Professional Documents

Culture Documents

CODEV Ch6

CODEV Ch6

Uploaded by

Sadegh SobhiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CODEV Ch6

CODEV Ch6

Uploaded by

Sadegh SobhiCopyright:

Available Formats

Menu

Search

Chapter 5

Resist Murphy’s Law: Tolerancing

You are probably familiar with Murphy’s Law: “Anything that can go wrong, will go

wrong.” Tolerancing is an attempt to resist Murphy’s Law, by understanding what

sorts of errors can occur, how badly they will affect optical performance, and what is

the probability of building a system that works.

CODE V has a number of tools for tolerancing, including a powerful feature called

TOR. Other tools are provided for analyzing user-defined tolerance criteria and for

Monte Carlo simulations.

Contents

Murphy’s Law...........................................................................................................120

Tolerancing and TOR................................................................................................123

Tolerance Types ........................................................................................................125

Tolerancing with the LDM and TOR........................................................................126

Understanding TOR Output......................................................................................137

Other Tolerance Analysis Features ...........................................................................142

CODE V Introductory User’s Guide 119

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Murphy’s Law

Search

Optical systems require precision in fabrication. Errors that might be insignificant

in many mechanical devices can cause terrible performance problems in an optical

system. Yet errors will certainly occur, since nothing can be built perfectly.

Tolerancing is concerned with understanding the types of errors that can occur in

building an optical system, and in predicting their effects before anything is built.

You can’t beat Murphy’s Law, but you can limit your exposure by knowing what

can go wrong, defining the limits of the errors, and predicting their effects.

What Can Go Wrong?

A centered optical system is defined by a few parameters, mainly the curvature,

thickness, and glass at each surface. But there are many things that can go wrong

with these few parameters, including:

• Wrong curvature (usually measured by test plate fit, DLF, plus cylindrical

irregularity, IRR)

• Wrong thickness (glass) or air space (mounting errors), measured by

delta-thickness (DLT)

• Wrong index of refraction or dispersion (DLN, DLV)

• Centering errors (front and back surfaces not on same axis, called wedge, or

total indicator runout—TIR)

• Mounting errors (elements or groups of elements tilted, shifted, or decentered

from their design positions)

In all, there are easily 7 or more potential manufacturing errors associated with each

optical surface. Complex systems with special surface types will have even more

potential errors. Each of these potential errors must be assigned an allowable range

or tolerance. For example, the glass element thickness for surface 8 (THI S8 5.5)

might be required to be held within plus or minus 20 microns (e.g., 5.500 mm ±

0.020 mm, or DLT S8 0.02). Such tolerance values are often simply guessed or they

may be assigned based on the “standard values” or on the assumed capability of the

optical shop or manufacturing process. CODE V offers more systematic ways to

determine these values.

120 CODE V Introductory User’s Guide

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

How Bad Can It Be?

Search With tolerances defined for the various manufacturing errors in the optical model,

the question now is, how bad can it be? This can actually mean two different

things. If you take a given set of tolerance values and say “simulate the

construction of this lens assuming that every construction parameter is correct to

within these tolerances,” then the question might be, what MTF or RMS wavefront

error will I get when I measure a sample lens? This is called sensitivity analysis,

since each error can cause a different effect depending on the sensitivity of the

design to each particular value.

The other way to interpret “how bad can it be?” is to say, how large an error will

cause a specified change in MTF, assuming everything else is perfect? This is

called inverse sensitivity, and it is one of the powerful features of TOR. Applying

this technique to all tolerances is called semi-automatic error budgeting. This

means that each tolerance is scaled to contribute roughly the same amount of error

to the system as any other parameter, which is a reasonable assumption. This is a

very systematic way to answer the question, “How bad can it be?,” although other

factors may affect the tolerance values in many cases (most of these other factors

are handled by tolerance limits, which keep things within practical bounds).

Compensators

An important aspect of optical assembly is the ability to make adjustments during

assembly to compensate partially for the accumulated and random set of errors that

have occurred in the fabrication and assembly. These adjustments are called

compensators. Anything that can be a tolerance can in principle be a compensator.

The most common compensators are focal shifts or other air space adjustments.

You will find that the selection of effective compensators is one of the most

important tolerancing tools, often transforming very tight (small) tolerances to very

reasonable values. Compensator selection requires some familiarity with possible

mounting methods, since there must be a physical means to accomplish the desired

shift over the required range.

Statistics

Unfortunately, there is no way to hold everything perfectly except for a single error.

In reality, all errors will occur simultaneously and randomly, although within the

assigned tolerance limits (you hope). This means there is no way to predict the

exact performance of a particular real lens built with a given set of tolerances. If

you build 1,000 lenses, each will have slightly different performance. The best you

can do is to predict the statistical distribution of the results. You can say something

like, “If I build 1,000 lenses, 980 of them will have a performance within 11% of

the nominal design.” If 11% degradation is acceptable, and if 98% yield is

CODE V Introductory User’s Guide 121

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

acceptable, you are done. If not, then you need to do something—perhaps tighten

some tolerances, or provide some adjustment (a compensator) that improves the

Search

quality or yield. In the worst case, you may need to redesign the lens to be less

sensitive.

CODE V’s tolerance features (TOR and others) offer exactly these types of

statistical predictions, and allow you to change tolerances, adjustments

(compensators), and other assumptions in order to find solutions before hardware is

built.

The Cost of Failure

Successful tolerancing allows you to specify a set of realistic tolerances and

effective compensators that will allow the optics to be built with good performance

and yield. One alternative is to assign the tightest possible tolerance to every

parameter and not worry about the compensation (or “just tweak the focus”). The

cost of this can be very high—working to unnecessarily tight tolerances raises

fabrication time and cost. Even worse is the possibility that the tightest possible

tolerances, combined with ineffective compensators, will lead to expensive optics

that don't perform well.

