Professional Documents

Culture Documents

Cat Faa Ii-Iii R0

Cat Faa Ii-Iii R0

Uploaded by

FRANCISCO CINTORA COTAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cat Faa Ii-Iii R0

Cat Faa Ii-Iii R0

Uploaded by

FRANCISCO CINTORA COTACopyright:

Available Formats

CAT II/III Maintenance Program Manual

ORIGINAL

Aeropuerto Internacional de Toluca, Estado de México .

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: I

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

FORMAL REVISIONS RECORD

Rev.

Revision Date Insertion Date Inserted by

No.

Original APR/13/09

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: I

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

Intentionally Left in Blank

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: I

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -3-

UPDATING AND APPROVAL CONTROL TABLE

Revision Revision

Approval Date Principal Maintenance Inspector FAA

No. Date

ORIGINAL APR/13/09

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: I

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -4-

Intentionally Left in Blank

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: I

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -5-

TEMPORARY REVISIONS RECORD

Airbus A319 VOI-RRT-124

* Note: Prior to the removal of any temporary revision from the binder, the Technical Publications Engineer

must ensure that it has been incorporated into the new issue revision of the manual received. Then the

recipient will enter the revision superseding each Temporary Revision, the date of removal and his/her

name.

Superseded

Temporary

Issue Insertion by* revision Removal Removed *

Revision Inserted by Pages

date Date No. Date * by

No.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: I

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -6-

Intentionally Left in Blank

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: II

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL

PAGE: -1-

LIST OF EFFECTIVE PAGES

DESCRIPTION PAGE No. REVISION REVISION DATE

SECTION I I-1 ORIGINAL Apr/13/09

I-2 ORIGINAL Apr/13/09

I-3 ORIGINAL Apr/13/09

I-4 ORIGINAL Apr/13/09

I-5 ORIGINAL Apr/13/09

I-6 ORIGINAL Apr/13/09

SECTION II II-1 ORIGINAL Apr/13/09

II-2 ORIGINAL Apr/13/09

SECTION III III-1 ORIGINAL Apr/13/09

III-2 ORIGINAL Apr/13/09

SECTION IV IV-1 ORIGINAL Apr/13/09

IV-2 ORIGINAL Apr/13/09

SECTION 1 01.00-1 ORIGINAL Apr/13/09

01.00-2 ORIGINAL Apr/13/09

SECTION 2 02.00-1 ORIGINAL Apr/13/09

02.00-2 ORIGINAL Apr/13/09

SECTION 3 03.00-1 ORIGINAL Apr/13/09

03.00-2 ORIGINAL Apr/13/09

SECTION 4 04.00-1 ORIGINAL Apr/13/09

04.00-2 ORIGINAL Apr/13/09

SECTION 5 05.00-1 ORIGINAL Apr/13/09

05.00-2 ORIGINAL Apr/13/09

05.00-3 ORIGINAL Apr/13/09

05.00-4 ORIGINAL Apr/13/09

SECTION 6 06.00-1 ORIGINAL Apr/13/09

06.00-2 ORIGINAL Apr/13/09

SECTION 7 07.00-1 ORIGINAL Apr/13/09

07.00-2 ORIGINAL Apr/13/09

07.00-3 ORIGINAL Apr/13/09

07.00-4 ORIGINAL Apr/13/09

SECTION 8 08.00-1 ORIGINAL Apr/13/09

08.00-2 ORIGINAL Apr/13/09

08.00-3 ORIGINAL Apr/13/09

08.00-4 ORIGINAL Apr/13/09

SECTION 9 09.00-1 ORIGINAL Apr/13/09

09.00-2 ORIGINAL Apr/13/09

SECTION 10 10.00-1 ORIGINAL Apr/13/09

10.00-2 ORIGINAL Apr/13/09

SECTION 11 11.00-1 ORIGINAL Apr/13/09

11.00-2 ORIGINAL Apr/13/09

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: II

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL

PAGE: -2-

LIST OF EFFECTIVE PAGES

DESCRIPTION PAGE No. REVISION REVISION DATE

SECTION 12 12.00-1 ORIGINAL Apr/13/09

12.00-2 ORIGINAL Apr/13/09

SECTION 13 13.00-1 ORIGINAL Apr/13/09

13.00-2 ORIGINAL Apr/13/09

SECTION 14 14.00-1 ORIGINAL Apr/13/09

14.00-2 ORIGINAL Apr/13/09

SECTION 15 15.00-1 ORIGINAL Apr/13/09

15.00-2 ORIGINAL Apr/13/09

SECTION 16 16.00-1 ORIGINAL Apr/13/09

16.00-2 ORIGINAL Apr/13/09

SECTION 17 17.00-1 ORIGINAL Apr/13/09

17.00-2 ORIGINAL Apr/13/09

SECTION 18 18.00-1 ORIGINAL Apr/13/09

18.00-2 ORIGINAL Apr/13/09

18.00-3 ORIGINAL Apr/13/09

18.00-4 ORIGINAL Apr/13/09

18.00-5 ORIGINAL Apr/13/09

18.00-6 ORIGINAL Apr/13/09

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: III

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

CONTENTS

DESCRIPTION SECTION

FORMATS REVISIONS RECORD I

LIST OF EFFECTIVE PAGES II

CONTENTS III

ACRONYMS IV

GENERAL INFORMATION 01

IDENTIFICATION OF OPERATOR AND AIRCRAFT(S) 02

PERSON RESPONSIBLE FOR THE REVISION OF THIS 03

MANUAL

PROCEDURE TO REVISE THE MANUAL 04

MAINTENANCE PROCEDURES FOR ENSURE

CONTINUED AIRWORTHINESS RELATIVE TO THE 05

CAT II/III OPERATIONS.

PERSONNEL ASSIGNED TO MAINTENANCE 06

IN THE CAT II/III SYSTEMS.

CAT II/III REQUIRED COMPONENTS IDENTIFICATION 07

PERIODIC VERIFICATION OF THE CAT II/III SYSTEMS 08

PROGRAM.

IDENTIFICATION OF DISCREPANCIES 09

IN THE CAT II/III SYSTEMS.

REPORT OF DISCREPANCIES IN THE 10

CAT II/III SYSTEMS

IDENTIFICATION OF THE REPETITIVE 11

DISCREPANCIES FOR CAT II/III SYSTEMS.

TEST TO AFTER PERFORMED WORKS 12

IN THE CAT II/III SYSTEMS.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: III

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

CONTENTS (Cont.)

DESCRIPTION SECTION

REMOTION OF THE STICKER FORMAT VOI-CCS-134 13

CONTINUES MONITORING OF THE CAT II/III 14

OPERATIONS FOR PURPOSE OF QUALITY CONTROL.

PERIODIC AIRCRAFT EVALUATION IN THE 15

CAT II/III SYSTEM.

TEST EQUIPMENT/CALIBRATION STANDARDS. 16

INITIAL AND RECURRENT MAINTENANCE TRAINING. 17

FORMS 18

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: IV

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

Acronyms

A/C Aircraft Maintenance Manual

ACARS Aircraft Communication Addressing and Reporting System

AD Airworthiness Directive

ADIRU Air Data & Inertial Reference Unit

AFM Aircraft Flight Manual

AMM Aircraft Maintenance Manual

APU Auxiliary Power Unit

ATA Air Transport Association

ATC Air Traffic Control

ASB Alert Service Bulletin

BITE Built in test equipment

BSCU Brakes and Steering Control Unit

CAT Category

CFDIU Centralized Fault Display Interface Unit

CFR Code of Federal Regulations

DMC Display Management Computer

EACM Electronic Flight Instrument System

EIS Electronic Instrument System

ELAC Elevator Aileron Computer

FAA Federal Aviation Administration

FAC Flight Augmentation Computer

FAR FAA Regulations

FCU Flight Control Unit

FMGC Flight Management and Guidance Computer

FSDO Flight Standards District Offices

FWC Flight Warning Computer

GDL Guadalajara Station

GMM General Maintenance Manual

GND Ground

JAA Joint Aviation Authorities

MCC Maintenance Control Center

MCDU Multipurpose Control and Display Units

MPD Maintenance Planning Data

MMR Multi Mode Receiver

MRBR Maintenance Review Board Report

ND Navigation Display

OCC Operational Control Center

PFD Primary Flight Display

PMI Principal Maintenance Inspectors

PAI Principal Avionics Inspector

RA Radio Altimeter Transmitter/Receiver

SB Service Bulletin

SDAC System Data Acquisition Concentrator

VOR/MKR Very High Frequency Omnibearing Range/Marker Beacon

e.g. Example Given

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: IV

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

Intentionally Left in Blank

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 01.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

1. General information.

This Maintenance Program is developed by Volaris in order maintain the capability for

the aircraft systems related to CAT II/III Weather Minima for Take Off, Landing, and

Rollout operations for the Volaris fleet.

