Professional Documents

Culture Documents

Combined Footing Design

Combined Footing Design

Uploaded by

Aditya KasarCopyright:

Available Formats

You might also like

- Pile Foundation Design SpreadsheetDocument7 pagesPile Foundation Design SpreadsheetmuhannedNo ratings yet

- Pile Cap DesignDocument35 pagesPile Cap Designعصام السامرائي100% (2)

- Check For SBC P/A M /Z M /Z: Provided Area Is OkayDocument2 pagesCheck For SBC P/A M /Z M /Z: Provided Area Is OkayVikunj TilvaNo ratings yet

- Design of Formwork For Column R0 - 3.7 MTRDocument5 pagesDesign of Formwork For Column R0 - 3.7 MTRrahul1433No ratings yet

- Page 1+1 of 9Document3 pagesPage 1+1 of 9Sabbir ChowdhuryNo ratings yet

- Calculation Sheet: 7007 Design For The Slab - Top & Bottom Mesh PP BK DataDocument3 pagesCalculation Sheet: 7007 Design For The Slab - Top & Bottom Mesh PP BK Dataasif billalNo ratings yet

- Project: Architect: Footing No.Document4 pagesProject: Architect: Footing No.Maninder ChaudharyNo ratings yet

- 11design of Axially Loaded Column With, Uniaxial MomentDocument3 pages11design of Axially Loaded Column With, Uniaxial MomentJames AswaNo ratings yet

- DESIGN OF FLOOR SLAB (0.15m Thick)Document9 pagesDESIGN OF FLOOR SLAB (0.15m Thick)Living Life100% (1)

- Loads:: Housing Layout-Sd-EastDocument2 pagesLoads:: Housing Layout-Sd-Eastpvrk_78No ratings yet

- Grade Slab ACI 150thkDocument7 pagesGrade Slab ACI 150thkraahul_nNo ratings yet

- Pad Foundation DesignDocument4 pagesPad Foundation Designg4goharNo ratings yet

- Neutral AxisDocument2 pagesNeutral AxispandianNo ratings yet

- Beam DesignDocument54 pagesBeam DesignLagnajit DasNo ratings yet

- Beam Design TemplateDocument9 pagesBeam Design TemplateWinston AdvinculaNo ratings yet

- Tensile Reinforcement For Bending: Check For Punching ShearDocument2 pagesTensile Reinforcement For Bending: Check For Punching ShearShindiya LalNo ratings yet

- Two Way Slab Design - 2 KN m2Document16 pagesTwo Way Slab Design - 2 KN m2pandianNo ratings yet

- Isolated Footing (R or S)Document19 pagesIsolated Footing (R or S)Shaniha kkNo ratings yet

- Description Formula Units Location at Base: Provide Minimum SteelDocument1 pageDescription Formula Units Location at Base: Provide Minimum Steelp_ignatiusNo ratings yet

- Base Plate Design Is 800 2007Document147 pagesBase Plate Design Is 800 2007pandian100% (1)

- Circular Foundation Design For PoleDocument2 pagesCircular Foundation Design For PoleJayNo ratings yet

- Final Pile Design - ResultantDocument3 pagesFinal Pile Design - Resultantvishnumani3011No ratings yet

- Input Data: Package: Bridge Name: Pier Name: 1. General Input DataDocument7 pagesInput Data: Package: Bridge Name: Pier Name: 1. General Input DataTuanNo ratings yet

- Cantilever Walkway Design WS1Document2 pagesCantilever Walkway Design WS1Raju SainiNo ratings yet

- Design of Pile and Pile Cap BeamDocument4 pagesDesign of Pile and Pile Cap Beamshivendra kumarNo ratings yet

- Busugan Part 2 Design BSDSDocument257 pagesBusugan Part 2 Design BSDSmarco miguelNo ratings yet

- Two Way SlabDocument13 pagesTwo Way SlabAnna Lorraine AquinoNo ratings yet

- Composite BeamDocument2 pagesComposite BeamJustin MusopoleNo ratings yet

- 4.beam Design Singly and DoublyDocument10 pages4.beam Design Singly and DoublyReuben James BangaoilNo ratings yet