122 CODE V Introductory User’s Guide

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Tolerancing and TOR

Search

The previous section was intended to give a general introduction to the problem of

optical tolerancing, without a lot of technical detail. Now we will start to consider

how you can actually solve these problems with CODE V.

Tolerancing Goals

The primary objective in tolerancing an optical system is to determine the

combination of dimensional ranges for fabricated elements which will minimize

manufacturing cost while satisfying performance, packaging, and appearance

requirements. It is an important part of the lens design process. The TOR option,

found on the Analysis > Tolerancing menu, has been developed to eliminate most

of the practical difficulties involved in tolerancing. TOR enables the designer to

concentrate on the optical system and its performance, rather than on extensive and

costly calculations and indirect results that may be difficult to interpret.

TOR Functions

TOR directly relates the manufacturing errors to measurable performance

requirements, either polychromatic diffraction MTF (at a specified frequency and

orientation), RMS wave front error, fiber coupling efficiency, or polarization

dependent loss. Four separate menu items access the four quality modes (MTF,

RMS Wavefront Error, Fiber Coupling Efficiency, and Polarization Dependent

Loss) all found on the Analysis > Tolerancing menu). TOR’s basic unit of

information is the change in the quality criterion (MTF, RMS wavefront, coupling

efficiency, or polarization dependent loss) caused by a parameter change of a

certain amount. This sensitivity calculation includes the effect of adjustable

parameters (compensators) specified by the user to simulate the assembly

procedures of focusing, tilting the image plane, etc., to maximize the performance.

Boresight (i.e., shift of line of sight) correction and distortion change output are

available as options.

In some of the following discussions we will occasionally use the term MTF drop

to describe a performance degradation due to manufacturing errors. You should

recognize that the discussion applies equally well to degradation in the other quality

criteria used in TOR, RMS wavefront error, fiber coupling efficiency, or

polarization dependent loss, depending on what you choose to use for your optical

system.

CODE V Introductory User’s Guide 123

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Semi-Automatic Error Budgeting

Search Semi-automatic error budgeting (also called inverse sensitivity mode) means that

the program can select an appropriate set of tolerance parameters, ranges for the

parameters, and specific values that provide a predetermined individual MTF drop.

As with other CODE V features, the extensive defaults used in these calculations

can be easily overridden in part or in full (this is why it is only semi-automatic).

Statistical calculations are automatically done to predict overall system

performance. Well-labeled tolerance output tables aid in communication with other

technical staff.

Interactive Tolerancing

After any initial TOR run, sensitivities are saved with the lens data so certain

subsequent tolerance analysis can be done more quickly (no ray tracing is required),

provided the lens data remains unchanged. Interactive tolerancing uses this saved

data to allow you to change tolerance values and immediately see their effects on

predicted performance. This is found on the Analysis > Tolerancing > Interactive

Tolerancing menu and can only be accessed after a standard TOR run has been

done (MTF, RMS Wavefront Eror, Fiber Coupling Efficiency, and Polarization

Dependent Loss).

If you are going to close the lens before using interactive tolerancing, you can save

it with Save Lens As. You can then restore the lens with the saved TOR coefficient

data and immediately use interactive tolerancing.

Other Tolerancing Options

In addition to the TOR option, CODE V has several other tolerancing features.

TOD (Analysis > Tolerancing > Distortion menu) is nearly identical in operation

to TOR, but uses chief ray distortion derived from wave front differentials as its

quality criterion. TOL is an older option based on primary aberrations (available

only on the command line; see Chapter 22 in the CODE V Reference Manual for

more information on this feature). Two macro-based user-defined tolerancing

features are also available, TOLFDIF (Analysis > Tolerancing > User- Finite

Differences menu) and TOLMONTE (Analysis > Tolerancing > User- Monte

Carlo menu). Both of these features require that you define a set of tolerance values

to evaluate and that you save the lens with these values before using the feature.

This chapter will focus primarily on the TOR option, although other features will be

discussed in a section at the end.

See the CODE V Reference Manual or Help for complete information on any of

these features.

124 CODE V Introductory User’s Guide

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Tolerance Types

Search

CODE V supports many types of tolerances, a few of which are listed here.

Tolerances are considered to be part of the lens data and thus are defined and

reviewed in the LDM, as will be shown in the next section. Most tolerances are

linear quantities that are measured in lens units (most often mm). Angular errors are

measured in radians (this is different from construction data tilts and field angles,

which are measured in degrees). Not all possible tolerances are included in

automatically generated default sets; you can always add or remove tolerances from

default sets, using the Review > Tolerances menu. Some tolerance types have

special definitions. Here are just three examples of the many tolerance types.

Test plate fit (DLF)—A measure of the closeness of fit between a surface and a

reference test plate surface, measured as the number of interference fringes

(Newton's Rings). Irregularity (IRR) is also measured in this test, as elliptical

deviations from the nominally circular rings.

Wedge—When the front and rear surfaces of an element do not share a common

axis, the error can be described as surface tilt, or more commonly as a wedge,

described as TIR (total indicator runout), from the device and method of

measurement in the shop.

Barrel Tilts (BTI)—When a group of surfaces is tilted as a unit, this is called a

barrel tilt (in radians). Barrel tilts require a surface range, and the first surface in the

range is the default pivot point, though this can be changed with offsets in X, Y,

and Z.

