesD1400 PDFmemoNo ratings yet

- Data Sheet Tolerance For Concrete SurfacesDocument10 pagesData Sheet Tolerance For Concrete SurfacesPedro RYNo ratings yet

- Paint Application Standard No. 2: SSPC: The Society For Protective CoatingsDocument6 pagesPaint Application Standard No. 2: SSPC: The Society For Protective CoatingsreghouacheNo ratings yet

- ASTM B 499 09 Yr 14 Coating MeasurementDocument5 pagesASTM B 499 09 Yr 14 Coating MeasurementPrabath Nilan GunasekaraNo ratings yet

- Paint Application Standard No. 2: SSPC: The Society For Protective CoatingsDocument7 pagesPaint Application Standard No. 2: SSPC: The Society For Protective CoatingsreghouacheNo ratings yet

- SSPC Pa2Document7 pagesSSPC Pa2frankcengel100% (1)

- Calculating Pavement Macrotexture Mean Profile Depth: Standard Practice ForDocument4 pagesCalculating Pavement Macrotexture Mean Profile Depth: Standard Practice ForAbel CameoNo ratings yet

- ASTM D 1186 Pelicula SecaDocument3 pagesASTM D 1186 Pelicula SecaFelipe montana100% (1)

- ASTM E384 (2022) - Part4Document1 pageASTM E384 (2022) - Part4david4231993No ratings yet

- E 1438 - 91 R96 - Rte0mzgtotfsotyDocument2 pagesE 1438 - 91 R96 - Rte0mzgtotfsotypechugonisNo ratings yet

- ERM 200 Series Info Produit E@Document16 pagesERM 200 Series Info Produit E@Chintan MaisuriyaNo ratings yet

- ASTM D 1186 - Pintura PDFDocument3 pagesASTM D 1186 - Pintura PDFVicente Francisco Caballero100% (2)

- Usbr1012 PDFDocument4 pagesUsbr1012 PDFYCNo ratings yet

- 5249.dynamic Properties of SoilDocument13 pages5249.dynamic Properties of SoilBibhu PrasadNo ratings yet

- Astm B 244 2009Document4 pagesAstm B 244 2009egemetsatisNo ratings yet

- 2 of 2Document5 pages2 of 2Nevena StojkovicNo ratings yet

- Norma - ASTM G171-03 - Standard Test Method For Scratch Hardness of Materials Using A Diamond StylusDocument7 pagesNorma - ASTM G171-03 - Standard Test Method For Scratch Hardness of Materials Using A Diamond StylusBacana CwbNo ratings yet

- D 1186 - 01nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied To A Ferrous Base1Document4 pagesD 1186 - 01nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied To A Ferrous Base1kyeong cheol leeNo ratings yet

- Astm A 418.aDocument8 pagesAstm A 418.aGlauber MartinsNo ratings yet

- B Sa-435Document2 pagesB Sa-435Antonio GutierrezNo ratings yet

- Rapid Indentation Hardness Testing of Metallic Materials: Standard Test Method ForDocument4 pagesRapid Indentation Hardness Testing of Metallic Materials: Standard Test Method ForrizkyrNo ratings yet

- Adaptive Tests of Significance Using Permutations of Residuals with R and SASFrom EverandAdaptive Tests of Significance Using Permutations of Residuals with R and SASNo ratings yet

- Bundle Adjustment: Optimizing Visual Data for Precise ReconstructionFrom EverandBundle Adjustment: Optimizing Visual Data for Precise ReconstructionNo ratings yet

- High-Performance Gradient Elution: The Practical Application of the Linear-Solvent-Strength ModelFrom EverandHigh-Performance Gradient Elution: The Practical Application of the Linear-Solvent-Strength ModelNo ratings yet

- Jis B-1186Document21 pagesJis B-1186nate anantathatNo ratings yet

- Measurement Procedure - Type 1 GagesDocument1 pageMeasurement Procedure - Type 1 Gagesnate anantathatNo ratings yet

- Description of Gages: 3.3 Area MeasurementDocument1 pageDescription of Gages: 3.3 Area Measurementnate anantathatNo ratings yet

- Ployed in Measuring The Thidescription of Gages: 3.3 Area MeasurementDocument1 pagePloyed in Measuring The Thidescription of Gages: 3.3 Area Measurementnate anantathatNo ratings yet

- Description of Gages: 3.3 Area MeasurementDocument1 pageDescription of Gages: 3.3 Area Measurementnate anantathatNo ratings yet

- Specification Specification For Welding Repairs: Laser Interferometer Gravitational Wave ObservatoryDocument1 pageSpecification Specification For Welding Repairs: Laser Interferometer Gravitational Wave Observatorynate anantathatNo ratings yet

- Technician Clarified Schedule For McDonalnds PDFDocument1 pageTechnician Clarified Schedule For McDonalnds PDFnate anantathatNo ratings yet

- 1-Catalog HRP PDFDocument2 pages1-Catalog HRP PDFnate anantathatNo ratings yet

- RFI-Form Updated 3.07.2018.......Document6 pagesRFI-Form Updated 3.07.2018.......nate anantathatNo ratings yet

- Selection A387Document1 pageSelection A387nate anantathatNo ratings yet

- Fastener Torque Table SAE Grade - Engineers Edge PDFDocument1 pageFastener Torque Table SAE Grade - Engineers Edge PDFnate anantathatNo ratings yet

