Professional Documents

Culture Documents

Automatic Hot Cutter, Construction

Automatic Hot Cutter, Construction

Uploaded by

MossstazzzaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automatic Hot Cutter, Construction

Automatic Hot Cutter, Construction

Uploaded by

MossstazzzaCopyright:

Available Formats

AUTOMATIC

HOT KNIFE CUTTER

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

How to operate

1. An example (Cutting length : 70mm, Cutting quantity : 120 pcs)

▷ Turn on the POWER SW.

▷ Set the temperature.(It is normally used at 250°~350°C. About 5 minutes after turn-on

& set it, it will be reached to set-temperature. (For more detail, refer to the appended

"How to use temperature Controller KX4")

※ Caution : When a work is over, set the temperature at zero and turn the cooling

fan 10 minutes or so and power off.

▷ Set cutting length. (Press the following buttons in order.)

☞ LENGTH

⇒ 7

⇒

0

LENGTH

CLEAR ⇒ S ET

▷ Set cutting quantity.

☞ Q ‘TY

1

⇒ EXTRA ⇒

SPEED

2 ⇒

0

LENGTH

CLEAR ⇒ SE T

▷ Running of knife-front roller

Turn on MOTOR SW to prevent cut materials from clinging to the knife blade.

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

▷ Press START button.

☞ START

2. Key functions

0

LENGTH

CLEAR : Current length on display will be back to “0” at a stop.

RESET

: All of current length and current q‘ty on display will be back to "0".

5

M/CUT : Moving knife only.

① to cut the material for test.

② to take out the material jammed between knife blades.

③ for balancing of knife blades in exchange.

1

EXTRA : Cutting additional one.

SHIFT

ESC : Restoring to normal condition in ERROR(red LED)

- It don't remove number and length.

and inputting parameter or program.

4 6

FEED FEED : to move the roller manually for mounting the material on the machine

or for feeding it forwards or backwards.

― Speed up (The current speed appears on the left-upside of LCD display with

SPEED

2

"%". Normal speed : 50%, Maximum speed : 100%)

8

SPEED

― Speed up (The current speed appears on the left-upside of LCD display with

"%". Normal speed : 50%, Maximum speed : 0%)

* Speed up & down is possible in any time(operation or stop) and set-speed will

not be changed even though you press RESET button or power off & on.

←

DEL : to correct rang data.

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

FILE

: Function for label cutting

: To cut with sensor

: to prevent the cut material from clinging to the knife blade.

MOTOR SW

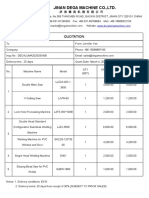

3. Specification

Max. Range of Packing Size

Model Main Cutting Cutting Power Cutting Q'ty/min. Machine Size

Cutting Cutting (Gross

Name Materials Knife Supply (Length: 50mm) (Net Weight)

Width Length weight)

HOT KNIFE

Ribbon tape, AC110/220V 15mm~ 820×370×380 540×470×430

CUTTER Hot 90mm 120~140 cuts

Small webbing 50/60Hz 300M (20.5kgs) (25kg)

4. Caution for use

- Before use, please confirm the voltage and make ground(earth) connection.

- Do not access hands or any object close to the working knife. (for safety)

- When the knife blade becomes dull, please use it after grinding with the grinding machine.

(Please do not let the unskilled person grind manually or install the knife blade.)

EXCHANGE OF KNIFE

1) First of all, move up the upper knife to top level and power off and remove pressure

from the upper knife after unscrewing 2 bolts by 4mm wrench

2) Take off the upper knife frame by 6mm wrench

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

Mount of roll

Fix the roll triangle by 4mm-wrench.

Exchange of fuse

Take off the power plug and exchange as picture.

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

How to solve hairy-label problem

Sometimes you can see a label, one

side is sealed well, but the other side

is not sealed well.

Just like left image.

This problem is caused by the wrong

height of the front feeding (upper)

roller.

Here we'll call "pressing roller" "upper

front feeding roller".

The left-above image shows the ideal height, between upper front feeding roller and hot

knife.