Note: The only groups of surfaces that CODE V can recognize for default tolerance

purposes are single and cemented lens elements. Although other groups of surfaces

may form a group for construction purposes, CODE V does not know the mount

structure, and thus has no way to know that this is a group. For example, if you know

that surfaces 8 through 15 are a subassembly, you must add BTI S8..15 (and other

group tolerances) to the default set, or the errors of placement of this group will not

be simulated.

Starting on page 10-4 the CODE V Reference Manual has descriptions of all

available tolerances.

CODE V Introductory User’s Guide 125

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Tolerancing with the LDM and TOR

Search

You can run TOR in several ways, with various degrees of control over the

tolerances and compensators that are used, the type of calculations done, and the

amount of output. Although you can make an all-default TOR run, you usually use

the LDM to prepare the lens and define tolerances before running TOR.

All-default TOR Run

An all-default TOR run is the quickest way to run TOR, since it lets CODE V do all

the work. If you open a lens file that contains no tolerances and run TOR, the

program will automatically generate a default set of tolerances and compensators

before doing the TOR calculations.

1. Choose the File > Open menu and locate the lens file cooke1.len in the

CODE V supplied lens directory, which is at C:\CODEVxxx\lens in a default

installation.

The figure below illustrates this lens system:

The lens is a Cooke triplet (f/4.5, 20° semi-FOV, 50 mm focal length). This

sample lens has no pre-defined tolerances.

2. Choose the Analysis > Tolerancing > RMS Wavefront Error menu.

The RMS wavefront error dialog box is displayed, with Polychromatic RMS

selected as the quality criterion.

126 CODE V Introductory User’s Guide

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Search

3. Click OK to start the run.

The program will produce many lines of output from this small amount of input

(the equivalent command input for this run is TOR;GO). The tolerances are a

standard default set, used in inverse sensitivity mode with a single compensator

(Z shift of the image surface, i.e., re-focus). Scroll the output window text tab

to see the output. We won’t explain this particular output, since you will per-

form a similar run in a moment. That run will be more typical, with explicit

definition of tolerances, a compensator, and some TOR control settings. We

will discuss the output of that run.

CODE V Introductory User’s Guide 127

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Setting Up Tolerances

Search As mentioned earlier, tolerances are actually considered to be part of the lens data,

and as such they are defined, viewed, and edited in the LDM. They are also saved in

the .len file when the lens is saved.

1. Choose the File > Open menu and locate the lens file cooke1.len in the

CODE V supplied lens directory.

This is the same predefined lens file that you opened in the previous procedure;

you need to reopen this lens file to ensure the correct results in this procedure.

2. Choose the Review > Tolerances menu.

The Tolerances and Compensators window is displayed. Note that this win-

dow is empty, since cooke1.len does not include any tolerances by default.

3. Click the Autofill button at the top of the spreadsheet to open the Tolerance

Spreadsheet Autofill dialog box.

The default settings (generate default tolerances for all surfaces) are good in this

case.

4. Click OK to define the tolerances.

The tolerances displayed in the Tolerances and Compensators window are

standard default values. Scroll down and notice that 53 default tolerances have

been generated for this six-surface centered lens. You could use right-click to

128 CODE V Introductory User’s Guide

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

add (Insert) or remove (Delete) tolerances from this list. Every cell that is not

grayed-out is editable (e.g., double-click a Type item to change it to a different

Search

type).

Tip: To change the width of any columns in this window, right-click on a column

header and choose Column Width (120 works pretty well for the Type column).

No calculations have yet been done to see the effect of these tolerances (that’s

what TOR will do). You must still define a defocus compensator; once you start

to define tolerances and compensators, CODE V assumes you will define all

that you need, and nothing is generated automatically.

5. Right-click on the End of Data line in the Compensators spreadsheet at the

bottom of the Tolerances and Compensators window.

6. Choose Insert from the shortcut menu.

7. Double click the Start Surface cell and select Image surface.

8. Double-click the Type cell for this new compensator and scroll to locate and

select DLZ - Surface Z-Displacement as the compensator, as shown below.

CODE V Introductory User’s Guide 129

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Search

In the case of the image surface, thickness (DLT) and Z displacement (DLZ) are

equivalent, and you don't really need to change from the default value except as

a demonstration. In general, DLT changes the thickness by pushing back follow-

ing surfaces, while DLZ only shifts the surface, leaving other surfaces

unchanged.

9. Click the Commit button at the top, or click anywhere in the tolerance list to

commit the data for the DLZ Si compensator just defined.

10. Choose the File > Save Lens As menu to save a copy of the lens with the newly

defined tolerances and compensator.

TOR Lens Preparations

Now you are almost ready to run TOR, this time with diffraction MTF. Before you

do, you should make sure that the lens is at its best focus position. Although TOR

uses wave-based calculations (RMS or diffraction MTF), it will work fine with

even a poorly corrected lens. But the lens should be adjusted to simulate as closely

as possible the end-use configuration. Since most optical systems are used at best

focus, you should normally be sure the lens model is at best focus. Results from

TOR can change substantially with focus.

1. Choose the Analysis > Diffraction > MTF menu to display the MTF dialog

box.

2. On the Frequency/Calculation tab, enter 75 for the maximum frequency and

15 for the increment in frequency.

3. Click the Graphics tab and enter 75 for the maximum plot frequency.

4. Click OK to run MTF.

130 CODE V Introductory User’s Guide

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

5. Click the Quick Best Focus icon on the Quick Analysis tool bar:

Search This will run Wavefront Analysis option with the Replace Focus command,

analyzing the RMS wavefront error of the system and setting the image surface

defocus (THI Si) to maximize it. This is not exactly the same as optimizing the

MTF, but it's a reasonable approximation.

6. Re-run the MTF calculation by clicking the Execute button on the MTF

window.

