Professional Documents

Culture Documents

Reversible Aqueous Zinc/manganese Oxide Energy Storage From Conversion Reactions

Reversible Aqueous Zinc/manganese Oxide Energy Storage From Conversion Reactions

Uploaded by

ShofiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reversible Aqueous Zinc/manganese Oxide Energy Storage From Conversion Reactions

Reversible Aqueous Zinc/manganese Oxide Energy Storage From Conversion Reactions

Uploaded by

ShofiCopyright:

Available Formats

ARTICLES

PUBLISHED: 18 APRIL 2016 | ARTICLE NUMBER: 16039 | DOI: 10.1038/NENERGY.2016.39

Reversible aqueous zinc/manganese oxide energy

storage from conversion reactions

Huilin Pan1, Yuyan Shao1*, Pengfei Yan2, Yingwen Cheng1, Kee Sung Han2, Zimin Nie1,

Chongmin Wang2, Jihui Yang3, Xiaolin Li1, Priyanka Bhattacharya1, Karl T. Mueller4,5 and Jun Liu1*

Rechargeable aqueous batteries such as alkaline zinc/manganese oxide batteries are highly desirable for large-scale energy

storage owing to their low cost and high safety; however, cycling stability is a major issue for their applications. Here we

demonstrate a highly reversible zinc/manganese oxide system in which optimal mild aqueous ZnSO4 -based solution is used

as the electrolyte, and nanofibres of a manganese oxide phase, α-MnO2 , are used as the cathode. We show that a chemical

conversion reaction mechanism between α-MnO2 and H+ is mainly responsible for the good performance of the system. This

includes an operating voltage of 1.44 V, a capacity of 285 mAh g−1 (MnO2 ), and capacity retention of 92% over 5,000 cycles.

The Zn metal anode also shows high stability. This finding opens new opportunities for the development of low-cost, high-

performance rechargeable aqueous batteries.

E

nergy storage is critical for renewable integration and two-phase reactions have been claimed, for example, spinel

electrification of the energy infrastructure1–8 . Many types ZnMn2 O4 22,25,28 , tunnel-type Znx Mn2 O4 24 , layered birnessite26 ,

of rechargeable battery technologies are being developed. layered Zn-buserite, and/or their complex composite24,29 . Also,

Examples include traditional lead-acid batteries based on Mn K-edge X-ray absorption spectra of Zn/MnO2 show evidence

conversion reactions and Li-ion batteries based on intercalation. only for the redox reaction of Mn during charge/discharge24,26,27 .

Although today’s Li-ion batteries have high energy density, it is still However, the reaction mechanism involved remains a topic

expensive to scale up. On the other hand, lead-acid batteries are of discussion.

low-cost aqueous systems and much easier to scale up for stationary Herein, we demonstrate a highly reversible conversion reaction

applications. Nevertheless, the use of lead causes significant in aqueous Zn/MnO2 systems using α-MnO2 nanofibres as the

environmental concerns besides the low energy density and limited cathode. High capacity and high reversibility can be achieved over

life span, even though lead-acid batteries still account for more than 5,000 cycles, with a capacity retention of 92%. The morphological

half of the global battery market. An alternative, low-cost aqueous and structural evolution of a MnO2 nanofibre cathode were

energy storage system is highly desirable9–11 . carefully investigated during electrochemical reactions by means

So far, a variety of aqueous batteries using alkaline cations, of transmission electron microscopy (TEM), scanning TEM/energy

for example, Li+ , Na+ , K+ , Mg2+ and/or mixed metal ions, as dispersive spectroscopy (STEM–EDS) mapping coupled with X-ray

charge carriers have been reported in the literature12–16 . Recently, diffraction (XRD) methods, and nuclear magnetic resonance

a new concept—aqueous Zn ion batteries—has been studied using (NMR) spectroscopy to reveal the conversion reaction processes.

a high-capacity Zn metal anode (819 mAh g−1 ), whereas most The Zn anode has also been examined carefully. This study provides

previous studies focused on Zn ion intercalation mechanisms and insights necessary to address the challenges faced in the practical use

showed limited long-cycle stability17 . A family of Prussian blue of the Zn/MnO2 system for energy storage.

analogues has lately been reported as zinc intercalation cathodes

in Zn ion batteries. However, these cathodes deliver limited Electrochemical performance of Zn/MnO2 batteries

capacities (around 50 mAh g−1 ) and suffer O2 evolution due to α-MnO2 nanofibres were synthesized with a hydrothermal method

the high operating voltage (about 1.7 V versus Zn)18,19 . Recently, and used as the cathode in a Zn/MnO2 battery chemistry study.

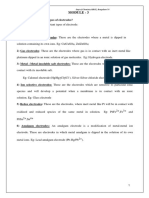

alkaline Zn/MnO2 batteries have been shown to be rechargeable for The XRD pattern in Fig. 1a shows the crystalline phase of α-MnO2

extended cycles using a shallow cycling protocol (typically no more (JCPDS: 44-0141). The TEM image in Fig. 1b shows a homogeneous

than 0.2–0.5 e− per 1 mol MnO2 )20,21 . Meanwhile, fully cycled (1 e− one-dimensional (1D) nanofibre structure of α-MnO2 . The length

per 1 mol MnO2 ) rechargeable Zn/MnO2 cells have been studied of α-MnO2 nanofibre extends to a few micrometres, with a

using α-, γ-phase, or amorphous MnO2 as the cathode in mild diameter of about 50 nm. The inset in Fig. 1b shows high-resolution

aqueous electrolytes22–24 . The MnO2 cathode suffers significant transmission electron microscopy (HRTEM) images, capable of

capacity fading during roughly the initial 20 cycles25–27 . These resolving the lattice, of 1D α-MnO2 nanofibres with a lattice distance

studies also focus on Zn2+ ion intercalation in the MnO2 framework of 0.345 nm for the (220) crystal plane. This indicates that the as-

as the main charge storage mechanism. Several types of intercalation prepared α-MnO2 is highly crystalline, with the [220] axis as the

products through two-phase or a series of complex single- and preferred orientation for 1D fibres30 .