The purpose of this CAT II/III maintenance program is maintain and ensure total

system performance, accuracy, availability, reliability, and integrity for the operations

on CAT II / III in accordance with the Maintenance Program Document (by Airbus),

Maintenance Program (by Volaris), Manufactures Requirements (Service Bulletin) and

authority requirements ( Normative, AD’s, etc).

The training program of Volaris assures that all Maintenance personnel who perform

work on the aircraft are familiarized with the procedure defined in this CAT II/III

Maintenance Program Manual.

Copies of this manual must are distributed in to the principal base and onboard of each

aircraft as specified in the section 4 and in the table 4.1 of this manual.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 01.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

Intentionally Left in Blank

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 02.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

2. Identification of Operator and Aircraft(s)

The aim of this manual is to ensure that the Volaris aircraft approved for Category II

and Category III operations will be maintained within current FAA regulations and to

specifications required for Cat II /III operation.

Volaris operate with aircraft Airbus model A319 and A320. The A319 aircraft with a

single coach class seating configuration 138 or 144 seats, and the A320 aircraft with a

single coach configuration 174 seats.

Volaris operates, the following Airbus Aircraft (see Table 2.1):

TABLE 2.1 VOLARIS FLEET

No. REGISTER MSN TYPE

1 N473TA 1140 A319-132

2 N474TA 1159 A319-132

7 N501VL 2979 A319-133

16 N502VL 3463 A319-132

17 N503VL 3491 A319-132

18 N504VL 3590 A319-132

These are operated in accordance with 14 CFR Part 91 and maintained in accordance

with 14 CFR Part 43, 14 CFR 91.189 and 91.191, and 14 CRF 129 and 129.14

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 02.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

Intentionally Left in Blank

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 03.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

3. Person responsible for the revision of this Manual.

In Volaris, the Engineering Manager is responsible for ensuring that the aircraft

included in this program (see Table 2.1) are maintained in compliance with the

maintenance requirements of this continuous airworthiness maintenance program.

Additionally, the Technical Publications Engineer (see GMM section 2.14 for duties and

responsibilities of the Technical Publications Engineer) is responsible for distribution,

control and revision of this manual.

Volaris Engineering Manager is responsible for maintaining this manual on updated

condition.

Revised material will be marked by a vertical line in a left hand margin. All Revision will

be promptly provided to the FAA PMI or PAI for review and approval. Upon approval,

the Technical Publications Engineer will produce sufficient copies for all manual

holders. A list of effective pages will be provided with each revision therefore the

manual holder can ensure update condition of it.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 03.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

Intentionally Left in Blank

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 04.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

4. Procedure to Revise the Manual.

The FAA will send a letter of approval of this CAT II/III Maintenance Program Manual to

Volaris and this letter must be inserted on the cover page of this manual. As revisions

to this manual are required, Engineering Manager, or his designee will submit the

proposed revision to the PMI assigned inspector to Volaris on the FAA Dallas Fort

Worth International Field Office (DFW IFO), for review and approval consideration.

After approval, Engineering Manager through Technical Publications Engineer will

ensure that each authorized holder of this manual receives and inserts the revision

within 10 business days from the date of approval.

Once CAT II/III Maintenance Program Manual revision has been approved by the FAA,

the Technical Publications Engineer is responsible for the distribution of all revisions to

this manual.

Copies of all revisions and amendments of this manual are distribute to specific

furnished persons and departments. Each person (Manager, Chief, and Supervisor)

who retains a copy of this manual shall be responsible for the insertion of revised

pages and for the destruction of obsolete information.

For the copies designated for the Aircraft, the Technical Publications Engineer will send

a digital copy of this manual to Volaris Engineering Operations Department and they

will be responsible to update this manual on the T-book (laptop) that is onboard of the

A/C for consult purpose.

In case that an extra copy is required (other than the controlled copies) for a specific

purpose, the words “REFERENCE ONLY” must be stamped on the first or front page

and the manual shall be identified as a “Non – Controlled Copy”.

Each copy of this manual will have an assigned control number on the cover sheet,

beginning with the letters “VOI-CATII/III” followed by a consecutive number. The

Technical Publications Engineer will keep a master list of the assigned control number

delivered to each manual holder. The same case will apply when a copy of this manual

is required for contract maintenance vendor.

The following table (Table 4.1) shows a list of the “Controlled Copies” distribution of the

CAT II/III Maintenance Program Manual.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 04.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

TABLE 4.1CAT II/III Maintenance Program Manual Distribution.

No. Area Control No. Number of copies

1 Technical Director VOI-CATII/III-001 1 hard copy and 1 digital copy

2 FAA DFW-IFO PMI VOI-CATII/III-002 1 hard copy and 1 digital copy

3 Quality Assurance Chief VOI-CATII/III-003 1 hard copy and 1 digital copy

4 Operations Manager VOI-CATII/III-004 1 hard copy and 1 digital copy

Engineering and Maintenance

5 VOI-CATII/III-005 1 hard copy and 1 digital copy

Manager

6 Operations Engineering Chief VOI-CATII/III-006 1 hard copy and 1 digital copy

7 Maintenance Chief VOI-CATII/III-007 1 hard copy and 1 digital copy

8 Quality Control Chief VOI-CATII/III-008 1 hard copy and 1 digital copy

9 Stockroom Chief VOI-CATII/III-009 1 hard copy and 1 digital copy

10 Engineering Chief VOI-CATII/III-010 1 hard copy and 1 digital copy

11 Technical Publications Engineer VOI-CATII/III-011 1 hard copy and 1 digital copy

12 MCC VOI-CATII/III-012 1 hard copy and 1 digital copy

13 Reliability Engineer VOI-CATII/III-013 1 hard copy and 1 digital copy

14 CUN station VOI-CATII/III-014 1 digital copy

15 GDL station VOI-CATII/III-015 1 digital copy

16 MTY station VOI-CATII/III-016 1 digital copy

17 TIJ station VOI-CATII/III-017 1 digital copy

18 N474TA VOI-CATII/III-018 1 digital copy

19 N473TA VOI-CATII/III-019 1 digital copy

20 N501VL VOI-CATII/III-020 1 digital copy

21 N502VL VOI-CATII/III-021 1 digital copy

22 N503VL VOI-CATII/III-022 1 digital copy

23 N504VL VOI-CATII/III-023 1 digital copy

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 05.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

5. Maintenance Procedures for ensure continued airworthiness relative to the

CAT II/III operations.

To ensure the continued airworthiness on the CAT II/III operations, Volaris apply a

continued program for maintenance based in the MPD and other requirements for the

authority and the manufacture of the aircraft.

The manufacture establish in the Maintenance Planning Document (MPD), in the

section 2 paragraph c, see figure 5.1, and with Maintenance Review Board Report

(MRBR) in the section A paragraph k, see figure 5.2, (both documents issued by

Airbus), that the Category II/III landing capabilities are inherent functions of the basic

design standard of the aircraft and scheduled tasks necessary for these operations

have been considered in the development of the MPD.

Others requirements for continued airworthiness of the Category II/III systems issued

by the authority or by the manufacture of the aircraft (e. g. AD’s, Service Bulletin,

Vendor recommendations, etc) will be controlled as specified on the General

Maintenance Manual (section 5) and in the case that will be necessary a revision of this

manual will be done.

In order to ensure the integrity of all CAT II/III systems, all Volaris maintenance

program tasks it should be identified as CAT II/III maintenance task by planning

department.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 05.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

Figure 5.1Copy of the section 2 paragraph c from the MPD

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 05.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -3-

Figure 5.2 Copy of the section A paragraph k from the MRBR

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 05.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -4-

Intentionally Left in Blank

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 06.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

6. Personnel assigned to Maintenance in the CAT II/III systems.

The maintenance jobs for CAT II/III systems may be performed only by trained and

qualified Volaris or contracted personnel.