Notice that the MTF curves are slightly improved. We will use 15 cycles/mm

as the tolerancing frequency. Note that the radial (0°) and tangential (90°) azi-

muth MTF curves for the off-axis fields are substantially different. You could

choose one of the azimuths for tolerancing (TAN is the default) though it is best

to include both. To do so requires duplicating the off-axis fields.

7. Choose the Lens > System Data menu and go to the Fields/Vignetting page in

the System Data window.

8. Insert two new fields into the spreadsheet on the Fields/Vignetting page. You

can insert a field by right-clicking over an existing field row and choosing

Insert from the shortcut menu. Once you’ve added two new rows, copy and

paste values from existing fields into the new fields (you can use the Copy and

CODE V Introductory User’s Guide 131

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Paste features in the Edit menu to do this). The result should be five fields, with

the field data matching what is shown in the following illustration.

Search

9. Choose the File > Save Lens menu to update the saved copy of the lens, which

will now include the tolerance definitions and the five fields (YAN 0 14 14

20 20).

TOR Input Dialog

To begin the TOR run, choose the Analysis > Tolerancing > MTF menu to open

the Tolerancing - MTF dialog box. You will make changes on two of the six tabs,

and review the default settings on two others.

Performance Measures Tab

By default, the Performance Measures tab is in the foreground when you open the

TOR dialog box. This time you will use polychromatic MTF as the tolerance

criterion, and this is already highlighted. For MTF, you must select the spatial

frequency and azimuth (target orientation) for each field point. You will use 15

cycles/mm for all fields, and enter RAD for fields 3 and 5, leaving the default of

TAN for the other fields (RAD and TAN will be identical for the axis due to

symmetry).

132 CODE V Introductory User’s Guide

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Search

1. For Spatial Frequency, enter 15 in the Lines per MM field for all five fields.

2. For Azimuth, click in the initially blank Lines Orientation cell and use the

down arrow four times to create 5 field entries (or use right-click Insert).

Double-click the Field row and set row 2 to field 2, row 3 to field 3, etc. Change

the orientation from TAN to RAD for fields 3 and 5, as shown above.

Computational Controls Tab

Settings on the Computational Controls tab determine how the tolerances will be

calculated. There are two modes, inverse sensitivity (the default) and sensitivity.

Inverse sensitivity mode will generate tolerance values by trying to set values that

produce a predetermined change in the performance measure (a 0.01 drop in MTF

by default). Sensitivity mode will calculate the MTF change caused by the current

set of tolerances (with values supplied by you, from defaults, or some

combination). Inverse mode is the most useful mode in early tolerancing phases,

and you can use it with the default drop of 0.01 for this example.

CODE V Introductory User’s Guide 133

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Search

No inputs are required on this tab.

Output Controls Tab

The Output Controls tab affects the amount and type of output that TOR gives

you. The extended output mode (command FUL) lists coefficient values that allow

you to manually recalculate individual sensitivities without redoing an entire run.

You can use the default mode of “Standard” for this run. The Output Threshold

(SEL) controls the sensitivity values that are displayed, selecting only those

parameters whose MTF change exceeds the threshold. This reduces the amount of

output and helps you to focus on those tolerances that are driving the performance

(for various reasons, primarily tolerance limits, the MTF change for many

parameters is small). You can use the default. Distortion evaluation (DST) adds a

table showing how the tolerances affect chief ray positions. Use the default for this

as well.

134 CODE V Introductory User’s Guide

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Search

No inputs are required on this tab.

Tolerance Limits Tab

The Tolerance Limits tab allows you to edit the limiting values used for all

tolerance types. The default values reflect typical industry practices for moderately

high quality optical fabrication. If you are designing specialized, high quality

optics, or high-volume plastic optics, the limits should be modified to reflect actual

fabrication practices that may be tighter or looser than the default settings.

Tip: Although the limits only apply to the current TOR calculation, you can

enter the limits for your optical shop and use Option Set to save this as a

“template” for future TOR runs (you might call it “My Shop Limits”). Start

every TOR input by loading this option set, then modify other tabs as needed.

CODE V Introductory User’s Guide 135

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Search

• No inputs are required on this tab.

• Click OK to start the calculation.

136 CODE V Introductory User’s Guide

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Understanding TOR Output

Search

With the LDM tolerance inputs and TOR settings just described, you have asked

TOR to use the tangential and radial MTF at 15 cycles/mm as the quality criterion,

and for each manufacturing error, to find the value of the error that produces an

MTF drop of 0.01 for the most sensitive of the three field angles. In fact, you may

not see the value 0.01 very often in the output, as other factors often prevent the

0.01 drop from being reached.

Sensitivity Tables

There is one sensitivity table for each field (the 20° full-field is shown below, for

tangential MTF). The table starts with information about the number of rays traced

(always worth a look to check for problems) and the nominal performance at this

field point. This is followed by the long list of sensitivities.

You can interpret the sensitivity data in the following way (taking DLF S2 as an

example): an error of 2 fringes of power on surface 2 will cause a change of MTF of

+0.008 if positive, and -0.007 if negative. These changes assume that the

CODE V Introductory User’s Guide 137

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

compensating parameter (DLZ S7, image surface defocus) is changed by

+0.038 mm and -0.038 mm, respectively. Scrolling down the table, you will find the

Search

following line:

DSY S1..2 0.0200000v 0.026 -0.031 0.000000

This shows that the largest MTF change (-0.031) is caused by a -0.020 mm

y-decentration of the front element (DSY S1..2). Notice that the compensator value

for this tolerance is zero. This is because a centered tolerance (DLZ Si or focus)

cannot compensate for an asymmetric error. You could add decentered

compensators (there is no specific limit on the number of tolerances or

compensators), assuming that it were mechanically and economically feasible to

test and make such adjustments.

