Professional Documents

Culture Documents

Datasheet

Datasheet

Uploaded by

William Evans0 ratings0% found this document useful (0 votes)

31 views2 pagesThe document provides information on the Trident modular intervention system from Trendsetter Engineering. It is a low-cost, flexible system designed for subsea well intervention. The system can be reconfigured for hydraulic intervention, riserless light well intervention, or use as an open-water intervention riser system. It has a compact design allowing rapid mobilization and integration onto vessels. The system provides dual barriers for well control and can complete safety sequences like emergency shutdown in under 35 seconds.

Original Description:

OWS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides information on the Trident modular intervention system from Trendsetter Engineering. It is a low-cost, flexible system designed for subsea well intervention. The system can be reconfigured for hydraulic intervention, riserless light well intervention, or use as an open-water intervention riser system. It has a compact design allowing rapid mobilization and integration onto vessels. The system provides dual barriers for well control and can complete safety sequences like emergency shutdown in under 35 seconds.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

31 views2 pagesDatasheet

Datasheet

Uploaded by

William EvansThe document provides information on the Trident modular intervention system from Trendsetter Engineering. It is a low-cost, flexible system designed for subsea well intervention. The system can be reconfigured for hydraulic intervention, riserless light well intervention, or use as an open-water intervention riser system. It has a compact design allowing rapid mobilization and integration onto vessels. The system provides dual barriers for well control and can complete safety sequences like emergency shutdown in under 35 seconds.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

TECHNICAL

INFORMATION

SHEET

TRIDENT MODULAR INTERVENTION SYSTEM

A Low Cost, Flexible Well Intervention Solution

Trendsetter's new Trident series of subsea well intervention systems has

been designed from the tree interface up, to provide a cost effective and

operationally robust solution for the next evolution of well intervention

needs and in compliance with the latest industry standards.

The Trident Intervention series is available in three bore and pressure varia-

tions: 5-1/8" 20,000psi, 6-3/8" 15,000psi, and 7-3/8" 10,000psi.

Based around innovative and compact valve technology, the Trident Lower

Riser Package (LRP) provides the versatility and functionality to be utilized

for Hydraulic Intervention, Riserless Light Well Intervention (RLWI) or

Open-Water Intervention Riser System (OWIRS) by changing out the

plug-and-play upper modules including the Emergency Disconnect Pack-

age (EDP) with tapered stress joint and the Pressure Control Head (PCH)

with lubricator assembly. In addition, the system is suitable for well testing

and flow back operations.

Due to the compact design, the Trident system is uniquely suited for rapid

mobilization and seamless integration into vessels and rigs of availability

providing a safe, cost-effective and time efficient intervention solution

regardless of the geographic location, intervention type or vessel selected.

Trident provides not only downhole access for hydraulic, wire line and

KEY FEATURES

coiled tubing well operations, but is designed first and foremost to provide

the necessary environmental barriers, ensuring personal safety and

environmental responsibility. Single system reconfigurable for Hydraulic

Intervention, Riserless Light Well Intervention

With API 17G qualified shear and seal capability for up to 2-3/8" coiled

and use as an Open-Water Intervention Riser

tubing, Trident is capable of completing Emergency Shut Down (ESD) in

System.

under 15 seconds, Emergency Disconnect Sequence (EDS) in less than 35

seconds and his full Deadman/Auto-Shear (DMAS) compliant.

Available in a wide range of bore size and

working pressure options up to 20,000psi

Provides peace of mind with dual barrier

well control and unparalleled shear / seal

capabilities

Compact footprint allows for reduced logistics

requirements and no modifications to vessel or

rig of availability.

Safety sequences including ESD, EDS, DMAS

accomplished in less than 35 seconds

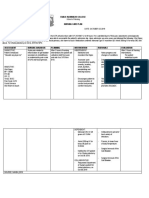

IT’S THE TECHNOLOGY INSIDE THAT COUNTS SPECIFICATIONS

Tapered Stress Integrated 5.125” - 20,000psi /

Joint TC11 Hub Accumulation Production Bore Size / 6.375“-15,000psi /

Working Pressure Rating 7.375”-10,000psi

Annulus Riser Revolution Valve Annulus Bore Size 2.0625 in.

