Professional Documents

Culture Documents

Cairn-Tsg-L-Sp-0005-B2 Specification For Painting (Above Ground & Underground Piping, Structural

Cairn-Tsg-L-Sp-0005-B2 Specification For Painting (Above Ground & Underground Piping, Structural

Uploaded by

Shivashankar Durga MedisettiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cairn-Tsg-L-Sp-0005-B2 Specification For Painting (Above Ground & Underground Piping, Structural

Cairn-Tsg-L-Sp-0005-B2 Specification For Painting (Above Ground & Underground Piping, Structural

Uploaded by

Shivashankar Durga MedisettiCopyright:

Available Formats

TECHNICAL SERVICES GROUP

SPECIFICATION FOR PAINTING (ABOVE GROUND & UNDERGROUND PIPING, STRUCTURAL

STEEL,TANKS AND EQIPMENT)

CAIRN-TSG-L-SP-0005 -B2

CAIRN ENGINEERING STANDARD

B2 18/10/2021 RE-ISSUED FOR IMPLEMENTATION AS JCP MM/RG

B1 24/09/2012 ISSUED FOR IMPLEMENTATION N Rao Vijay B AA

Revision Date Description Originator Checker Approver

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

TECHNICAL SERVICES GROUP

SPECFICATION FOR PAINTING (PIPING STRUCTURAL)

CAIRN-TSG-L-SP-0005 B1

Page 2 of 15

REVISION RECORD

Revision Philosophy

All revisions for review will be issued at A1, with subsequent A2, A3, etc as required.

All revisions approved for issue or implementation will be issued at B1, with subsequent B2, B3, etc as required.

All revisions approved for issue or design and construction will be issued at C1, with subsequent C2, C3, etc as

required.

Narrative sections revised from previous pprove issues are to be noted in the table below and/or highlighted

using the appropriate revision status thus: | A2

Previous revision highlighting to be removed at subsequent issues.

Drawings/diagrams revised from previous approved issues are highlighted by 'clouding' the affected areas and

by the use of a triangle containing the revision status.

Revision History

Revision Date of Reason for change

No. issue

A1 Aug 2012 Issued for review

B1 24/09/2012 Issued for Implementation

B2 18/10/2021 Re-issued for implementation

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

TECHNICAL SERVICES GROUP

SPECFICATION FOR PAINTING (PIPING, STRUCTURAL & TANK INTERNALS)

CAIRN-TSG-L-SP-0005 B2

Page 3 of 15

TABLE OF CONTENTS

1.0 SCOPE 4

2.0 CODES, REGULATIONS AND STANDARDS 4

3.0 GENERAL 5

4.0 MATERIAL 5

5.0 EXTENT OF PAINTING 5

6.0 AMBIENT LIMITATIONS 6

7.0 SURFACE PREPARATION 6

8.0 PRIMING AND FINISHING 7

9.0 INSPECTION AND TESTING 8

10.0 APPROVED PAINT MANUFACTURERS 9

11.0 GUARANTEE 10

12.0 ACCEPTANCE CRITERIA 10

13.0 APPENDIX 1.0 COLOUR CODE 10

14.0 APPENDIX 2.0 PAINT SYSTEM 11

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

TECHNICAL SERVICES GROUP

SPECFICATION FOR PAINTING (PIPING, STRUCTURAL & TANK INTERNALS)

CAIRN-TSG-L-SP-0005 B2

Page 4 of 15

1.0 SCOPE

This specification covers the selection of materials and procedures to be followed in the course of surface

preparation and the application of external protective paint / wrap etc to above-ground and undergroung

piping, tanks, vessels, structural steel and other equipment , whether they are prepared and protected in

the shop or field. It is understood that contractor shall carry out the work in all respect with the best quality

of materials and workmanship and in accordance with best engineering practice. It shall be deemed that

supply of all types of material, tools & tackles and labor required to execute the painting work is in

contractor’s scope of work.

1.1 Definition

Company :The company means Vedanta, Cairn oil and gas and its subsidiaries or authorized

representatives.

Vendor/Contractor: The Vendor or Contractor is the party that manufactures and supplies equipment and

service to perform the duties specified by the Company.

2.0 CODES, REGULATIONS AND STANDARDS

2.1 External painting and protective coating shall meet or exceed the requirement s of the latest edition of

the following codes, regulations and standards, except as superseded herein. In cases where more than

one code, regulation or standard apply to the same condition, the most stringent shall be followed. In the

event of a conflict between this specification and other specification or Correspondence, the Company

shall be consulted and a ruling, in writing, shall be obtained before any work is started.

National Association of Corrosion Engineers (NACE)

NACE RP0287 Field Measurement of Surface Profile of Abrasive Blast Cleaned Steel

Surface Using a Replica Tape

RAL German Institute for Quality Assurance and Certification

RAL Colors

BS 4800 Color Chart

Society of Protective Coating (The Steel Structures Painting Council Manual):

SSPC SP1 Solvent

SSPC SP2 Hand Tool Cleaning

SSPC SP3 Power Tool Cleaning

SSPC SP5 White Metal Blast Cleaning

SSPC SP6 Commercial Blast Cleaning

SSPC SP7 Brush-Off Blast Cleaning

SSPC SP10 Near White Blast Cleaning

SSPC SP11 Power Tool Cleaning to Bare Metal

SSPC PA 1 Shop, Field and Maintenance Painting

SSPC PA 2 Measurement of Dry Coating Thickness with Magnetic Gages

SSPC PA Guide 3 Guide to Safety in Paint Application

SSPC PA Guide 8 Guide to Top Coating Zinc Rich Primers

SSPC AB 1 Mineral and Slag Abrasives

SSPC AB 2 Cleanliness of Recycled Ferrous Metallic Abrasives

SSPC VIS 1 Visual Standard for Abrasives Blast Cleaned Steel

SSPC VIS 3 Visual Standard for Power and Hand Cleaned Steel

SSPC, Volume 1 Good Painting Practice

SSPC, Volume 2 Systems and Specification

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

TECHNICAL SERVICES GROUP

SPECFICATION FOR PAINTING (PIPING, STRUCTURAL & TANK INTERNALS)

CAIRN-TSG-L-SP-0005 B2

Page 5 of 15

ASTM Standards

ASTM D4541 Standard Test Method for Pull-Off Strength of Coating Using Portable

Adhesion Testers

ASTM D4417 Standard Test Methods for field Measurement of Surface Profile of Blast

Cleaned Steel

ASTM D5162 Standard Practice for Discontinuity (Holiday) Testing on Nonconductive

Protective Coating on Metallic Substrates

ASME A13.1 Scheme for identification of piping system : American National standard Institute.