- BS 8110 Data Given: Calculation SheetDocument10 pagesBS 8110 Data Given: Calculation SheetLee See VoonNo ratings yet

- Crack Width Check (CoP Concrete 2013) CPRDocument4 pagesCrack Width Check (CoP Concrete 2013) CPRAndrew WtchengNo ratings yet

- 27L1 - B33 Deflection SummaryDocument5 pages27L1 - B33 Deflection SummaryaadityasNo ratings yet

- STAIRDocument4 pagesSTAIRJoe BirdNo ratings yet

- Stair KagiggrDocument8 pagesStair KagiggrRabin BhattaraiNo ratings yet

- Kuantum - Design of Eccentric FootingDocument18 pagesKuantum - Design of Eccentric FootingAamir SuhailNo ratings yet

- Laporan Pondasi Pasar R.2Document34 pagesLaporan Pondasi Pasar R.2Dio Akbar HakimNo ratings yet

- Isolated Footing Design: Foundation Type: IFDocument7 pagesIsolated Footing Design: Foundation Type: IFBhuwan JoshiNo ratings yet

- End Span L-Beam DesignDocument7 pagesEnd Span L-Beam DesignAlexZaNo ratings yet

- Two Way SlabDocument9 pagesTwo Way SlabMehul Paþel100% (1)

- Purlin and RunnerDocument8 pagesPurlin and RunnerBabu Sundararaman0% (1)

- Corner Wall Design - CulvertDocument5 pagesCorner Wall Design - CulvertSuresh MahalingamNo ratings yet

- Pad Foundation DesignDocument4 pagesPad Foundation DesignNaison StanleyNo ratings yet

- Design as per TR-34, 3rd Edition with fibres Amazon FC 69 kNDocument8 pagesDesign as per TR-34, 3rd Edition with fibres Amazon FC 69 kNAhmed ElsheikhNo ratings yet

- BeamDocument2 pagesBeamWintun73No ratings yet

- Project: Beam Number: Engineer: Date:: Design Doubly Reinforcement Rectangular BeamDocument4 pagesProject: Beam Number: Engineer: Date:: Design Doubly Reinforcement Rectangular BeamAnonymous e2wolbeFsNo ratings yet

- 4.substructure PH 2Document16 pages4.substructure PH 2snehaNo ratings yet

- Calculation Sheet: Title: Pengecekan B4 Terhadap Beban Eskalator 0 LRT Jakarta 28/12/2018Document3 pagesCalculation Sheet: Title: Pengecekan B4 Terhadap Beban Eskalator 0 LRT Jakarta 28/12/2018MuhammadFurqanMuhsininNo ratings yet

- C7CH20050 - Wall - Reinforcement - WR2Document20 pagesC7CH20050 - Wall - Reinforcement - WR2Mahadev Sastry100% (1)

- Design of Isolated Footing For CheckingDocument3 pagesDesign of Isolated Footing For CheckingNizar AhamedNo ratings yet

- Design of Isolated Footing For CheckingDocument3 pagesDesign of Isolated Footing For CheckingNizar AhamedNo ratings yet

- Wall Design - CulvertDocument5 pagesWall Design - CulvertSuresh Mahalingam100% (1)

- Combined FootingDocument2 pagesCombined Footingsantosh-a-biraj-330750% (6)

- Project: Subject:: Design of SheathingDocument2 pagesProject: Subject:: Design of Sheathingbmurali19783190No ratings yet

- 05.08.2009 - Cable Trench SectionsDocument22 pages05.08.2009 - Cable Trench SectionsandyhrNo ratings yet

- Design Sheet: DPWH DesignedDocument5 pagesDesign Sheet: DPWH DesignedEdward Albert Mendoza BañagaNo ratings yet

- Design of Two Way Slab Marked: General Data: Girls/Boys Hostel For Tamilnadu DR - Ambedkar Law UniversityDocument3 pagesDesign of Two Way Slab Marked: General Data: Girls/Boys Hostel For Tamilnadu DR - Ambedkar Law Universitysantosh bharathyNo ratings yet

- Crack Width Calculation-FinalDocument4 pagesCrack Width Calculation-Finalbalaji gmscNo ratings yet

