Professional Documents

Culture Documents

RA-Alumino-Thermic Welding

RA-Alumino-Thermic Welding

Uploaded by

Ali Usman AliOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RA-Alumino-Thermic Welding

RA-Alumino-Thermic Welding

Uploaded by

Ali Usman AliCopyright:

Available Formats

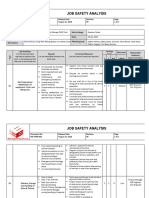

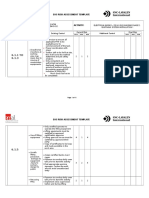

Contract No. : C0303 Package No.

: A

Etihad Rail Package 2A Sheet No. : 16 Date : 29/08/2020

Health and Safety Risk Assessment

Operation: Track works Risk Assessment No: 29

Location : Ruwais Rail Head Person Completing Assessment: Antonino Buccieri

Activity: Alumino-Thermic Welding Assessment Date: 29/08/2020

Ite Activity Hazards Initial Precautions Final Responsibility Monitoring

m Risk Risk Responsibilit

y

1 Transportation - Unfamiliar with road High - Safety induction before Medium Site Construction

of the and Site access 3x3= 9 commencing the job 2x2= 4 Engineer/Super Manager

operatives to condition - Driver must possess valid visor/Safety

the workplace - Incompetent driver driving license Officer

- Vehicle breakdown - Pre-vehicle inspection must

- Skidding be conducted before

- Traffic accident journey

- Collision - Conduct driver’s TBT

before commencing the job

- All drivers to be fully

briefed on all existing

hazards, road bends, level

crossing and traffic speed

limit

- Team Managers /

Supervisor must Plan the

journey and necessary

survey the roads before

commencing the job.

- Drivers must be physically

healthy and have enough

rest prior to transportation

- Periodic maintenance of

vehicle

- In place warning signs

- Should be aware about

emergency hotline in case

of any accident

2 Site - Movement of vehicle Mediu - Safety induction before Medium Site Construction

Inspection, and equipment m commencing the job 2x2= 4 Engineer/Super Manager

survey and - Unfamiliar with site 2x3= 6 - In place warning signs visor/Safety

preliminary situation - Wear the necessary PPE Officer

activities - Slip, trip and fall of - Site safety orientation

operators. - Housekeeping

- Contemporaneous - Speed of the Equipment be

activities maintained at lowest to

- Adverse weather avoid any unusual

condition derailment.

- Provision of welfare

facilities

- Call emergency hotline in

case of any accident

3 Checks & - Poor Planning Mediu - Task Briefing to the team. Low Site Construction

Preliminary - Injuries due to hand m - Permit to work for the 1x2= 2 Engineer/Super Manager

Activities /Power tools 2x2= 4 activity. visor/Safety

- Lack of Trained - Presence of HSE Team Officer

Operatives member.

- Clamp should be removed

by Trained Operatives.

- Work area should be

identified and post signs.

- Personnel on ground to

have high visibility clothing

and hard hats, safety

glasses. Steel toe boots.

- Only experienced personnel

to involving the task.

- Proper training and

instruction shall be given on

correct use of equipment.

Operatives shall not give

equipment issued in their

name to any unauthorized

personnel.

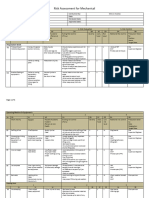

4 Cleaning of the - Dust Mediu - All workers must wear the Medium Site Engineer / Construction

rail headpieces - Cut, abrasion and m Personal Protection 2x2=4 Supervisor/ Manager

to be welded Laceration 3x2= 6 Equipment required. Safety Officer

- Injury to person - Only competent person

- Run-over by the shall do the task

machine - Barricade the working area

- Work supervision must in-

place

- HSE supervision must in-

place

- Adequate rest work interval

breaks while working under

direct sun and using hand

tools.

- Avoid machine movement

in the area during work.

5 Removal of - Cut, abrasion and Mediu - All workers must wear the Medium Site Engineer / Construction

the joints Laceration m 3x2= Personal Protection 2x2=4 Supervisor/ Manager

fixing - Injury to person 6 Equipment required. Safety Officer

- Run-over by the - Only competent person

machine shall do the task and use

- Physical Harm the tools required for

operation.