1

Energy & Environment Directorate, Pacific Northwest National Laboratory, Richland, Washington 99352, USA. 2 Environmental Molecular Sciences

Laboratory, Pacific Northwest National Laboratory, Richland, Washington 99352, USA. 3 Department of Materials Science & Engineering, University of

Washington, Seattle, Washington 98195, USA. 4 Physical and Computational Sciences Directorate, Pacific Northwest National Laboratory, Richland,

Washington 99352, USA. 5 Department of Chemistry, Pennsylvania State University, University Park, Pennsylvania 16802, USA.

*e-mail: yuyan.shao@pnnl.gov; jun.liu@pnnl.gov

NATURE ENERGY | VOL 1 | MAY 2016 | www.nature.com/natureenergy 1

© 2016 Macmillan Publishers Limited. All rights reserved

ARTICLES NATURE ENERGY DOI: 10.1038/NENERGY.2016.39

a b

(220)

0.345 nm

10 20 30 40 50 60 70 80

2θ (°) 500 nm

Figure 1 | Structural and morphological characterization of MnO2 . a,b, X-ray diffraction data (a) and TEM image (b) for α-MnO2 nanofibres. The inset of b

shows lattice fringes along the (220) planes.

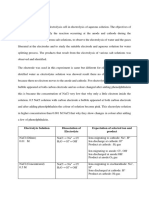

b 270 270

a

Capacity (mAh g−1)

180 180

1.75

90 90

0 10 20 30

Voltage (V) versus Zn

1.50 0

300 mV 0 100 200 300 400

Cycles

c

60 120

Equivalent capacity

1.25

Zn/Mn mole ratio

loss (mAh g−1)

100

45

First 80

1.00 Second

0 70 140 210 280 30 60

0 5 10 15 20 25

Capacity (mAh g−1)

Cycles

Figure 2 | Electrochemical behaviours of Zn/MnO2 batteries with 2 M ZnSO4 as electrolyte. a,b, Charge/discharge curves of a Zn/MnO2 battery in the

initial two cycles (a) and cycling performance at C/5 (b) of the cell with 2 M ZnSO4 electrolyte (1C = 308 mAh g−1 , capacity is based on the mass of

MnO2 ). The inset in b is an enlargement of the cyclic data during the initial cycles. c, Elemental analysis of dissolved Mn2+ ions in the aqueous electrolyte

during cycling (the red and blue dot lines correspond to the mole ratio between Zn2+ and Mn2+ ions in the electrolyte and the equivalent capacity loss on

cycling, respectively).

In contrast to the conventional primary alkaline MnO2 battery31 , the Mn concentration (measured by the inductively coupled plasma

a mild aqueous ZnSO4 electrolyte was used for the rechargeable (ICP) technique) in the electrolyte solution (Fig. 2c). However, the

Zn/MnO2 battery in this work. Figure 2a shows that α-MnO2 increase in content of dissolved Mn2+ ions slows down after the

nanofibre exhibits an average operating voltage of about 1.44 V initial ten cycles (Fig. 2c). This is probably because the Mn2+ ions

versus Zn and reversible capacities of 210 and 255 mAh g− 1

MnO2

at C/5 gradually dissolved in the electrolyte change the equilibrium of Mn

in the initial two cycles, respectively—higher than the previously dissolution from the MnO2 electrode, and thus suppress significant

reported values22,26 . It is interesting that the Zn/MnO2 battery shows continuous Mn2+ dissolution. This process is consistent with the

rather different charge/discharge curves for the initial two cycles, reduced trend in capacity fading in the following cycles (Fig. 2b).

and a nontrivial overpotential of about 300 mV (C/5) in the initial Finally, a probable self-stabilization in capacity was observed over

cycle, which are rarely seen in intercalation electrode materials32 — hundreds of cycles as a result of the natural dissolution of MnO2 ,

this will be discussed in depth later (note: there is still a overpotential but this takes extended cycling and suffers a significant capacity

gap of about 200 mV even at C/100). The total overpotential is taken loss (Fig. 2b).

roughly as the voltage difference between charge and discharge On the basis of the above observation, we pre-added Mn2+

at the midpoint of the voltage profiles (Supplementary Fig. 1). ions into the electrolyte to change the dissolution equilibrium

Although a high reversible capacity can be delivered in the first of Mn2+ from the MnO2 electrodes, and thus stabilize the

two cycles, a rapid deterioration in capacity was observed for the electrodes themselves. Figure 3a shows cyclic voltammetry (CV)

Zn/MnO2 battery upon cycling (Fig. 2b). We ascribed this capacity curves of Zn/MnO2 batteries in electrolytes, with and without

fading to the dissolution of Mn2+ from Mn3+ disproportionation into MnSO4 , revealing a similar redox behaviour that indicates the

the electrolyte during cycling. This is confirmed by an analysis of MnSO4 additive did not affect the redox reactions in the MnO2

2 NATURE ENERGY | VOL 1 | MAY 2016 | www.nature.com/natureenergy

© 2016 Macmillan Publishers Limited. All rights reserved

NATURE ENERGY DOI: 10.1038/NENERGY.2016.39 ARTICLES

a 800 b 320

No additive C/3

With MnSO4 additive 1C

240

400

Capacity (mAh g−1)

Current (µA)

160 No additive

0.1 M MnSO4 additive

0

80

−400

0

1.00 1.25 1.50 1.75 2.00 0 15 30 45 60

Voltage (V) versus Zn Cycles

c d

100

1.8

100

Coulombic efficiency (%)

Capacity retention (%)