When the hot knife moved down completely, the gab between upper front feeding roller

and lower front feeding roller should be the same with thickness of label. In this case,

the label can have proper time to be sealed and then be pulled out well.

Next page, you can see some problems caused by wrong height of upper front feeding

roller.

If it is higher than hot knife, the material won't be pulled out, so cut labels would stick to

hot knife.

And the upper front feeding roller is lower than hot knife, the front feeding roller will pull

out the label before the label is sealed well.

So the other side will be hairy.

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

Case 1. The front feeding roller is higher than hot-knife.

As you can see left image, the upper

front feeding roller is higher than

hot-knife.

In this case, the label can't be pulled

out. So the label will stick to hot knife.

And you can see the labels as blow

image.

You can also see left image, when you turned off the front

feeding roller switch.

Case 2. The front feeding roller is lower than the hot-knife.

As you can see left image, the upper

front feeding roller is lower than

hot-knife.

In this case, the front feeding roller

pulled out the label before the label is

sealed well.

So the one side is sealed well and the

other side is hairy, just like below

image.

The next page, you can see how to adjust the height of upper front feeding roller.

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

Please set proper height of upper front feeding

roller, refer to below images.

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

Part Drawing A (Feeding part)

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

Part List A (Feeding part)

Part No. Description Part No. Description

A-1 Clamping Bolt(M3×5L) A-23 Stepping Motor

A-2 Upper Cap of Cooling Fan A-24 Clamping Bolt(M4×13L)

A-3 Cooling Fan(Small) A-25 Ball Bearing(#696)

A-4 Check Nut(M4) A-26 Guide-clamping Bracket

A-5 Clamping Bolt(M4×10L) A-27 Stopper

A-6 Safety-grill of Cooling Fan A-28 Lower Roller

A-7 Pressure-control Bolt A-29 Upper Roller

A-8 Pressure-control Spring Cover A-30 Front-guide Pin

A-9 Pressure-control Spring A-31 Lever Shaft

A-10 Detent Screw(M4×6L) A-32 Guide Ring

A-11 Slide Block of Upper Roller A-33 Knob Bolt of Guide Ring

A-12 Slide Lever A-34 Round Screw(M4×5L)

A-13 Clamping Washer A-35 Lever Bracket

A-14 Wrench Bolt(M4×14L) A-36 Clamping Bolt(M5×5L)

A-15 Tie Bar of Stepping Motor A-37 Lever

A-16 Bearing Cover A-38 Right Roller Bracket

A-17 Clamping Bolt(M3×5L) A-39 Clamping Bolt(M3×5L)

A-18 Feed-timing Gear(MXL30T) A-40 Left Roller Bracket

A-19 Detent Screw(M4×6L) A-41 Oilless

A-20 Drive-timing Gear(MXL20T) A-42 Space Plate of Roller Bracket

A-21 Detent Screw(M3×6L)

A-22 Timing Belt(MXL75)

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

Part Drawing B (Cutting part)

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

Part List B (Cutting part)

Part No. Description Part No. Description

B-1 Clamping Bolt(M8×15L) B-38 Lower Knife Case

B-2 Neck Washer of Hot-knife Bracket B-39 Ball Bearing(#6004)

B-3 Upper Knife Case B-40 Snap Ring

B-4 Heat Sensor B-41 +

Motor Reduction Gear

B-5 Heater B-42 Motor Supporter

B-6 Hot-Knife Bracket B-43 Motor Key

B-7 Hot-Knife B-44 Clamping Bolt(M5×42L)

B-7b Detent Screw(M5×8)(M6×20) B-45 Counting Sensor

B-8 Vertical Axle B-46 Clamping Bolt(M3×18L)

B-9 Shaft Ring B-47 Clamping Bracket

B-10 Detent Screw(M4×4L) B-48 Right Pressure Plate

B-11 Pressing Plate Cover B-49 Left Pressure Plate

B-12 Clamping Bolt(M4×6L) B-50 Clamping Bolt of Pressure Plate

B-13 Front Cover B-51 Pressure Spring

B-14 Clamping Bolt(M3×5L) B-52 Wrench Bolt(M5×15L)