- Barricade the working area

- Work supervision must in-

place

- HSE supervision must in-

place

- Adequate rest work interval

breaks

6 Handling - Skin and Eye Irritation Mediu - Safety induction before Low Site Construction

chemicals due to contact. m commencing the job 2x1=2 Engineer/Super Manager

involved in the - Ingestion or inhalation 2x2=4 - Pre-task briefing visor/Safety

process. of welding powder. - Site safety supervision Officer

- Accidental release - Mandatory use of PPE

- Fire - Pre-use inspection of

- explosion machine, tools and

equipment prior to job

execution

- In case of contact Rinse

with hot water and soap.

- Wash the clothes before

reuse

- For inhalation, ingestion or

any other severe effect Let

a doctor come if the victim

continues to feel unwell.

- Avoid contact to the

elements

- Use proper PPE

- In-place work supervision

- In-place HSE Supervision

- Sure the Availability of

MSDS

- Set up fire extinguisher

- Only competent workers

will do the task.

- Store the chemicals in

designated areas away

from worksite.

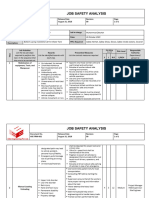

7 Aluminotherm - Burns High - Only Certified Medium Site Construction

ic Welding - Fire 3x4=12 Operator/welder should be 2x2=4 Engineer/Super Manager

- Welding Smoke allowed to perform the visor/Safety

- Explosion activity. Officer

- Damage to Eyes - Approved Welding

- Rupture of pipe or Procedure should be

hoses followed

- Manual Handling - Before starting work, Check

- Flying Objects the condition of the

- Noise preheating equipment and

- Chemical exposure if there are enough

consumables, connection,

flexible joints, hoses,

manometer, pressure

reducers and batteries

everything must be in

perfect condition.

- Valves and/or gas cocks

must be opened only using

the appropriate spanner so

as to avoid forcing which

could produce cracks,

breakage or gas leaks.

- Do not allow tubes to be

pulled and do not use them

to interrupt the gas flow.

- Spread out the tubes in

wide curves, protected

from contact with any

sharp objects.

- Cut off the gas flow using

the taps of the torch

whenever the torch is not

in use or for other

operation on the torch.

- Put down the lighted torch

only in the predetermined

position at the welding site

so that the flame does not

come into contact with the

cylinders, combustible

materials and cannot harm

any persons present.

- Keep the acetylene

cylinders in a vertical or

almost vertical position and

make sure that the gas flow

does not exceed one fifth of

the cylinder capacity per

hour.

- Do not empty the cylinders

completely so stop using

them when the pressure

inside is one bar (about 1

Kg/cm2.)

- At the end of a job close the

valves of the cylinders,

release the gas from the

tubes one at a time until

the manometers have

returned to zero and loosen

the adjusting screws of the

pressure reduction valves.

- Make sure that sparks

and/or incandescent

material cannot reach the

persons and/or flammable

materials during welding

work.

- All workers must wear the

Personal Protection

Equipment including,

Leather gloves, Safety

shoes, Leggings, Safety

goggles with side

protections against spark

and ear muff.

- COSHH risk assessment

should be conduct and the

MDSD should available on

site.

- Gas equipment should be

inspected before the

activity.

- Material and chemical like

Crucible, igniters, moulds,

luting sand should be

stored in designated area.

8 Grinding the - Cut, abrasion and High - All workers must wear the Medium Site Engineer / Construction

welds Laceration 3x3= 9 Personal Protection 2x2=4 Supervisor/ Manager

- Run-over by the Equipment required. Safety Officer

machine - Only competent person

- Dust shall do the task

- Noise - Barricade the working area

- Burn - Work supervision must in-

- Fire and explosion place

- HSE supervision must in-

place

- Stop work in case of heavy

wind.

- Move workers to safe

place.

- Adequate rest work interval

breaks

- Install Fire Extinguisher in

the welding area.