Combined Footing Design

Combined Footing Design

Uploaded by

Aditya KasarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Combined Footing Design

Combined Footing Design

Uploaded by

Aditya KasarCopyright:

Available Formats

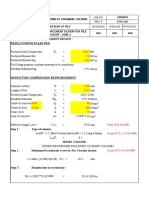

PROJECT SARBOTTAL STEEL

BUILDING NAME INPUT DATA DESIGN BY SOHEL

CF1

BUILDING TYPE CONCRETE GRADE M25 CHECKS REVISION DATE

BUILDING FLOORS STEEL GRADE Fe500 OUTPUT DATA R0 04.02.2021

LOAD DATA

DESIGN : COMBINED FOOTING Reactive Force

Design Data P1= 900 KN

Dimensions of the footing P2= 900 KN

Length Lx

=

5 m fck = 25 N/mm2 SBC= 150 KN/m2

Width Lz

=

3.2 m fy = 500 N/mm 2

Column Size

C/C of Column M3 Cx1= 0.3 m Cx2= 0.3 m

L =

Column Sizes

m 131.83 Cz1= 0.45 m Cz2= 0.45 m

3

M1 M2 105.47

105.47

Design Calculation

Assume the thickness of slab as

D 450 mm

Cover to Footing C 65 mm

Assume dia of reinf.= ᵩ 12 mm

Effective Depth d 379 mm

Two Way Shear/ Punching Shear Check 0.379 m

For Column-1 Cx1= 0.3 m

Vertical Load,P1= 900 Cz1= 0.45 m

KN

Punching Area=(Cx1+d)*(Cz1+d) 0.562891 Cx1+d 0.679 m

m2

Punching Perimeter=(2*Cx1+2*Cz1+4*d) 3.016 Cz1+d 0.829 m

m

Punching Stress, ζp'=(

718.108043928424 2*Cx1+2*Cz1+4*d 3.016 m

P1-q*(Cx1+d)*(Cz1+d))/(2*Cx1+2*Cz1+4*d)*d KN/m2

0.72 q= 140.63 KN/m2 SBC 1500 KN/m2

N/mm2

Permissible Punching Stress, ζp,as per IS

1.25 As q<SBC OK

456:2000 = 0.25sqrt(fck) N/mm2

AS ζp'<ζp Depth is Safe

For Column-2 Cx2= m

0.3

Vertical Load,P2= 900 Cz2= m

KN 0.45

Punching Area=(Cx2+d)*(Cz2+d) 0.562891 Cx2+d 0.679 m

m2

Punching Perimeter=(2*Cx2+2*Cz2+4*d) 3.016 Cz2+d 0.829 m

m

Punching Stress, ζp'=(

718.105581725958 2*Cx2+2*Cz2+4*d 3.016 m

P2-q*(Cx2+d)*(Cz2+d))/(2*Cx2+2*Cz2+4*d)*d

KN/m2

0.72 Base Pressure, q= 140.63 KN/m2 SBC 150 KN/m2

N/mm2

Permissible Punching Stress, ζp,as per IS

1.25 As q<SBC OK

456:2000 = 0.25sqrt(fck) N/mm2

AS ζp'<ζp Depth is Safe

Loading Diagram

(Equal Overhang on both sides)

M1= Longittudinal Moment(For Cantilever to Support Moment)

M2= Longittudinal Moment(For Cantilever to Support Moment)

M3= Longittudinal Moment(Span Moment)

M4= Transverse Moment(For Cantilever to Support Moment)

Calculation for Longitudinal Moment: M1, M2 & M3

Lx= 5m

Lz= 3.2 m

L= 3m

L/2= 1.5 m

a= 1m

b= 1m

Lz/2= 1.6 m

R1=w*L/2 316.40625 KN-m

Guiding Base Pressure,Ultimate for footing 1.5*q 210.94 KN/m2/m

design, w=1.5*q Sign Convention:

M1= (w*a^2)/2= 105.47 KN-m Clockwise Moment Positive

M2= (w*b^2)/2= 105.47 KN-m Anticlockwise Moment Negative

M3= M1+w*((L/2)^2)/2)-R1*L/2 -131.83 KN-m

Absolute Value of M1, M2 & M3

Abs(M1)= 105.47 KN-m

Abs(M2)= 105.47 KN-m

Abs(M3)= 131.83 KN-m

Calculation for Transverse Moment: M4, M5

M4= w*((Lz/2)^2)/2 270 KN-m

M5= 0 KN-m

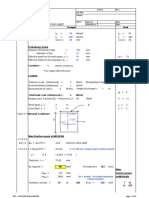

Calculation for Reinforcement

Reinf. for M1:

105.47 KN-m

M1=

379 mm D= 450 mm

d=

1000 mm

b=

25 N/mm2 500 N/mm2

fck= fy=

Let, x is neutral axis depth,

x/d=1.2-sqrt((1.2^2-(6.68Mu/fck*b*d^2)) 0.08

Lever Arm, Z=d*(1-0.416*x/d) 366.39

Ast= Mu/(0.87*fy*z) mm2

661.75

Ast(min), 0.12% 540 mm2

Max of Ast & Ast(min) )= 661.75

Ast (Required)= 661.75

Ast(Provided)= 753.6 mm2

Ast(Prov) > Ast(req) Hence, OK

Let 12 DIA BAR IS USED

Provide 12 Φ@ 150 C/C

Reinf. for M2:

105.47 KN-m

M2=

379 mm D= 450 mm

d=

1000 mm

b=

25 N/mm2 500 N/mm2

fck= fy=

Let, x is neutral axis depth,

x/d=1.2-sqrt((1.2^2-(6.68Mu/fck*b*d^2)) 0.08

Lever Arm, Z=d*(1-0.416*x/d) 366.39

Ast= Mu/(0.87*fy*z) mm2

661.75

Ast(min), 0.12% 540 mm2

Max of Ast & Ast(min) )= 661.75

Ast (Required)= 661.75

Ast(Provided)= 753.6 mm2

Ast(Prov) > Ast(req) Hence, OK

Let 12 DIA BAR IS USED

Provide 12 Φ@ 150 C/C

Reinf. for M3:

131.83 KN-m

M3=

379 mm D= 450 mm

d=

1000 mm

b=

25 N/mm2 500 N/mm2

fck= fy=

Let, x is neutral axis depth,

x/d=1.2-sqrt((1.2^2-(6.68Mu/fck*b*d^2)) 0.11

Lever Arm, Z=d*(1-0.416*x/d) 361.66

Ast= Mu/(0.87*fy*z) mm2

837.96

Ast(min), 0.12% 540 mm2

Max of Ast & Ast(min) )= 837.96

Ast (Required)= 837.96

Ast(Provided)= 904.32 mm2

Ast(Prov) > Ast(req) Hence, OK

Let 12 DIA BAR IS USED

Provide 12 Φ@ 125 C/C

Reinf. for M4:

270 KN-m

M4=

379 mm D= 450 mm

d=

1000 mm

b=

25 N/mm2 500 N/mm2

fck= fy=

Let, x is neutral axis depth,

x/d=1.2-sqrt((1.2^2-(6.68Mu/fck*b*d^2)) 0.23

Lever Arm, Z=d*(1-0.416*x/d) 342.74

Ast= Mu/(0.87*fy*z) mm2

1810.96

Ast(min), 0.12% 540 mm2

Max of Ast & Ast(min) )= 1810.96

Ast (Required)= 1810.96

Ast(Provided)= 2009.6 mm2

Ast(Prov) > Ast(req) Hence, OK

Let 16 DIA BAR IS USED

Provide 16 Φ@ 100 C/C

Reinf. for M5:

0 KN-m

M5=

379 mm D= 450 mm

d=

1000 mm

b=

fck= 25 N/mm2 fy= 500 N/mm2

Let, x is neutral axis depth,

x/d=1.2-sqrt((1.2^2-(6.68Mu/fck*b*d^2)) 0

Lever Arm, Z=d*(1-0.416*x/d) 379

Ast= Mu/(0.87*fy*z) mm2

0

Ast(min), 0.12% 540 mm2

Max of Ast & Ast(min) )= 540

Ast (Required)= 540

Ast(Provided)= 628 mm2

Ast(Prov) > Ast(req) Hence, OK

Let 10 DIA BAR IS USED

Provide 10 Φ@ 125 C/C

You might also like

- Pile Foundation Design SpreadsheetDocument7 pagesPile Foundation Design SpreadsheetmuhannedNo ratings yet

