Professional Documents

Culture Documents

ECU Handbook

ECU Handbook

Uploaded by

NM Group0 ratings0% found this document useful (0 votes)

6 views4 pagesOriginal Title

ECU-Handbook

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

6 views4 pagesECU Handbook

ECU Handbook

Uploaded by

NM GroupCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

A Handbook of Automotive Zembitel

Electronic Control Units (ECU) ——a

ur Go-to Guide Regarding our Control System Design and Development Services

Pe ar wen mn mes

aneey manage system

Eng Conel Unit

‘Ac ystamt Emon Conta System

Seating Systems

captive Light Conta

Front ear Wiper

Power Window

ear Defogger

‘Autonoeus Guidance System ACY)

Inti Pang Asi yates

Forwar Colson Waring Syste

‘ot take Star :

coc Powe Sting (EPS) ystems antes

A bouquet of automotive software and logic burnt on an industry-grade microcontroller! This is

essentially what we term as an Electronic Control Unit (ECU). And this of course, is easier said than

done.

But do note that an Electronic Control Unit (ECU) is at the heart of Automotive Electronics. In the

1970's, Electronics in general made its present felt in our lives. And automotive industry was one of

its early adopters and beneficiaries.

Back then, the first Automotive ECU was built to control the engine. It was called the Engine Control

Unit.

Volkswagen, as many would guess, was the first OEM to deploy an ECU (Control Unit) in a vehicle.

Fast forward to 2019, Electronic Control Modules now control almost every aspect of a vehicle; viz;

Engine, Transmission, Braking, Body Control and what not.

Our Expertise in Electronic Control Module Development

For more than a decade, our automotive experts have witnessed how an Electronic Control Unit has

grown into a smart and complex system. They have also developed in-depth expertise in their ability

to understand and achieve the necessary compliance with standards like ISO 26262 (ASIL B/ ASIL C/

ASIL D), AUTOSAR, MISRA C and more.

Our automotive control unit development services are therefore, aligned to such standards and

growing needs of industry.

Delivering quality ECU software and hardware development services to customers, have led to our

team's expertise in several ECU applications such as:

= Seating Control ECU

= Body Control Module

= Adaptive Lighting Control

= HVAC Systems

= Infotainment Systems and Instrument Clusters

= Electronic Power Steering

= Transmission Control Unit

= Powertrain Control Unit

We focus in delivering three major value-adds, while partnering with our customers for an ECU

development project:

* Cost-Effectiveness- Achieved through reusable in-vehicle networking

and vehicle diagnostics stacks such CAN FD, UDS, DoIP, Bootloader,

OBD-II, J1939 and others

* Compliance for ASIL B/ ASIL C/ ASIL D as per the requirement- Achieved

through in-house Functional Safety Experts/Consultants expertise in ISO

26262 certified tools like CANTATA

* Reduced Time-to-market- We follow the Model Based Development

approach to auto-generate code from models. It reduces turn-around

time and enhances accuracy of the application. The reusable stacks and

expertise in various tools such as CANTATA, RTRT, IAR Embedded

WorkBench, Vflash, MATLAB/Simulink, ORCAD, Hyperlynx and more

Block Diagram of an EV Body Control Module ECU

fone

Automotive ECU Development Services

BB Automotive ECU Hardware & Firmware Development

1SO 26262 compliant h/w and s/w development.

+ Board Support Package design and development.

Device driver development.

In-vehicle networking protocol stacks, middleware and application development.

BLDC and PMSM motors, sensors and actuator integration.

¥3 AUTOSAR 4.0 compliant ECU software development

AUTOSAR RTE, BSW and COM stack configuration and integration

» AUTOSAR MCAL development.

Communication & I/O Drivers development.

Tools expertise: Comasso, Vector , ECU Spectrum, KSAR AUTOSAR.

DaVinci Developer tool for architecture design.

EB Model-based development of Automotive ECU product

+ MATLAB/Simulink and auto code generation (Target Link and RTW).