Interface Configured For Riser Water Depth Rating 10,000 fsw

Retention Trim EE

Annulus Bore-Riser

Temperature Class API 6A - U

Connector With

Retention Poppet Production Bore Control Type Electro-Hydraulic (Primary)

Riser Connector ROV (Secondary)

ROV Interfaces Hot Stab(s) and Torque Bucket(s) as per API 17H

Annulus Bore TC2V

Slickline

Annulus Inboard Integrated Shear/Seal Capability Braided Line

Connector With EOD Independent Coiled Tubing: 2-3/8” x .203” ,130ksi

Accumulation

Emergency Shut Down (ESD)

Annulus Bore Safety System and Sequences

Emergency Disconnect Sequence (EDS)

2 1/16 FSC Deadman (DM)

Gate Valve Auto-Shear (AS)

Sheer Seal Safety System Timings <35 Seconds

Crossover 2-1/16” Revolution Valves EDP / LRP Dimensions 10’10” x 8’3” x 15’9” / 34,476lbs.

Manual Gate Valve (6-3/8” 15,000psi OWIRS) (L X W X H / Weight)

Open-Water Intervention Riser System

Hydraulic Intervention (OWIRS) Riserless Light Well Intervention

(HI) (RLWI)

AN INNOVATIVE SOLUTION FOR SUBSEA INTERVENTION

USA Manufactured by:

Visiting address: Trendsetter Engineering

10430 Rodgers Road Leader in Contemporary Subsea Solutions

Houston, Texas 77070

tel+1 281-465-8858

www. trendsetterengineering.com

You might also like

- Wireline 2Document178 pagesWireline 2William EvansNo ratings yet

- Wireline 3Document154 pagesWireline 3William EvansNo ratings yet

- 03.subsea Tree DesignDocument47 pages03.subsea Tree DesignWilliam EvansNo ratings yet

- 5-650kva 60HZ en PDFDocument26 pages5-650kva 60HZ en PDFAndrésRozoNo ratings yet

- NG7-40.5 Z Isatallation GuideDocument27 pagesNG7-40.5 Z Isatallation GuideWenceslao EscorzaNo ratings yet

- Catalogo Heein-Recloser (With R200 Control) 17.07) PDFDocument16 pagesCatalogo Heein-Recloser (With R200 Control) 17.07) PDFLuis Perdomo100% (1)

- 4 Corners Gold Rush Lesson PlanDocument3 pages4 Corners Gold Rush Lesson Planapi-267003013No ratings yet

- Carbon Footprint of Organic FertilizerDocument5 pagesCarbon Footprint of Organic FertilizerSteve Savage100% (6)

- F F F F: Downloaded From Manuals Search EngineDocument2 pagesF F F F: Downloaded From Manuals Search EngineZsolt KántorNo ratings yet

- Helix Well Ops 15k Irs 7 LTR 06-17-2020 FinalDocument4 pagesHelix Well Ops 15k Irs 7 LTR 06-17-2020 FinalWilliam EvansNo ratings yet

- Light Well Intervention System - LWISDocument2 pagesLight Well Intervention System - LWISWilliam EvansNo ratings yet

- GVR Recloser: For Pole Mounting and Substation ApplicationsDocument2 pagesGVR Recloser: For Pole Mounting and Substation ApplicationsOscar MorenoNo ratings yet

- Model Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32ADocument2 pagesModel Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32AAnurag JainNo ratings yet

- 01097GB Series 076Document4 pages01097GB Series 076Han LinNo ratings yet

- BKR ModelosDocument1 pageBKR ModelosAdrian CerritosNo ratings yet

- Solid Insulation Type LBS (SILO) - Catalog PDFDocument14 pagesSolid Insulation Type LBS (SILO) - Catalog PDFgede_trinataNo ratings yet

- 8DJH Compact Broschuere ENDocument4 pages8DJH Compact Broschuere ENgeneralsoftware softNo ratings yet

- Open System 2Document5 pagesOpen System 2William EvansNo ratings yet

- Manuals Os2 Release Relay Instruction Manual Fisher en en 5903250Document16 pagesManuals Os2 Release Relay Instruction Manual Fisher en en 5903250fisheriano2049No ratings yet

- ST&R Interchangeable Riserless Intervention System (IRIS)Document4 pagesST&R Interchangeable Riserless Intervention System (IRIS)William EvansNo ratings yet

- Tomahawk 625Document4 pagesTomahawk 625Marcos GarciaNo ratings yet

- Data SheetDocument4 pagesData SheetByronNo ratings yet

- WFDTH Waterflow Detector: Sprinkler Systems MonitoringDocument2 pagesWFDTH Waterflow Detector: Sprinkler Systems MonitoringArgile-assholeNo ratings yet

