Professional Documents

Culture Documents

9K688N

9K688N

Uploaded by

Helar Armejo VasquezCopyright:

Available Formats

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Nuclear Cheat SheetDocument8 pagesNuclear Cheat SheetM J RhoadesNo ratings yet

- Lesson Plan in Electricity (Electrical Tools, Supplies and Materials)Document5 pagesLesson Plan in Electricity (Electrical Tools, Supplies and Materials)Jessa Bahi-an100% (12)

- Tower Light Inspection ChecklistDocument19 pagesTower Light Inspection ChecklistMOHAMMED RIYAN TNo ratings yet

- EHVT 69kv Class PII With FoilDocument9 pagesEHVT 69kv Class PII With FoilAntonio GresiaNo ratings yet

- Gelport: 1. General Product InformationDocument1 pageGelport: 1. General Product InformationAugusto CunhaNo ratings yet

- WMS-FOC Splicing & Testing - Rev.ADocument11 pagesWMS-FOC Splicing & Testing - Rev.Anice hossain100% (4)

- Truck Loading Arms (D 32)Document7 pagesTruck Loading Arms (D 32)Elias EliasNo ratings yet

- IEC-60364-8-1 v13 NP Draft2Document21 pagesIEC-60364-8-1 v13 NP Draft2Electrician 013No ratings yet

- BQ5477Document10 pagesBQ5477Helar Armejo VasquezNo ratings yet

- Instruction For MV TerminationDocument7 pagesInstruction For MV TerminationWilfrid DutruelNo ratings yet

- 25 K VInstall GuideDocument23 pages25 K VInstall GuideMarcelo ConchaNo ratings yet

- Esd 4872 Au 5 09 PDFDocument10 pagesEsd 4872 Au 5 09 PDFGuler RahimNo ratings yet

- Kit de Terminacion TFT-150R-G TYCO ELECTRONICSDocument22 pagesKit de Terminacion TFT-150R-G TYCO ELECTRONICSWilbert ACNo ratings yet

- TE S Raychem Cable Accessories: Scan QR Codes and Get Video SupportDocument8 pagesTE S Raychem Cable Accessories: Scan QR Codes and Get Video SupportHossam AlzubairyNo ratings yet

- 2178CL-S Series F/O Splice Case: InstructionDocument13 pages2178CL-S Series F/O Splice Case: InstructionHữu Khánh NguyễnNo ratings yet

- Procedure For Cable Termination& Splicing Rev01Document5 pagesProcedure For Cable Termination& Splicing Rev01Syed MujahidNo ratings yet

- Rosemount 5400 Series Spare Part InstructionDocument14 pagesRosemount 5400 Series Spare Part InstructionEdinsonUribeTorresNo ratings yet

- Gelcap Insulating Splice Cover For 600V CableDocument2 pagesGelcap Insulating Splice Cover For 600V CableHelar Armejo VasquezNo ratings yet

- 4500 9 HDF 1 2 - Splicing - InstructionsDocument24 pages4500 9 HDF 1 2 - Splicing - InstructionsOWEMNo ratings yet

- Cable Termination - Installation Instructions - 755LR - IsDocument5 pagesCable Termination - Installation Instructions - 755LR - Isvladimir_71No ratings yet

- DTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionDocument10 pagesDTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionMuhammad Lathieful HaqNo ratings yet

- TOA Wall Mount Antenna Yw-4500Document20 pagesTOA Wall Mount Antenna Yw-4500Yoshinori SaitoNo ratings yet

- Idw DocumentDocument16 pagesIdw DocumentFerran MunyósNo ratings yet

- Installation Instruction No. 132101F/02.2008 Seik 14, 24, 34Document5 pagesInstallation Instruction No. 132101F/02.2008 Seik 14, 24, 34Sonia Noval LlorianNo ratings yet

- 33kV Elbow ManualDocument6 pages33kV Elbow ManualElliza IshakNo ratings yet

- Module 6 TelecomDocument29 pagesModule 6 TelecomMADRIAGA, CYRILLE MAE RUMANo ratings yet

- 92213701-Tii 320&321&325&326-RevD 0510 InstNtDocument1 page92213701-Tii 320&321&325&326-RevD 0510 InstNtjosettttNo ratings yet