- Remove un-necessary

combustible and flammable

materials in the area.

- Provide Fire watch

- Qualified trained workers

shall carry out work

- Wear necessary PPE

- Use the right tools in the

right job

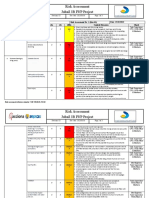

9 Site welfare - Lack of Welfare Mediu - Portable toilets and wash Low Site Engineer / Construction

facilities facilities m rooms must in place and 1x2=2 Supervisor/ Manager

- Lack of first aid facility 3x2=6 regular cleaning Safety Officer

- Inadequate - Drinking water must be

maintenance. available at all times,

- Fire containers must be sealed

- Slip, trip, fall and check regularly

- No or inadequate - First aid box, first aider

supply of water must be available and

- Inadequate emergency hotline must be

illumination posted

- Housekeeping

- Emergency evacuation plan

- Fire extinguishers must in

place

- Additional lighting

10 Waste - No identified area for Mediu - Compliance to waste Low Site Engineer / Construction

Management waste disposal and m management plan 1x2=2 Supervisor/ Manager

segregation 3x2=6 - Training to all operatives Safety Officer

- No chemical storage - Regular housekeeping

- Area - Segregation of waste

- Oil and chemical spill - MSDS must be available at

- Slip, trip, fall site

- Fire - Minimization of waste

generation encourages

waste segregation at

source, recycle reuse

and/or utilize in an

environmental friendly

manner.

- Regular collection and

disposal with registered

service provider

- Provision of drip trays and

spill kits

- Provision of Bund Wall for

storage tanks

-

11 Housekeeping - Slip, trip, fall Mediu - Housekeeping on daily Low Site Engineer / Construction

- Fire m basis. 1x2=2 Supervisor/ Manager

3x2=6 - Fire Extinguisher to be Safety Officer

provided on site

- Skips must be available on

site for regular disposal of

waste

- Trash bins must be in place

- Food waste must be

disposed separately and

regularly

Risk Matrix (Severity=Probability x Consequence)

Severity Consequence (Potential severity of consequences of injury or damage)

Probability (Likelihood) 1 2 3 4 5

Insignificant Minor Moderate Major Catastrophic

(1) Rare -

1 2 3 4 5

Never occurred

(2) Possible

2 4 6 8 10

Has occurred

(3) Likely

3 6 9 12 15

Occurred more than once

(4) Often

4 8 12 16 20

Occurs several times / year

(5) Frequent

5 12 15 20 25

Occurs frequently

Risk Legend

1-3 Low No action required, unless escalation of risk is possible.

Activity or industry can operate subject to management and /or

4-6 Medium

modification

Activity or industry should be modified to include remedial planning and

8-12 High

action and be subject to detailed EHS assessment.

15-25 Extreme Activity or industry should not proceed in current form.

You might also like

- 27 - Drainage WorksDocument4 pages27 - Drainage WorksRafee Pie100% (6)

- HIRARC-RC Piling Work - GEMSB PDFDocument4 pagesHIRARC-RC Piling Work - GEMSB PDFadi zariff100% (1)

- Risk Assessment For EquipmentDocument6 pagesRisk Assessment For Equipmentabou bakar100% (5)

- JSA For Electrical Work TCF3-HaradhDocument6 pagesJSA For Electrical Work TCF3-HaradhShaikh Abu bakarNo ratings yet

- F5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionDocument13 pagesF5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionTaiwo Oshin100% (1)

- Concrete Surface Coating JSA-027Document5 pagesConcrete Surface Coating JSA-027shivgovind pal100% (1)

- Method Statement For Access Road & Platform Construction in Hill Area (HSE)Document5 pagesMethod Statement For Access Road & Platform Construction in Hill Area (HSE)Rajesh100% (1)

- F5B-BMJV-0001-AHA-HSE 00 AHA For Precast Storm Drain and Subdrain Uty.Document13 pagesF5B-BMJV-0001-AHA-HSE 00 AHA For Precast Storm Drain and Subdrain Uty.Taiwo Oshin100% (1)