International Standard Organization – ISO

ISO 2808 Paint and Vanishes – Determination of Film Thickness

ISO 4624 Paint and Vanishes – Pull-off Tests for Adhesion

ISO 8501-1 Preparation of Steel Substrates Before Application of Paint and Related

Products-Visual Assessment of Surface Cleanliness

ISO 8502 Preparation of Steel Substrates Before Application of Paint and Related

Products- Tests for the Assessment of Surface Cleanliness

ISO 8504-2 Preparation of Steel Substrates Before Application of Paint and Related

Products –Surface Preparation Methods

Indian Environment (Protection) Rules, 1986 and its subsequent amendments

Indian Air (Pollution and Prevention) Act, 1981 and its subsequent amendments

Codes, Regulations Statutes of Authorities having jurisdiction in location of installation.

2.2 Some requirement in this specification may be modified by specific requirements in the Purchase

Specification or other project drawing. In case of conflict, the specific requirements supersede this

specification.

2.3 Any deviation from this specification must be approved, in writing, by Company. Such written approval

must be obtained prior to the commencement of any work which would Constitute such a deviation.

3.0 GENERAL

3.1 Workmanship

Work shall be done by qualified and competent craftsmen, in a neat and workmanlike manner, conforming

to code requirements and industry standards (SSPC, Volume 1, Good Painting Practice).

3.2 Marking Conditions

Where elevated structures require marking for safety consideration, they shall be marked in accordance

with the requirements or the Authority having jurisdiction.

4.0 MATERIALS

4.1 Storage of Materials

Materials shall be stored in Manufacturer’s containers, clearly marked with Manufacturer’s labels, under

Manufacturer’s specified storage condition.

4.2 Manufacturer’s Recommendations

Materials shall be used and applied in accordance with Manufacturer’s recommendation, which shall take

precedence over this specification.

EXTENT OF PAINTING

4.3 Surface to be Painted

4.3.1 All surfaces subject to weathering, rushing or corrosion by exposure to the elements shall be painted.

All carbon steel, stainless steel and alloy steel surfaces shall be painted per the appropriate system

listed in Appendix 2.0.

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

TECHNICAL SERVICES GROUP

SPECFICATION FOR PAINTING (PIPING, STRUCTURAL & TANK INTERNALS)

CAIRN-TSG-L-SP-0005 B2

Page 6 of 15

5.1.2 All items contained in the package unit as necessary.

5.1.3 All structural steel work,pipe,structural steel supports ,walkways ,handrail ladders ,platform, equipment,

vessels, tanks, underground piping etc.

5.1.4 Painting under insulation for CS,AS and SS as specified.

5.1.5 Repair work of damaged pre-erection/ fabrication and weld joints in the field/site before and after

erection.

5.1.6 External/ internal surface of MS chimney with or without refractory lining.

5.1.7 Identification colour bands on all piping as required including insulated aluminium clad,galvanized ,ss

Piping as per DECO-RX-L-SP-4007

5.1.8 Identification lettering /numbering for equipment and piping as per DECO-RX-L-SP-4007

5.1.9 Carbon steel surfaces having an operating temperature less than or equal to 120 °C which are

insulated or fireproofed shall, as m minimum, be coated per System 7 in Appendix 2.0.

5.2 Surface NOT to be Painted

5.2.8 The fo9llowing are not to be painted and must be protected from painting:

Porcelain

Gauge Glasses

Meter Faces

Valve Stem and Threads

Working Surface of Equipment

Name Plates

Aluminum, Uninsulated Stainless Steel, Plastic and Fiberglass

Insulation or Fireproofing

Galvanized surface

Factory Finished Control Panels

Factory Finished Instrument Cases and Meters

Factory Finished Building

5.2.9 Concrete, Transite, Masonry, Stucco. etc., Shall not be painted unless specified be Company.

5.2.10 Masking or compounds used to protect non-painted surface must be removed prior to completion of

the job.

6.0 EQUIPMENT

6.1 All tools, brushes, rollers ,spray guns,blast materail,handpower tools for cleaning and all

equipments,scaffolding materail ,shot & grit blasting equipments & compressor etc.required to be

used shall be suitable for the work, to be arranged by the Contactor.

6.2 Mechanical mixer shall be used for paint mixing operations in case of two pack systems.

7.0 AMBIENT LIMITATIONS

7.1 Surface Preparation and Paint Application

Unless otherwise specified in writing by the coating Manufacturer, no surface preparation or application

paint shall take place under the following conditions:

Air temperature is below 10 °C

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

TECHNICAL SERVICES GROUP

SPECFICATION FOR PAINTING (PIPING, STRUCTURAL & TANK INTERNALS)

CAIRN-TSG-L-SP-0005 B2

Page 7 of 15

Surface temperature is below 5 °C

Surface temperature is 3 °C or less than Dew Point

Relative humidity is 85% or above

Wet or damp atmosphere

Wet surfaces

Rain, mist or fog is present

Wind speed above 25 kmph

Atmosphere contaminated by dirt, dust, oil, product or any other pollutant

7.2 Ventilation

During all stages of surface preparation an application of paint, adequate ventilation must be assured.

8.0 SURFACE PREPARATION

The type of surface preparation shall be in accordance with Appendix 2.0 All oils and grease contamination

shall be removed from the surface in accordance with SSPC-SP-1, ‘Solvent Cleaning’ and using bio-

degradable water soluble cleaner prior to blasting.

8.1 Abrasive Blast Cleaning

8.1.1 The Steel surface shall be cleaned by abrasive blast cleaning. Refer to paint Manufacturers data

sheets for degree of blast.