- 8510C - 15, - 50, - 100 Piezoresistive Pressure Transducer: Features DescriptionDocument3 pages8510C - 15, - 50, - 100 Piezoresistive Pressure Transducer: Features Descriptionedward3600No ratings yet

- Epp 2154Document4 pagesEpp 2154RazkulNo ratings yet

- DMDAMNN224-ECT en Us LetterDocument2 pagesDMDAMNN224-ECT en Us LetterLUIS SANCHEZ SANZCHEZNo ratings yet

- Danfoss RTDocument12 pagesDanfoss RTSerge Yannick MimboeNo ratings yet

- NMSB Iiib K12Document2 pagesNMSB Iiib K12Mohamed SolimanNo ratings yet

- 24-013, 24-014 Catalog Page PDFDocument2 pages24-013, 24-014 Catalog Page PDFAndres Felipe TapiaNo ratings yet

- X Limiter Full Range Current Limiting Fuse Catalog Ca132050enDocument8 pagesX Limiter Full Range Current Limiting Fuse Catalog Ca132050enFernando RodríguezNo ratings yet

- 422solenoid DSDocument4 pages422solenoid DSargaNo ratings yet

- A121x DatasheetDocument15 pagesA121x DatasheetCelsoNo ratings yet

- System Specifications: Samsung DVM S Eco Series, Heat Condensing UnitDocument2 pagesSystem Specifications: Samsung DVM S Eco Series, Heat Condensing UnitShirley BarreraNo ratings yet

- Breaker Manual HPA 12Document6 pagesBreaker Manual HPA 12mukesh_kht1100% (1)

- Breaker Manual HPA 12Document6 pagesBreaker Manual HPA 12mukesh_kht1No ratings yet

- DS8110 Standard EU ENDocument6 pagesDS8110 Standard EU ENJuan Jose FloresNo ratings yet

- Service Manual: Mod.: F400-SAEV-TS F400 SAEW TS F400 SAEC TSCDocument18 pagesService Manual: Mod.: F400-SAEV-TS F400 SAEW TS F400 SAEC TSCCông ty CP Công nghệ An PhúcNo ratings yet

- Panzerflex L 2Document2 pagesPanzerflex L 2Nino BallatanNo ratings yet

- Model Back-To-Back Check/shuttle Valve With Signal at Port 2Document2 pagesModel Back-To-Back Check/shuttle Valve With Signal at Port 2Erasmo LimaNo ratings yet

- Dynamicroll EngDocument8 pagesDynamicroll Engsebastian.taflan86No ratings yet

- Data Sheet EB1.12ATEX 2X.23.1Document6 pagesData Sheet EB1.12ATEX 2X.23.1julio.b200No ratings yet

- Senzor Presiune-Bct-22Document6 pagesSenzor Presiune-Bct-22IonNo ratings yet

- Model Flow Divider Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32ADocument2 pagesModel Flow Divider Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32AErasmo LimaNo ratings yet

- Delayed Coking Bottom Unheading: EngineeringDocument4 pagesDelayed Coking Bottom Unheading: Engineeringanup kumar nayakNo ratings yet

- ASCO SOV CatalogueDocument12 pagesASCO SOV Catalogueparth sapariaNo ratings yet

- PC9 2 PDFDocument4 pagesPC9 2 PDFcarlosorizabaNo ratings yet

- DKRCC PD CH0 B2 02 PDFDocument9 pagesDKRCC PD CH0 B2 02 PDFZvonimir PalacNo ratings yet

- Vickers DCV With Manual LatchDocument12 pagesVickers DCV With Manual LatchIon Logofătu AlbertNo ratings yet

- 010 BullDocument8 pages010 BullYsidro MundarainNo ratings yet

- WDCL Damaged-Control-Line Replacement Safety Valve SystemDocument4 pagesWDCL Damaged-Control-Line Replacement Safety Valve SystemDavid Pit FermiereNo ratings yet

- AM007KNNDCH+AA+SUBMITTAL M4Way 12272017Document2 pagesAM007KNNDCH+AA+SUBMITTAL M4Way 12272017Gilberto Alfaro De la ONo ratings yet

- 3-Way Flow Control Valves: 1 DescriptionsDocument6 pages3-Way Flow Control Valves: 1 Descriptionsmuhammad taufik rahmanNo ratings yet

- Submittal AM240BXVGJHAADocument2 pagesSubmittal AM240BXVGJHAASaul AguilarNo ratings yet