- Pile Cap DesignDocument35 pagesPile Cap Designعصام السامرائي100% (2)

- Check For SBC P/A M /Z M /Z: Provided Area Is OkayDocument2 pagesCheck For SBC P/A M /Z M /Z: Provided Area Is OkayVikunj TilvaNo ratings yet

- Design of Formwork For Column R0 - 3.7 MTRDocument5 pagesDesign of Formwork For Column R0 - 3.7 MTRrahul1433No ratings yet

- Page 1+1 of 9Document3 pagesPage 1+1 of 9Sabbir ChowdhuryNo ratings yet

- Calculation Sheet: 7007 Design For The Slab - Top & Bottom Mesh PP BK DataDocument3 pagesCalculation Sheet: 7007 Design For The Slab - Top & Bottom Mesh PP BK Dataasif billalNo ratings yet

- Project: Architect: Footing No.Document4 pagesProject: Architect: Footing No.Maninder ChaudharyNo ratings yet

- 11design of Axially Loaded Column With, Uniaxial MomentDocument3 pages11design of Axially Loaded Column With, Uniaxial MomentJames AswaNo ratings yet

- DESIGN OF FLOOR SLAB (0.15m Thick)Document9 pagesDESIGN OF FLOOR SLAB (0.15m Thick)Living Life100% (1)

- Loads:: Housing Layout-Sd-EastDocument2 pagesLoads:: Housing Layout-Sd-Eastpvrk_78No ratings yet

- Grade Slab ACI 150thkDocument7 pagesGrade Slab ACI 150thkraahul_nNo ratings yet

- Pad Foundation DesignDocument4 pagesPad Foundation Designg4goharNo ratings yet

- Neutral AxisDocument2 pagesNeutral AxispandianNo ratings yet

- Beam DesignDocument54 pagesBeam DesignLagnajit DasNo ratings yet

- Beam Design TemplateDocument9 pagesBeam Design TemplateWinston AdvinculaNo ratings yet

- Tensile Reinforcement For Bending: Check For Punching ShearDocument2 pagesTensile Reinforcement For Bending: Check For Punching ShearShindiya LalNo ratings yet

- Two Way Slab Design - 2 KN m2Document16 pagesTwo Way Slab Design - 2 KN m2pandianNo ratings yet

- Isolated Footing (R or S)Document19 pagesIsolated Footing (R or S)Shaniha kkNo ratings yet

- Description Formula Units Location at Base: Provide Minimum SteelDocument1 pageDescription Formula Units Location at Base: Provide Minimum Steelp_ignatiusNo ratings yet

- Base Plate Design Is 800 2007Document147 pagesBase Plate Design Is 800 2007pandian100% (1)

- Circular Foundation Design For PoleDocument2 pagesCircular Foundation Design For PoleJayNo ratings yet

- Final Pile Design - ResultantDocument3 pagesFinal Pile Design - Resultantvishnumani3011No ratings yet

- Input Data: Package: Bridge Name: Pier Name: 1. General Input DataDocument7 pagesInput Data: Package: Bridge Name: Pier Name: 1. General Input DataTuanNo ratings yet

- Cantilever Walkway Design WS1Document2 pagesCantilever Walkway Design WS1Raju SainiNo ratings yet

- Design of Pile and Pile Cap BeamDocument4 pagesDesign of Pile and Pile Cap Beamshivendra kumarNo ratings yet

- Busugan Part 2 Design BSDSDocument257 pagesBusugan Part 2 Design BSDSmarco miguelNo ratings yet

- Two Way SlabDocument13 pagesTwo Way SlabAnna Lorraine AquinoNo ratings yet

- Composite BeamDocument2 pagesComposite BeamJustin MusopoleNo ratings yet

- 4.beam Design Singly and DoublyDocument10 pages4.beam Design Singly and DoublyReuben James BangaoilNo ratings yet