8.1.2 All rough welds, burrs, silvers, laminates, porosity, weld splatter and surface projections shall be

ground smooth or filled prior to and after blasting operations, if revealed, prior to coating.

8.1.3 Sand blasting or other material producing silica shall not be used. Abrasive to be used for blast

cleaning carbon steel and low alloy steel surfaces are listed below as specified in ISO-8504-2.

Chilled Iron Grit or Shot

SS grits/shots or Aluminium oxidegrits/shots for SS surface

Non & metallic Iron Grit or Shot

Non Metallic Abrasive (Aluminum, Oxide, Copper Slag Garnet)

Grit Spec-Particles that are predominately angular have fractured faces and sharp edges and

are less than half round in shape.

Vendor shall follow SSPC AB 1 and SSPC AB 2, as applicable. vendor may propose alternate abrasive

material for Company approval.

8.1.4 Profile depth of the abrasive blast cleaned surface shall not be less than 50 microns nor be greater

than 75 microns. Refer to paint Manufacturers data sheets for proper anchor profiles.

8.1.5 Grade surface finish shall be in accordance with ISO 8501-1 as listed below:

Sa 1– “Light Blast Cleaning”

Sa 2– “Through Blast Cleaning”

Sa 2 ½ - “Very Through Blast Cleaning”

Sa 3 – “Blast Cleaning to Virtually Clean Steel”

8.1.6 The blast cleaned surface shall be coated with one application of specified primer during the same day

as blasted, prior to sundown of the day and before any visible rusting occurs. Blast cleaned surfaces

allowed to set overnight shall be re-blasted prior to priming.

8.1.7 If indoor facilities are used with controlled environments then blasting and coating operations may be

conducted around the clock, so long as environmental conditions are within specified acceptable

parameters.

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

TECHNICAL SERVICES GROUP

SPECFICATION FOR PAINTING (PIPING, STRUCTURAL & TANK INTERNALS)

CAIRN-TSG-L-SP-0005 B2

Page 8 of 15

8.1.8 The compressed air for blasting and coating shall be free of water, oil and other contaminants. Air

compressor shall not be allowed to deliver air at a temperature above 110 °C. Equipment such as air

dryer, filters, coolers, and other equipment necessary for clean dry air shall be the responsibility of the

Vendor. The Company will not provide plant, utility or instruments air for blasting and coating purposes.

8.1.9 No coating shall be permitted to be applied over scale, rust, oil, grit or other foreign material, All

abrasive shall be removed by brush, air blast or vacuum type cleaner prior to applying primer. Care

shall be exercised to assure that the cleaned surface is not. contaminated with any foreign material or

fingerprints prior to applying primer.

8.1.10 Surface preparation of fabricated items to be painted in the shop shall be done in an area free of dust

and contaminants from other shop work.

8.1.11 Field weld joints shall be blast cleaned to the required degree of clealiness and anchor profile as

recommeded by the paint manufacturer to achieve adhesion.

9.0 PRIMING AND FINISHING

9.1 Manufacturer’s Recommendations

The Paint Manufacturer’s recommendations on application and surface preparation are to take precedence

over these general specifications.

9.2 Application Procedures

9.2.1 Area lighting shall be more than 500 Lux.

9.2.2 The preferred method of coating application shall be conventional or airless spray. Conventional spray

coating shall not be carried out when temperature is less than 4 °C or more than 40 °C. Traps or

separators shall be provided to remove oil and water from the air. The air from the spray gun impinging

on the steel substrate shall show no condensed water or oil. Compressed air for blasting and coating

shall be free of all moisture, oil and other contaminants.

9.2.3 Brush or roller application may be used for touch up and repair or when area cannot be coated with

spray. Stripe coating shall be applied on weld joints and inaccessible area with brush application to

achieve required DFT prior to spray application.

9.2.4 The gun shall be at right angles to the surface and 20 cm to 25 cm from the surface. where air operated

equipment is used, the operator’s hood or head gear shall be ventilated by clean, cool air served

through regular filter, to prevent blast cleaning residuals from being inhaled.

9.2.5 Each pass of the gun shall overlap by 50%.

9.2.6 Spraying should be continuous until all material is used up avoiding long periods of pause.

9.2.7 Inorganic and organic zinc paints shall be kept agitated at all times. Refer to paint Manufacturers data

sheets

9.2.8 Any material being used which exceeds its pot life shall be removed from the paint pot, destroyed and

the paint pot and lines thoroughly cleaned with suitable tool cleaner (as per Manufacturer’s

recommendation)

9.2.9 Paint shall not be thinned beyond Manufacturer’s recommendation and if Company requires it, a

viscosity check shall be made.

9.2.10 No spraying shall be done within 10 cm of unprepared surfaces.

9.2.11 Prime coating shall be applied soon after preparation-before flash rusting occurs. If rust bloom forms

after blasting, the affected area shall be re-blasted before application of the first coating.

9.2.12 Minimum and maximum overcoat windows shall be observed. If exceeded, refer to paint Manufacturer

data sheets which may require solvent wipe, seep blasting, sanding or washing.

9.2.13 Care shall be taken to apply a stripe coat by brush to all welds, edges, corners and “ hard to reach”

areas after the primer with the intermediate coat.

9.2.14 During all blasting operations, the Vendor shall exercise caution and employ masks, shields, etc., to

assure that the coated surfaces adjacent to the blast area are protected from over blast damage by

stray or rebounding blast particles. Calibrated pressure gauges on blasting pot, compressor inlet line

shall be made available. All the equipment shall be properly grounded to earth. Blasters shall use

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

TECHNICAL SERVICES GROUP

SPECFICATION FOR PAINTING (PIPING, STRUCTURAL & TANK INTERNALS)

CAIRN-TSG-L-SP-0005 B2

Page 9 of 15

leather aprons, blasting hood with clean air supply. Blasting nozzles shall be of venturi bore typw and

blasting shall be carbon impregenated type to avoid static electricity. Dead man’s handle shall be

available on the blasting hose at all times. Proper moisture traps shall be fitted on the blasting pot

assembly. All areas affected by over blast shall be repaired by the Vendor as specified by the Company

at no additional cost to the Company.