- Duct Installation of Fiber Optic Cable PDFDocument9 pagesDuct Installation of Fiber Optic Cable PDFnecmettinsengunNo ratings yet

- INST. INST. 673 - BDBZ For Item 30Document8 pagesINST. INST. 673 - BDBZ For Item 30Zubab PanniNo ratings yet

- 3M Cold Shrink QT-III Silicone Rubber Indoor Tubular Termination KitDocument20 pages3M Cold Shrink QT-III Silicone Rubber Indoor Tubular Termination KitJRNo ratings yet

- Cable Splicing Procedure 005Document6 pagesCable Splicing Procedure 005RenzNo ratings yet

- 15kV PM Joints - Straight - KSU - 500-500sq - MMDocument8 pages15kV PM Joints - Straight - KSU - 500-500sq - MMabd elmohsen saedNo ratings yet

- Poly Hopper Service Motor Kit: Installation InstructionsDocument2 pagesPoly Hopper Service Motor Kit: Installation Instructions77ztfNo ratings yet

- Mid-Span Access of Loose-Tube Ribbon Fiber Optic Cable PDFDocument12 pagesMid-Span Access of Loose-Tube Ribbon Fiber Optic Cable PDFMehdi SHNo ratings yet

- E-Link 1000LR Antenna Quick Install Guide 980-0200-001A - 021811 - FinalDocument2 pagesE-Link 1000LR Antenna Quick Install Guide 980-0200-001A - 021811 - FinalIsrar ZiaNo ratings yet

- RVR / Outlander Sport / Asx Floor Illumination (Blue) MZ360353EX Installation and Handling InstructionsDocument12 pagesRVR / Outlander Sport / Asx Floor Illumination (Blue) MZ360353EX Installation and Handling InstructionsKip ClayNo ratings yet

- ISTRCSSJ25ENGDocument6 pagesISTRCSSJ25ENGHector Vidal Rodriguez ValdezNo ratings yet

- J6182FDocument5 pagesJ6182FHelar Armejo VasquezNo ratings yet

- 15kV Front Connector - KSU - 500sq - MMDocument7 pages15kV Front Connector - KSU - 500sq - MMabd elmohsen saedNo ratings yet

- Compact SureGround Grounding KitDocument2 pagesCompact SureGround Grounding KitWesdi DNo ratings yet

- Quick Term III 3MDocument11 pagesQuick Term III 3MGRUPO GENELCONo ratings yet

- 15kV Indoor Termination - KSU - 500sq - MMDocument6 pages15kV Indoor Termination - KSU - 500sq - MMabd elmohsen saedNo ratings yet

- YW-4500 Wall-Mounted Wireless Antenna: WarningDocument20 pagesYW-4500 Wall-Mounted Wireless Antenna: WarningTito SetiajiNo ratings yet

- Cable Gland Installation InstructionsDocument2 pagesCable Gland Installation InstructionsJairo WilchesNo ratings yet

- Distribution Plastic TiesDocument4 pagesDistribution Plastic TiesanonymousNo ratings yet

- HVT Series Terminations 15-35kV Class High Voltage Termination For LC Shield CableDocument6 pagesHVT Series Terminations 15-35kV Class High Voltage Termination For LC Shield Cable20353124No ratings yet

- Cat6 /6A Modular Plug: 3 Prong 50U" Gold PlatedDocument2 pagesCat6 /6A Modular Plug: 3 Prong 50U" Gold PlatedAndrés CisnerosNo ratings yet

- Terminal Con Copa 3M Cold Shrink QT-III 769X-S-4 KitsDocument20 pagesTerminal Con Copa 3M Cold Shrink QT-III 769X-S-4 KitsEnrique G.No ratings yet

- SF6170 K VDocument8 pagesSF6170 K VMuchlis AlatasNo ratings yet

- Sitesgfilescozyhq596files2020 093300XL20Transducer20Accessories20Datasheet20 20145668.pDocument15 pagesSitesgfilescozyhq596files2020 093300XL20Transducer20Accessories20Datasheet20 20145668.pqdzungNo ratings yet