Note: There can only be one value for each tolerance and compensator, as you

can verify by comparing particular tolerance entries between fields. Each

tolerance will produce a different effect on each field, and in fact one field will

always be the worst case that determines the tolerance value in an inverse

sensitivity run.

Probable Change in MTF is a statistical value based on combining all the defined

tolerances. Additional statistics are printed at the end of each sensitivity table and

are explained below.

Can errors make things better?

Many of the errors introduce positive changes in MTF. But how can an error cause

the MTF to increase? The reason is that the system is not optimized specifically for

this MTF frequency at this field. We assume that the overall design is optimized to

its purpose and that any single tolerance error of a particular sign might improve

this particular MTF value. But when many errors are applied simultaneously, the

likelihood of an overall improvement is virtually nil.

Note also that when compensators are calculated, they are limited to removing the

degradation of performance caused by the error, but they cannot improve the

system beyond the nominal performance.

Effects of Limits and Rounding

The Manufacturing Errors in the table are obtained by trying to make each value

give a change specified drop (0.01 default) in MTF, including the effect of any

applicable compensators. Very few parameters reach this, however, and most are

nowhere near this. Rounding of tolerances to convenient values limits the range in

138 CODE V Introductory User’s Guide

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

some cases. But the most common cause of this is the use of limits: TOR places

upper and lower bounds on all tolerances to prevent unrealistic values

Search

(microscopically tight or very loose). These limits are displayed in the text output.

The centered limits are shown below (note that the program also displays the limits

for decentered tolerances).

As discussed earlier, you can modify the limits on the Tolerance Limits tab in the

TOR dialog box. The TOR section of the CODE V Reference Manual (Chapter 22)

explains the factors that determine values in more detail.

Probability Distributions, Cross Terms, and Statistics

After all the sensitivities are calculated, they must be used to make statistical

predictions. The assumptions, calculations, methods, and output tables are

discussed in the CODE V Reference Manual (Chapter 22, Tolerancing; see

especially the sections titled, “Description of Output” on page 22-46 and

“Technical Notes” on page 22-65). Here are a few of the key points:

• Errors are assumed to lie within the tolerance bounds and to follow a specific

probability distribution (you can change some aspects of this on the Probability

Functions tab—click on this tab and press F1 for help on this subject).

• Statistical predictions are based on an algebraic formulation. This “simulated

Monte Carlo” is valid for large numbers (N > 10) of independent errors. A

macro for true Monte Carlo simulation is also available (tolmonte.seq).

CODE V Introductory User’s Guide 139

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

• Cross terms are included in the statistics, i.e., errors can combine with or

partially cancel the effects of other errors.

Search

A table such as the one below is displayed for each field.

The interpretation of the cumulative probability table is that 97.7% of the systems

built will have a change in MTF of -0.054 or smaller from the design MTF for this

field, assuming the lens is built to the tolerances used in the lens model. The other

percentages can be interpreted the same way (50% represents the mean, while

84.1%, 97.7%, and 99.9% represent confidence levels of 1σ, 2σ, and 3σ,

respectively). The note on the right side of the table describes what is something

like a worst case, assuming that all parameters are fabricated at the extremes of the

allowable range.

Compensator Range

The probable change of compensator also approximates the 2σ level. This means

that if the compensator (focus shift in this case) can vary by ±0.5 mm, this range

will allow compensation for about 98% of the systems built (i.e., 2% of the systems

will have combinations of centered errors too large to be focused out by this range

of motion). This information provides guidance for mount designers as well.

140 CODE V Introductory User’s Guide

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Tolerance Output Tables

Search At the end of every TOR run, tables of centered and decentered tolerances are

displayed, collecting all the data from the sensitivity tables in a compact format.

The tolerance limits are displayed following each table. The Decentered

Tolerances table is shown below.

Performance Summary Table

The Performance Summary table collects in a single table the nominal and

probable change values (for system performance and for compensator range). This

is where you can take a quick look at the results of the tolerance run and see if the

Design + Tol column will meet your as-built performance specification.

CODE V Introductory User’s Guide 141

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Other Tolerance Analysis Features

Search

As mentioned earlier in this chapter, there are other tolerance features in CODE V,

including TOD (chief ray distortion tolerancing) and TOL (primary aberration

tolerancing, an older tolerance method included for compatibility with older

versions of CODE V). In addition, there are two forms of user-defined tolerancing

that are implemented as CODE V macros for maximum user flexibility.

User-defined tolerancing means that the quality criterion is defined by you in the

form of a macro that follows a certain format. This means that you must be able to

write such a macro if you can’t use one of the supplied examples. User-defined

tolerancing is also restricted to sensitivity mode, which means you must somehow

determine a reasonable set of tolerance values to evaluate. In most cases, an inverse

sensitivity TOR run for RMS wavefront error is a good way to determine a

reasonable starting set of tolerances (just using the default values may not be

reasonable for a particular optical system). You must also save the lens in a .len file

including the calculated tolerance values.

The two forms of user-defined tolerancing are:

• TOLFDIF.SEQ—FDIF means “finite differences,” and this is a difference

from TOR, which uses differential methods to evaluate tolerances. Finite

difference means that the lens is evaluated in its nominal state, then perturbed,

and the nominal result subtracted from the perturbed result to get the difference

caused by the perturbation. Once all the errors are evaluated (one tolerance at a

time), statistics are done similar to those in TOR.

• TOLMONTE.SEQ—This macro applies perturbations for all tolerances

simultaneously to create a “Monte Carlo sample,” which is evaluated by the

user’s evaluation macro. When a fairly large number of samples is generated

(50 or more), statistics and probability curves are generated based on all the

samples.