9.2.15 Wet film thickness gauges shall be used during application to ensure proper film build. Type 1 or Type

2 DFT gauges shall be used or taking dry film thickness of coating between and after and after each

coat has fully Cured.DFT gauges shall be calibrated before each use.

9.2.16 Blasting and coating operations shall be done after all hydro-test and NDE testing are completed for

shop fabricated equipment and piping. Similarly, the coating of field welded piping joints shall be done

after the completion of hydro-test NDE testing.

9.3 Types of Primer and Tie-Coat

See Appendix 2.0 for types of primer and tie-coat paints. Where 2 or more coats of finish and tie-coat are

to be applied, each coat shall be of contrasting color. Protective coating System No. 13 for underground

piping shall be cold applied tape wrapping as per approved manufacturer’s recommendations. Cold applied

tape wrapping shall be applied only by qualified /certified applicators as recommeded by the manufacturer.

For irregular surfaces, components in buried piping, approved tape wrapping shall be done as per

manufacturer’s recommedation to achive 100% covering and free from holidays. For transition areas form

underground piping to above ground piping, the cold applied tape wrapping shall extend at least 300 mm

above the ground.

9.4 Types of Finish Paint

See Appendix 2.0 for types of finish paint. Where 2 or more coats of finish are to be applied, each coat

shall be contrasting color so as to aid visual inspection for holiday, coverage and wear, etc.

9.5 Wood

Wood shall be given a single coat of al latex wood primer and finished with a non-chalking interior/exterior

latex.

10.0 INSPECTION AND TESTING

10.1 The Company’s representative shall have access to all work while being performed and shall be given

sufficient notification to complete all required inspections.

10.2 All prepared surfaces shall be subject to inspection by Company’s representative and approval before

primer is applied. Acceptance of the blast cleaned surface will be made by Company’s representative

based on visual comparison with ‘Anchor Pattern Standards’ or ‘ Surface Profile Comparator’. Vendor

shall maintain surface preparation cleanliness per SSPC VIS 1 or SSPC VIS 3 (Visual Standards).

Measurement of surface profile shall be per NACE RP 0287 or ASTM D 4417 and ISO 8502 with Testex

Tape and dial micrometer.

10.3 Measurement of paint dry film thickness shall be made with a Mikrotest or similar approved gauge for each

coat of the total system. The dry film thickness measurement shall be per SSPC PA 2 and ISO 2808

Method 6. Spot check measurement of paint wet film thickness shall be made per ISO 2808 Method 7B.

Failure to meet specified thickness requirement shall cause work to be rejected.

10.4 The painted surfaces will be subject to a random holiday test to verify painting is holiday free in accordance

with ASTM D5162. Voltage will be determined according to material applied . DC type detectors are

preferred. Repairs to holiday will be made according to Paint Manufacture’s recommendation. Cold applied

tape wrap (system 13) shall be holiday tested in accordance to NACE RP 0188 and 100% holiday free

prior to backfilling. Underground piping holiday testing shall only be done with pulse type dru spark detector

having spring type probes. Internal painting/lining of the tanks & vessels / equipment shall be 100% holiday

tested in accordance to applicable standards and as recommended by the paint manufacturer.

10.5 The applied paint shall adhesion tested in accordance with ASTM D4541 and ISO 4624. Where practical,

to avoid damaging the paint on equipment, a test plate of the same material as equipment shall be prepared

and painted concurrent with the equipment being painted. The adhesion test shall be done on the test plate

after paint is completely cured. The adhesion test shall be done on the test plate after paint is completely

cured. The adhesion test shall be performed on the test plate after application of the primer to the steel

substrate and after the subsequent coats.

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

TECHNICAL SERVICES GROUP

SPECFICATION FOR PAINTING (PIPING, STRUCTURAL & TANK INTERNALS)

CAIRN-TSG-L-SP-0005 B2

Page 10 of 15

10.6 The Vendor QA/QC representative shall ensure 100% of the painted area is devoid of bare metal and is

free of holiday. The Vendor QA/QC representative shall also ensure that the DFT requirements and color

codes have been achieved as per the requirements of this specification.

10.7 All pipes shall have the proper color code bands per the process fluid service for ease of identification.

The color codes for various services shall be per the Company piping specification.

10.8 Work may be rejected due to poor workmanship is defined as inadequate drying or curing , dirt and dust

inclusions, overspray, pin-holes, runs and sags, failing adhesion test, failing holiday test or inadequate film

build.

10.9 Acceptable finish work must be free of abrasions and must be uniform in color and appearance.

10.10 An inspection report shall be submitted to Company prior to final acceptance of the paint work.The

inspection report shall include, as a minimum, the following:

Name of the Contractor and Responsible Personnel

Dates when work was carried out

Equipment and technique used

Material receipt condition

Type and calibration of instrument used

Weather and ambient condition

Painting periods

Condition of surface before preparation

Tools and methods used to prepare surface

Condition after preparation

Information on systems being applied

Mixing and testing prior to application

Paint application techniques

Type of quality control checks carried out and results

Compliance or non-compliance with specification

11.0 APPROVED PAINT MANUFACTURERS

The approved Manufacturers for the external paints are as follows:

Akzo Nobel(international Paint)

CDC Carboline

M/s Grauer & Weil (India) Ltd.

Asian Paints

Berger Paints Ltd.

Knasai Nerolac Paints Ltd.,Mumbai ( Including Ameron, USA Products)

Jotun Paints

Hempel Paints

Sigma Kalon Protective Coating

Stanvac Paints (Superon)

Raychem

Denso Tapes

Seal For Life India Pvt. Ltd ( Poyolefin tapes, STOPAQ, Polyken tapes 942/955/1600HT)

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

TECHNICAL SERVICES GROUP

SPECFICATION FOR PAINTING (PIPING, STRUCTURAL & TANK INTERNALS)

CAIRN-TSG-L-SP-0005 B2

Page 11 of 15

Vendor shall use the above listed Manufacturers only for the external paints. Vendor shall obtain prior

Company approval in writing if a manufacturer other than listed above is to be used. All the paints and cold

applied tapes shall have an approved Procedure Qualification Test record prior to application on the actual

job.