- Toshiba TV 20AF45 - 20AF45C - SVM PDFDocument50 pagesToshiba TV 20AF45 - 20AF45C - SVM PDFcarlos avilaNo ratings yet

- 15kV Outdoor Termination - KSU - 500sq - MMDocument5 pages15kV Outdoor Termination - KSU - 500sq - MMabd elmohsen saedNo ratings yet

- 005 038Document11 pages005 038shaicoNo ratings yet

- KAT0815-0001-E Single Pole Insulated Conductor RailDocument36 pagesKAT0815-0001-E Single Pole Insulated Conductor RailirinaNo ratings yet

- WAGO For Network RailDocument14 pagesWAGO For Network Railgrilleflapper.00No ratings yet

- Tricks For Cable Accessories InstallationDocument30 pagesTricks For Cable Accessories InstallationcxfuentesNo ratings yet

- Installation Instructions For General Duty Safety Switches Directives D'installation Pour Interrupteurs de Sécurité UniverselsDocument6 pagesInstallation Instructions For General Duty Safety Switches Directives D'installation Pour Interrupteurs de Sécurité UniverselscarteauNo ratings yet

- Nordmende n2121cb Chassis Giii-08Document34 pagesNordmende n2121cb Chassis Giii-08PE TruNo ratings yet

- p220 en Inb43Document10 pagesp220 en Inb43Sambit MohapatraNo ratings yet

- 114-6053 High-Performance Modular Plug ConnectorsDocument10 pages114-6053 High-Performance Modular Plug ConnectorsDiegoNo ratings yet

- PII 1C 17.5kV CWS HKOTDocument6 pagesPII 1C 17.5kV CWS HKOTDaniel GarciaNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- J6182FDocument5 pagesJ6182FHelar Armejo VasquezNo ratings yet

- G H J K: Edyce Arrigoni Edyce ArrigoniDocument1 pageG H J K: Edyce Arrigoni Edyce ArrigoniHelar Armejo VasquezNo ratings yet

- Edr 5253Document10 pagesEdr 5253Helar Armejo VasquezNo ratings yet

- BQ5477Document10 pagesBQ5477Helar Armejo VasquezNo ratings yet

- HVS-S-1520S-M Series: Suggested Installation Equipment (Not Supplied With Kit) Recommended Tyco Electronics TorchesDocument6 pagesHVS-S-1520S-M Series: Suggested Installation Equipment (Not Supplied With Kit) Recommended Tyco Electronics TorchesHelar Armejo VasquezNo ratings yet

- Gelcap Insulating Splice Cover For 600V CableDocument2 pagesGelcap Insulating Splice Cover For 600V CableHelar Armejo VasquezNo ratings yet

- Gelport Sealed Bus Connector P/N Gp-350-Xx-Connscrew Gp-500-Xx-Connscrew 502-47264 (I) Rev. 0Document19 pagesGelport Sealed Bus Connector P/N Gp-350-Xx-Connscrew Gp-500-Xx-Connscrew 502-47264 (I) Rev. 0Helar Armejo VasquezNo ratings yet

- Engineering Test Report: Test Laboratory Markham, OntarioDocument22 pagesEngineering Test Report: Test Laboratory Markham, OntarioHelar Armejo VasquezNo ratings yet

- Miniwedge Gel Cover P/N 3-1199125-2 (GHFC-MW - (B10) ) 502-47233 REV. 0Document10 pagesMiniwedge Gel Cover P/N 3-1199125-2 (GHFC-MW - (B10) ) 502-47233 REV. 0Helar Armejo VasquezNo ratings yet

- Gelport Sealed Bus Connector To Accommodate 500kcmil Conductor P/N Gb-500-3P-Connscrew 502-47308 (I) Rev. 0Document19 pagesGelport Sealed Bus Connector To Accommodate 500kcmil Conductor P/N Gb-500-3P-Connscrew 502-47308 (I) Rev. 0Helar Armejo VasquezNo ratings yet

- 408 9921Document4 pages408 9921Helar Armejo VasquezNo ratings yet

- Instruction Sheet Aluminum Shearbolt ConnectorDocument2 pagesInstruction Sheet Aluminum Shearbolt ConnectorHelar Armejo VasquezNo ratings yet