+ ECU Testing

Unit, Integration and Functional testing services

+ Model in loop (MIL testing)

Hardware in Loop (HIL testing)

4. [ERPs eee ne)

+ ASILB, ASILC, and ASIL D compliant automotive control unit development

+ Support for Hazard Analysis and Risk Assessment (HARA) and Failure Modes &

Effect Analysis (FMEA)

+ Gap Analysis, Safety Assessment and Functional Safety Workflow of existing ECU

solutions

* Hardware Architectural Metrics (SPFM, LFM & PMHF) derivation using FMEDA

method

EW In-Vehicle Networking & Vehicle Diagnostics Services

+ Unit testing (white box), integration testing, functional testing, MIL and HIL testing

+ Project experience in CAN (ISO 11898), LIN (SAE J2602), FlexRay, MOST

+ Integration, configuration and customization of UDS (ISO 14229), J1939, KWP2000,

ISOBUS, OBD2

+ Integration of 3rd party automotive stacks

CONNECT WITH U:

INDIA :+91 80 41694200 USA : +1-248-385-2017

GERMANY: +49 711-60 17 47-789 UK: +49 170 1688028

EMAIL : sales@embitel.com

Get in touch with our Team:

‘Aneesh Adkadkam Ratish Bhatt Kuldeep Singh

‘BU Head - Automotive Business Manager- Business Manager-Automotive (Europe)

‘sales@embitel.com ‘Automotive (North America) Kuldeep s@embiteLcom

‘atish.bhat@embitel.com

CMMIDEV/3"

yan

Iso 26262

No

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Communication Register Map of EN8400Document5 pagesCommunication Register Map of EN8400NM GroupNo ratings yet

- Widgets in TheioxDocument11 pagesWidgets in TheioxNM GroupNo ratings yet

- WWW Scribd Com Document 457144453 Diagnostic Cods Nem For Problem 1 1 PDFDocument20 pagesWWW Scribd Com Document 457144453 Diagnostic Cods Nem For Problem 1 1 PDFNM GroupNo ratings yet

- User Manual - GW3KDocument17 pagesUser Manual - GW3KNM GroupNo ratings yet

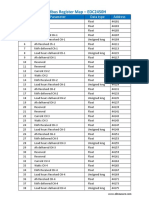

- Modbus Register Map-EDC2450HDocument2 pagesModbus Register Map-EDC2450HNM GroupNo ratings yet

- Arr Return DCDocument1 pageArr Return DCNM GroupNo ratings yet

- 27 27t Auto, 225autoDocument4 pages27 27t Auto, 225autoNM GroupNo ratings yet

- BleRaw Log 17-01-2022Document4 pagesBleRaw Log 17-01-2022NM GroupNo ratings yet

- AR Invoice - 222324747 - 20220924 - 190005Document2 pagesAR Invoice - 222324747 - 20220924 - 190005NM GroupNo ratings yet

- ElnetppsDocument1 pageElnetppsNM GroupNo ratings yet

- 2023 01 03 - 073427673760 Cash InvoiceDocument1 page2023 01 03 - 073427673760 Cash InvoiceNM GroupNo ratings yet

- User Manual - ELNet - PPS - AppDocument12 pagesUser Manual - ELNet - PPS - AppNM GroupNo ratings yet

- NPCIL Recruitment 2022 For 225 Executive Trainee PostsDocument17 pagesNPCIL Recruitment 2022 For 225 Executive Trainee PostsNM GroupNo ratings yet

- Paytm Prepaid PaymentsDocument11 pagesPaytm Prepaid PaymentsNM GroupNo ratings yet

- BS IV Common Rail SystemDocument151 pagesBS IV Common Rail SystemNM GroupNo ratings yet

- 16logical Prog. FunctionDocument9 pages16logical Prog. FunctionNM GroupNo ratings yet

- TT Release News 2.8.121Document3 pagesTT Release News 2.8.121NM GroupNo ratings yet

- ELNet EV Charging ManualDocument12 pagesELNet EV Charging ManualNM GroupNo ratings yet

- Nexas: Nexlink Nl102Plus User ManualDocument24 pagesNexas: Nexlink Nl102Plus User ManualNM GroupNo ratings yet

- Status of Regular Manpower in NIELIT Headquarters As On 26-11-2020Document3 pagesStatus of Regular Manpower in NIELIT Headquarters As On 26-11-2020NM GroupNo ratings yet

- Automotive Software and Electronics 2030 FinalDocument48 pagesAutomotive Software and Electronics 2030 FinalNM GroupNo ratings yet

- AdvtDocument9 pagesAdvtNM GroupNo ratings yet

- Date:-24 March, 2021Document2 pagesDate:-24 March, 2021NM GroupNo ratings yet

- User Manual-PM - PE5120Document47 pagesUser Manual-PM - PE5120NM Group50% (2)

- 002 Annexure 7 Power Point Presentation On Kvah BillingDocument14 pages002 Annexure 7 Power Point Presentation On Kvah BillingNM GroupNo ratings yet

- ME Admissions ScheduleDocument1 pageME Admissions ScheduleNM GroupNo ratings yet