- Tarpaulin Industry ProfileDocument4 pagesTarpaulin Industry ProfileAnukrishnaNo ratings yet

- VCE Task 02 Ankit ChoudharyDocument6 pagesVCE Task 02 Ankit ChoudharyAnkit JaiswalNo ratings yet

- Welspun Enterprises Limited Project: Am2 Group Risk AssessmentDocument4 pagesWelspun Enterprises Limited Project: Am2 Group Risk AssessmentDwijendra ChanumoluNo ratings yet

- JHA For Pipe Work-01.09Document3 pagesJHA For Pipe Work-01.09Anonymous Xb3zHio100% (1)

- Hazard Identification and Risk Assessment Worksheet.: Zubair New Degassing Station Project Caravan LiftingDocument2 pagesHazard Identification and Risk Assessment Worksheet.: Zubair New Degassing Station Project Caravan LiftingNaveed AhmedNo ratings yet

- Attachments 3 - Risk Assessment For Structure Work of FoudationDocument4 pagesAttachments 3 - Risk Assessment For Structure Work of FoudationAnh VàngNo ratings yet

- Hazard Identification, Risk Assessment and Determining Control (Hiradc)Document8 pagesHazard Identification, Risk Assessment and Determining Control (Hiradc)mohd addin100% (1)

- Undergruound Cable PullingDocument6 pagesUndergruound Cable PullingDhaneswar SwainNo ratings yet

- Paint Work Using Mobile Crane PSO FSD.Document5 pagesPaint Work Using Mobile Crane PSO FSD.fiazhussaindbxNo ratings yet

- RA-for Glass Installation 30-04-2022Document6 pagesRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- 1 Earth WorksDocument5 pages1 Earth WorksMuhammad Shahid Iqbal100% (1)

- Risk Assessment 2A1Document10 pagesRisk Assessment 2A1Illias ShaikNo ratings yet

- Risk Assessment For Mechanical: Preparation WorkDocument3 pagesRisk Assessment For Mechanical: Preparation Workahmedalderbi801No ratings yet

- RA-Containment WorksDocument17 pagesRA-Containment WorkshseNo ratings yet

- ARK JSA Manual Excavation A 3Document9 pagesARK JSA Manual Excavation A 3REMYANo ratings yet

- ARK JSA Manual ExcavationDocument8 pagesARK JSA Manual ExcavationMohammed Ali QaziNo ratings yet

- ARK JSA Manual ExcavationDocument8 pagesARK JSA Manual ExcavationREMYA50% (2)

- Bottom Installation of Fire Water Tank - JSA FWTDocument7 pagesBottom Installation of Fire Water Tank - JSA FWTfiazhussaindbxNo ratings yet

- F5B-BMJV-0001-AHA-HSE 00 AHA For RC Pipes InstallationDocument15 pagesF5B-BMJV-0001-AHA-HSE 00 AHA For RC Pipes InstallationTaiwo Oshin100% (1)

- Vehicle & Equipment Movement JSADocument3 pagesVehicle & Equipment Movement JSAfiazhussaindbxNo ratings yet

- Fabrication Work Shop RADocument4 pagesFabrication Work Shop RASalah Abd Eldayem67% (3)

- CM Project Risk AssessmentDocument6 pagesCM Project Risk AssessmentangeloNo ratings yet

- Project Safety Analysis Civil Expansion of Bulk Oil Storage Depot at DaulatpurDocument6 pagesProject Safety Analysis Civil Expansion of Bulk Oil Storage Depot at DaulatpurM Waqas HabibNo ratings yet

- Job Hazard Analysis Worksheet: SupervisorDocument8 pagesJob Hazard Analysis Worksheet: SupervisorAl Mughsar CompanyNo ratings yet

- F5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionDocument11 pagesF5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionTaiwo OshinNo ratings yet

- Erection of Tanks JSADocument4 pagesErection of Tanks JSASalah Abd EldayemNo ratings yet

- Lifting Operations - Risk AssessmentDocument3 pagesLifting Operations - Risk AssessmentkhanalNo ratings yet