B-15 Slide Ram B-53 Neck Washer

B-16 Clamping Bolt(M6×75L) B-54 Crank Bundle

B-17 Check Nut(M6) B-55 Cam

B-18 Flat-head Washer Spring B-56 Niddle Bearing

B-19 Counting-sensor Bracket B-57 E-Ring

B-20 Shaft Rubber-bushing B-58 Front Feeding Roller

B-21 LM Guide B-59 Front Feeding Sub-roller

B-22 Wrench Bolt(M5×20L) B-60 Roller Shaft Bracket

B-23 LM Bearing B-61 Clamping Bolt(M3×12L)

B-24 Detent Screw(M4×6L) B-62 DC Motor

B-25 Verical Axle Ring B-63 DC Motor Bracket

B-26 Detent Screw(M4×6L) B-64 Clamping Bolt(M3×4L)

B-27 Roller-clamping Bracket B-65 Flat-head Bolt(M3×4L)

B-28 Pressing Roller B-66 Vertical Control Nut

B-29 Roller Shaft B-67 Flat Washer

B-30 Ball Bearing(#686) B-68 Heater Wiring Spring

B-31 Heating Plate B-69 Heater Wiring Pipe(1)

B-32 Silicon Plate B-70 Heater Wiring Pipe(2)

B-33 Heating Plate Bracket B-71 Upper Pipe Bracket

B-34 Bracket Side Cover B-72 Wrench Bolt(M4×15L)

B-35 Flat-head Bolt(M3×8L) B-73 Lower Pipe Bracket

B-36 Wrench Bolt(M5×15L) B-74 Wrench Bolt(M4×15L)

B-37 Hexagon-head Bolt(M4×8L)

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

Part Drawing C (Other part)

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

Part List C (Other part)

Part No. Description Part No. Description

C-1 Roll-hanger Wheel C-30 Clamping Bolt(M3×5L)

C-2 Clamping Bolt of Holder C-31 Left Cover

C-3 Holder C-32 Rubber Bushing

C-4 Roll-hanger Shaft C-33 Separated Terminal

C-5 Roll-hanger Shaft Washer C-34 Clamping Bolt(M3×6L)

C-6 Check Nut(M6) C-35 SSR(Solid State Relay)

C-7 Roll Hanger C-36 Clamping Bolt(M4×8L)

C-8 Flat-head Bolt(M6×16L) C-37 Sponge

C-9 Neck Washer of Roll-hanger C-38 Base

C-10 Existence Detector C-39 Clamping Bolt(M4×8L)

C-11 Clamping Bolt(M3×5L) C-40 Condenser

C-12 Clamping Bolt C-41 Terminal

C-13 Rear Guide-pin Bracket C-42 Transformer

C-14 Wrench Bolt(M4×15L) C-43 Clamping Bolt(M4)

C-15 Rear Tension-guide Block C-44 Cooling Fan(Large)

C-16 Detent Screw(M4×6L) C-45 Clamping Bolt(M3×6L)

C-17 Guide Ring C-46 Temperature-controller (KX4)

C-18 Upper Guide Plate C-47 Temperature-controller Socket

C-19 Clamping Bolt(M3×5L) C-48 Control Cover

C-20 Micro Limit Switch C-49 Control Circuit Board(MB)

C-21 Plate Nut C-50 ROM

C-22 Limit Switch Bracket C-51 Operation Circuit Board(OP)

C-23 Clamping Bolt(M2×10L) C-52 Drive Circuit Board(DR)

C-24 Clamping Bolt(M3×5L) C-53 SMPS(Power Supply,SP)

C-25 Knob Bolt C-54 Toggle Switch

C-26 Power Cord C-55 Power Switch

C-27 Clamping Bolt(M3×5L) C-56 Urethane Panel

C-28 AC Connector(IN-PUT) C-57 Rectification Board

C-29 AC Connector(OUT-PUT)

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

HOW TO DO AUTO-TUNING

After changing a part or parts (temp. sensor or heater or temp. controller), you can experience

that there are much temperature-deviation between set temperature(SV) and present

temperature(PV).

In this case, by auto-tuning, you can reduce temperature-deviation between SV and PV.

Please do follow steps for auto-tuning.