You can start each of these macros from the menu at Analysis > Tolerancing >

User - Finite Differences or User - Monte Carlo. A dialog box for the macro will

open. How to use these macros is described in detail in the CODE V Reference

Manual, in “User-Defined Tolerancing” on page 22-107.

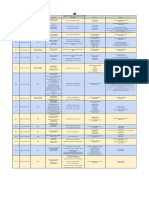

The following table compares the basic capabilities of TOR, TOLFDIF, and

TOLMONTE.

142 CODE V Introductory User’s Guide

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Search

Supported

Tolerancing Supported

Algorithm Performance Comments

Method Tolerances

Metric

TOR Wavefront RMS Wavefront CODE V- Fast and accurate for

Differentials Error supported small tolerances.

tolerances Includes cross-terms.

Diffraction MTF (e.g., DLR,

DLT, etc.)

Fiber Coupling

Efficiency

Polarization

Dependent Loss

TOLFDIF Finite Any that CODE V CODE V- Reasonably fast, but

Macro Differences can compute supported does not include

tolerances & cross-terms. May not

user-defined be as accurate for

tolerances some performance

metrics

TOLMONTE Monte Carlo Any that CODE V CODE V- Accurate if many

Macro Simulation can compute supported trials are run, but slow

tolerances & (can be > 100x slower

user-defined than TOR)

tolerances

CODE V Introductory User’s Guide 143

Chapter 5 Resist Murphy’s Law: Tolerancing

Menu

Search

144 CODE V Introductory User’s Guide

You might also like

- Volume Holographic Gratings (VHG) in ZemaxDocument39 pagesVolume Holographic Gratings (VHG) in ZemaxLeandro Bertoluzzi100% (2)

- Lecture4 - Tolerancing in ZemaxDocument14 pagesLecture4 - Tolerancing in ZemaxĐại NguNo ratings yet

- CODEV Ch5Document42 pagesCODEV Ch5Sadegh SobhiNo ratings yet

- CODEV Ch5Document42 pagesCODEV Ch5Sadegh SobhiNo ratings yet

- Biology 1 For Ocr (Cambridge Ocr Advanced Science) (PDFDrive)Document281 pagesBiology 1 For Ocr (Cambridge Ocr Advanced Science) (PDFDrive)Marinaldo100% (1)

- Stop Shift TheoryDocument75 pagesStop Shift TheoryPaulinaNo ratings yet

- CODEV Chapter10Document20 pagesCODEV Chapter10Sadegh SobhiNo ratings yet

- CODEV Ch9Document20 pagesCODEV Ch9Sadegh SobhiNo ratings yet

- CODEV Ch3Document26 pagesCODEV Ch3Sadegh SobhiNo ratings yet

- CODEV Ch8Document26 pagesCODEV Ch8Sadegh SobhiNo ratings yet

- CODEV Ch2Document16 pagesCODEV Ch2Sadegh SobhiNo ratings yet

- CODEV Ch7Document12 pagesCODEV Ch7Sadegh SobhiNo ratings yet

- CODEV Ch4Document34 pagesCODEV Ch4Sadegh SobhiNo ratings yet

- ﺰﻨﻟ ﯽﺣاﺮﻃ Tessar راﺰﻓا مﺮﻧ زا هدﺎﻔﺘﺳا ﺎﺑ ZemaxDocument33 pagesﺰﻨﻟ ﯽﺣاﺮﻃ Tessar راﺰﻓا مﺮﻧ زا هدﺎﻔﺘﺳا ﺎﺑ ZemaxPouyan NasrNo ratings yet

- 521.tutorial - Zemax Tolerancing - HaynesDocument10 pages521.tutorial - Zemax Tolerancing - Haynesodane3113No ratings yet

- Syllabus For Optical Engg.Document16 pagesSyllabus For Optical Engg.ersumitkmrNo ratings yet

- Designing A Double-Gauss Lens, The Hard Way: David Shafer David Shafer Optical Design Fairfield, CT, 06824 #203-259-1431Document22 pagesDesigning A Double-Gauss Lens, The Hard Way: David Shafer David Shafer Optical Design Fairfield, CT, 06824 #203-259-1431resuscitatNo ratings yet

- Design of A 10x, 0.25 N.A., Microscope ObjectiveDocument20 pagesDesign of A 10x, 0.25 N.A., Microscope ObjectiveaqsaehsanNo ratings yet

- Tolerance On Material Inhomogenity and Surface Irregularity - Wen RuiDocument14 pagesTolerance On Material Inhomogenity and Surface Irregularity - Wen RuiKrishna ReddyNo ratings yet

- Zoom LensDocument19 pagesZoom Lenssathis_nskNo ratings yet

- CodeV-Optical DesignDocument8 pagesCodeV-Optical DesignChang MingNo ratings yet

- 2009 Class Summary Essay - Vineeth AbrahamDocument40 pages2009 Class Summary Essay - Vineeth AbrahamRachel OnealNo ratings yet

- Analytical Study and Optical Design of Offner Based Hyperspectral Imager in Vnir RegionDocument69 pagesAnalytical Study and Optical Design of Offner Based Hyperspectral Imager in Vnir RegionTanushrii Ramesh100% (1)

- DLP System OpticsDocument26 pagesDLP System OpticsAnonymous kg7YBMFHNo ratings yet

- BOOK (SPIE) - Field Guide To Optomechanical Design and AnalysisDocument161 pagesBOOK (SPIE) - Field Guide To Optomechanical Design and Analysisjiawei liuNo ratings yet

- Ug Zemax Manual 2006Document698 pagesUg Zemax Manual 2006ivbakalskiNo ratings yet