- DLDFMCN224D Full en Us A4Document5 pagesDLDFMCN224D Full en Us A4Mykola TitovNo ratings yet

- SPEC 11669 Rev C Product Specification Subsea LF CIMVDocument2 pagesSPEC 11669 Rev C Product Specification Subsea LF CIMVshengguoNo ratings yet

- (GIS) 145kV - Catalog - EN - 201712Document20 pages(GIS) 145kV - Catalog - EN - 201712Mehdi OunnarNo ratings yet

- CK GR 012020Document5 pagesCK GR 012020vrallamcitoNo ratings yet

- Automated Adjustable ChokeDocument2 pagesAutomated Adjustable ChokeMohamed ShetaNo ratings yet

- Changeover SwitchesDocument16 pagesChangeover SwitchesBENNo ratings yet

- Balanza Eagle DCS302 ELECTDocument2 pagesBalanza Eagle DCS302 ELECTCristhoper Jhorkaef Meza HuanhuayoNo ratings yet

- Codo PortafusibleDocument6 pagesCodo PortafusibleElvis Jesus Landa ReyesNo ratings yet

- Scooptram EST2D: Underground Electric Loader With 3.6 Tonne Load CapacityDocument5 pagesScooptram EST2D: Underground Electric Loader With 3.6 Tonne Load CapacityAditi DasNo ratings yet

- JW - SF6 Gas LBS Catalog - 200210 (S)Document6 pagesJW - SF6 Gas LBS Catalog - 200210 (S)HopNo ratings yet

- P611 Silicon Glass Fused Pressure TransmitterDocument2 pagesP611 Silicon Glass Fused Pressure TransmitterPrihartono Danan WingusNo ratings yet

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Hammer Wing Union Adapters - Rev. 11012022Document12 pagesHammer Wing Union Adapters - Rev. 11012022William EvansNo ratings yet

- Sec 2 Completion DesignDocument74 pagesSec 2 Completion DesignWilliam Evans100% (1)

- B2B - Hydraulic Flow DiagramsDocument21 pagesB2B - Hydraulic Flow DiagramsWilliam EvansNo ratings yet

- Conflict Is Part of Life and LeadershipDocument40 pagesConflict Is Part of Life and LeadershipWilliam EvansNo ratings yet

- Subsea Well Access RWISDocument2 pagesSubsea Well Access RWISWilliam EvansNo ratings yet

- DPE00 - Dowel Extractor Tool KitDocument1 pageDPE00 - Dowel Extractor Tool KitWilliam EvansNo ratings yet

- DETG 3-24-2011 Brian SkeelsDocument14 pagesDETG 3-24-2011 Brian SkeelsWilliam EvansNo ratings yet

- Maintenance ExpectationsDocument18 pagesMaintenance ExpectationsWilliam EvansNo ratings yet

- 2021 WCE Annual ReportDocument65 pages2021 WCE Annual ReportWilliam EvansNo ratings yet

- CoiledTubing For Downhole Applications (Tenaris)Document24 pagesCoiledTubing For Downhole Applications (Tenaris)William EvansNo ratings yet

- Sec 3 Well ServicingDocument38 pagesSec 3 Well ServicingWilliam EvansNo ratings yet

- Wireline 4Document170 pagesWireline 4William EvansNo ratings yet

- Sec 1 GeologyDocument26 pagesSec 1 GeologyWilliam EvansNo ratings yet

- Wireline 5Document98 pagesWireline 5William EvansNo ratings yet

- BlueCoil Technology (Tenaris High Strength)Document12 pagesBlueCoil Technology (Tenaris High Strength)William EvansNo ratings yet

- Drilling A SS WellDocument61 pagesDrilling A SS WellWilliam EvansNo ratings yet

- Wireline 1Document188 pagesWireline 1William Evans100% (1)

- How Well Is DrilledDocument46 pagesHow Well Is DrilledWilliam EvansNo ratings yet

- ValvesDocument1 pageValvesWilliam EvansNo ratings yet

- Slickline Operations Safety PracticesDocument4 pagesSlickline Operations Safety PracticesWilliam Evans100% (1)

- RespiratoryDocument18 pagesRespiratoryWilliam EvansNo ratings yet

- Nigeria Slickline Operations ManualDocument226 pagesNigeria Slickline Operations ManualWilliam Evans100% (1)