Voltage (V) versus Zn

1.6 5C 92% 75

75

1.4

50

50

1.2

25 25

1.0

10C 5C 2C 1C

0 0

0 70 140 210 280 0 1,000 2,000 3,000 4,000 5,000

Capacity (mAh g−1) Cycles

Figure 3 | Improved electrochemical performance of Zn/MnO2 batteries in optimal aqueous electrolyte. a,b, Comparison of CV scanning (0.1 mV s−1 ,

second cycle) (a) and the cycling performance (b) of MnO2 electrodes with and without 0.1 M MnSO4 additive in a 2 M ZnSO4 aqueous electrolyte at C/3

and 1C, respectively. c,d, Rate performance (c) and the long-term cyclic performance (d) of a Zn/MnO2 battery using an electrolyte with a MnSO4 additive.

electrodes. The two pairs of redox peaks are consistent with the Chemical conversion reaction

two plateaux in the charge/discharge curves shown in Fig. 2a. TEM was used to investigate the morphological and structural

However, with the MnSO4 additive in the electrolyte, the cycling evolution of α-MnO2 electrodes during charge/discharge

performance of the MnO2 electrode is significantly improved in Zn/MnO2 aqueous batteries. Figure 4a shows that the

(Fig. 3b). It is highly likely that pre-addition of 0.1 M Mn2+ α-MnO2 electrode underwent marked changes in morphology

will provide an appropriate equilibrium between Mn2+ dissolution when discharged to 1 V in the first cycle. Pristine well-defined

(from the electrode to the electrolyte, as shown in Fig. 1c) micrometre-long nanofibres were transformed to short nanorods

and the re-oxidation of Mn2+ in the electrolyte, leading to high and nanoparticle aggregates (marked by yellow and blue rectangles

stability of the electrode. Pre-addition of Mn2+ above or below respectively). HRTEM was used to characterize the structural

the equilibrium amount does not address the capacity fading change, as shown in Fig. 4b,c. Short nanorods predominantly

issue well (see detailed dissolution in Supplementary Discussion 1: exhibit a crystalline structure with a lattice distance of 0.33 nm and

Dissolution/oxidation of Mn2+ /MnO2 reactions). Adding MnSO4 to some disordered regions (Fig. 4b). The short nanorods are a newly

the electrolyte also greatly improves the utilization of MnO2 active formed discharge product different from the pristine α-MnO2 , as

material, delivering a higher capacity than that without MnSO4 . can be seen from the difference in the crystalline orientation (arrow

Decent capacities of 285 and 260 mAh g− 1

MnO2

were delivered for indicates the extension outline of the nanorod). In addition, the

cells at current rates of C/3 and 1C, respectively, higher than nanoparticle aggregates in the discharged state consist of ∼5 nm

previously reported values33 . Moreover, the Zn/MnO2 battery with particles with a uniform lattice distance of 0.26 nm, as characterized

the MnSO4 additive shows an excellent rate capability, achieving in Fig. 4c. It was previously reported that Zn2+ ions intercalate

−1

high capacities of 207, 161 and 113 mAh gMnO at 2C, 5C and 10C, 2

into α-MnO2 to form spinel ZnMn2 O4 , or a tunnel or layered

respectively (Fig. 3c). The high rate performance could be ascribed Znx MnO2 phase22,24,26 . However, our TEM results showed that the

to the stabilization and excellent kinetics of the MnO2 electrodes lattice fringes of 0.33 and 0.26 nm from the discharged products

and the Zn anodes (to be discussed below)34–36 . Furthermore, the do not match the reported intercalated phases in the literature.

Zn/MnO2 battery with the MnSO4 additive also exhibits excellent In fact, they are consistent with the d spaces from the (210) and

long-cycle stability, with a high-capacity retention of 92% after (020) planes in monoclinic MnOOH, as evidenced by the XRD

5,000 cycles at a rate of 5C (Fig. 3d). This indicates that a patterns of the MnOOH phase formed shown in Supplementary

Zn/MnO2 system using a mild aqueous electrolyte is very promising Fig. 2. The formation of MnOOH indicates a possible, alternative

for a high-performance, long-life, environmentally-friendly, cost- conversion reaction to Zn2+ ion intercalation into MnO2 . It is

effective energy storage solution. very likely that MnO2 reacts with a proton from water to form

NATURE ENERGY | VOL 1 | MAY 2016 | www.nature.com/natureenergy 3

© 2016 Macmillan Publishers Limited. All rights reserved

ARTICLES NATURE ENERGY DOI: 10.1038/NENERGY.2016.39

a b c d

0.26 nm

0.33 nm

Nanorod 0.26 nm STEM-HAADF

Nanoparticle 0.26 nm

aggregates

0.26 nm

Disordered

200 nm 5 nm zone 5 nm

Mn

e f g

Nanorod

0.34 nm

(220) α-MnO2 O

Nanoparticle

aggregates

100 nm 5 nm 5 nm

Zn

Figure 4 | TEM/HRTEM images of MnO2 electrodes during electrochemical process. a–c,e–g, MnO2 electrodes discharged to 1 V (a–c) and then charged

back to 1.8 V in the first cycle (e–g). The yellow and blue rectangular regions have a morphology typical for short nanorods and nanoparticle aggregates,

respectively. The arrows in b and f indicate the growth directions of the short nanorods. d, STEM-HAADF image of short nanorods and STEM–EDS

mappings of the elemental distributions of Mn, O and Zn in the MnO2 electrode in the discharged state during the first cycle. Electrolyte, 2 M ZnSO4

aqueous electrolyte with 0.1 M MnSO4 additive.