- Taylor-Hobson Alignment Telescope Specs PDFDocument16 pagesTaylor-Hobson Alignment Telescope Specs PDFenticoNo ratings yet

- CODEV Ch1Document10 pagesCODEV Ch1Sadegh SobhiNo ratings yet

- ANSI-IESNA LM-63-02 - Standard File Format For The Electronic Transfer of Photometric Data PDFDocument17 pagesANSI-IESNA LM-63-02 - Standard File Format For The Electronic Transfer of Photometric Data PDFHarry RamirezNo ratings yet

- Optical Designs For Fundus Imaging: From Traditional DesktopDocument93 pagesOptical Designs For Fundus Imaging: From Traditional DesktopMauricio Rodriguez50% (2)

- Barlow LensDocument5 pagesBarlow Lenslm2kNo ratings yet

- Aspheric Lens Design PDFDocument1 pageAspheric Lens Design PDFAnonymous HGOomkn69No ratings yet

- Aspheric Lenses Design PDFDocument9 pagesAspheric Lenses Design PDFTuan Do100% (1)

- Simulation of Wave Front Propagation With ZEMAX: Sara Casalbuoni and Rasmus Ischebeck DesyDocument48 pagesSimulation of Wave Front Propagation With ZEMAX: Sara Casalbuoni and Rasmus Ischebeck DesyZeynep Nilüfer Güven ÖztürkNo ratings yet

- The Iris DiaphragmDocument8 pagesThe Iris DiaphragmRandy WigginsNo ratings yet

- CODE V Optical Design Software: Design, Optimize and Fabricate Reliable Imaging OpticsDocument8 pagesCODE V Optical Design Software: Design, Optimize and Fabricate Reliable Imaging OpticsDeaw EggTofuNo ratings yet

- Is Iso 18369 1 2006Document57 pagesIs Iso 18369 1 2006Joresp Espinoza100% (1)

- 09 Principles of OpticsDocument7 pages09 Principles of OpticsedNo ratings yet

- How To Measure MTFDocument64 pagesHow To Measure MTFamtcorporationNo ratings yet

- Canon Eos 70dDocument2 pagesCanon Eos 70dSandro Campagnoli0% (1)

- Zeiss About Lens DistortionDocument28 pagesZeiss About Lens DistortionAdrian StannardNo ratings yet

- Dental Lab 3D Scanners - How They Work and What Works Best PDFDocument5 pagesDental Lab 3D Scanners - How They Work and What Works Best PDFKalimuthu PsNo ratings yet

- Lecture3 OptimisationDocument23 pagesLecture3 OptimisationlowteckweeNo ratings yet

- Optics of LithographyDocument143 pagesOptics of LithographyChang MingNo ratings yet

- Ze Max ManualDocument657 pagesZe Max ManualMaricela DelgadilloNo ratings yet

- ODZ - Optical Design With Zemax 6 Advanced HandlingDocument21 pagesODZ - Optical Design With Zemax 6 Advanced Handlingfitzgerald1633100% (1)

- ZeMax ManualDocument766 pagesZeMax Manualかざま よしひろNo ratings yet

- Optical Aberrations in Head-Up Displays - DiazDocument98 pagesOptical Aberrations in Head-Up Displays - DiazElke AnderssonNo ratings yet

- Laser Beam ShapingDocument6 pagesLaser Beam ShapingPatrick Gretzki100% (1)

- (Optical Sciences and Applications of Light) Sun, Haiyin - Lens Design - A Practical guide-CRC Press (2017)Document374 pages(Optical Sciences and Applications of Light) Sun, Haiyin - Lens Design - A Practical guide-CRC Press (2017)Vivian Amos100% (2)

- Zemax Tutorial V03Document15 pagesZemax Tutorial V03vlavanyakumarNo ratings yet

- IAT14 - Imaging and Aberration Theory Lecture 1 Paraxial OpticsDocument40 pagesIAT14 - Imaging and Aberration Theory Lecture 1 Paraxial OpticsShiva MohammadzadehNo ratings yet

- The Importance of Induced Aberrations in The Correction of Secondary ColorDocument11 pagesThe Importance of Induced Aberrations in The Correction of Secondary ColorDannyNo ratings yet

- ME5286 Lecture1 2017Document79 pagesME5286 Lecture1 2017Workneh AlamrieNo ratings yet

- Iris Valves Pharma Design: FluidtecqDocument2 pagesIris Valves Pharma Design: FluidtecqmehtahemalNo ratings yet

- Polarized Light Microscopy Principles and Practice PDFDocument15 pagesPolarized Light Microscopy Principles and Practice PDFIgor GabrielNo ratings yet

- LightTools Illumination Design Software. Design, Analyze, Optimize and Deliver Illumination OpticsDocument8 pagesLightTools Illumination Design Software. Design, Analyze, Optimize and Deliver Illumination OpticsVinsmoke SanjiNo ratings yet

- 01 (производство) Schwiegerling, Jim - Optical specification, fabrication, and testing-SPIE Press (2014)Document218 pages01 (производство) Schwiegerling, Jim - Optical specification, fabrication, and testing-SPIE Press (2014)lauraNo ratings yet

- Diffractive Optics From Holo /or: Services & CapabilitiesDocument4 pagesDiffractive Optics From Holo /or: Services & Capabilitiesasdfasdfsharklasers100% (1)

- OLYMPUS Stream Software PDFDocument20 pagesOLYMPUS Stream Software PDFFALRepresentaionesNo ratings yet

- First Optical Validation of A Schwarzschild Couder Telescope: The ASTRI SST-2M Cherenkov TelescopeDocument6 pagesFirst Optical Validation of A Schwarzschild Couder Telescope: The ASTRI SST-2M Cherenkov TelescopeegiroNo ratings yet