The duties and responsibilities for the Volaris maintenance personnel are including in

the General Maintenance Manual (see Section 2 of the GMM) and include all the

Volaris maintenance personnel involved with the maintenance of aircraft systems and

components.

All maintenance jobs performed on the Volaris A/C´s is responsibility of Volaris

including all jobs performed by the subcontracted personnel

The General Maintenance Manual (GMM) defined the criteria adopted by Volaris with

respect to the Contracted Maintenance policies (see section 5.19 of GMM).

All maintenance personnel (own and subcontracted) should have adequate training

with respect to the procedures established in the General Maintenance Manual and in

the training program defined in this CAT II/III Maintenance Manual (see section 17 of

this manual).

The Volaris and subcontracted maintenance personnel must have a training record in

accordance with the section 11.03 of the General Maintenance Manual and the section

17 of this manual.

Only these qualified personnel can perform works in the CAT II/III systems for the

Volaris Fleet and these personnel should identified whit the sticker stamp format VOI-

CIS-173.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 06.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

Intentionally Left in Blank

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 07.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

7. CAT II/III required components identification.

For Volaris Fleet the capability to make operations based on CAT II/III procedures is

determinated for the systems installed on the aircraft.

The Aircraft systems associated with CAT II/III operations are indicated on the next

Table:

Table 7.1 CAT II/III Associated Aircraft

System

SYSTEM DESCRIPTION ATA CODE

AUTO FLIGHT 22

FLIGHT CONTROLS 27

HYDRAULIC POWER 29

ICE AND RAIN PROTECTION 30

INDICATING/RECORDING

31

SYSTEMS

LANDING GEAR 32

NAVIGATION 34

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 07.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

The Minimum Equipment required for the CAT II/III operations are established by

Airbus in the Aircraft Flight Manual (AFM) in the section 4.03.00 page P8.

One list of the Minimum Equipment Required by Volaris Fleet is showed in the follow

table:

Table 7.2 Minimum Equipment Required for CAT II/III

Component Description Quantity ATA

Flight Management and Guidance

FMGC 2 22

Computer

FCU Flight Control Unit 1 22

ADIRU Air Data & Inertial Reference Unit 3 34

MMR Multi Mode Receiver 2 34

Antenna G/S Antenna Glide Slope 1 34

Antenna LOC Antenna Localizer 1 34

RA Radio Altimeter Transmitter/Receiver 2 34

Antenna RA Antenna of Radio Altimeter/RX & TX 2 34

ELAC Elevator Aileron Computer 2 27

FAC Flight Augmentation Computer 2 27

SDAC System Data Acquisition Concentrator 2 31

FWC Flight Warning Computer 2 31

CFDIU Centralized Fault Display Interface Unit 1 31

MCDU Multipurpose Control & Display Unit 2 22

DMC Display Management Unit 3 31

PFD Primary Flight Display 2 31

ND Navigation Display 2 31

Very High Frequency Omnibearing

VOR/MKR 2 34

Range/Marker Beacon

VOR Antenna Antenna VOR 2 34

MKR Antenna Antenna MKR 1 34

BSCU Brakes and Steering Control Unit 2 32

Actuator-Rudder Trim 1 27

Limitation Unit-Rudder Travel 1 27

Servo Actr-Yaw Damper 2 27

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 07.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -3-

The next is a list of the components associated with the Minimum Equipment

required.

Table 7.3 Components associated whit the CAT II/III systems

Minimum Equipment List Required Associated Components

AP/FD FMGC

AP disconnect P/B FCU

AUTOTHRUST FMGC

ILS RECEIVER MMR, G/S Antenna, LOC Antenna

Attitude Indication ADIRU,PFD/ND,DMC

PFD/ND PFD/ND, DMC

Radio Altimeter RA, RA Antenna

Auto Call Out Radio Altimeter FWC

DH Indication FWC, RA

FWC FWC

"AP OFF" warning FWC

"AUTOLAND" Light FWC

Rain Repellent (If activated) or Rain Repellent (If activated) or

Windshield wipers Windshield Wipers

Windshield Heat Windshield Heat

Nosewheel Steering Nosewheel Steering

Anti –Skid Anti -Skid

BSCU Channel BSCU

Beam Excessive Deviation MMR

FMA FMGC, DMC, PFD

"A/THR OFF" caution FWC

Rudder Travel Limit Rudder Travel Limit

Yaw-Damper/Rudder Trim Yaw-Damper/Rudder Trim

ELAC ELAC

ADR/IR ADIRU

FAC FAC

Hydraulic Circuit Hydraulic System

FMGC Electrical Supply Split FMGC

This systems and component are associated with the customized Minimum Equipment

List (MEL by Volaris) to ensure the safety of the operations.

The Minimum Equipment list is a FAA approved document.

The capability for the CAT II/III operations of the Volaris fleet is directly affected for any

failure discrepancies on the systems and components mentioned.

The procedure to troubleshoot any of the CAT II/III systems or associated components

is described in the section 10 of this manual.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 07.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -4-

7.1 Component program for CAT II/III systems.

The policy and procedures for Receiving, Rejected, Storing, Storage, Quarantine, and

Shipping of components is defined on the Section 9 of the GMM.

The components will be receiving by the stockroom as is mentioned on Section 9 of the

GMM, all corresponding documentation for the components are including on section 9

of GMM.

Additional of the procedure described on the Section 9 of the GMM, once the

components have been received and identified as CATII/III component (See table 7.2)

by Quality Control personnel the component must be identified with the sticker format

VOI-CAT-171 (see chapter 18.2 of this manual).

CAT II/III

VOI-CAT-171

Once the component CATII/III has been identified, the quality control personnel will

send the component to the stock room for its respective storage.

For the correct manage of the CATII/III components it is important consider that all

CATII/III components must be identified by the sticker format VOI-CAT-171.

The procedure for dispatch and reception is the same for all components and is defined

in the section 9.18 of the GMM.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 08.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

8. Periodic Verification of the CAT II/III Systems Program.

As indicated in the General Maintenance Manual in the section 05.01 (Airframe,

powerplant and Accessories Maintenance) the volaris Maintenance Program is based

on the requirements of the Maintenance Planning Document (MPD).

The MPD establishing in the section 2 paragraph c, that the Category II/III landing

capabilities are inherent functions of the basic design standard of the aircraft and

scheduled tasks necessary for these operations have been considered in the

development of this MPD.

The next list shows the task concerning to the Category II/III operations systems and is

based in the volaris Maintenance Program:

Table 1.0 MAINTENANCE PROGRAM BY CAT II / III

TASK 100% AIRCRAFT

DESCRIPTION

NUMBER INTERVAL APPLICABILITY

221000-01-1 AUTO PILOT/FLIGHT DIRECTOR (AP/FD)

OPERATIONAL CHECK OF AP DISENGAGEMENT AND 12000 FH

LOCKING DEVICES OF SIDE STICK CONTROLLER AND OR ALL

RUDDER PEDALS. 80 MO

CAT II / III

223000-01-1 AUTOTHRUST

18000 FH

OPERATIONAL CHECK OF ENGINE/AUTOTHRUST SYSTEM

OR ALL

ISOLATION.

10 YE

CAT II / III

226000-01-1 FLIGHT AUGMENTATION (FAC)

600 FH

OPERATIONAL CHECK OF AUTOMATIC CHANGEOVER

OR ALL

(AFS TEST).