MnOOH (MnO2 + H+ + e− ↔MnOOH). Interestingly, whereas For the charged state, the short nanorods mainly retain their

the H+ ions react with MnO2 , the sequent OH− ions react with morphology, whereas both the lattice distance and crystallinity

ZnSO4 and H2 O in the aqueous electrolyte to form a large flake-like revert to those of the original α-MnO2 electrode, which implies

ZnSO4 [Zn(OH)2 ]3 · xH2 O and reach a neutral charge in the a reversible structure change (Fig. 4d,e). This is consistent with

system. This reaction product was not stable under the high-energy the reversible charge/discharge behaviours of Zn/MnO2 aqueous

electron beam of TEM, but is clearly confirmed in the strong batteries shown above. The nanoparticle aggregations also show

XRD signal (Supplementary Fig. 3a), which dominated the XRD a similar morphology after charging back as they do in the

patterns of other phases, for example, α-MnO2 , and MnOOH, as discharged state. At the same time, the consequent formation of

shown in Supplementary Fig. 2. This reaction was also supported ZnSO4 [Zn(OH)2 ]3 · xH2 O on the cathode side is also reversible

by the 1 H NMR study in Supplementary Fig. 4, which confirms and stable with the hydrogenation/dehydrogenation of the MnO2

the formation of ZnSO4 [Zn(OH)2 ]3 · xH2 O after discharge. The cathode (Supplementary Fig. 3a,d).

above conversion reaction is further confirmed by the STEM–EDS As discussed above, the structure/morphology of α-MnO2

mapping of the MnO2 electrode in the discharged state. Comparing evolves from original micrometre-long nanofibres to a well-mixed

the distribution of the elements Mn, O and Zn in Fig. 4d reveals that composite of short nanorods and nanoparticle aggregations after the

the short nanorods and nanoparticles consist of O and Mn, and no initial cycle, which stabilizes and enhances the structural mechanics

evidence of Zn (note: H atoms cannot be detected in STEM–EDS and kinetics of the electrodes by releasing strain and reducing

mapping). In contrast, Zn is mainly distributed on the flake-like the diffusion length for ions and electrons in the nanocomposite

solid, that is, ZnSO4 [Zn(OH)2 ]3 · xH2 O, as confirmed by the TEM structure, resulting in the excellent rate and cycling stability of

and STEM–EDS mapping in Supplementary Fig. 3b,c. Different the Zn/MnO2 aqueous batteries. In addition, the evolution of the

from previous reports of Zn interaction into MnO2 , both TEM morphology from the original α-MnO2 micro-nanofibres to short

and STEM–EDS mapping evidently confirm the above conversion nanorods and nanoparticle aggregations adds extra surface energy

reaction to form MnOOH. (The background of the Zn mapping to the Gibbs free energy of the α-MnO2 electrode after charging, in

results from associated side products during the formation of comparison to that of the original α-MnO2 fibres; this accounts for

MnOOH on the cathode.) The reaction mechanism of the active the voltage difference between first discharge and second discharge

conversion reaction between MnO2 and H+ is further confirmed as shown in Fig. 2a (see detailed explanation in Supplementary

by the fact that only very limited capacity (capacitor behaviour) Discussion). This phenomenon of a voltage difference in the first

can be delivered in organic Zn2+ -ion-based electrolytes owing to two cycles has also been observed and discussed in other conver-

the absence of H+ ions in organic electrolytes (note: the Zn anode sion reactions from metal oxides electrode materials in lithium-

functions well in an organic electrolyte, as seen from the reversible and sodium-ion batteries37–39 . Furthermore, such thermodynamic

stripping/plating of Zn in Supplementary Fig. 5a). After adding factors, for example, the volume and surface energy variations dur-

H2 O into organic Zn-based electrolytes, the Zn/α-MnO2 battery ing electrochemical processes in the present MnO2 cathode, also

exhibits a similar electrochemical behaviour to that in an aqueous account for the existence of a total overpotential of ∼200 mV in

electrolyte (Supplementary Fig. 5b). the MnO2 electrodes even at a zero-current density (Supplementary

4 NATURE ENERGY | VOL 1 | MAY 2016 | www.nature.com/natureenergy

© 2016 Macmillan Publishers Limited. All rights reserved

NATURE ENERGY DOI: 10.1038/NENERGY.2016.39 ARTICLES

a 40% KOH 2 M ZnSO4 + 0.1 M MnSO4 b

Zn in 40% KOH Zn in ZnSO4 Zn in ZnSO4

12 h 12 h 400+ h

2 Increase in

polarization

5 µm

Voltage (V)

0

0.06

0.24 mA cm−2 0.48 mA cm−2 0.72 mA cm−2 c 342 Zn

0.03 228

−1

Voltage (V)

±38 mV ±35 mV ±35 mV 114

0.00 Zn

O S

0

2 4 6 8 10

−0.03 Energy (keV)

−2

−0.06

0 40 80 120 160 200 240

Time (h)

−3

0 5 10 15 60 120 180 240 5 µm

Test time (h)

Figure 5 | Characterization of Zn anode electrodes. a, Zn stripping/plating from Zn/Zn symmetrical cells at 0.24 mA cm−2 in a 40 wt% alkaline

electrolyte and at 0.24–0.72 mA cm−2 in a mild 2 M ZnSO4 with 0.1 M MnSO4 aqueous electrolyte, respectively. The stripping/plating capacities of the Zn

electrodes (1.25 cm2 ) are 0.3, 0.6 and 0.9 mAh in each cycle. The inset of a shows optical images of cycled Zn anodes in alkaline and mild aqueous

electrolytes. b, SEM image of a pristine Zn anode. c, SEM image and EDX spectrum (inset) of a Zn anode after 120 cycles (240 h) in 2 M ZnSO4 with 0.1 M

MnSO4 aqueous electrolyte.

Fig. 6). This phenomenon is consistent with the significant voltage The reactions of the rechargeable aqueous Zn/MnO2 chemistry

hysteresis of Zn/MnO2 batteries—that is, ∼200 mV of voltage hys- can be formulated as below:

teresis even at C/100 (Supplementary Fig. 1)38 .