- Referring manual, please set your common temperature. (ex, 300 ) ℃

- After PV's reaching set temperature, press “ ” and “ ” simultaneously.

(referring to below image(left))

If so, with AT lamp blinks, auto-tuning begins.

- After finishing auto-tuning, AT lamp will turn off.

- While auto-tuning, if you want to stop auto-tuning, plesae press “ ” and “ ”

simultaneously. If so, AT lamp turns off and auto-tuning stops.

- If you change SV (set temperature) during auto-tuning, auto-tuning stops and

temp. controller will use previous parameter.

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

Trouble-shooting

No Troubles Appicable model Causes & Measures

- Check if electric cord is connected well.

1 No power supply All models

- Check if the fuse blows out or not.

- Check if there is inserted any alien

substance in roller.

Feeding roller - If current length on display is changed,

All models

doesn't work. exchange drive board.

- If current length on display is not changed,

exchange Control board(MB).

Power is on,

2

but no work Knife doesn't - Check if pressure plates of upper knife are

All models

work. too much fastened or not.

LCD display - After opening the cover, check the connetion.

All models

doesn't work. (especially between Operation & MB board)

All functions - Check if auto-stop device lies down. If any,

Al models

don't work raise it up.

Hot cutter - Check if temperature goes up to set-degree.

3 Material is not cut.

(H, LH, SH, HX) - Check if knife blades are even(parallel).

- Check if blades are damaged or weared.

- After making both knives close each other

4 Material is cut onesidedly. All models by M/CUT button and check if they are even

or not. (If they are not even, adjust them by

bolts)

Cut-length is different from - Test cutting after loosening material from the

5 All models

set-length. reel by hand or attaching feeding device.

It cuts before the cutting line Label cutter - Move the sensor towards knife side as long

6

of labels. (S, SH) as the difference by pushing.

It cuts after the cutting line Label cutter - Move the sensor towards counter-knife side

7

of labels. (S, SH) as long as the difference by pushing.

- Trouble in Mark sensor →

Check if the sensor is connected well or not.

ERROR CODE [064] Label cutter

Check if the sensor is adjusted well or not.

>Sensor check Er (S, SH)

(FILE NO 001)

Check if it is label problem or not.

- Trouble in cutting motor or cutting sensor →

Upper knife moves 1~3 sec. and ERROR

on display. Check the connection of cutting

ERROR CODE [065]

All models sensor. If not, exchange the cutting sensor.

>CUT I/O Error!

Upper knife doesn't move and ERROR on

ERROR display. Exchange the cutting motor or drive

8 on LCD board.

& LED

→

STOP INPUT !! - Auto stop device is pressed down or shortage.

All models

CHECK STOP INP! raise up the device and check shortage.

(C)ACORD CTRL-OP

All models

- Bad connected ROM → Press ROM by hand

AMC-T3KA VER1.7D or connect it again. (If not, change MB board)

→

- Change of FILE 003 in program by noise or

※

mis-operation Initialize the controller.

+

ERROR CODE[065] How to Initialize(programs to be initial) :

All models

>CHECK CODE[003] press SET SHIFT/ESC buttons and

RESET button at the same time.

(Press RESET later than other two keys.)

Operator feels electric current - Connect the earth cord(green) to any bolt of

9 All models

in touch of machine. backside of machine.

After exchange ROM, you should do initialize the controller, due to error message,

10 if you cannot do initialization, please press "SHIFT/ESC' button to escape error message screen

and then initialize the controller.

Hilltop Products Ltd Tel: 01942 723101

Parkside Business Park Fax: 01942 273817

Kirkstead Way Email: sales@hilltop-products.co.uk

Golborne www.hilltop-products.co.uk

Warrington, WA3 3PY

You might also like

- 1 BIBO Touch (New Board) 3D Printer Operation Manual V3.0a28 PDFDocument82 pages1 BIBO Touch (New Board) 3D Printer Operation Manual V3.0a28 PDFJohn100% (2)

- FKJZ Face Mask Making Machine ManualDocument29 pagesFKJZ Face Mask Making Machine ManualEddy SanchezNo ratings yet

- J23-016B ManualDocument12 pagesJ23-016B ManualCarmen Méndez AnTonyNo ratings yet