6 MO

CAT II / III

226000-02-1 FLIGHT AUGMENTATION (FAC)

6000 FH

OPERATIONAL CHECK OF FAC 2 FUNCTIONS OR ALL

40 MO

CAT II / III

226000-03-1 FLIGHT AUGMENTATION (FAC)

6000 FH

OPERATIONAL CHECK OF "RETURN TO LOWSPEED"

OR ALL

FUNCTION

40 MO

CAT II / III

272100-04-1 RUDDER MECHANICAL CONTROL

24000 FH

REMOVE YAW DAMPER SPRING ROD FOR WORKSHOP

OR ALL

CHECK

13 YE

CAT II / III

272100-08-1 RUDDER MECHANICAL CONTROL

LUBRICATION OF RUDDER PEDAL ADJUSTMENT

20 MO ALL

MECHANISM

CAT II / III

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 08.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

272145-01-1 RUDDER CABLE TENSION REGULATOR

11000 FH

CHECK TENSION REGULATOR POINTER IS WITHIN THE

OR ALL

LIMITS

73 MO

CAT II / III

272400-01-1 RUDDER HYDRAULIC ACTUATION

600 FH

OPERATIONAL CHECK OF RUDDER SERVOCONTROLS

OR ALL

WITH INDIVIDUAL HYDRAULIC SYSTEMS

4 MO

CAT II / III

272400-02-1 RUDDER HYDRAULIC ACTUATION

18000 FH

CHECK RUDDER SERVOCONTROL AND HINGE BEARINGS

OR ALL

FOR EXCESSIVE PLAY AND CONDITION

10 YE

CAT II / III

272400-03-1 RUDDER HYDRAULIC ACTUATION

5500 FH

LUBRICATION OF RUDDER HINGE BEARING NO 6 WITH

OR ALL

GREASE MAT. NO. 04-004

15 MO

CAT II / III

275117-01-1 FLAP/SLAT COMMAND SENSOR UNIT

REMOVE CSU FOR WORKSHOP CHECK OF FRICTION

40 MO ALL

BRAKE

CAT II / III

279000-01-1 ELECTRICAL FLIGHT CONTROL SYSTEM

12000 FH

OPERATIONAL CHECK OF COMPUTERS

OR ALL

ENGAGEMENT/DISENGAGEMENT

80 MO

CAT II / III

279000-05-1 ELECTRICAL FLIGHT CONTROL SYSTEM

OPERATIONAL CHECK :

- OF LOGICS ACTIVATING ELAC 1, ELAC 2, AND SEC.1

STANDBY POWER SUPPLIES. 400 FH

- TO CONFIRM ABILITY OF SEC.1 AND SEC.2 TO ACHIEVE OR ALL

PITCH CONTROL 80 DY

- TO CONFIRM ABILITY OF SIDESTICK PRIORITY

FUNCTION

CAT II / III

315000-01-1 CENTRAL WARNING SYSTEMS/ELECTRONIC

INSTRUMENT SYSTEM (EIS)

6000 FH

OPERATIONAL CHECK OF CORRECT OPERATION OF PFD- OR ALL

ND AND ECAM-ND MANUAL TRANSFER 40 MO

CAT II / III

315000-02-1 CENTRAL WARNING SYSTEMS/ELECTRONIC

INSTRUMENT SYSTEM (EIS)

6000 FH

OPERATIONAL CHECK OF CORRECT OPERATION OF EFIS

OR ALL

AND ECAM DMC AUTOMATIC AND MANUAL TRANSFER

40 MO

CAT II / III

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 08.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -3-

315000-03-1 CENTRAL WARNING SYSTEMS/ELECTRONIC

INSTRUMENT SYSTEM (EIS)

6000 FH

OPERATIONAL CHECK OF BRIGHTNESS CONTROL OR ALL

THROUGH MCDU. 40 MO

CAT II / III

315000-04-1 CENTRAL WARNING SYSTEMS/ELECTRONIC

INSTRUMENT SYSTEM (EIS)

6000 FH

OPERATIONAL CHECK OF DMC3 POWER SUPPLY OR ALL

TRANSFER WHEN BUSBAR 101XP IS LOST. 40 MO

CAT II / III

341300-01-1 AIR DATA

OPERATIONAL CHECK OF OVERSPEED WARNING 12000 FH

OR ALL

VMO/MMO USING CFDS.

80 MO

RVSM AND CAT II / III

341300-02-1 AIR DATA

12000 FH

OPERATIONAL CHECK OF AIR DATA SWITCHING

OR ALL

FUNCTION.

80 MO

RVSM AND CAT II / III

341300-03-1 AIR DATA

OPERATIONAL CHECK OF OVERSPEED WARNINGS 12000 FH

VFE/VLE USING CFDS. OR ALL

80 MO

RVSM AND CAT II / III

341300-04-1 AIR DATA

6000 FH

OPERATIONAL CHECK OF ALTITUDE COMPARISON

OR ALL

WARNING.

40 MO

RVSM AND CAT II / III

341300-05-1 AIR DATA

OPERATIONAL CHECK OF THE 5-MINUTE TIME DELAY OF 12000 FH

ADIRU 2 AND 3 POWER DISCONNECTION IN EMERGENCY OR ALL

CONFIGURATION. 80 MO

RVSM AND CAT II / III

341300-07-1 AIR DATA

12000 FH

FLUSHING OF TOTAL PRESSURE LINES OR ALL

80 MO

RVSM AND CAT II / III

341400-01-1 ATTITUDE, HEADING AND POSITION

6000 FH

OPERATIONAL CHECK OF ATT/HDG SWITCHING

OR ALL

FUNCTION

40 MO

RVSM AND CAT II / III

341400-02-1 ATTITUDE, HEADING AND POSITION

OPERATIONAL CHECK OF ATTITUDE AND HEADING 6000 FH

COMPARISON WARNING OR ALL

40 MO

RVSM AND CAT II / III

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 08.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -4-

344200-01-1 RADIO ALTIMETER

OPERATIONAL CHECK AND DETAILED INSPECTION FOR

CONTAMINATION OF RADIO ALTIMETER FAN 6000 FH

OR

ALL

NOTE: DEPENDING ON OPERATING ENVIRONMENT & 40 MO

OPERATOR´S EXPERIENCE, A HIGHER INITIAL INTERVAL NOTE

MAY BE USED.

RVSM AND CAT II / III

E. O. AUTO FLIGHT MANAGEMENT AND GUIDANCE

VA-22-0005 RO AFS TEST & LAND III CAPABILITY TEST TO OUTPUT THE

6000 ALL

AIRCRAFT ON THE CAT II/III CONDITIONS AFTER “C”

CHECK.

Other elements may affect the capability of operation on CAT II/III (e. g., AD’s, Service

Bulletins, Vendor recommendations, or other), these elements has been evaluated and

analyzed by the procedure described in the GMM section 5, and if is required any

particular case will be included in this CAT II/III Program Manual.

NOTE: If any of the periodic task schedule show any failure in the CAT II/III

systems is necessary to apply the procedure described in the section 9 and

section 10 of this Manual.

All the tasks that have been performed on the CAT II/III systems are controlled in the

computerized system called Airsoft as indicated in the GMM section 5.02. These task

and procedures will be programmed based in the MPD, EO, SB Alerts , AD, aircraft

parts on stock, tool calibration control, shelf life control, task cards, inspections, cards,

hard time components, flight time and cycles, deferred items control, etc.

Engineering, Maintenance, Quality Control, Stockroom and other Departments will only

have system access to consult their respective needs. The access is controlled by user

name and requires a password to avoid tampering with the main databases.

Planning, Control and Records Engineer will be responsible to enter and update the

information into the Airsoft system from various maintenance documents, such as

Flight and Maintenance Logbooks, Engineering Orders, Maintenance Checks,

Airworthiness Directives, Hard Time Components, Work Orders, etc.

Planning, Control and Records Engineer will schedule through the Airsoft system and

its main data base time controls (hours, cycles and days) the accomplishment of

maintenance tasks for CAT II/III (i. e. AD, time control components and parts, aircraft

checks, inspections, etc.) besides, the Planning, Control and Records Engineer will

provide a feedback into the Airsoft system to generate all Work Orders required to

maintain aircraft airworthiness.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 9.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

9. Identification of discrepancies in the CAT II/III systems.

The following parameters provide information for establish the aircraft status for CAT

II/III systems:

• The Post Flight Report: is generates in the aircraft after the engine shut down,

or for the case in that the post flight report is not printer, can be retrieved

through the MCDU, and it is a list of the fault data of the last flight in order to

facilitate maintenance data transmission between the crew and ground

maintenance personnel.

• The Status page: is generated on the Low ECAM (Electronic Centralized

Aircraft Monitor) display and show maintenance data in accordance with the

aircraft status.

• The generated reports on the Maintenance and Flight Logbook form VOI-MFL-

108 on Pilot Report section may be generated by the Pilot in command or by

maintenance technicians.

Before of each flight, the technician should verify the status of the CAT II/III systems

making a check of the “Post Flight Report”, the logbook report entries and all reports

generates in the “STATUS” page on the lower ECAM display.