12.0 GUARANTEE

Vendor shall guarantee painting against poor workmanship and improper application. Guarantee

(Warranty) provisions are specified in the Company Standard Terms and Conditions, and shall apply to

Vendor and Vendor’s sub-contractors and /or suppliers. Vendor shall repair at his own expense any defects

noted during the guarantee period.

13.0 ACCEPTANCE CRITERIA

13.1 The finished work shall not contains any runs, sags, or other application flaws which could lead to

premature coating failure.

13.2 No work shall be considered complete or accepted until the coated surface thickness are within the

required parameters.

13.3 No work shall be considered complete or accepted until all area of the coated surface are holiday free for

System 13.

13.4 No work shall be considered complete or accepted until adhesion test is performed and results are

satisfactory.

13.5 No work shall be considered complete or accepted until the coating is fully cured.

14.0 APPENDIX 1.0 COLOR CODE

RAL COLOR

ITEM EQUPMENT COLOR

(Note 1)

1 Tanks (except U/G), Vessels, Towers Medium Grey 7004

2 Storage Bullets White 9003

3 Vendor Supplied Equipment Medium Grey 7004

Structural, Skids(except for handrails, safety cages

4 Medium Grey 7004

and ladders)

5 Handrails, Safety Cages and Ladders Safety yellow 1021

Process Gas Piping(including Inlet, Sales, Multi-

6 Medium Grey 7004

Phase Gas Streams)

7 Instrument Gas Piping Medium Grey 7004

8 Fuel Gas Piping Safety yellow 1021

Process Hydro-Caron Liquid Piping(Including Inlet,

9 Medium Grey 7004

Sales, Multi-Phase Oil Streams)

10 Instrument Air Medium Grey 7004

11 Drain, Flair, Relief Piping Medium Grey 7004

12 Fire and Emergency Systems Safety Red 3001

13 Water(Except Firewater) Medium Grey 7004

High Pressure Gas and Water(Over 10,204kPa or

14 Medium Grey 7004

1480 psi)

15 Amine Streams(Or Other Gas Sweetening Agents) Medium Grey 7004

16 Glycol and Glycol/Water Streams Medium Grey 7004

17 Refrigerant Streams Medium Grey 7004

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

TECHNICAL SERVICES GROUP

SPECFICATION FOR PAINTING (PIPING, STRUCTURAL & TANK INTERNALS)

CAIRN-TSG-L-SP-0005 B2

Page 12 of 15

18 Flare and Other stacks Black 9004

Note 1 :

Vendor shall cross-reference appropriate US federal standards for colors, if required.

BS 4800 or RAL color code shall be used.

In case of Medium Grey (RAL 7004) for Fuel gas piping, a yellow colour of band safety yellow to be

applied.

Vendor shall follow Cairn specification for color coding and lettering / stenciling DECO-RX-L-SP-4007-

B1

Where appropriate for Safety reasons, the following color scheme shall be applied:

1 Dangerous Obstructions Black/Yellow (in Alternate Brands)

2 Dangerous or Exposed Parts of Machinery Alert Orange

3 Fire Equipment and Services Red

4 First Aid Equipments Dark Green

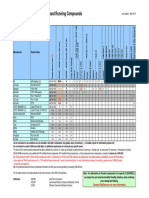

15.0 APPENDIX 2.0 PAINT SYSTEMS

SURFA

SPEC SPEC SPEC

CE PRIMER FINISH

SYSTEM SERVICE DFT(∪ TIE COAT DFT(∪ DFT(∪

PREP. COAT COAT

m) m) m)

(SSPC)

3 coats of

Painting two

Two

under componen

componen

insulation -ts Epoxy

t Inorganic 3X80

System 1 for CS, SP 10 65-75 phenolic

Zinc = 240

LTCS and coating

Silicate,

SS -45º to cured with

Self-Cured

20 ºC polyamine

hardner

Structural

Steel, Inorganic

Piping Zinc Acrylic

High Build

Process, SP10 Silicate or Aliphatic

System 2 50-75 Polyamide 75-100 50-75

Equipment, (Note 1) Zinc rich polyuretha

Epoxy

Storage Epoxy ne

Tanks>=20

º to 93 ºC

Engines,

Generators

,

Compresso Acrylic

SP1 &

rs, Electric 75- Aliphatic

System 3 SP3 Epoxy 50-75

Motors, 125 polyuretha

(Note 2)

Pumps and ne

related

equipments

<=93 ºC

Piping,

Inorganic Modified Modified

System 4 Process SP6 50-75 25-40 25-40

Zinc-Rich Silicone Silicone

Equipment

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

TECHNICAL SERVICES GROUP

SPECFICATION FOR PAINTING (PIPING, STRUCTURAL & TANK INTERNALS)

CAIRN-TSG-L-SP-0005 B2

Page 13 of 15

s, Storage Ethyl

Tanks>93 Silicate

ºC to (Note 4)

215ºC

Piping,

Process Inorganic Heat Heat

Equipment Zinc-Rich Resistanc Resistanc

System 5 s, Storage SP10 Ethyl 50-75 e Silicone 25-40 e Silicone 25-40

Tanks> Silicate Acrylic Acrylic

215ºC to (Note 4) Enamel Enamel

260 ºC

Piping,

Process

Equipment Inorganic

s, Storage Zinc-Rich Thermal

System 6 Tanks> SP10 Ethyl 50-75 None 0 Spray 25-40

260 degree Silicate Aluminum

C to 540 (Note 3,4)

degree

C(Note 3)

Carbon

Steel to be

Insulated Epoxy 100- Epoxy 100-

System 7 SP10 None 0

and/or Phenolic 150 Phenolic 150

Fireproofed

, ≤205 °C

High

Temperat

ure Silicon

50 µ DFT

or one

coat of

60µ

DFT/coat

Carbon Engineere

Steel to be d Epoxy

Inorganic

Insulated , poly

System 8 SP6 Zinc 65-75 None 0 50/60

>250°C to Siloxane

Silicate

500°C coating or

(Note 8) high build

cold

applied

inorganic

co-

polymer

based

aluminium

coating

Stacks &

Furnaces, Thermal

System 9 >240°C to SP10 (Note 5) None 0 Spray 25-40

540°C Aluminum

(Note 8)