- Seikitech HW User Manual, T SeriesDocument12 pagesSeikitech HW User Manual, T SeriesKen Dizzeru0% (1)

- Shimano-Dendoumaru-4000hp (6 Button)Document32 pagesShimano-Dendoumaru-4000hp (6 Button)Julie FraserNo ratings yet

- FGC-9 MkII GuideDocument194 pagesFGC-9 MkII GuideAlexis Boulangeot100% (3)

- BJ-03MAX ManualDocument23 pagesBJ-03MAX ManualezequielNo ratings yet

- Manual Cortadora de DiscoDocument14 pagesManual Cortadora de DiscoMartha JaquelinNo ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Me TBC 52RTDocument16 pagesMe TBC 52RTprotigaNo ratings yet

- Operation Manual: Pneumatic Ribbon CoderDocument6 pagesOperation Manual: Pneumatic Ribbon CoderLuis Enrique Barreto GarciaNo ratings yet

- ThermocutDocument5 pagesThermocutCesar MatuteNo ratings yet

- Artcut Bridge ManualDocument25 pagesArtcut Bridge Manualjosemijosemi100% (1)

- 450vs+ User ManualDocument13 pages450vs+ User ManualSuwanna ChamnongsangNo ratings yet

- HYDRAULIC paper cutter manualDocument20 pagesHYDRAULIC paper cutter manuals.house.pdpNo ratings yet

- Operation Manual: Beveling and Deburring Device B5Document13 pagesOperation Manual: Beveling and Deburring Device B5bulentNo ratings yet

- Usage Manual: H Serial Cutting PlotterDocument12 pagesUsage Manual: H Serial Cutting Plotterrays.illustrationsanddesignsNo ratings yet

- Laser Engraving Machine PDFDocument24 pagesLaser Engraving Machine PDFJuan Carlos Arroyave PosadaNo ratings yet

- TECHNICAL PROPOSAL For 0 5-4X1300 Automaitc Slitting Line PDFDocument12 pagesTECHNICAL PROPOSAL For 0 5-4X1300 Automaitc Slitting Line PDFTjNo ratings yet

- Model 52H Hydraulic Shear: Operation, Parts & Maintenance ManualDocument10 pagesModel 52H Hydraulic Shear: Operation, Parts & Maintenance ManualOmar SalmonNo ratings yet

- BIQU B1 User ManualDocument26 pagesBIQU B1 User ManualLoris PerraudinNo ratings yet

- Operation ManualDocument19 pagesOperation ManualJorge Kacic M.No ratings yet

- 4350T 4350CT 4350FCTDocument52 pages4350T 4350CT 4350FCTluverygNo ratings yet

- Instruction Manual: MIG210SDocument20 pagesInstruction Manual: MIG210SMani ShankerNo ratings yet

- Proxxon Thermocut Manual PDFDocument5 pagesProxxon Thermocut Manual PDFabansoNo ratings yet

- Model EngineersWorkshop February 2022Document70 pagesModel EngineersWorkshop February 2022KoushikKc Chatterjee100% (3)

- Cutok ManualDocument12 pagesCutok Manualpylon_403985644No ratings yet

- Service Guide BookDocument29 pagesService Guide BookSupport BiomedNo ratings yet

- Manual Plotter COLETECHDocument16 pagesManual Plotter COLETECHJuan Carlos CosmeNo ratings yet

- Taladro Magnetico Rotabest Mini 36-50 Manual OperacionDocument12 pagesTaladro Magnetico Rotabest Mini 36-50 Manual OperacionAtahualpa Bulganin Infante YañezNo ratings yet

- CX - ABA-1300 LDPE Three Layers Film Blown MachineDocument6 pagesCX - ABA-1300 LDPE Three Layers Film Blown Machinehoseinifizik1No ratings yet

- DGWMX-303D Busbar Punching Cutting Bending Machine From Shuohao Machinery PDFDocument8 pagesDGWMX-303D Busbar Punching Cutting Bending Machine From Shuohao Machinery PDFAdnan Naeem MalikNo ratings yet

- Surebind 3 Service ManualDocument106 pagesSurebind 3 Service ManualFatema NasreenNo ratings yet