- I) ..Iri.i.r, Rin-,,.r r1,: 1e0 L118 1 LQZDocument4 pagesI) ..Iri.i.r, Rin-,,.r r1,: 1e0 L118 1 LQZnate anantathatNo ratings yet

- Metric Bolt Torque Table NM - CNCexpoDocument1 pageMetric Bolt Torque Table NM - CNCexponate anantathat100% (1)

- Tsshield: Instruction ManualDocument17 pagesTsshield: Instruction Manualnate anantathatNo ratings yet

- PIPE AND TUBE - Comparison of SpecificationsDocument4 pagesPIPE AND TUBE - Comparison of Specificationsnate anantathatNo ratings yet

- Tsshield: Instruction ManualDocument37 pagesTsshield: Instruction Manualnate anantathatNo ratings yet

- Calibration CertificateDocument2 pagesCalibration Certificatenate anantathatNo ratings yet

- Calibration Certificate ครั้งที่2Document2 pagesCalibration Certificate ครั้งที่2nate anantathatNo ratings yet

- Shimadzu AA-7800 Series BrochureDocument20 pagesShimadzu AA-7800 Series BrochureTNo ratings yet

- NTU - GAT (Subject) Test DistributionDocument1 pageNTU - GAT (Subject) Test DistributionMuzammil HussainNo ratings yet

- 03d - LATTICE ENERGI (Uo)Document21 pages03d - LATTICE ENERGI (Uo)Oktanio PraviakoNo ratings yet

- Universiti Tun Hussein Onn Malaysia Department of Mechanical EngineeringDocument11 pagesUniversiti Tun Hussein Onn Malaysia Department of Mechanical EngineeringAriff ShasteraNo ratings yet

- Allen: Chemical KineticsDocument4 pagesAllen: Chemical KineticsBidhan Chandra SarkarNo ratings yet

- Fig 1432-1432L-1432C-1432LC Hatt DS 0922Document1 pageFig 1432-1432L-1432C-1432LC Hatt DS 0922Dan HawthorneNo ratings yet

- Periodic TableDocument40 pagesPeriodic TableRaveendra MungaraNo ratings yet

- 3.3 (B) Mole N MassDocument20 pages3.3 (B) Mole N MassFidree AzizNo ratings yet

- Matrix Stimulation Manual Rev4.0Document129 pagesMatrix Stimulation Manual Rev4.0DZPRO KORANo ratings yet

- Edexcel - IAS - Organic Chemistry - 1Document21 pagesEdexcel - IAS - Organic Chemistry - 1mostafa barakatNo ratings yet

- AC Series: From 5 To 24 LitresDocument4 pagesAC Series: From 5 To 24 Litresali abdiNo ratings yet

- Inquiries Research Titles SOP ExamplesDocument10 pagesInquiries Research Titles SOP ExamplesEunice Pineza ManlunasNo ratings yet

- Hidden Details of NCERT (Bio)Document7 pagesHidden Details of NCERT (Bio)Sezein DuaNo ratings yet

- Acetophenone H NMRDocument2 pagesAcetophenone H NMRkobir96100% (1)

- Assay Pani Tailing 11060122001675 Pt. GorontaloDocument19 pagesAssay Pani Tailing 11060122001675 Pt. GorontaloSiti InayahNo ratings yet

- Msds BibagDocument5 pagesMsds Bibagasvs33No ratings yet

- 16 Water ChemistryDocument21 pages16 Water ChemistryMohit KambojNo ratings yet

- Mastersizer 3000 How It WorksDocument2 pagesMastersizer 3000 How It Worksscata1117No ratings yet

- Self-Directed Learning Module in Science: Quarter 1, Weeks 3 To 4Document26 pagesSelf-Directed Learning Module in Science: Quarter 1, Weeks 3 To 4Ma. Victoria LlameraNo ratings yet

- DT Cartridge Filters: High-Performance Hydraulic FiltrationDocument8 pagesDT Cartridge Filters: High-Performance Hydraulic FiltrationLe DuNo ratings yet

- Nature Ofcorrosive and Abrasive Wear in Ball Mill GrindingDocument16 pagesNature Ofcorrosive and Abrasive Wear in Ball Mill Grindinggtorrentes1No ratings yet

- Lecture4 - Part5 - Hopper Design in PracticeDocument30 pagesLecture4 - Part5 - Hopper Design in PracticecamNo ratings yet

- Viii Nstse Level-1 Mock Test-2-5Document15 pagesViii Nstse Level-1 Mock Test-2-5puneet manglaNo ratings yet

- 140706DARV14050 - EXCO00 - 147 - Geotechnical Survey ReportDocument147 pages140706DARV14050 - EXCO00 - 147 - Geotechnical Survey ReportBilel MahjoubNo ratings yet

- ACI 364.10T-14 TechNoteDocument4 pagesACI 364.10T-14 TechNotedddNo ratings yet

- Tyrosinase MechanismDocument22 pagesTyrosinase MechanismEti ApriyantiNo ratings yet

- 19.05.2021 - TESTING LIST - SIDE VISOR D26A-Rev.01 (To Vendor Test Lab)Document3 pages19.05.2021 - TESTING LIST - SIDE VISOR D26A-Rev.01 (To Vendor Test Lab)haryonoari68No ratings yet

- ShikharDocument18 pagesShikharABHIJEET ANAND JHANo ratings yet