External

Amine Amine

System Surface of 150- 150-

SP10 Cured None 0 Cured

10 Storage 200 200

Epoxy Epoxy

Tank Floor

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

TECHNICAL SERVICES GROUP

SPECFICATION FOR PAINTING (PIPING, STRUCTURAL & TANK INTERNALS)

CAIRN-TSG-L-SP-0005 B2

Page 14 of 15

Spray can

Galvaspra

Organic

System Galvanizing 37.5- y/cold

SP7 Zinc Rich None 0

11 Repair 62.5 galvanizin

Epoxy

-g

compond

SP-10 Two One coat One coat

(15-25 µ componen of two of two

surface -ts Epoxy componen componen

Insulated

profile) phenolic -ts Epoxy -ts Epoxy

System Stainless

Note-9 coating 80 phenolic 80 phenolic 80

12 steel 0º to

cured with coating coating

125º C

polyamine cured with cured with

hardner polyamine polyamine

hardner hardner

SP-10 One coat One coat

Note-9 of 125µ of 125µ

DFT/coat DFT/coat

Engineere Engineer-

-d Epoxy ed Epoxy

poly poly

Siloxane Siloxane

Insulated

coating or 125 coating or 125

System Stainless

high build high build

12.1 steel 126º

cold cold

to 400º C

applied applied

inorganic inorganic

co- co-

polymer polymer

based based

aluminium aluminiu-

coating m coating

Primer for

External

Cold Outer

Coating of Inner wrap

applied wrap (as

Buried (as per

Tape wrap per

System Carbon manufactu Min 1 Min 1

SP-10 (As per 25-50 manufactu

13 Steel rer’s mm mm

manufactu rer’s

Piping recommed

rer’s recommen

<175°C ation)

recommen dation)

(Note7)

dation)

System SP10 50-75 Glass

Acrylic

14 Flake

Inhibitive Aliphatic

Plated Epoxy

Polyamide 500- Polyureth

Non-Skid with 50

Epoxy 625 ane

Surface Aluminum

Primer (minimum

Oxide

40% solid)

Granules

Carbon Organic

High-Build

System Steel Near Zinc Rich 100- Aliphatic

Sp6 50-75 polyamide 50-75

15 cooling Epoxy 150 urethane

Epoxy

tower (Note 4)

NOTES:

1. Surface preparation of structural steel may be reduced SSPC SP10 to SSPC-SP6

2. Solvent clean per SSPC-SP1 followed by power tool cleaning per SSPC-SP3

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

TECHNICAL SERVICES GROUP

SPECFICATION FOR PAINTING (PIPING, STRUCTURAL & TANK INTERNALS)

CAIRN-TSG-L-SP-0005 B2

Page 15 of 15

3. Above 400°C operating temperature, do not apply primer

4. At least 80% zinc in dry film for an organic zinc

5. Apply one”mist” coat to fill blast profile,followed thirty(30) minutes later with finish coat to specified DFT

6. Vendor may submit for company approval the manufacturer standard point system for

engines,compressors,electric motors,generators,pumps and related OEM equipment

7. Vendor shall confirm with the paint manufacturer the temperature limits on the coatings being used

8. The blast cleaning abrasives for SS steel surface shall be SS grits/shots or Aluminium oxide grits/shots

TABLE 1: COATING SYSTEMS FOR INTERIOR OF TANKS AND VESSELS

This document is controlled electronically and is uncontrolled when printed

Sensitivity: Internal (C3)

You might also like

- Piping Tie in Procedure Rev ADocument15 pagesPiping Tie in Procedure Rev AAnh Võ95% (21)

- SAEP-13 - 09 - 19 - 22 - NTC.1 (Fina)Document101 pagesSAEP-13 - 09 - 19 - 22 - NTC.1 (Fina)Ayman AdilNo ratings yet

- Sharan JSWDocument30 pagesSharan JSWLAXMI GUNTUKNo ratings yet

- Vedanta: Vedanta L Mited C O GasDocument13 pagesVedanta: Vedanta L Mited C O GasfirozNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument23 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument33 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- E in 100 PDFDocument87 pagesE in 100 PDFTae BangsenNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument18 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument17 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument30 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Section-III - CDU - Rev 1Document10 pagesSection-III - CDU - Rev 1adil khanNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Project No. P12513 Feed For New Flow Suction Tank On Bu Hasa CdsDocument6 pagesProject No. P12513 Feed For New Flow Suction Tank On Bu Hasa CdssarathNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument35 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab Jacob100% (1)

- Ips-mbd18002-In-517 Rev. A - Ls Top MountedDocument8 pagesIps-mbd18002-In-517 Rev. A - Ls Top MountedNikhil KarkeraNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument22 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument18 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument25 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument33 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Wps 001Document19 pagesWps 001Rizwan.descon DesconNo ratings yet

- Random Packing: From Competitive Products To Advanced SolutionsDocument16 pagesRandom Packing: From Competitive Products To Advanced SolutionsiazcuzcNo ratings yet

- Engineering PortfolioDocument55 pagesEngineering PortfolioCarlos WotchoskiNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument28 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- R272PFC RRX R PLN 1001 A2Document97 pagesR272PFC RRX R PLN 1001 A2Joemon T JoyNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument89 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Pt. Adiprotek Envirodunia Pt. Pdpde Gas: Epcc Usm Metering Station at Simpang Abadi JambiDocument8 pagesPt. Adiprotek Envirodunia Pt. Pdpde Gas: Epcc Usm Metering Station at Simpang Abadi JambiAdhya RazanNo ratings yet

- 20G12-MF-0010 - RA Heat & Mass Balance Diagram-2 PDFDocument7 pages20G12-MF-0010 - RA Heat & Mass Balance Diagram-2 PDFahmedNo ratings yet