- BS 8110 Data Given: Calculation SheetDocument10 pagesBS 8110 Data Given: Calculation SheetLee See VoonNo ratings yet

- Crack Width Check (CoP Concrete 2013) CPRDocument4 pagesCrack Width Check (CoP Concrete 2013) CPRAndrew WtchengNo ratings yet

- 27L1 - B33 Deflection SummaryDocument5 pages27L1 - B33 Deflection SummaryaadityasNo ratings yet

- STAIRDocument4 pagesSTAIRJoe BirdNo ratings yet

- Stair KagiggrDocument8 pagesStair KagiggrRabin BhattaraiNo ratings yet

- Kuantum - Design of Eccentric FootingDocument18 pagesKuantum - Design of Eccentric FootingAamir SuhailNo ratings yet

- Laporan Pondasi Pasar R.2Document34 pagesLaporan Pondasi Pasar R.2Dio Akbar HakimNo ratings yet

- Isolated Footing Design: Foundation Type: IFDocument7 pagesIsolated Footing Design: Foundation Type: IFBhuwan JoshiNo ratings yet

- End Span L-Beam DesignDocument7 pagesEnd Span L-Beam DesignAlexZaNo ratings yet

- Two Way SlabDocument9 pagesTwo Way SlabMehul Paþel100% (1)

- Purlin and RunnerDocument8 pagesPurlin and RunnerBabu Sundararaman0% (1)

- Corner Wall Design - CulvertDocument5 pagesCorner Wall Design - CulvertSuresh MahalingamNo ratings yet

- Pad Foundation DesignDocument4 pagesPad Foundation DesignNaison StanleyNo ratings yet

- Design as per TR-34, 3rd Edition with fibres Amazon FC 69 kNDocument8 pagesDesign as per TR-34, 3rd Edition with fibres Amazon FC 69 kNAhmed ElsheikhNo ratings yet

- BeamDocument2 pagesBeamWintun73No ratings yet

- Project: Beam Number: Engineer: Date:: Design Doubly Reinforcement Rectangular BeamDocument4 pagesProject: Beam Number: Engineer: Date:: Design Doubly Reinforcement Rectangular BeamAnonymous e2wolbeFsNo ratings yet

- 4.substructure PH 2Document16 pages4.substructure PH 2snehaNo ratings yet

- Calculation Sheet: Title: Pengecekan B4 Terhadap Beban Eskalator 0 LRT Jakarta 28/12/2018Document3 pagesCalculation Sheet: Title: Pengecekan B4 Terhadap Beban Eskalator 0 LRT Jakarta 28/12/2018MuhammadFurqanMuhsininNo ratings yet

- C7CH20050 - Wall - Reinforcement - WR2Document20 pagesC7CH20050 - Wall - Reinforcement - WR2Mahadev Sastry100% (1)

- Design of Isolated Footing For CheckingDocument3 pagesDesign of Isolated Footing For CheckingNizar AhamedNo ratings yet

- Design of Isolated Footing For CheckingDocument3 pagesDesign of Isolated Footing For CheckingNizar AhamedNo ratings yet

- Wall Design - CulvertDocument5 pagesWall Design - CulvertSuresh Mahalingam100% (1)

- Combined FootingDocument2 pagesCombined Footingsantosh-a-biraj-330750% (6)

- Project: Subject:: Design of SheathingDocument2 pagesProject: Subject:: Design of Sheathingbmurali19783190No ratings yet

- 05.08.2009 - Cable Trench SectionsDocument22 pages05.08.2009 - Cable Trench SectionsandyhrNo ratings yet

- Design Sheet: DPWH DesignedDocument5 pagesDesign Sheet: DPWH DesignedEdward Albert Mendoza BañagaNo ratings yet

- Design of Two Way Slab Marked: General Data: Girls/Boys Hostel For Tamilnadu DR - Ambedkar Law UniversityDocument3 pagesDesign of Two Way Slab Marked: General Data: Girls/Boys Hostel For Tamilnadu DR - Ambedkar Law Universitysantosh bharathyNo ratings yet

- Crack Width Calculation-FinalDocument4 pagesCrack Width Calculation-Finalbalaji gmscNo ratings yet