- 7A784BDocument7 pages7A784BHelar Armejo VasquezNo ratings yet

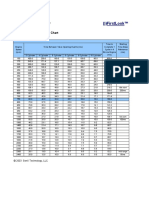

- Firstlook Timing ChartDocument1 pageFirstlook Timing ChartNorman Varela SandinoNo ratings yet

- Electric Light and Power Jul-Ago PDFDocument44 pagesElectric Light and Power Jul-Ago PDFjegva7875No ratings yet

- Best Polysilicon Technologies Russ HamiltonDocument15 pagesBest Polysilicon Technologies Russ HamiltonBenYi Chou100% (1)

- CuproBraze 34Document2 pagesCuproBraze 34Vinod SaleNo ratings yet

- Circuit Elements: Unit 2Document3 pagesCircuit Elements: Unit 2duy phanNo ratings yet

- B310PDC - PDF CatalougeDocument3 pagesB310PDC - PDF CatalougeEswaranNo ratings yet

- Product Manual - AECDocument164 pagesProduct Manual - AECcristian ortegaNo ratings yet

- Nemko - Nemko India - 2019-07-15Document2 pagesNemko - Nemko India - 2019-07-15Rahul mishraNo ratings yet

- Service Schedule For All MachinesDocument47 pagesService Schedule For All MachinesGENOVIC MPEMBANo ratings yet

- FSK-628D Gobernador Electronico de MotorDocument35 pagesFSK-628D Gobernador Electronico de Motorsoldadores motoresNo ratings yet

- Steam Hydrocarbon Reforming, Hydrogen Reformer, Steam Methane Reformer - Products and Services - SELAS FLUID A Linde Engineering Division MemberDocument1 pageSteam Hydrocarbon Reforming, Hydrogen Reformer, Steam Methane Reformer - Products and Services - SELAS FLUID A Linde Engineering Division Membernizam17100% (1)

- B78417A1698A003 - EPCOS 1698 CoilDocument3 pagesB78417A1698A003 - EPCOS 1698 CoilDwp BhaskaranNo ratings yet

- 1 s2.0 S0301421516305055 MainDocument8 pages1 s2.0 S0301421516305055 MainAli AhmadNo ratings yet

- Vacuum Pump SlidesDocument19 pagesVacuum Pump SlidesABNo ratings yet

- Physics of Nuclear MedicineDocument90 pagesPhysics of Nuclear MedicineArvindhanNo ratings yet

- Qualification of Gas Turbine Engines For U. S. Navy Shipboard UseDocument5 pagesQualification of Gas Turbine Engines For U. S. Navy Shipboard Usejwpaprk1No ratings yet

- Circuit Breakers, Fuses and Switches-1Document19 pagesCircuit Breakers, Fuses and Switches-1a_mutic100% (1)

- Powerware: For Critical Power ProtectionDocument2 pagesPowerware: For Critical Power Protectionandy175No ratings yet

- Extended Response 5 QDocument3 pagesExtended Response 5 Q12-057 MOHAMMAD MUSHFIQUR RAHMAN100% (1)

- Vacon 100 HVAC Product BrochureDocument4 pagesVacon 100 HVAC Product Brochureknightfelix12No ratings yet

- Fdci222 Fdcio222 Fdcio224 DsDocument4 pagesFdci222 Fdcio222 Fdcio224 DsElisabeta StefanNo ratings yet

- Parabolic Trough Collector - MainDocument17 pagesParabolic Trough Collector - MainAbhijitNo ratings yet

- DN-X500/DN-X900: Dj Mixer / Dj-Mixer / Melangeur Dj / Dj Mixer / Dj Mixer / Dj Mixer / Dj Mixer / 混音台Document63 pagesDN-X500/DN-X900: Dj Mixer / Dj-Mixer / Melangeur Dj / Dj Mixer / Dj Mixer / Dj Mixer / Dj Mixer / 混音台Erson MarquezNo ratings yet

- Test - T NG H P Unit 6Document3 pagesTest - T NG H P Unit 6Hoàng Phi NgaNo ratings yet