- HQA20221122Document11 pagesHQA20221122mosab aliNo ratings yet

- HTW 320Document88 pagesHTW 320essafiwalidNo ratings yet

- DDGJ-1.2-1500-LY Operaion ManualDocument14 pagesDDGJ-1.2-1500-LY Operaion Manualsandeep7426No ratings yet

- Bonding NotesDocument6 pagesBonding NotesDerek YoungNo ratings yet

- Instruction Manual: & Standard EquipmentDocument8 pagesInstruction Manual: & Standard EquipmentAjiNo ratings yet

- Splicing Tapes: Product Bulletin - PB206 Uncoated Abrasive Belt Splicing TapesDocument2 pagesSplicing Tapes: Product Bulletin - PB206 Uncoated Abrasive Belt Splicing TapesrjferreiraengNo ratings yet

- Philips-59586202-Mg3740 15 Dfu RonDocument272 pagesPhilips-59586202-Mg3740 15 Dfu RonSmaranda AlinaNo ratings yet

- X3SA Manual V.01Document9 pagesX3SA Manual V.01adrianNo ratings yet

- Dip Brazing: Parts To Be Dip Brazed AreDocument10 pagesDip Brazing: Parts To Be Dip Brazed AreRavin SinghNo ratings yet

- Operating Manual: ReferenceDocument26 pagesOperating Manual: Referencestayin40No ratings yet

- Strapack - Iq400 ManualDocument16 pagesStrapack - Iq400 ManualEduardo Jesus RomeroNo ratings yet

- Machines Used For UPVC Window DoorDocument11 pagesMachines Used For UPVC Window DoorArsalan AmjidNo ratings yet

- CX - ABA-1300 HDPE Three Layers Film Blown MachineDocument6 pagesCX - ABA-1300 HDPE Three Layers Film Blown Machinehoseinifizik1No ratings yet

- OWI 535 ManualDocument39 pagesOWI 535 ManualJavier Oliveros100% (1)

- Reatech-Rebar Tools AmarrarDocument7 pagesReatech-Rebar Tools AmarrarCristian Gonzalo Fiorilo BravoNo ratings yet

- Product Instruction Manual A4 Pouch Laminating System Peak Lite - PL220Document4 pagesProduct Instruction Manual A4 Pouch Laminating System Peak Lite - PL220pointing140No ratings yet

- Betty Cutter Operation ManualDocument24 pagesBetty Cutter Operation ManualJaffer AftabNo ratings yet

- IR3 V1 InstructionDocument28 pagesIR3 V1 InstructionMolina JesusNo ratings yet

- Craftsman Plate Joiner 900.277300Document31 pagesCraftsman Plate Joiner 900.277300Dan CarsonNo ratings yet

- GB Ua PL Ro de Hu SK CZDocument28 pagesGB Ua PL Ro de Hu SK CZLohon TatianaNo ratings yet

- FXZ 160A (EnglishDocument17 pagesFXZ 160A (EnglishIdir IfriNo ratings yet

- 2023 - Brosur GMP Laminating All Series - PT. Neosys IndonesiaDocument14 pages2023 - Brosur GMP Laminating All Series - PT. Neosys IndonesiaRinaNo ratings yet

- PI 3 Machines With 2 Lanes Log Saw & 2 Boxes Packing MachineDocument8 pagesPI 3 Machines With 2 Lanes Log Saw & 2 Boxes Packing MachineMURALITHHARANNo ratings yet

- Model Engineers Workshop March 2022Document68 pagesModel Engineers Workshop March 2022alemao7x1 Diehl100% (1)

- Philips-58918785-Mg3720 15 Dfu TurDocument200 pagesPhilips-58918785-Mg3720 15 Dfu TurAli KeskinNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Short Rolling Concept Hard But Kinda GoodDocument7 pagesShort Rolling Concept Hard But Kinda GoodMossstazzzaNo ratings yet

- Proceso Bof en InglesDocument25 pagesProceso Bof en InglesMossstazzzaNo ratings yet

- Experiment Short and BadDocument15 pagesExperiment Short and BadMossstazzzaNo ratings yet