Cathode: H2 O ↔ H+ + OH−

MnO2 + H+ + e− ↔ MnOOH

Zn anode 1

Zn2+ + OH− + 16 ZnSO4 + x6 H2 O ↔

The Zn anode was also examined in an effort to understand the 2

high reversibility of the Zn/MnO2 cell chemistry. To a certain

1

6

ZnSO4 [Zn(OH2 )]3 · xH2 O

degree, the reaction of MnO2 + H+ + e− ↔MnOOH in the present Anode: 12 Zn ↔ 12 Zn2+ + e−

Zn/MnO2 battery is similar to that in a MnO2 cathode in a primary Overall: MnO2 + 12 Zn + x6 H2 O + 16 ZnSO4 ↔

alkaline MnO2 battery31 . However, the critical difference lies in the

MnOOH + 16 ZnSO4 [Zn(OH2 )]3 · xH2 O

reaction at the Zn anode side. Figure 5 shows a comparison of

the stability and reversibility of a Zn/Zn symmetric cell in alkaline Based on the total mass of cathode, anode and electrolyte

and mild aqueous electrolytes. In the alkaline electrolyte, there is involved in the above reactions, these reactions provide an energy

a sudden increase in polarization after 12 h for only six cycles of density of ∼170 Wh kg−1 (at C/3). The available energy density

Zn stripping and plating. We ascribe this to the formation of an of the Zn/MnO2 battery is about five times higher than existing

insulating ZnO powder layer to a critical thickness, as shown by commercial lead-acid batteries40 .

the XRD pattern in Supplementary Fig. 7, and a loose and powder- The combination of a highly reversible Zn anode and a MnO2

like of Zn plate surface after cycling in the alkaline electrolyte nanofibre cathode in a mild aqueous electrolyte (that is, 2 M ZnSO4

(inset in Fig. 5a), which results from the irreversible reaction of with 0.1 M MnSO4 in this research) presents a potentially high-

Zn + 2OH− →Zn(OH)2 + 2e− →ZnO + H2 O. In contrast, in capacity aqueous battery chemistry with high reversibility and

a mild 2 M ZnSO4 with 0.1 M MnSO4 aqueous electrolyte, the high cycling stability, that is both environmentally benign and

Zn/Zn symmetric cell shows the excellent kinetics and stability safe. For practical applications, the electrochemical reactions and

of Zn stripping/plating. After more than 120 cycles, the Zn plate stability need to be carefully evaluated. In particular, conversion

still exhibits a smooth, dense surface (inset of Fig. 5a). Figure 5b,c reactions involving both electrode materials and electrolytes are

shows a comparison of SEM images of Zn electrodes before and more complex than intercalation chemistry. The reactions between

after cycling. It can be seen that the Zn electrode exhibits a dense, the cathode, anodes and electrolytes need to be carefully controlled

dendrite-free surface morphology after 120 cycles (Fig. 5b,c). A and optimized. Although this could be a significant challenge, a

similar surface morphology for the Zn anode was also observed good understanding and clarification of the fundamental reactions

in a Zn/MnO2 full cell (Supplementary Fig. 9). This would be in the Zn/MnO2 system is an important step towards a more

very important for the long-term cycling stability of Zn/MnO2 practical system in the future.

batteries. The energy-dispersive X-ray (EDX) spectrum indicates

that the Zn deposition layer surface consists mainly of Zn metal, Conclusion

resulting from the highly reversible plating/stripping of Zn metal in We studied the reversibility of aqueous Zn/MnO2 battery chemistry.

mild electrolyte. The MnO2 nanofibre cathode is highly reversible and stable

NATURE ENERGY | VOL 1 | MAY 2016 | www.nature.com/natureenergy 5

© 2016 Macmillan Publishers Limited. All rights reserved

ARTICLES NATURE ENERGY DOI: 10.1038/NENERGY.2016.39

in a mild ZnSO4 aqueous electrolyte with a MnSO4 additive, 10. Luo, J.-Y., Cui, W.-J., He, P. & Xia, Y.-Y. Raising the cycling stability of aqueous

which suppresses Mn2+ dissolution into the electrolyte. This lithium-ion batteries by eliminating oxygen in the electrolyte. Nature Chem. 2,

Zn/MnO2 cell also exhibits an excellent rate capability and a 760–765 (2010).

11. Lu, Y., Goodenough, J. B. & Kim, Y. Aqueous cathode for next-generation

high-capacity retention of 92% after 5,000 cycles. The structural alkali-ion batteries. J. Am. Chem. Soc. 133, 5756–5759 (2011).

and morphological evolution of α-MnO2 electrodes have been 12. Köhler, J., Makihara, H., Uegaito, H., Inoue, H. & Toki, M. LiV3 O8 :

comprehensively investigated by TEM and STEM–EDS mapping, characterization as anode material for an aqueous rechargeable Li-ion battery

which explains the electrochemical behaviour and reveals an system. Electrochim. Acta 46, 59–65 (2000).

alternative conversion reaction mechanism between MnOOH and 13. Luo, J. Y. & Xia, Y. Y. Aqueous lithium-ion battery LiTi2 (PO4 )3 /LiMn2 O4 with

MnO2 other than Zn2+ ion intercalation into MnO2 . The high high power and energy densities as well as superior cycling stability. Adv. Funct.

Mater. 17, 3877–3884 (2007).

reversibility of the Zn anode was also demonstrated in a mild ZnSO4 14. Wessells, C. D., Huggins, R. A. & Cui, Y. Copper hexacyanoferrate

aqueous electrolyte. The combination of the reversible Zn anode and battery electrodes with long cycle life and high power. Nature Commun.

the MnO2 cathode could lead to a promising battery chemistry that 2, 550 (2011).

is potentially highly reversible, highly stable and safe. 15. Pasta, M., Wessells, C. D., Huggins, R. A. & Cui, Y. A high-rate and long cycle

life aqueous electrolyte battery for grid-scale energy storage. Nature Commun.