- Validation Certificate - PIPENET 1.6Document1 pageValidation Certificate - PIPENET 1.6ani_datNo ratings yet

- Ips I in 115Document39 pagesIps I in 115hrmoeziNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument20 pagesNational Oil Corporation: Rev Date Description Checked ApprovedALI BEN AMORNo ratings yet

- C 3031 Ih 8-F TSP002 Att00Document21 pagesC 3031 Ih 8-F TSP002 Att00Joseph Samir Eshak100% (1)

- SPCL Offer 9 (New) - 03.12.09Document55 pagesSPCL Offer 9 (New) - 03.12.09ptn999No ratings yet

- IPS-MBD20031-In-512 - Data Sheet of Rotameter - ADocument3 pagesIPS-MBD20031-In-512 - Data Sheet of Rotameter - ANikhil KarkeraNo ratings yet

- Ario Damar - Sriwijaya Oil & Gas Development: Document No. CT-F17795-TE2-31-E-002-001Document5 pagesArio Damar - Sriwijaya Oil & Gas Development: Document No. CT-F17795-TE2-31-E-002-001idilfitriNo ratings yet

- 0721 Presentation To IOCLDocument48 pages0721 Presentation To IOCLShruti DuttNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument28 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument15 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- Integrated Lean and Bim Processes For Modularised Construction - A Case StudyDocument13 pagesIntegrated Lean and Bim Processes For Modularised Construction - A Case StudyJuan CorvalánNo ratings yet

- 0006 SP 03Document11 pages0006 SP 03Tarik MoumeneNo ratings yet

- TechnimontDocument3 pagesTechnimonttonoxtonoxNo ratings yet

- 2c-Rev.1-Special Auxiliary Pipe SupportDocument27 pages2c-Rev.1-Special Auxiliary Pipe SupportcaochieuNo ratings yet

- Surge Vessel Testing: (Update As of 30th April 2015)Document2 pagesSurge Vessel Testing: (Update As of 30th April 2015)Syed AliNo ratings yet

- 2A P220 Accumulator Process Data Sheet PDFDocument3 pages2A P220 Accumulator Process Data Sheet PDFAhmed MusallamNo ratings yet

- VMS PDFDocument1 pageVMS PDFritoh8657No ratings yet

- GM479-R0731-000-PR-RP-0002 - 0-Isolation, Vent & Drain PhilosophyDocument42 pagesGM479-R0731-000-PR-RP-0002 - 0-Isolation, Vent & Drain PhilosophySuper 7100% (1)

- UntitledDocument24 pagesUntitledTuan LuuNo ratings yet

- 7S92-06011-CO-TP-541 MST For GRE Pipe Modification (ORV-D) r0Document17 pages7S92-06011-CO-TP-541 MST For GRE Pipe Modification (ORV-D) r0abdelmalek boudjemaaNo ratings yet

- Process Courses and Seminars March 21Document1 pageProcess Courses and Seminars March 21svnaik14No ratings yet

- 305-78-Me-Dts-00020 (171-T202)Document9 pages305-78-Me-Dts-00020 (171-T202)Gorkem DoraNo ratings yet

- RFP Documentation EPC G3 CCPP272 01Document208 pagesRFP Documentation EPC G3 CCPP272 01gujunjss100% (1)

- TF1 - 2M90 - 221103 - 2 - (10-GT-8001) General Arrangement Drawing - A1Document4 pagesTF1 - 2M90 - 221103 - 2 - (10-GT-8001) General Arrangement Drawing - A1nguyen duy thanhNo ratings yet

- Ips e in 100Document87 pagesIps e in 100charleselitb92No ratings yet

- SGIL Profile (SG)Document21 pagesSGIL Profile (SG)Soumitra GuptaNo ratings yet

- N.STD - Unit of MeasurementDocument12 pagesN.STD - Unit of MeasurementMatteoNo ratings yet

- Manual For Procurement of PPPs 2022 Clean v10 (Draft)Document86 pagesManual For Procurement of PPPs 2022 Clean v10 (Draft)Yogesh Sindhu100% (1)

- O7 08572-TRHT-AE-GN-00-OO-205 - Rev 0Document27 pagesO7 08572-TRHT-AE-GN-00-OO-205 - Rev 0kerkar mohammedNo ratings yet

- Construction Specification For Pressure Testing of PipingDocument30 pagesConstruction Specification For Pressure Testing of PipingHà HuệNo ratings yet

- 00250600BCST49051 Cdfe02 38Document38 pages00250600BCST49051 Cdfe02 38Mohammed HijaziNo ratings yet

- MOU Jan22Document8 pagesMOU Jan22Sujith Madatt ParambuNo ratings yet

- Safety and Handling: Technical Data SheetDocument15 pagesSafety and Handling: Technical Data SheetRonak MotaNo ratings yet

- CAIRN TSG L SP 0005 B1 Specification For Painting (Piping & Structural)Document13 pagesCAIRN TSG L SP 0005 B1 Specification For Painting (Piping & Structural)S. Mark100% (1)

- CAIRN-TSG-L-SP-0011-B2-Specification For Application of Torque For Flange JointsDocument13 pagesCAIRN-TSG-L-SP-0011-B2-Specification For Application of Torque For Flange JointsShivashankar Durga MedisettiNo ratings yet

- CAIRN-TSG-L-SP-0006-B2-Insulation (Piping)Document31 pagesCAIRN-TSG-L-SP-0006-B2-Insulation (Piping)Shivashankar Durga MedisettiNo ratings yet

- CAIRN-TSG-L-SP-0003-B1-Specification For Piping Fabrication and ErectionDocument7 pagesCAIRN-TSG-L-SP-0003-B1-Specification For Piping Fabrication and ErectionShivashankar Durga MedisettiNo ratings yet

- CAIRN-TSG-L-SP-0002-B2-Valve Material Specification (VMS)Document162 pagesCAIRN-TSG-L-SP-0002-B2-Valve Material Specification (VMS)Shivashankar Durga MedisettiNo ratings yet