- Little Concepts About Welding and Thermal CuttingDocument20 pagesLittle Concepts About Welding and Thermal CuttingMossstazzzaNo ratings yet

- Milling Cold CuttingDocument20 pagesMilling Cold CuttingMossstazzzaNo ratings yet

- TLE 7 Group 5Document1 pageTLE 7 Group 5Ciel QuimlatNo ratings yet

- CORTEC Compact Valves - Critical ServiceDocument2 pagesCORTEC Compact Valves - Critical ServiceAndresNo ratings yet

- Sl. No Equipment List ModelDocument3 pagesSl. No Equipment List ModelJamal Mohamed RahamathullahNo ratings yet

- Panelboards - Electrical Design GuideDocument1 pagePanelboards - Electrical Design GuidezeliteNo ratings yet

- BOQ - Hearts & Arrows Office 04sep2023Document13 pagesBOQ - Hearts & Arrows Office 04sep2023ChristianNo ratings yet

- What Is MemoryDocument5 pagesWhat Is MemorySuhana SinghNo ratings yet

- Solar Module Sun Well WD-A-CC-087A 100WDocument1 pageSolar Module Sun Well WD-A-CC-087A 100WMidhat MalikNo ratings yet

- Simplex 4100-0033Document2 pagesSimplex 4100-0033vlaya1984No ratings yet

- Minox 071 Tube 2019Document1 pageMinox 071 Tube 2019MBI Heineken RonaldNo ratings yet

- C&E Mini PlantDocument1 pageC&E Mini PlantpavanNo ratings yet

- Aling - Experience KatalogDocument43 pagesAling - Experience KatalogCsaba VargaNo ratings yet

- Volvo Avtobus Manual PDFDocument148 pagesVolvo Avtobus Manual PDFRicadoNo ratings yet

- Susol VCB E 1405Document220 pagesSusol VCB E 1405tawanda1984No ratings yet

- Installation, Start-Up and Service Instructions: 50HJ006-014 Single-Package Rooftop Cooling Units 50 HZDocument52 pagesInstallation, Start-Up and Service Instructions: 50HJ006-014 Single-Package Rooftop Cooling Units 50 HZchaefaure4aNo ratings yet

- Modulating Gas Furnaces Final VersionDocument22 pagesModulating Gas Furnaces Final Versionapi-595091630No ratings yet

- Aircraft InstrumentsDocument12 pagesAircraft Instrumentssaumya irugalbandaraNo ratings yet

- AIB - GVS - 20 Bomba de VacioDocument11 pagesAIB - GVS - 20 Bomba de VacioRico GonzalezNo ratings yet

- TM9 243Document232 pagesTM9 243Christophe BrissonnetNo ratings yet

- ListAIS140ason02012019Details 1188Document3 pagesListAIS140ason02012019Details 1188Shubham Singh Tomar100% (1)

- Oil Purification GTP 05.05 PDFDocument2 pagesOil Purification GTP 05.05 PDFAbdulaziz AlrawiNo ratings yet

- 250DDocument2 pages250DRonald ShecklerNo ratings yet

- Col CVT-LSCS SSDocument2 pagesCol CVT-LSCS SSzoraima sulbaran camposNo ratings yet

- I - HRG0U25703 - Panel-Mounted Cab Assembly (Option)Document48 pagesI - HRG0U25703 - Panel-Mounted Cab Assembly (Option)JOAO BIANCHININo ratings yet

- Product Data Sheet: Acti9 IC2000 Indoor (2 - 2000 Lux) Twilight SwitchDocument2 pagesProduct Data Sheet: Acti9 IC2000 Indoor (2 - 2000 Lux) Twilight SwitchMohammed AbdulkareemNo ratings yet

- Rih - Esp Diagram Report 19-03-2014Document2 pagesRih - Esp Diagram Report 19-03-2014fauzan kartiyasaNo ratings yet

- Chimera ManualDocument48 pagesChimera Manualrichard limNo ratings yet

- DMC500 ManualDocument16 pagesDMC500 Manualroops04No ratings yet

- Yaskawa SGMS SGDS User ManualDocument177 pagesYaskawa SGMS SGDS User ManualsunhuynhNo ratings yet