- Metering Skid ErectionDocument4 pagesMetering Skid ErectionNature BeautiesNo ratings yet

- RA Construction For Sub-Base & Road Base WorksDocument17 pagesRA Construction For Sub-Base & Road Base WorksBleep NewsNo ratings yet

- Risk Assessment-Concrete Casting by Using PumpsDocument3 pagesRisk Assessment-Concrete Casting by Using PumpsSarfraz Randhawa100% (2)

- Job Safety Assessment (Jsa)Document19 pagesJob Safety Assessment (Jsa)Saravanan Sara0% (1)

- JHADocument8 pagesJHARayyan ramosNo ratings yet

- Risk Assessment For Generator EquipmentDocument6 pagesRisk Assessment For Generator Equipmentabou bakar0% (1)

- Site DumpersDocument4 pagesSite DumpersDanijel PindrićNo ratings yet

- Job Hazard Analysis (ASSEMBLY)Document4 pagesJob Hazard Analysis (ASSEMBLY)Syafiq NorizanNo ratings yet

- Identification & Evaluation of HSE Aspects & Hazards Risk Assessment & Control FormDocument30 pagesIdentification & Evaluation of HSE Aspects & Hazards Risk Assessment & Control FormImam AliNo ratings yet

- Risk Assessment ReportDocument4 pagesRisk Assessment ReportRiyas MangodanNo ratings yet

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- Jsa CheckDocument2 pagesJsa CheckAbhi SandiNo ratings yet

- Job Safety Analysis - Cement SiloDocument7 pagesJob Safety Analysis - Cement SiloArgi Bramantara100% (1)

- Jsa 14Document6 pagesJsa 14Abhi SandiNo ratings yet

- Generic TPL JsaDocument83 pagesGeneric TPL JsaSanjay Kumar GhadaiNo ratings yet

- ARK-JSA-06 Concrete FDN PDFDocument8 pagesARK-JSA-06 Concrete FDN PDFREMYA100% (1)

- Lifting Operation (JSA)Document4 pagesLifting Operation (JSA)abdullah ashrafNo ratings yet

- Risk Assessment Ubderground Electric Power SupplyDocument4 pagesRisk Assessment Ubderground Electric Power SupplySameer Abdul RaufNo ratings yet

- Risk Assessment For General ActivitiesDocument25 pagesRisk Assessment For General Activitiesabou bakar67% (3)

- Job Step Description of Job Step Potential Hazard Potential Consequences Control Barriers Action Party Recovery BarriersDocument4 pagesJob Step Description of Job Step Potential Hazard Potential Consequences Control Barriers Action Party Recovery Barriers王志伟No ratings yet

- Hot Work JSA FSDDocument3 pagesHot Work JSA FSDfiazhussaindbxNo ratings yet

- Lifting Operation BNQDocument2 pagesLifting Operation BNQsathiamurti100% (1)

- HIRA No. 08 Rev 04 - Lifting ActivityDocument7 pagesHIRA No. 08 Rev 04 - Lifting ActivityVenkadesh PeriathambiNo ratings yet

- Safe Use of Site Dumpers On Construction SitesDocument4 pagesSafe Use of Site Dumpers On Construction SitesMusharaf ShahNo ratings yet

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Document11 pages012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanNo ratings yet

- Job Safety Analysis of Asphalt Overlay WorksDocument15 pagesJob Safety Analysis of Asphalt Overlay WorksShaheer AhmedNo ratings yet

- P&M Equipment RegisterDocument6 pagesP&M Equipment RegisterAli Usman AliNo ratings yet

- Blank Close Out FormateDocument25 pagesBlank Close Out FormateAli Usman AliNo ratings yet

- RA-Unloading of Rails On The First Layer of BallastDocument4 pagesRA-Unloading of Rails On The First Layer of BallastAli Usman AliNo ratings yet

- Cause and Effect MatrixDocument1 pageCause and Effect MatrixAli Usman AliNo ratings yet

- USP Acido AscorbicoDocument7 pagesUSP Acido AscorbicoKevin De LeonNo ratings yet