- (Download PDF) Electrical Wiring Residential 19Th Edition Ray C Mullin Online Ebook All Chapter PDFDocument42 pages(Download PDF) Electrical Wiring Residential 19Th Edition Ray C Mullin Online Ebook All Chapter PDFjames.pickett954100% (15)

9K688N

9K688N

Uploaded by

Helar Armejo VasquezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9K688N

9K688N

Uploaded by

Helar Armejo VasquezCopyright:

Available Formats

ELB-15/28-600

ELB-15/28-610

600A T-Body Elbow Connectors for jacketed

concentric neutral (JCN) and concentric neutral

(CN) cables up to 15/28kV class

Kit Contents

1 Conductive cap Conductive

cap Elbow

1 Insulating plug

1 Stud

1 Elbow

1 Compression lug (with crimp chart) Stud

1 Cable adapter Insulating

5 Silicone lubricant plug

1 Installation instruction

Suggested Installation Equipment (not supplied with kit)

• Cable preparation tools Optional

• Clean, lint-free cloths test point

• Non-conducting abrasive cloth, 120 grit or finer

• Connector(s) and installation tools

Safety Instructions

DANGER: When installing electrical power system

accessories, failure to follow applicable personal safety Compression lug

requirements and written installation instructions could

result in fire or explosion and serious or fatal injuries.

As Tyco Electronics has no control over field conditions Cable adapter

which influence product installation, it is understood

that the user must take this into account and apply his

own experience and expertise when installing product.

All apparatus must be de-energized during installation Fig. 101

or removal of parts.

General Information Customer Service

The Tyco Electronics ELB-15/28-600 and ELB-15/28- For 24 hour customer service, call 800-327-6996.

610 15/28kV class 600A elbows are used to terminate

high-voltage cable on deadfront apparatus transformers

and switchgear or make separable splice or junction

connections. They are fully shielded, fully submersible

and are interchangeable with all other manufacturers

that certify compliance with IEEE standard 386.

PII 55921 1 PCN 9K688N-000

Revision AB Effective Date: June 18, 2009

Installation Instructions

1. Check kit

Check kit components to insure proper fit with the

cable diameter dimensions, conductor size, and mating

products.

2. Cut cable

Position the cable so that it is parallel to the apparatus

faceplate and is located in the final assembled position

with enough slack to allow movement of elbow to

CL Bushing

insulated parking bushing. Cut cable 1-3/4“ (45mm) 1-3/4” (45mm)

from the centerline of the mating bushing. If using a Cut

jacket sealing device park it on the cable now. Follow

instructions in the jacket sealing kit after elbow

Cable

Transformer

assembly is complete.

Park jacket

sealing device

Fig. 102

3. Prepare cable

If jacketed neutral cable, remove outer jacket 12” 12” (304mm)

(304mm) from end of cable. If unjacketed neutral

cable, bind neutral wires using red marking tape at Concentric 2-1/4" 9-3/4"

14”(355mm). Fold back neutral wires allowing enough neutral wires (57mm) (247mm)

extra length to connect to ground and allow elbow

movement to insulated parking bushing. Remove semi-

con insulation shield 9-3/4” (247mm) from the end of

Extruded semi-con 1" (25mm) Cable

the cable with a straight, smooth, squared cut. Do not insulation shield insulation

cut or nick the insulation. Wrap two turns of marking

tape 1” (25mm) from end of semi-con shield. This will Marking tape

be a guide for the cable adapter location. Fig. 103

4. Remove insulation

Remove insulation exposing conductor between 4-3/8” 4-3/8” - 4-5/8”

and 4-5/8”. (111mm-118mm)

Marking tape Cable Bare

insulation conductor

Fig. 104

PII 55921 2 PCN 9K688N-000

Revision AB Effective Date: June 18, 2009

5. Chamfer and clean insulation 1/4”

45 0 (6mm)

Remove sharp edge of insulation by chamfering the end

of the cable insulation at a 450 angle, approximately

1/4” back. Thoroughly clean the insulation with a Clean

Chamfer

solvent dampened cloth, wiping from conductor

toward cable semi-con shield. Ensure that all traces of

conductive residue are removed. Marking tape Cable Fig. 105

insulation

6. Lubricate and install cable adapter

Lubricate Lubricate

Lubricate exposed cable insulation with silicone grease inside

always working toward cable semi-con shield. Lubricate

inside of cable adapter. Install cable adapter, small end

first, over cable using a twisting motion until it is flush Marking tape Cable Cable

with the edge of the tape marker. insulation adapter

Fig. 106

7. Ensure position of cable adapter

The cable adapter has a step molded into the cable Slide

Marking tape

entrance.