3, 1149 (2012).

Methods 16. Chen, L., Zhang, L., Zhou, X. & Liu, Z. Aqueous batteries based on mixed

Material synthesis. In a typical synthesis of α-MnO2 , 0.003 M MnSO4 · H2 O and

monovalence metal ions: a new battery family. ChemSusChem

2 ml 0.5 M H2 SO4 were added to 90 ml deionized water and magnetically stirred

7, 2295–2302 (2014).

until a clear solution was obtained. Then, 20 ml 0.1 M KMnO4 aqueous solution

17. Lee, J.-S. et al. Metal–air batteries with high energy density: Li–air versus

was slowly added into the above solution. The mixture was stirred at room

Zn–air. Adv. Energy Mater. 1, 34–50 (2011).

temperature for 2 h. The solution was then transferred to a Teflon-lined autoclave

18. Zhang, L., Chen, L., Zhou, X. & Liu, Z. Towards high-voltage aqueous

and heated at 120 ◦ C for 12 h. After cooling, the obtained material was collected

metal-ion batteries beyond 1.5 V: the zinc/zinc hexacyanoferrate system. Adv.

by centrifugation, washed three times with water, and dried using a vacuum oven

Energy Mater. http://dx.doi.org/10.1002/aenm.201400930 (2015).

at room temperature.

19. Trócoli, R. & La Mantia, F. An aqueous zinc-ion battery based on copper

hexacyanoferrate. ChemSusChem 8, 481–485 (2015).

Characterizations. X-ray diffraction (XRD) measurements were performed using

20. Mondoloni, C., Laborde, M., Rioux, J., Andoni, E. & Lévy-Clément, C.

a Rigaku Miniflex II diffractometer with Cu Kα radiation (λ = 1.5406 Å). An FEI

Rechargeable alkaline manganese dioxide batteries: I. In situ X-ray diffraction

Titan 80–300 microscope equipped with an objective lens corrector at 300 kV was

investigation of the (EMD-type) insertion system. J. Electrochem. Soc. 139,

employed for the TEM images. Scanning/TEM and EDS mapping were

954–959 (1992).

performed on a JEOL ARM200CF microscope at 200 kV, which is equipped with

21. Hertzberg, B., Sviridov, L., Stach, E. A., Gupta, T. & Steingart, D.

a probe corrector and high-efficiency silicon drift EDS detector with a 100 mm2

A manganese-doped barium carbonate cathode for alkaline batteries.

X-ray sensor. 1 H Nuclear magnetic resonance (NMR) analyses were conducted

J. Electrochem. Soc. 161, A835–A840 (2014).

using a 1.6 mm HX probe using single-pulse excitation on a 600 MHz NMR

22. Xu, C., Li, B., Du, H. & Kang, F. Energetic zinc ion chemistry: the rechargeable

spectrometer (Agilent) under magic angle spinning at 35 kHz.

zinc ion battery. Angew. Chem. 124, 957–959 (2012).

23. Xu, C., Du, H., Li, B., Kang, F. & Zeng, Y. Reversible insertion properties of zinc

Electrochemical measurements. Using an electrochemical process, α-MnO2

ion into manganese dioxide and its application for energy storage. Electrochem.

electrodes were prepared by mixing α-MnO2 powder, carbon black and poly

Solid State Lett. 12, A61–A65 (2009).

vinylidene fluoride at a weight ratio of 7:2:1 in N -methyl pyrrolidone solvent,

24. Alfaruqi, M. H. et al. Electrochemically induced structural transformation in a

then coating the slurry onto carbon sheets. The α-MnO2 mass loading is

γ-MnO2 cathode of a high capacity zinc-ion battery system. Chem. Mater. 27,

1–5 mg cm−2 (Supplementary Fig. 8). Zn/MnO2 batteries were assembled using

3609–3620 (2015).

an α-MnO2 electrode as the cathode, glass fibre as the separator and Zn foil as

25. Xu, D. et al. Preparation and characterization of MnO2 /acid-treated CNT

the anode in CR2032 coin cells. The electrolyte used was 2 M ZnSO4

nanocomposites for energy storage with zinc ions. Electrochim. Acta 133,

with/without 0.1 M MnSO4 as an additive in H2 O. The conventional alkaline

254–261 (2014).

MnO2 batteries were assembled using a similar process, except for the use of

26. Lee, B. et al. Electrochemically-induced reversible transition from the tunneled

40 wt% KOH aqueous electrolyte. A symmetrical Zn/Zn cell was assembled using

to layered polymorphs of manganese dioxide. Sci. Rep. 4, 6066 (2014).

Zn foil as both working and counter electrodes, using 2 M ZnSO4 with 0.1 M

27. Alfaruqi, M. H. et al. Enhanced reversible divalent zinc storage in a structurally

MnSO4 as the electrolyte. 0.1 M ZnTf2 was dissolved into dimethyl sulfoxide

stable α-MnO2 nanorod electrode. J. Power Sources 288, 320–327 (2015).

(DMSO) as an organic Zn electrolyte. For the water-addition organic electrolyte,

28. Xu, C., Chiang, S. W., Ma, J. & Kang, F. Investigation on zinc ion storage in

5 M H2 O was added into the above electrolyte. The charge/discharge was carried

alpha manganese dioxide for zinc ion battery by electrochemical impedance

out on a LANHER battery tester (Wuhan).

spectrum. J. Electrochem. Soc. 160, A93–A97 (2013).

29. Lee, B. et al. Elucidating the intercalation mechanism of zinc ions into

Received 28 October 2015; accepted 4 March 2016; [α]-MnO2 for rechargeable zinc batteries. Chem. Commun.

published 18 April 2016 51, 9265–9268 (2015).