- Paducah Gaseous Diffusion Plant CleanupDocument1 pagePaducah Gaseous Diffusion Plant CleanupJames BruggersNo ratings yet

- Project On Green MarketingDocument42 pagesProject On Green Marketingsoudy0960% (5)

- Sop CNT 45 Waste Management Procedure For Contractors: Revision ListDocument15 pagesSop CNT 45 Waste Management Procedure For Contractors: Revision Listchaitra rNo ratings yet

- Emulsions - Cationic Quick SettingDocument8 pagesEmulsions - Cationic Quick SettingAlvaro CPNo ratings yet

- I. A. Members of The Household: Family Service and Progress Record Head of The Family: Family Number: AddressDocument15 pagesI. A. Members of The Household: Family Service and Progress Record Head of The Family: Family Number: AddressMaria HyacinthNo ratings yet

- Civil Firestop.Document16 pagesCivil Firestop.imranNo ratings yet

- Diploma in Medical Laboratory TechnologyDocument19 pagesDiploma in Medical Laboratory TechnologyShankaray0% (1)

- Udaipur Smart City Final BookDocument115 pagesUdaipur Smart City Final Bookkritikasinghk20No ratings yet

- Zero Waste PRACRESEARCHDocument13 pagesZero Waste PRACRESEARCHSai ImboNo ratings yet

- CWTS 2.module 3Document17 pagesCWTS 2.module 3Ke NtNo ratings yet

- Site Development Plan: Cell 1 (For Costruction) Cell 3 (Future Expansion)Document1 pageSite Development Plan: Cell 1 (For Costruction) Cell 3 (Future Expansion)Sasheen Dela CruzNo ratings yet

- DLL - Science 5 - Q1 - W7Document7 pagesDLL - Science 5 - Q1 - W7Lucele Pasinag CorderoNo ratings yet

- Waste To Energy: A Possibility For Puerto Rico, 5-2007Document57 pagesWaste To Energy: A Possibility For Puerto Rico, 5-2007Detlef LoyNo ratings yet

- Aba 2506Document7 pagesAba 2506Mutiso BrianNo ratings yet

- D3E8019F79F-T10n - 10-Pin Connector (VW A4 CL T10n)Document4 pagesD3E8019F79F-T10n - 10-Pin Connector (VW A4 CL T10n)Ahmed MohsenNo ratings yet

- Tahun 6 SemuaDocument19 pagesTahun 6 SemuanantabogaNo ratings yet

- MSC Project BU2019PGMCH04Document19 pagesMSC Project BU2019PGMCH04SanjeevKumarNo ratings yet

- Performance Evaluation of The UASB Sewage Treatment Plant at James Town (Mudor), AccraDocument7 pagesPerformance Evaluation of The UASB Sewage Treatment Plant at James Town (Mudor), AccramanojNo ratings yet

- 9527354Document23 pages9527354Sujal VermaNo ratings yet

- 1st Q. - PT in Science 5Document7 pages1st Q. - PT in Science 5reynalyn suangcoNo ratings yet

- P Q Q P Q Q: Design of Sanitary Sewer SystemDocument10 pagesP Q Q P Q Q: Design of Sanitary Sewer SystemNaziemi AhmadNo ratings yet

- Solid Waste ManagementDocument42 pagesSolid Waste ManagementKathir RaviNo ratings yet

- CE-703 (C) - CBGS: B.Tech., VII SemesterDocument3 pagesCE-703 (C) - CBGS: B.Tech., VII Semesterसोनू जगतापNo ratings yet

- Eco InnovationDocument60 pagesEco InnovationΠετρόπουλος Α. ΣπήλιοςNo ratings yet

- A Reviewofinnovationsindisbondingtechniquesforrepair 2014Document9 pagesA Reviewofinnovationsindisbondingtechniquesforrepair 2014Cristian GarciaNo ratings yet

- It-Docu Academic Project - Yabut-Tayco - FinalDocument78 pagesIt-Docu Academic Project - Yabut-Tayco - FinalJared Gabriel Sangalang TaycoNo ratings yet