Cable

When sliding the cable adapter on you should feel a adapter

positive stop when the step in the adapter meets the

step in the semicon of the cable. The positive stop

should be felt at the same location as the tape mark.

Semicon Adapter step

D0 NOT slide adapter past this step. If you suspect you

step

have slid the adapter past the step, pull adapter off and

repeat step 7. When you are certain that the cable is in

the correct position, secure cable adapter in position by PVC tape

wrapping five half lapped layers of PVC tape over the Cable

small end of the cable adapter and over the marking adapter

Fig. 107

tape.

8. Install compression connector

Copper conductor: Remove protective cap and fully 1/2" (13mm)

insert conductor into compression lug.

Aluminum conductor: Prepare aluminum conductor Lug

Parallel

by wire brushing just prior to insertion into connector. Place first crimp here flats

Remove protective cap and fully insert conductor into

Bushing

compression lug.

Connector must be fully seated on cable conductor.

Align flats of lug and bushing before crimping. Start

crimps at the lug end 1/2” (13mm) below shoulder of

compression connector and work down. Crimp the Transformer

compression lug following the crimping instruction

supplied with the lug. Wipe all excess inhibitor from

connector and cable adapter surfaces. Fig. 108

PII 55921 3 PCN 9K688N-000

Revision AB Effective Date: June 18, 2009

9. Check dimension Check dimension

after crimping

The distance from the end of the lug to the cable adapter

after crimping should be between 6-1/2” to 7-1/2”

(165mm – 190mm). Otherwise redo assembly.

6-1/2” to 7-1/2”

(165 -190mm)

Fig. 109

10. Install elbow on cable

Clean and evenly lubricate the entire surface of cable Optional test

adapter with silicone grease. Lubricate inside the cable point facing

entrance of the elbow wiping 360º around the entire installer

surface and at least 2” (50mm) deep. If test point elbow

is used, ensure that test point is facing towards installer.

Push elbow onto cable adapter until lug eye is centered

in the 600A interface. You must ensure that the cable

2” Elbow

adapter does not move while installing the elbow.

Clean and Clean and

Lubricate Lubricate

inside surface

2” (50mm)

Fig. 110

11. Assemble elbow on bushing

Bushing

Clean and lubricate the entire mating surfaces of

bushing and elbow interfaces. Push elbow onto

apparatus bushing. Transformer

Clean

and lubricate

mating

surfaces

Fig. 111

PII 55921 4 PCN 9K688N-000

Revision AB Effective Date: June 18, 2009

12. Prepare insulating plug

Hand tighten the threaded stud into the insulating plug Insulating

or mating part. Clean and lubricate the mating surfaces plug

of insulating plug and elbow interface. Stud

Transformer

Clean

and lubricate

mating

surfaces

Fig. 112

13. Install insulating plug

Push plug into the elbow and tighten to apparatus

Apply torque

bushing using a torque wrench and 1” socket. Tighten

55ft-lbs

plug clock-wise exerting 55 ft-lbs (75 N-m) of torque.

The insulating plug provides a capacitive test point for

detecting system voltage. The ELB-15/28-610 elbow

Transformer

has an integral capacitive test point on the body. Follow

VOLTAGE TEST directions on page 7.

ELB-15/28-610

optional test point

Fig. 113

PII 55921 5 PCN 9K688N-000

Revision AB Effective Date: June 18, 2009

14. Install conductive cap

Clean and lubricate inner surface of conductive cap with Conductive

lubricant supplied. Push cap onto insulating plug until it cap

snaps into place.

Clean Transformer

and lubricate

inside

surface

Fig. 114

15. Ground system

Connect grounding eye of elbow with a minimum #14

AWG copper drain wire to cable concentric neutral

wires or to common ground point.