30. Hongen, W., Zhouguang, L., Dong, Q., Yujie, L. & Wei, Z. Single-crystal

α-MnO2 nanorods: synthesis and electrochemical properties. Nanotechnology

References 18, 115616 (2007).

1. Tarascon, J. M. & Armand, M. Issues and challenges facing rechargeable 31. Cheng, F. Y., Chen, J., Gou, X. L. & Shen, P. W. High-power alkaline Zn–MnO2

lithium batteries. Nature 414, 359–367 (2001). batteries using γ-MnO2 nanowires/nanotubes and electrolytic zinc powder.

2. Armand, M. & Tarascon, J. M. Building better batteries. Nature Adv. Mater. 17, 2753–2756 (2005).

451, 652–657 (2008). 32. Sun, J. et al. Overpotential and electrochemical impedance analysis on Cr2 O3

3. Liu, J. et al. Materials science and materials chemistry for large scale thin film and powder electrode in rechargeable lithium batteries. Solid State

electrochemical energy storage: from transportation to electrical grid. Adv. Ion. 179, 2390–2395 (2008).

Funct. Mater. 23, 929–946 (2013). 33. Alias, N. & Mohamad, A. A. Advances of aqueous rechargeable lithium-ion

4. Larcher, D. & Tarascon, J. M. Towards greener and more sustainable batteries battery: a review. J. Power Sources 274, 237–251 (2015).

for electrical energy storage. Nature Chem. 7, 19–29 (2015). 34. Hu, Y. S., Kienle, L., Guo, Y. G. & Maier, J. High lithium electroactivity of

5. Jiang, J. et al. Recent advances in metal oxide-based electrode architecture nanometer-sized rutile TiO2 . Adv. Mater. 18, 1421–1426 (2006).

design for electrochemical energy storage. Adv. Mater. 24, 5166–5180 (2012). 35. Chan, C. K. et al. High-performance lithium battery anodes using silicon

6. Qu, D. Studies of the activated carbons used in double-layer supercapacitors. nanowires. Nature Nanotech. 3, 31–35 (2008).

J. Power Sources 109, 403–411 (2002). 36. Lee, H.-W. et al. Ultrathin spinel LiMn2 O4 nanowires as high power cathode

7. Simon, P. & Gogotsi, Y. Materials for electrochemical capacitors. Nature Mater. materials for Li-ion batteries. Nano Lett. 10, 3852–3856 (2010).

7, 845–854 (2008). 37. Delmer, O., Balaya, P., Kienle, L. & Maier, J. Enhanced potential of

8. Zhai, Y. et al. Carbon materials for chemical capacitive energy storage. Adv. amorphous electrode materials: case study of RuO2 . Adv. Mater.

Mater. 23, 4828–4850 (2011). 20, 501–505 (2008).

9. Li, W., Dahn, J. R. & Wainwright, D. S. Rechargeable lithium batteries with 38. Zhong, K. et al. Investigation on porous MnO microsphere anode for lithium

aqueous electrolytes. Science 264, 1115–1118 (1994). ion batteries. J. Power Sources 196, 6802–6808 (2011).

6 NATURE ENERGY | VOL 1 | MAY 2016 | www.nature.com/natureenergy

© 2016 Macmillan Publishers Limited. All rights reserved

NATURE ENERGY DOI: 10.1038/NENERGY.2016.39 ARTICLES

39. Pan, H. et al. Sodium storage and transport properties in layered Na2 Ti3 O7 Author contributions

for room-temperature sodium-ion batteries. Adv. Energy Mater. Y.S. and J.L. proposed the research. H.P., Y.S. and J.L. designed the experiments. H.P. and

3, 1186–1194 (2013). Y.S. performed the material process, characterization, electrochemical measurements and

40. Divya, K. C. & Østergaard, J. Battery energy storage technology for power analysed the data. Y.C. synthesized the material. P.Y., Y.C. and C.W. conducted the TEM

systems—An overview. Electr. Power Syst. Res. 79, 511–520 (2009). and STEM mapping. K.S.H. and K.T.M. performed NMR characterization. H.P.,

Y.S. and J.L. co-wrote the paper. All authors discussed the results and commented on

the manuscript.

Acknowledgements

This work is supported by the US Department of Energy (DOE), Office of Basic Energy Additional information

Sciences, Division of Materials Sciences and Engineering, under Award Supplementary information is available online. Reprints and permissions information is

KC020105-FWP12152. The TEM, NMR and XRD work were performed using EMSL, a available online at www.nature.com/reprints. Correspondence and requests for materials

National Scientific User Facility sponsored by the Department of Energy’s Office of should be addressed to Y.S. or J.L.

Biological and Environmental Research and located at PNNL. PNNL is a Multi-Program

National Laboratory operated for DOE by Battelle. The work at UW was supported by Competing interests

Inamori Foundation. The authors declare no competing financial interests.

NATURE ENERGY | VOL 1 | MAY 2016 | www.nature.com/natureenergy 7

© 2016 Macmillan Publishers Limited. All rights reserved

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Australian Standard: Cathodic Protection of Metals Part 5: Steel in Concrete StructuresDocument73 pagesAustralian Standard: Cathodic Protection of Metals Part 5: Steel in Concrete StructuresSelim50% (2)

- Development of A Vanadium Redox Flow Battery For Energy StorageDocument91 pagesDevelopment of A Vanadium Redox Flow Battery For Energy StorageShofiNo ratings yet

- 7.1: Crystal Structure: CrystallographyDocument11 pages7.1: Crystal Structure: CrystallographyShofiNo ratings yet

- Accepted Manuscript Functional Materials LettersDocument6 pagesAccepted Manuscript Functional Materials LettersShofiNo ratings yet