Note: On the daily and transit check are including the revision of all items above

mentioned.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 9.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

9.1 CAT II/III operational modes for the Volaris fleet.

The CAT II/III operational capabilities are related in the Aircraft Flight Manual as follow:

1) CAT 2

2) CAT 3 SINGLE

3) CAT 3 DUAL

Each related operational capabilities described in AFM is associated with one of the

CAT II/III operations modes related bellow:

1) CAT II Manual Approach.

2) CAT II Automatic Approach.

3) CAT IIIA with Fail Passive Automatic Landing System.

4) CAT IIIA with Fail Operational Automatic Landing System.

5) CAT IIIB with Fail Operational Automatic Landing System.

On the Volaris MEL each operational capabilities is associated with certain CAT II/III

operational modes.

The current most operational mode approved for the Volaris Fleet is to CAT II/IIIA and

this is for the ground facilities installed on Mexican Airports.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 10.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

10. Report of discrepancies in the CAT II/III systems.

Aircraft without reports:

If the aircraft does not indicate a failure message, the aircraft is on condition to perform

landings on full CAT II/III and is not necessary to do any maintenance action by the

technician.

Aircraft with reports:

The technician must perform the next procedure:

• If the aircraft present any failure message or failure report, the technician in

conjunction with the MCC must identify if the failure have an impact in the CAT

II/III systems.

• If the failure is confirmed and have effects on CAT II/III systems or with its

associated components, the technicians in conjunction with the MCC must be

doing a failure analysis.

• The technician must perform all works necessary to return the CAT II/III system

to normal condition for operation in accordance with the maintenance standard

and procedures provides in the Volaris General Maintenance Manual and

Airbus Maintenance Manual.

• When the failure message is corrected before the next flight and are not

required changes of components (e. g. BITE TEST or doing a reset procedure

given on the AMM), the technician should filling the logbook using the normal

GMM procedure and the aircraft will continue in conditions for the CAT II/III

operations.

• When the failure messages is corrected before of the next flight and it has been

required a change of components, the technician must perform the test

established in the section 12 of this manual, additionally he will to accomplish

with all test reference on the AMM corresponding to the specific task in order to

can return the A/C to the normal condition for CAT II/III operations.

• If is not possible the immediately return of the CAT II/III systems to the normal

condition of operation, then the technicians in coordination with Maintenance

Control Center (MCC) must accomplish the Deferred Maintenance Procedure to

establish if the aircraft is in airworthiness condition as is mentioned on GMM

section 5.08.

• If the failure can be deferred the technician must record on the Maintenance

and Flight Logbook form VOI-MFL-108 on the maintenance pilot report

sections: “(M) Operations CAT II/III is restricted”.

• The technician must fill out the form CAT II/IIIA sticker number VOI-CCS-134.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 10.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

• The technician in coordination whit the Maintenance Control Center (MCC)

must record the deferral reference getting of the MEL in the section

“MEL:_________” of the sticker format VOI-CCS-134 (for reference see next

figure).

CAT II/CATIIIA

RESTRICTIONS

MEL:___________

VOI-CCS-134

• The technician must install the sticker (format VOI-CCS-134) in the right side of

the captain displays.

• At same time the MCC must notify the current status for the particular aircraft to

the Operational Control Center (OCC).

• The OCC must take the corresponding actions considering the current condition

of the aircraft.

• The objective of the sticker is to remind to the flight crew that the aircraft have

been downgraded on CAT II/III operations and the Flight crew should follow up

its own procedure with respect to the information recorded on the sticker form

VOI-CCS-134.

• The CAT II/III sticker form VOI-CCS-134 could be adhere to the A/C by any

volaris technician

• The sticker can not be removed for any person unless that the procedure to

remove this sticker has been accomplished (see section 13) but can be change

as indicated in the section 12. This is, only qualified training personnel on CAT

II/III system must remove the sticker or return the A/C to its original

configuration.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 11.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

11. Identification of the repetitive discrepancies for CAT II/III systems.

This procedure is for monitoring the failures messages that appear continuously on the

aircraft.

According with the Volaris Reliability Program there are defined 4 Alerts levels for

repetitive reports.

The Alert level 1:

Is for Identify the repetitive reports remained for 4 days.

Maintenance Control Center

• Monitoring all the report generated in the Volaris Fleet using OPCENTER,

AIRMAN and Logbook reports for identify the repetitive failure message in

the CAT II/III systems.

• Register the repetitive failures messages in the trouble Shooting Format

(see GMM format VOI-TSF-170).

• Analyze all the CAT II/III problems in accordance whit the approved

manufacturer’s manual.

• Programming the corrective actions in coordination with Maintenance Line

with Maintenance Planning for schedule lobs.

• Follow the repetitive message in accordance with the previous taken

corrective action.

• Close all repetitive messages that have been corrected.

For the Alert Level 2:

Is for Identify the repetitive reports remaining during 4 days or any other repetitive

message considered by Reliability area:

Maintenance Control Center

• Follow the repetitive message in accordance with the previous taken

corrective action.

• Programming the next corrective actions in coordination with Maintenance

Line or with Maintenance Planning for schedule lobs.

• If as required coordinate with the engineering area for additional support

• Close all repetitive message that has been corrected

Reliability department

• Monitoring the CAT II/III systems using the OPCENTER and AIRMAN

systems for the case that Alert 1 is not corrected.

• Monitoring of corrective actions taken for MCC.

• If required coordinate with MCC for reopen any repetitive message report.

Engineering department

• If required give support to the MCC for establishes the corrective actions.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 11.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

For the Alert Level 3:

Identify repetitive reports remaining during 8 days or any other repetitive message

considered by Reliability area:

Maintenance Control Center

• Follow the repetitive message in accordance with the previous taken

corrective action.

• Programming the next corrective actions in coordination with Maintenance

Line or with Maintenance Planning for schedule lobs.

• Close all repetitive messages that has been corrected.

Reliability department

• Monitoring the CAT II/III systems using the OPCENTER and AIRMAN

systems for the case in that the repetitive failure message is not corrected in

the interval of time for Alert 2.

• Monitoring of corrective actions taken.

• If required coordinate with MCC for reopen any repetitive message report.

Engineering department

• The Engineer must monitoring repetitive message.

• Is required give support to the MCC for establishes the corrective actions.

• Periodically monitoring of technical publications referents with the repetitive

message

• If as required make recommendations based on the technical publications.

For the Alert Level 4:

Identify repetitive reports remaining during 30 days or any other repetitive message

considered by Reliability area:

For this level the Maintenance Control Center Coordinate one meeting integrated by:

- reliability area

- The system engineer

- Maintenance chief

- Engineer chief

- Materials chief

- Quality control chief

- Engineer and Maintenance Manager

- Resident Customer Support Manager (if as required)

In that meeting are established the action correctives.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 12.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

12. Test to after performed works in the CAT II/III systems.

Every time that is performed any work in the CAT II/III systems, additional for the AMM

procedures it is necessary to accomplish the following tasks:

1. Perform the Operational Test of the Auto Flight Systems in accordance with the

Aircraft Maintenance Manual task 22-96-00-710-001.

2. Perform the Operational Test of the LAND CAT III Capability in accordance with

the Aircraft Maintenance Manual task 22-97-00-710-001.

Just in the case that the technician only had completed all the tasks mentioned by the

AMM and for the operational reasons there is no time to complete the extra tasks

mentioned above. The form VOI-CCS-134 must be set and completed with the legend:

CAT I ONLY.

The CATII/III sticker only could be remove form the A/C if, and only if the mentioned

task must be completed (Section 12 paragraph 1 and 2)

Note: The CAT II/III sticker form VOI-CCS-134 could be replaced by CAT II/III sticker

form VOI-CCS-134 with CAT I ONLY legend only when the test on paragraph 1 and 2

of this section can not be completed.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 12.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

Intentionally Left in Blank

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 13.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

13. For removal of the sticker format VOI-CCS-134.

This procedure is to ensure that the aircraft remain downgrade CAT II/III status until

successful corrective action has been verified for all discrepancies.

Each time that a discrepancy for the CAT II/III systems is finding and the failure is not

corrected immediately, the technician must perform the procedure described in the

section 10 for this Manual, and the technician must install the sticker (format VOI-CCS-

134) in the right side of the captain displays.