- Optical Design TolerancingDocument10 pagesOptical Design TolerancingMichal SlavNo ratings yet

- CODEV Chapter10Document20 pagesCODEV Chapter10Sadegh SobhiNo ratings yet

- CODEV Ch9Document20 pagesCODEV Ch9Sadegh SobhiNo ratings yet

- CODEV Ch8Document26 pagesCODEV Ch8Sadegh SobhiNo ratings yet

- CODEV Ch7Document12 pagesCODEV Ch7Sadegh SobhiNo ratings yet

- CODEV Ch4Document34 pagesCODEV Ch4Sadegh SobhiNo ratings yet

- CODEV Ch3Document26 pagesCODEV Ch3Sadegh SobhiNo ratings yet

- CODEV Ch2Document16 pagesCODEV Ch2Sadegh SobhiNo ratings yet

- CODEV Ch1Document10 pagesCODEV Ch1Sadegh SobhiNo ratings yet

- Test PartDocument1 pageTest PartSadegh SobhiNo ratings yet

- SteelDocument2 pagesSteelSadegh SobhiNo ratings yet

- Enhancing Students' Creativity Through STEM Project-Based LearningDocument8 pagesEnhancing Students' Creativity Through STEM Project-Based Learningahmad habibNo ratings yet

- Light - Reflection and Refraction - 2022-23 PYQDocument9 pagesLight - Reflection and Refraction - 2022-23 PYQnithishwarann097No ratings yet

- Science-7-Week-2 20Document20 pagesScience-7-Week-2 20Tricia BrunoNo ratings yet

- XI Physics Hand Book-2Document14 pagesXI Physics Hand Book-2amarbhagat7937No ratings yet

- Bacteriology Lab 3 - MicrosDocument2 pagesBacteriology Lab 3 - MicrosJiro Anderson EscañaNo ratings yet

- F71-F90 Dial IndicatorApplication PDFDocument20 pagesF71-F90 Dial IndicatorApplication PDFKiranNo ratings yet

- Light Reflection and Refraction Avanti inDocument4 pagesLight Reflection and Refraction Avanti inS Banerjee100% (1)

- Geometrical OpticsDocument20 pagesGeometrical OpticsPRIYAA A/P JAYASANKAR / UPMNo ratings yet

- With Air.: Set 63 - Page 1 Compiled by Mr. Lelon 012-6556593Document11 pagesWith Air.: Set 63 - Page 1 Compiled by Mr. Lelon 012-6556593lelon81No ratings yet

- 2 Reflection and RefractionDocument45 pages2 Reflection and RefractionAllyza Solomon100% (3)

- Cae ExercisesDocument17 pagesCae ExercisesGabrielaAndreeaNo ratings yet

- VERY FINAL Wave and Optics SyllabusDocument11 pagesVERY FINAL Wave and Optics SyllabusLyka AldayaNo ratings yet

- CSEC Physics - Definitions and FormulaeDocument39 pagesCSEC Physics - Definitions and FormulaeA.Benson100% (1)

- Uv U+v: Focal Length of Convex Lens AimDocument10 pagesUv U+v: Focal Length of Convex Lens AimMoghanNo ratings yet

- Reflection From Curved Surface (DB Sir) 29-11-19Document13 pagesReflection From Curved Surface (DB Sir) 29-11-19RishiNo ratings yet

- Created by C. Mani, Principal, K V No.1, AFS, Jalahalli West, BangaloreDocument19 pagesCreated by C. Mani, Principal, K V No.1, AFS, Jalahalli West, BangaloreNirmala Devi100% (1)

- Cbse Class 10th ScienceDocument5 pagesCbse Class 10th ScienceTHUGS of INDIANo ratings yet

- 649ebc263047c40018b894d1 - ## - Test Planner Yakeen NEET 3.0 2024Document2 pages649ebc263047c40018b894d1 - ## - Test Planner Yakeen NEET 3.0 2024suhaibkhan82797No ratings yet

- Instruction Manual: Fundus CameraDocument37 pagesInstruction Manual: Fundus Camerashakil ahmadNo ratings yet

- Full Download Test Bank For General Organic and Biological Chemistry 2nd Edition Frost PDF Full ChapterDocument36 pagesFull Download Test Bank For General Organic and Biological Chemistry 2nd Edition Frost PDF Full Chapterhastilyslockingdott0o100% (18)

- ItemsDocument125 pagesItemsAlejandro M AguirreNo ratings yet

- Geometric Physical OpticsDocument122 pagesGeometric Physical OpticsĐạt VũNo ratings yet

- TP Problem Set 1 - KeyDocument13 pagesTP Problem Set 1 - KeyJesebelle AlbanoNo ratings yet

- Problem SolvingDocument13 pagesProblem SolvingKarlyn RamosNo ratings yet

- Imbert Et Al AWPL Early Access 06924735Document4 pagesImbert Et Al AWPL Early Access 06924735Rui Vaz AlmeidaNo ratings yet

- To Study Reflection in Concave Mirror - Physics Astronomy Project TopicsDocument4 pagesTo Study Reflection in Concave Mirror - Physics Astronomy Project TopicsramNo ratings yet

- Reflections From A Plane Mirror: PurposeDocument60 pagesReflections From A Plane Mirror: PurposeMarilyn Castro LaquindanumNo ratings yet

- BSC O15Document716 pagesBSC O15jonnaNo ratings yet

- Dr. Mamta Dept of Ophthalmology RNT Medical College, UdaipurDocument56 pagesDr. Mamta Dept of Ophthalmology RNT Medical College, UdaipurGideon IrwandaNo ratings yet