Transformer

#14 AWG

drain wire

Fig. 115

PII 55921 6 PCN 9K688N-000

Revision AB Effective Date: June 18, 2009

Capacitive Voltage Test

The Tyco Electronics ELB-15/28-610 elbow is provided

with an integral capacitive test point on the body. Both

the ELB-15/28-600 and ELB-15/28-610 elbows kits

contain an insulating plug that has a test point as noted

in step 13. Complete the following steps to use the test

point:

Test

point

• Remove test point cap with a hotstick. Rather than

pulling directly in line with the test point assembly.

PEEL OFF AT AN ANGLE.

• Using a suitable sensing device, determine if the cable

is energized. DANGER: Use only voltage indicating Test

point

instruments specifically designed for capacitive test

points. Use of conventional voltage sensing devices

may provide a false “No Voltage” indication. The test

point must be dry and free of contaminants when

checking for voltage. To prevent serious or fatal injury

treat the elbow as energized until the “No Voltage” test

point indication is confirmed by other means.

• After voltage detection has been made, clean and

lubricate the inside surface of the test point cap with

silicone grease and replace it on the test point with a

hot stick. Fig. 116

The Information contained in these installation instructions is for use only by installers trained to make electrical power installations and is intended to describe the correct method

of installation for this product. However, Tyco Electronics Corporation has no control over the field conditions which influence product installation. It is the user’s responsibility to

determine the suitability of the installation method in the user’s field conditions. Tyco Electronics’ only obligations are those in Tyco Electronics’ standard Conditions of Sale for this

product and in no case will Tyco Electronics be liable for any other incidental, indirect or consequential damages arising from the use or misuse of the products.

TE logo and Tyco Electronics are trademarks. Copyright 2009 Tyco Electronics Corporation. All Rights Reserved.

PII 55921 7 PCN 9K688N-000

Revision AB Effective Date: June 18, 2009

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Nuclear Cheat SheetDocument8 pagesNuclear Cheat SheetM J RhoadesNo ratings yet

- Lesson Plan in Electricity (Electrical Tools, Supplies and Materials)Document5 pagesLesson Plan in Electricity (Electrical Tools, Supplies and Materials)Jessa Bahi-an100% (12)

- Tower Light Inspection ChecklistDocument19 pagesTower Light Inspection ChecklistMOHAMMED RIYAN TNo ratings yet

- EHVT 69kv Class PII With FoilDocument9 pagesEHVT 69kv Class PII With FoilAntonio GresiaNo ratings yet

- Gelport: 1. General Product InformationDocument1 pageGelport: 1. General Product InformationAugusto CunhaNo ratings yet

- WMS-FOC Splicing & Testing - Rev.ADocument11 pagesWMS-FOC Splicing & Testing - Rev.Anice hossain100% (4)

- Truck Loading Arms (D 32)Document7 pagesTruck Loading Arms (D 32)Elias EliasNo ratings yet

- IEC-60364-8-1 v13 NP Draft2Document21 pagesIEC-60364-8-1 v13 NP Draft2Electrician 013No ratings yet

- BQ5477Document10 pagesBQ5477Helar Armejo VasquezNo ratings yet

- Instruction For MV TerminationDocument7 pagesInstruction For MV TerminationWilfrid DutruelNo ratings yet

- 25 K VInstall GuideDocument23 pages25 K VInstall GuideMarcelo ConchaNo ratings yet

- Esd 4872 Au 5 09 PDFDocument10 pagesEsd 4872 Au 5 09 PDFGuler RahimNo ratings yet

- Kit de Terminacion TFT-150R-G TYCO ELECTRONICSDocument22 pagesKit de Terminacion TFT-150R-G TYCO ELECTRONICSWilbert ACNo ratings yet

- TE S Raychem Cable Accessories: Scan QR Codes and Get Video SupportDocument8 pagesTE S Raychem Cable Accessories: Scan QR Codes and Get Video SupportHossam AlzubairyNo ratings yet

- 2178CL-S Series F/O Splice Case: InstructionDocument13 pages2178CL-S Series F/O Splice Case: InstructionHữu Khánh NguyễnNo ratings yet