- FiltersDocument1 pageFiltersWilliam EvansNo ratings yet

- Slickline Service Tools Part 1Document8 pagesSlickline Service Tools Part 1William EvansNo ratings yet

- MaskDocument2 pagesMaskWilliam EvansNo ratings yet

- BakerDocument4 pagesBakerWilliam EvansNo ratings yet

- Wireline Advisory WilcoDocument5 pagesWireline Advisory WilcoWilliam EvansNo ratings yet

- Bicycle ProjectDocument4 pagesBicycle Projectgaming channelNo ratings yet

- UO Mixing Liquid PhaseDocument2 pagesUO Mixing Liquid PhaseKumara Haekal Hafidz AmrullahNo ratings yet

- IFU Acticor 439128-F EsDocument143 pagesIFU Acticor 439128-F EsMartin ArrietaNo ratings yet

- Sago Pudding - Recipes - Poh's KitchenDocument2 pagesSago Pudding - Recipes - Poh's KitchenXuxu TooNo ratings yet

- Notes-Nutrition in PlantsDocument3 pagesNotes-Nutrition in PlantsADHIL MOHAMMEDNo ratings yet

- Autoconceito ShavelsonDocument15 pagesAutoconceito ShavelsonJuliana SchwarzNo ratings yet

- A Review On Ultra High Performance Concrete Part II. Hydration, Microstructure and Properties PDFDocument10 pagesA Review On Ultra High Performance Concrete Part II. Hydration, Microstructure and Properties PDFNocifLyesNo ratings yet

- Over The Counter MedicinesDocument3 pagesOver The Counter MedicinesJhun Echipare100% (3)

- Waste Heat RecoveryDocument37 pagesWaste Heat Recoveryommech2020No ratings yet

- Case Study Booklet 2 PDFDocument43 pagesCase Study Booklet 2 PDFguddu yadavNo ratings yet

- Cavitation Models in PIPENETDocument3 pagesCavitation Models in PIPENETSamarth PawarNo ratings yet

- Emilio Aguinaldo College: School of NursingDocument2 pagesEmilio Aguinaldo College: School of NursingAwani ONo ratings yet

- 15 Proven Recipes To Most Desirable & Delicious Ice Creams.Document19 pages15 Proven Recipes To Most Desirable & Delicious Ice Creams.viaindiankitchenNo ratings yet

- MAC-LAB Assistant 5BDocument38 pagesMAC-LAB Assistant 5BAbdelhakszn SznNo ratings yet

- General Physics 1: ACTIVITY/ANSWER SHEET: Quarter 2Document1 pageGeneral Physics 1: ACTIVITY/ANSWER SHEET: Quarter 2Kashima KotaroNo ratings yet

- Science G7 Q2 LP4Document13 pagesScience G7 Q2 LP4Lovely GuintoNo ratings yet

- The Winnipeg Foundation 2014 Annual ReportDocument76 pagesThe Winnipeg Foundation 2014 Annual ReportChrisDcaNo ratings yet

- Beyond FurosemideDocument13 pagesBeyond FurosemideHeath HensleyNo ratings yet

- PLKS321 Unit 8.9 PMDocument56 pagesPLKS321 Unit 8.9 PMmonagomolemo9No ratings yet

- Mitsubishi Motors Vs Chrysler Philippines Labor UnionDocument2 pagesMitsubishi Motors Vs Chrysler Philippines Labor UnionKobe BullmastiffNo ratings yet

- SPE 13932 Wettability Part2 AndersonDocument17 pagesSPE 13932 Wettability Part2 AndersonSergio EduardoNo ratings yet

- Livebook ACBDocument420 pagesLivebook ACBShubhangi JagtapNo ratings yet

- Normal Lab ValuesDocument4 pagesNormal Lab Valuesrmelendez001No ratings yet

- Model ETR-9200 Automatic Tuning Smarter Logic ControllerDocument26 pagesModel ETR-9200 Automatic Tuning Smarter Logic ControllervhelectronicaNo ratings yet

- Cognitive Chapter 6 Cornell NotesDocument10 pagesCognitive Chapter 6 Cornell Notesvalcobacl.681.studNo ratings yet

- Dokumen - Tips - Diagnostic Test Mapeh 10Document4 pagesDokumen - Tips - Diagnostic Test Mapeh 10charry ruayaNo ratings yet

- Microbial Ecology of Sourdough Fermentations: Diverse or Uniform?Document19 pagesMicrobial Ecology of Sourdough Fermentations: Diverse or Uniform?roadrunner100% (1)