- Materials Science & Engineering R: Jun Ming, Jing Guo, Chuan Xia, Wenxi Wang, Husam N. Alshareef TDocument27 pagesMaterials Science & Engineering R: Jun Ming, Jing Guo, Chuan Xia, Wenxi Wang, Husam N. Alshareef TShofiNo ratings yet

- Journal of Energy ChemistryDocument27 pagesJournal of Energy ChemistryShofiNo ratings yet

- Materials Chemistry For Rechargeable Zinc-Ion Batteries: Chemical Society Reviews June 2020Document18 pagesMaterials Chemistry For Rechargeable Zinc-Ion Batteries: Chemical Society Reviews June 2020ShofiNo ratings yet

- Binder-Free Α-Mno2 Nanowires On Carbon Cloth As Cathode Material For Zinc-Ion BatteriesDocument14 pagesBinder-Free Α-Mno2 Nanowires On Carbon Cloth As Cathode Material For Zinc-Ion BatteriesShofiNo ratings yet

- 6d Stainless 1Document23 pages6d Stainless 1ShofiNo ratings yet

- Physical ProposalDocument1 pagePhysical ProposalJasmine Kaur 2K21/MSCCHE/23No ratings yet

- Lecture 5 Cathodic Protection Engineering - Assessment of Pipeline Condition Through Surveys - Part-I - WatermarkDocument23 pagesLecture 5 Cathodic Protection Engineering - Assessment of Pipeline Condition Through Surveys - Part-I - WatermarkPradip Gajjar100% (1)

- Electrochemical Reduction of CO To Oxalic Acid: V.S. Boor Thesis Defense 09-04-2020Document36 pagesElectrochemical Reduction of CO To Oxalic Acid: V.S. Boor Thesis Defense 09-04-2020Marcela FragozoNo ratings yet

- Module-3-Electro Chem PDFDocument11 pagesModule-3-Electro Chem PDFRaghav V BhatNo ratings yet

- Flow Batteries: by Trung Nguyen and Robert F. SavinellDocument3 pagesFlow Batteries: by Trung Nguyen and Robert F. Savinell何家銘No ratings yet

- Electrochimica Acta: Thomas Jurak, Sina S. Jamali, Yue ZhaoDocument13 pagesElectrochimica Acta: Thomas Jurak, Sina S. Jamali, Yue ZhaoTiara San MartinNo ratings yet

- Electrochemistry Chy2018Document48 pagesElectrochemistry Chy2018DubistWhiteNo ratings yet

- Electrolysis Aqueous SolutionDocument40 pagesElectrolysis Aqueous SolutionVictor OkosunNo ratings yet

- Potentiostatic TestDocument1 pagePotentiostatic TestKamal Hameed Al-taiyNo ratings yet

- Discussion Exp 2 Chm674Document4 pagesDiscussion Exp 2 Chm674Eva Lizwina MatinNo ratings yet

- The Oxidation of Niobium in The Temperature Range 450 176Document6 pagesThe Oxidation of Niobium in The Temperature Range 450 176Ion AlbertoNo ratings yet

- September 2016Document104 pagesSeptember 2016Alexander Reategui GarciaNo ratings yet

- Structural Materials: Unit 3Document53 pagesStructural Materials: Unit 3Jayashree MisalNo ratings yet

- CoulometryDocument19 pagesCoulometrykusumNo ratings yet

- Galvanic Corrosion When Carbon and Steel Are Bonded Together.Document5 pagesGalvanic Corrosion When Carbon and Steel Are Bonded Together.chris_996No ratings yet

- Oxidation Reduction Past PaperDocument8 pagesOxidation Reduction Past Paperrainbow100% (1)

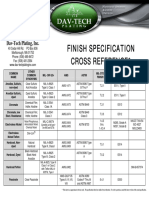

- Cross Reference Sheet PDFDocument1 pageCross Reference Sheet PDFSivaramSubramanianNo ratings yet

- X52 HidrogenDocument8 pagesX52 Hidrogenjhon ortizNo ratings yet

- An Investigation Into The Electrolyte Copper Sulphate Solution Was Carried Out As ShownDocument6 pagesAn Investigation Into The Electrolyte Copper Sulphate Solution Was Carried Out As ShownSiti AbidahNo ratings yet

- C Ch-11 ElectrochemistryDocument5 pagesC Ch-11 ElectrochemistryNo:1 Scamed idNo ratings yet

- Channel FUSDocument1 pageChannel FUSArunKumar RajendranNo ratings yet

- Chapter 1 - Introduction To CorrosionDocument36 pagesChapter 1 - Introduction To Corrosionmotasem100% (2)

- Chemistry - SPM Model Question Paper 3Document7 pagesChemistry - SPM Model Question Paper 3Law Jin YaoNo ratings yet

- JEE Main Adv Class XIII275941779Document33 pagesJEE Main Adv Class XIII275941779Shashin VyasNo ratings yet

- Gujarat State Eligibility Test: Subject: Chemical Sciences Code No.: 03 Gset SyllabusDocument3 pagesGujarat State Eligibility Test: Subject: Chemical Sciences Code No.: 03 Gset Syllabuschirag sabhayaNo ratings yet

- Computer Simulation As An Aid To Corrosion Control and ReductionDocument17 pagesComputer Simulation As An Aid To Corrosion Control and ReductionreddyNo ratings yet

- Measuring Lithium-Ion Polymer Cell Internal ResistanceDocument36 pagesMeasuring Lithium-Ion Polymer Cell Internal ResistanceBlackglassIXNo ratings yet

- Lesson-13 ElectrochemistryDocument41 pagesLesson-13 ElectrochemistryTeachingTrainingCoaching KnowledgeSharingSessionNo ratings yet

- Cyclic Voltammetry Lab ManualDocument3 pagesCyclic Voltammetry Lab ManualGourav DasNo ratings yet