The aircraft will be return to CAT II/III normal configuration until the next steps have

been accomplished:

1. All corrective action accomplished on the Aircraft has been satisfactory as is

mentioned on the AMM.

2. All tests described on section 12 of this manual have been satisfactory.

3. Verifying that any other message or report with respect to the CATII/III systems

has been reported and corrected.

Note: The step 3 is performed to verify that the CAT II/III systems are in

normal conditions for operation. If one or more of this steps is not

accomplished them the aircraft must remain in downgrade status.

4. If the step 1, step 2 and step 3 are accomplished then remove the sticker

Every time that the step 1, 2, and 3 were performed and has been satisfactory,

it will necessary to registry on the Maintenance and Flight Logbook format VOI-

MFL-108 on the maintenance actions section that these test were performed,

mentioned its respective AMM references and recording that the Aircraft is

“OK” for CAT II/III Operations.

Note: Only trained personnel could perform these tasks

5. The technician must inform to the Maintenance Control Center (MCC) that the

all discrepancies reports in the aircraft have been corrected.

6. The MCC must inform to the Operational Control Center (OCC)

7. The OCC must take the corresponding actions.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 13.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

Intentionally Left in Blank

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 14.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

14. Continues monitoring of the CAT II/III operations for purpose of Quality

Control.

For the purpose of recollect and register of data referent to the CAT II/III operations

Volaris use the next procedure:

• The Operational Area for Volaris must make periodic real or simulated CAT II/III

operations.

• Each CAT II/III operations can be performed in any low or normal visibility

condition, whenever that the ground systems and the aircraft system are

available in the condition described in the Operational General Manual.

• The Pilot in command is responsible of report all the CAT II/III operation that

has been performed and for this purpose he must fill out the CAT II/III logbook

(see format VOI-CLR-150 in the chapter 18.3 of this Manual).

• For the case in that any failure in the CAT II/III systems is presented the flight

crew must write the report in the Maintenance and Flight Logbook (see format

VOI-MFL-108) and the technician must performed the procedure described in

the section 9.

• The reliability area must capture and analyze all the data obtained in the CAT

II/II logbook and the Maintenance and Flight Logbook.

The relevant data for analysis is:

a. The total number of approaches tracked, the number of satisfactory

approaches tracked, by aircraft, and visibility (RVR).

b. The total number of unsatisfactory approaches, and reasons for

unsatisfactory performance, listed by appropriate category (e.g., poor

system performance, aircraft equipment problem/failure; ground facility

problem, ATS handling, lack of critical area protection, or other).

c. The total number of unscheduled removals of components of the related

avionics systems.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 14.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

Intentionally Left in Blank

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 15.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

15. Periodic Aircraft evaluation in the CAT II/III System.

To assure the integrity of the CAT II/III systems must accomplish with the next

procedure:

• At least one satisfactory approach should be accomplished within one period of

30 days.

• To assure that one satisfactory approach is accomplished in all Volaris fleet the

Reliability department must inform to Planning Control and Technical Records

Area which aircraft is near to due date of the period of 30 days.

• Planning Control and Technical Records must inform to the Operational Control

Center (OCC) when aircraft is near to due date of 30 days and the OCC must

program in the first opportunity one CAT II/III approach.

• For both, the satisfactory or unsatisfactory approaches has been reported by

the pilot in command in the Maintenance and Flight Logbook and in the CAT

II/III logbook see section 14 for this Maintenance Program.

• For unsatisfactory approach the technicians must check the status of the CAT

II/III systems in accordance with the section 9 oh this manual and if as required

must perform the procedure of the section 10.

• For the satisfactory approach the captain must report as follow:

o CAT II/III ok; or

o CAT III Dual; or

o CAT III Single; or

o CAT II Manual; or

o CAT II Automatic

These cases are only for reliability purpose and no show any discrepancy in the

CAT II/III systems. For this case the technician must report the next legend in

the aircraft fight logbook:

“No maintenance Action as required”

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 15.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

15.1 Not accomplished approach in the normal Periodic Aircraft evaluation.

For the case in that a satisfactory approach can’t has been performed within the period

of 30 days:

1. The Reliability department must inform to Maintenance Area for downgrade

the aircraft to CAT II/III operation.

2. The technician must write the phrase “CAT I Only” in the section

“MEL:_______.” of the sticker format VOI-CCS-134 and paste this in the

right side of the captain displays.

3. The technician must perform the procedure described in the section 09, 12

and 13 of this Maintenance Manual for upgrade the aircraft at the normal

CAT II/III status.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 16.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

16. Test Equipment/Calibration Standards.

This procedure involves the Test Equipments that may require a periodic re-evaluation

to ensure it has the required accuracy and reliability to return systems and components

to service following maintenance and Volaris is responsible for all the precision tooling,

measuring equipment and test equipment used in the CAT II/III systems.

The policies and procedures for the calibration of the equipment are defined in the

General Maintenance Manual section 9.15

Under no circumstance technical personnel can use precision tools, measuring devices

and/or test equipment with an unserviceable tag or a missing calibration identification

label. Also, any calibrated device that has been dropped or rendered in questionable

calibration condition can not be used.

The Quality Control is responsible for ensure that the calibration intervals are not

exceeded.

All calibrations procedures for the precision tooling, measuring equipment and test

equipment must be performed according with the intervals recommended by the

Original Equipment Manufactured (OEM). However, Volaris policy is to that the

calibration intervals must not exceed 365 days, and these intervals will be controlled

using electronic media and Airsoft software.

All test equipment will be labeled. The label will identify the unit by manufacturer,

model, and serial number. The attached Calibration Label VOI-CAL-125 (GMM section

13.22 and see figure 17.1 for reference) must indicate the last calibration date and the

next calibration due date. During the first week of each month the Stockroom personnel

will review the test equipment calibration record and will be responsible to issue work

orders to Repair shops or contract agencies to send the devices for calibration.

VOLARIS

CAL. DATE

CAL. DUE DATE

P/N:

S/N:

Q.C.:

VOI-CAL-125

Figure 17.1

Once the calibration is done, the test unit will be checked for proper labeling and the

equipment calibration history record will be updated and returned to the active file, prior

to the device being return to the Stockroom for maintenance use.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 16.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

When test and/or calibration of precision test equipment and tools is performed by

authorized vendors, they must report in written form to Volaris Quality Control the

following information.

• Condition upon reception

• In-tolerance

• Out of tolerance

• Repair performed or required

• Calibration data Sheet

• Date Calibrated and date next calibration is due

• Name, signature, and certification of person approving work

Volaris will maintain historical data on all calibrated equipment for a minimum of 5

years. A Volaris Inspector will verify the condition of all incoming calibrated equipment

returning to the Company before it is released for use.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 17.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

17. Initial and Recurrent Maintenance Training.

Volaris ensures training for maintenance personnel and contract maintenance

personnel through the use of aircraft manufacturer schools or by It is own training

center or any other training center certified by local authority and accomplish it with

Volaris internal training policies mentioned on the Volaris General Maintenance Manual

(GMM Section 11).

The training for CAT II/III include mechanics, avionics technicians, maintenance

inspectors, quality assurance, engineering personnel for initial and recurrent training.

The initial training is considered under the procedures established in the section 11 of

the GMM and the recurrent training is programmed annually or when for any reason

when person has not been involved in the maintenance for the similar aircraft or

systems of Volaris fleet for more of 6 months.

The courses must be completed with a minimum of 85 percent passing grade.

It will be necessary to do mandatory training that will include:

1. Operational concepts for CAT II/III operations.

2. Aircraft components and affected systems.

3. Revisions to approved CAT II/III Maintenance Program.

4. Use of the Minimum Equipment List Items.

Any technician can report discrepancies and downgrade the CAT II/III systems

following the steps defined in the section 10 of this manual and only for this specific

purpose is not required especial training in the CAT II/III systems.

The upgrade for return to CAT II/III aircraft capabilities and related task performance

must be done only by trained and qualified Maintenance Personnel.

Any Volaris Maintenance Technician that has accomplished successfully the CAT II/III

training should be identified adding a CAT II/III stamp format VOI-CIS-173 in the

Volaris personal identification.

CAT II/III

VOI TECH

Voi-CIS-173

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 17.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

Intentionally Left in Blank

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 18.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -1-

18. Forms

In this section contains the format used in this CAT II/III manual.