- RG6-S-00-1360-231 - 0001 - 3 Technical Specification For Dual Plate Check ValvesDocument12 pagesRG6-S-00-1360-231 - 0001 - 3 Technical Specification For Dual Plate Check ValvesShivashankar Durga MedisettiNo ratings yet

- RG6-S-00-1370-041 - 0001 - 3 Pressure Relief DevicesDocument6 pagesRG6-S-00-1370-041 - 0001 - 3 Pressure Relief DevicesShivashankar Durga MedisettiNo ratings yet

- RG6-S-00-1360-083 - 0001 - 4 Specification For Forged Valves Non-CryogenicDocument8 pagesRG6-S-00-1360-083 - 0001 - 4 Specification For Forged Valves Non-CryogenicShivashankar Durga MedisettiNo ratings yet

- RG6-S-00-1360-075 - 0001 - 4 Specification For GasketsDocument8 pagesRG6-S-00-1360-075 - 0001 - 4 Specification For GasketsShivashankar Durga MedisettiNo ratings yet

- Albuquerque HL - Indoor Cannabis Garden GuideDocument11 pagesAlbuquerque HL - Indoor Cannabis Garden Guidedetrick19707913No ratings yet

- Perhitungan Berdasarkan Astm D 388-17Document5 pagesPerhitungan Berdasarkan Astm D 388-17Iyus Darmawan PYNo ratings yet

- Catalogo de Productos de AceroDocument20 pagesCatalogo de Productos de AceroDiether CortezNo ratings yet

- The Role of Microbiology in The Design and Development of Pharmaceutical Manufacturing ProcessesDocument4 pagesThe Role of Microbiology in The Design and Development of Pharmaceutical Manufacturing ProcessesHari RamNo ratings yet

- PCR PresentationDocument24 pagesPCR PresentationUsman Haider100% (1)

- VAM Recommended Storage Running Compound Tables - Rev May 2014Document1 pageVAM Recommended Storage Running Compound Tables - Rev May 2014saptagunungNo ratings yet

- 1983 JACS, Robins, Wilson, Hansske. Nucleic Acid Related Compounds. 42. A General Procedure For The Efficient Deoxy of 2nd OHDocument7 pages1983 JACS, Robins, Wilson, Hansske. Nucleic Acid Related Compounds. 42. A General Procedure For The Efficient Deoxy of 2nd OHBilly BenNo ratings yet

- Analysis of Pinch Point in Liquid Vapour Heat Exchanger of R134a DMAC Vapour Absorption Refrigeration System 2013 Applied Thermal EngineeringDocument8 pagesAnalysis of Pinch Point in Liquid Vapour Heat Exchanger of R134a DMAC Vapour Absorption Refrigeration System 2013 Applied Thermal EngineeringMauri AltamiranoNo ratings yet

- White Goods Cleaner MSDS (2742)Document10 pagesWhite Goods Cleaner MSDS (2742)Alamana CmeNo ratings yet

- Radiation SafetyDocument129 pagesRadiation SafetyHamid Alilou100% (1)

- Rate ReactionDocument10 pagesRate ReactionTsabit AlbananiNo ratings yet

- Using of Taguchi Method To Optimize The Casting of Al-Si /al O CompositesDocument8 pagesUsing of Taguchi Method To Optimize The Casting of Al-Si /al O Compositesarun_premnathNo ratings yet

- Ductile Iron: Rio Tinto Iron & TitaniumDocument18 pagesDuctile Iron: Rio Tinto Iron & TitaniumarirodriguezdiazNo ratings yet

- ASTM Specifications - American Galvanizers AssociationDocument6 pagesASTM Specifications - American Galvanizers AssociationNsidibe EtimNo ratings yet

- Ak 96 Fluid Unit - Flow Path: (Upgrade Kit)Document1 pageAk 96 Fluid Unit - Flow Path: (Upgrade Kit)Mounir AngadNo ratings yet

- Chemical Shrinkage of Hydraulic Cement Paste: Standard Test Method ForDocument4 pagesChemical Shrinkage of Hydraulic Cement Paste: Standard Test Method ForAlejandroNo ratings yet

- Hybrid Reinforced Composite Material From Garbage To BiomaterialsDocument4 pagesHybrid Reinforced Composite Material From Garbage To BiomaterialsPrayogi WicaksanaNo ratings yet

- Scheme of Work Science Stage 8 v1Document50 pagesScheme of Work Science Stage 8 v1Ibnul Mubarok100% (3)

- Iso 11607Document18 pagesIso 11607Ilayaraja BoopathyNo ratings yet

- A Rapid HPLC Method For The Determination of Sulphonamides and Trimethoprim in Feed PremixesDocument5 pagesA Rapid HPLC Method For The Determination of Sulphonamides and Trimethoprim in Feed PremixesAhmed MosalamNo ratings yet

- OK - Effect of Dietary Butyric Acid SupplementationDocument8 pagesOK - Effect of Dietary Butyric Acid SupplementationOliver TalipNo ratings yet

- s28170-26 (Lincoln)Document51 pagess28170-26 (Lincoln)hanz bermejoNo ratings yet

- TECHNICALPart 4Document320 pagesTECHNICALPart 4সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- Homework 03 - Sem 1 - 2020-2021Document8 pagesHomework 03 - Sem 1 - 2020-2021Kim HânNo ratings yet

- CHAPTER 27: Fatty Acid Degradation: 27.1: Fatty Acids Are Processed in Three StagesDocument13 pagesCHAPTER 27: Fatty Acid Degradation: 27.1: Fatty Acids Are Processed in Three Stagesshyamalee97No ratings yet

- Exxonmobil Premium Afme 200 Fact SheetDocument1 pageExxonmobil Premium Afme 200 Fact SheetMahad AbdiNo ratings yet

- 12187-Texto Do Artigo-31072-1-10-20181002Document10 pages12187-Texto Do Artigo-31072-1-10-20181002nakeyahxoNo ratings yet

- Development of Food Chemistry Natural Products and Nutrition ResearchDocument198 pagesDevelopment of Food Chemistry Natural Products and Nutrition ResearchRoberta MorganaNo ratings yet