18.1 TheCAT II/III restrictions sticker format (VOI-CCS-134)

CAT II/CATIIIA

RESTRICTIONS

MEL:___________

VOI-CCS-134

This sticker must be fillet wiht the corresponding MEL reference.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 18.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -2-

18.2 CAT II/III Identify parts Sticker form (VOI-CAT-171)

CAT II/III

VOI-CAT-171

This sticker is for identify the componentes CAT II/III and must pasted for the Quality

Control inspetor.

TheCAT II/III components are idetify in the the table 7.2 of the CAT II/III maintenance

Manual.

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 18.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -3-

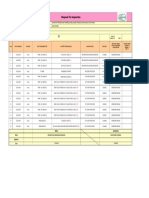

18.3 CAT II/III Landing Report Log

2 3

4

5 6 7

8 9 10

11

12 13 14

15 16 17 18

19

20

22

21

23

24

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 18.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -4-

Fill out instructions:

Número Descripción

1 Write the Aircraft Tail number.

2 Select writing one “X” in the option that defines the typeCAT II/III

operation.

3 Select writing one “X” in the corresponding option to describe if the

operation is actual, simulated or practice.

4 Select writing one “X” in the corresponding option to describe if the

operation is an approach or an approach and landing.

5 Write the Date of theCAT II/III operation is performed

6 Write the flight number

7 Write the name of the Pilot in Command

8 Write airport code using the three letters of the IATA code

9 Write The runway in that theCAT II/III operation was performed

10 Write the ILS category

11 Write the First Officer Name

12 Write wind direction reported.

13 Write the wing speed reported.

14 Write the Ceiling reported.

15 Write the RVR reported in the landing Zone

16 Write the RVR reported in the middle runway

17 Write the RVR reported in the end of the runway

18 Pilot in the command signature

19 For the approach or autoland write the deficiencies related to the

airborne equipment

20 Write the altitude in that the approach or autoland was abandoned

21 Select writing one “X” in the option that describe the classification by

which was abandoned the operation

22 Write the comments referents with the problem which the operation

was abandoned

23 Write the comments referents to the problem in the autoland and

touchdown performance

24 Selected written one “X” in the estimated touch down point

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 18.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -5-

18.4 Calibration Label

VOLARIS

CAL. DATE 1

CAL. DUE DATE 2

P/N: 3

S/N: 4

Q.C.: 5

VOI-CAL-125

Calibration label fill out instructions:

1 Calibration Date (last)

2 Calibration Due Date (next)

3 Part Number

4 Serial Number

5 Inspected by

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

REV. NUMBER: ORIGINAL DOCUMENT: CAT II/III

SECTION: 18.00

REV. DATE: Apr/13/09

CAT II/III MAINTENANCE PROGRAM MANUAL PAGE: -6-

18.5 CAT II/III Identified Technician Stamp (VOI-CIS-173)

CAT II/III

VOI TECH

Voi-CIS-173

This sticker is to identified the technician that has accomplished successfully the CAT

II/III training

Concesionaria Vuela Compañía de Aviación S. A. de C. V.

You might also like

- 1cae Oxford Aviation Academy Atpl Book 5 InstrumentationDocument668 pages1cae Oxford Aviation Academy Atpl Book 5 InstrumentationDenysadenisa98% (45)

- MM - PA-44-180 180T (SNs 4496001 and Up)Document1,992 pagesMM - PA-44-180 180T (SNs 4496001 and Up)Cristhian342100% (2)

- 1000 Questions Marathon (Aerodynamics)Document94 pages1000 Questions Marathon (Aerodynamics)Patrick Lawrence PiasanNo ratings yet

- A320 Handling of Different Class Fault MessagesDocument3 pagesA320 Handling of Different Class Fault MessagesKamran Khan Tareen100% (1)

- Part Number 761-892Document2,250 pagesPart Number 761-892Maicon FrancaNo ratings yet

- Embraer E-Jets E2 Airport Planning ManualDocument150 pagesEmbraer E-Jets E2 Airport Planning Manualramguna84100% (1)

- Airbus A320 Ceo NeoDocument2 pagesAirbus A320 Ceo NeoAjay KumarNo ratings yet

- Aot A35n012 19 PDFDocument4 pagesAot A35n012 19 PDFPanneer SelvamNo ratings yet

- A320 - CA42 Route Check Form-1.0Document1 pageA320 - CA42 Route Check Form-1.0Dahiya DeepakNo ratings yet

- P 1288Document74 pagesP 1288lamurtNo ratings yet

- Poh-2908-14 - Revision 17 - FullDocument1 pagePoh-2908-14 - Revision 17 - Fulltayo_bNo ratings yet

- Hydrofoils Tom SpeerDocument7 pagesHydrofoils Tom SpeerVeters2650% (1)

- Apm 190 PDFDocument136 pagesApm 190 PDFGreg SandovalNo ratings yet

- E190 SopsDocument136 pagesE190 SopsLuis PinedaNo ratings yet

- Airccraft General PDFDocument32 pagesAirccraft General PDFJefferson CastañedaNo ratings yet

- FRB Issue 2 Rev 0 July 2018 For Atr 42-320 For PrintingDocument33 pagesFRB Issue 2 Rev 0 July 2018 For Atr 42-320 For PrintingSujoy GhoshNo ratings yet

- Airport Planning Manual: APM-1901 15 AUGUST 2005Document138 pagesAirport Planning Manual: APM-1901 15 AUGUST 2005Santiago Aldana JimenezNo ratings yet

- Apm e Jetse2Document156 pagesApm e Jetse2Anonymous auYZu7HNo ratings yet

- Tendernotice 1Document30 pagesTendernotice 1Joseph CallistusNo ratings yet

- Equipment Accounting (Accounts Assistant) : Students' Text ANT-01-003Document261 pagesEquipment Accounting (Accounts Assistant) : Students' Text ANT-01-003Royal StudiosNo ratings yet

- WI-TM-042 Import Aircraft For MaintenanceDocument8 pagesWI-TM-042 Import Aircraft For MaintenanceIrfan FauziNo ratings yet

- CAO - IRI Part 21 Rev01Document170 pagesCAO - IRI Part 21 Rev01SHAHABAZI100% (1)

- Manual E190 AviónDocument142 pagesManual E190 AviónAdrian AguilarNo ratings yet

- WI-TM-043 Temporary Import For AircraftDocument8 pagesWI-TM-043 Temporary Import For AircraftIrfan FauziNo ratings yet

- A320 Family MEL Issue 2 R 14 DT - Oct-2019+Document1,138 pagesA320 Family MEL Issue 2 R 14 DT - Oct-2019+stn.engr. BbiNo ratings yet

- Ceo - Insa320ttw003 - Issue - 20 - Stayover Check PDFDocument6 pagesCeo - Insa320ttw003 - Issue - 20 - Stayover Check PDFLE THAI HONG VINHNo ratings yet

- Landing Gear Malfunction of A HS 125-700B Aircraft and Landing at Helsinki-Vantaa Airport On 3 September 1999Document32 pagesLanding Gear Malfunction of A HS 125-700B Aircraft and Landing at Helsinki-Vantaa Airport On 3 September 1999Fidel ArellanoNo ratings yet

- Airbus - Briefing Guide - 29 Aug 2019Document18 pagesAirbus - Briefing Guide - 29 Aug 2019nodynarenNo ratings yet

- Aircraft Physical ChecklistDocument18 pagesAircraft Physical Checklistralph93.aviationNo ratings yet

- AHM560 RA-73260, RA-73261 737-800 (Ver19)Document45 pagesAHM560 RA-73260, RA-73261 737-800 (Ver19)Cédric SorghoNo ratings yet

- Ahm560 Boy, BMP, Bve, Biz 737 800 (Ver15) PDFDocument52 pagesAhm560 Boy, BMP, Bve, Biz 737 800 (Ver15) PDFОлег Иванов100% (1)

- T006S52PDocument12 pagesT006S52PdiegoNo ratings yet

- 2024 CAR UpdateDocument1 page2024 CAR UpdatePrashantNo ratings yet

- PN-A320neo Engine (Jan 2019)Document2 pagesPN-A320neo Engine (Jan 2019)mehul da aviatorNo ratings yet

- Apm E170Document130 pagesApm E170FigueiredoNo ratings yet

- 100 Series Piston Single Engine Aircraft - Airworthiness ProgramDocument124 pages100 Series Piston Single Engine Aircraft - Airworthiness ProgramandrewNo ratings yet

- Ship Painting2Document290 pagesShip Painting2AniekanNo ratings yet

- Statement of The Categories of Documents-1Document39 pagesStatement of The Categories of Documents-1Iwi iwi StoreNo ratings yet

- Sit Li Io Gr3 w001 PLC Mapping Io List - Rev.b1 Re IfaDocument4 pagesSit Li Io Gr3 w001 PLC Mapping Io List - Rev.b1 Re IfaArifin Jr.No ratings yet

- Status Inspeksi & Pengujian - Proses: 1 Dari 2 02Document2 pagesStatus Inspeksi & Pengujian - Proses: 1 Dari 2 02Robiyatul AdawiyahNo ratings yet

- Classes of FaultDocument3 pagesClasses of FaultSara RazaNo ratings yet

- Arc StickerDocument13 pagesArc StickerRachyita SinghNo ratings yet

- Pages From D2F-F7Document1 pagePages From D2F-F7saradeepsNo ratings yet

- Ceo - Insa320ttw004 - Issue - 09 - Transit Check PDFDocument4 pagesCeo - Insa320ttw004 - Issue - 09 - Transit Check PDFLE THAI HONG VINHNo ratings yet

- 6.9 Distribution List: Designation Mode of Copy NumberDocument1 page6.9 Distribution List: Designation Mode of Copy Numberame_ravisinghNo ratings yet

- To Save A City The Berlin Airlift, 1948-1949Document135 pagesTo Save A City The Berlin Airlift, 1948-1949Bob Andrepont100% (2)

- Faa Form 8070-1Document2 pagesFaa Form 8070-1api-520948779No ratings yet

- FMS PreflightDocument16 pagesFMS PreflightJefferson CuNo ratings yet

- EO-2019-2187 (A321 Storage Not More Than 1 Year)Document18 pagesEO-2019-2187 (A321 Storage Not More Than 1 Year)phuoc vanNo ratings yet

- AOC PackageDocument3 pagesAOC Packageshikhil nairNo ratings yet

- Cabin Crew Member Manual Standards Operations Vol 2 Part f1Document46 pagesCabin Crew Member Manual Standards Operations Vol 2 Part f1ShikarijiNo ratings yet

- Bba 3RD YrDocument6 pagesBba 3RD YrAnwin AntonyNo ratings yet

- How To Handle Different Class Fault MessagesDocument3 pagesHow To Handle Different Class Fault Messagestenhero92No ratings yet

- Flight Design F2Document9 pagesFlight Design F2Ivan Gonzo SaboNo ratings yet

- Cavo D'arresto AeronauticoDocument184 pagesCavo D'arresto AeronauticoUppotappNo ratings yet

- AITP-L02 Appendix 04-04 Logbook Issue 4 - Sep 2019Document77 pagesAITP-L02 Appendix 04-04 Logbook Issue 4 - Sep 2019Naveen SoysaNo ratings yet

- SOM 10.3 F Register of Vessel Defect Report Rev 0.0Document1 pageSOM 10.3 F Register of Vessel Defect Report Rev 0.0Amit BhadauriaNo ratings yet

- Manual E195Document136 pagesManual E195Edoardo100% (1)

- Request For Inspection: 000000classification: InternalDocument2 pagesRequest For Inspection: 000000classification: InternalManikandan MNo ratings yet

- Request For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Document2 pagesRequest For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Manikandan MNo ratings yet

- H125 Technical Log Book Issue 01 Rev 00Document9 pagesH125 Technical Log Book Issue 01 Rev 00raviNo ratings yet

- Request For Inspection: 000000classification: InternalDocument1 pageRequest For Inspection: 000000classification: InternalManikandan MNo ratings yet

- Printed in GermanyDocument30 pagesPrinted in GermanyRembrandt Garcia MatusNo ratings yet

- 5 QMS Document Master List - Asset Resources Management (Fleet)Document2 pages5 QMS Document Master List - Asset Resources Management (Fleet)Safix YazidNo ratings yet

- Subject: ICAO / EASA Aerodrome Reference Code, FAA Airplane Design Group and Aircraft Approach Category For Airbus AircraftDocument3 pagesSubject: ICAO / EASA Aerodrome Reference Code, FAA Airplane Design Group and Aircraft Approach Category For Airbus AircraftwahyuNo ratings yet

- Request For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Document1 pageRequest For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Manikandan MNo ratings yet

- AIR CRASH INVESTIGATIONS - THE BOEING 737 MAX DISASTER PART 1 - The Crash of Lion Air Flight 610From EverandAIR CRASH INVESTIGATIONS - THE BOEING 737 MAX DISASTER PART 1 - The Crash of Lion Air Flight 610No ratings yet

- S76 C Specs Sheet 1 PDFDocument23 pagesS76 C Specs Sheet 1 PDFLavern P. Sipin100% (2)

- Space Shuttle Mission STS-41BDocument32 pagesSpace Shuttle Mission STS-41BAviation/Space History LibraryNo ratings yet

- C550 Maneuvers and Procedures Revision 3Document74 pagesC550 Maneuvers and Procedures Revision 3Maxi 76100% (2)

- ETOPS B777-300ER - Dedy Brian Ericson - FixDocument20 pagesETOPS B777-300ER - Dedy Brian Ericson - FixDedyBrianEricsonNainggolanNo ratings yet

- Routefinder: Online Flight PlannerDocument2 pagesRoutefinder: Online Flight PlannerRAdE0nEXENo ratings yet

- A Brief History of FlightDocument27 pagesA Brief History of FlightSuyog AbnaveNo ratings yet

- Section 5 Performance: Stall SpeedDocument12 pagesSection 5 Performance: Stall SpeedCleber WinklerNo ratings yet

- SupportDocument171 pagesSupportjsdhilipNo ratings yet

- Memory Items Left-Right Seat V3Document19 pagesMemory Items Left-Right Seat V3HeshNo ratings yet

- B734 FLT InsDocument6 pagesB734 FLT InsKhurram NaseemNo ratings yet

- Aerospace: Wind Tunnel Testing of ONERA-M, AGARD-B and HB-2 Standard Models at Off-Design ConditionsDocument20 pagesAerospace: Wind Tunnel Testing of ONERA-M, AGARD-B and HB-2 Standard Models at Off-Design ConditionsDream TeamNo ratings yet

- A330 MEL Rev03 04apr12Document1,202 pagesA330 MEL Rev03 04apr122kgmr4ggypNo ratings yet

- Study On Thin Airfoil Theory Performance Test of EDocument10 pagesStudy On Thin Airfoil Theory Performance Test of ENguyen Danh HauNo ratings yet

- AF 1 SixpackDocument20 pagesAF 1 SixpackJay ManNo ratings yet

- Air Distribution Schedule: Tag No. Flow L/S Qty. Used SizeDocument2 pagesAir Distribution Schedule: Tag No. Flow L/S Qty. Used SizeMohammed Abdul MoiedNo ratings yet

- Weight and BalanceDocument36 pagesWeight and BalancemanatottaNo ratings yet

- YTEFDocument5 pagesYTEFjoker hotNo ratings yet

- Adverse Yaw: Aileron Deflections To Produce A Roll To The RightDocument3 pagesAdverse Yaw: Aileron Deflections To Produce A Roll To The RightVigneshVickeyNo ratings yet

- MOCKUP - TRAINERCH1 3 GR 2Document33 pagesMOCKUP - TRAINERCH1 3 GR 2DAVID JOSHUA GALLENITONo ratings yet

- Civil Aviation Approved Training Organisations Regulations PDFDocument56 pagesCivil Aviation Approved Training Organisations Regulations PDFJunior Mebude SimbaNo ratings yet

- General Information General Information: (C) Jeppesen Sanderson, Inc., 2018, All Rights ReservedDocument23 pagesGeneral Information General Information: (C) Jeppesen Sanderson, Inc., 2018, All Rights ReservedGuillermo CortesNo ratings yet

- Ata22 A320Document25 pagesAta22 A320David MoralesNo ratings yet

- Ata 27Document179 pagesAta 27Ayan Acharya100% (3)