- Procedure For Cable Termination& Splicing Rev01Document5 pagesProcedure For Cable Termination& Splicing Rev01Syed MujahidNo ratings yet

- Rosemount 5400 Series Spare Part InstructionDocument14 pagesRosemount 5400 Series Spare Part InstructionEdinsonUribeTorresNo ratings yet

- Gelcap Insulating Splice Cover For 600V CableDocument2 pagesGelcap Insulating Splice Cover For 600V CableHelar Armejo VasquezNo ratings yet

- 4500 9 HDF 1 2 - Splicing - InstructionsDocument24 pages4500 9 HDF 1 2 - Splicing - InstructionsOWEMNo ratings yet

- Cable Termination - Installation Instructions - 755LR - IsDocument5 pagesCable Termination - Installation Instructions - 755LR - Isvladimir_71No ratings yet

- DTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionDocument10 pagesDTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionMuhammad Lathieful HaqNo ratings yet

- TOA Wall Mount Antenna Yw-4500Document20 pagesTOA Wall Mount Antenna Yw-4500Yoshinori SaitoNo ratings yet

- Idw DocumentDocument16 pagesIdw DocumentFerran MunyósNo ratings yet

- Installation Instruction No. 132101F/02.2008 Seik 14, 24, 34Document5 pagesInstallation Instruction No. 132101F/02.2008 Seik 14, 24, 34Sonia Noval LlorianNo ratings yet

- 33kV Elbow ManualDocument6 pages33kV Elbow ManualElliza IshakNo ratings yet

- Module 6 TelecomDocument29 pagesModule 6 TelecomMADRIAGA, CYRILLE MAE RUMANo ratings yet

- 92213701-Tii 320&321&325&326-RevD 0510 InstNtDocument1 page92213701-Tii 320&321&325&326-RevD 0510 InstNtjosettttNo ratings yet

- Duct Installation of Fiber Optic Cable PDFDocument9 pagesDuct Installation of Fiber Optic Cable PDFnecmettinsengunNo ratings yet

- INST. INST. 673 - BDBZ For Item 30Document8 pagesINST. INST. 673 - BDBZ For Item 30Zubab PanniNo ratings yet

- 3M Cold Shrink QT-III Silicone Rubber Indoor Tubular Termination KitDocument20 pages3M Cold Shrink QT-III Silicone Rubber Indoor Tubular Termination KitJRNo ratings yet

- Cable Splicing Procedure 005Document6 pagesCable Splicing Procedure 005RenzNo ratings yet

- 15kV PM Joints - Straight - KSU - 500-500sq - MMDocument8 pages15kV PM Joints - Straight - KSU - 500-500sq - MMabd elmohsen saedNo ratings yet

- Poly Hopper Service Motor Kit: Installation InstructionsDocument2 pagesPoly Hopper Service Motor Kit: Installation Instructions77ztfNo ratings yet

- Mid-Span Access of Loose-Tube Ribbon Fiber Optic Cable PDFDocument12 pagesMid-Span Access of Loose-Tube Ribbon Fiber Optic Cable PDFMehdi SHNo ratings yet

- E-Link 1000LR Antenna Quick Install Guide 980-0200-001A - 021811 - FinalDocument2 pagesE-Link 1000LR Antenna Quick Install Guide 980-0200-001A - 021811 - FinalIsrar ZiaNo ratings yet

- RVR / Outlander Sport / Asx Floor Illumination (Blue) MZ360353EX Installation and Handling InstructionsDocument12 pagesRVR / Outlander Sport / Asx Floor Illumination (Blue) MZ360353EX Installation and Handling InstructionsKip ClayNo ratings yet

- ISTRCSSJ25ENGDocument6 pagesISTRCSSJ25ENGHector Vidal Rodriguez ValdezNo ratings yet

- J6182FDocument5 pagesJ6182FHelar Armejo VasquezNo ratings yet

- 15kV Front Connector - KSU - 500sq - MMDocument7 pages15kV Front Connector - KSU - 500sq - MMabd elmohsen saedNo ratings yet

- Compact SureGround Grounding KitDocument2 pagesCompact SureGround Grounding KitWesdi DNo ratings yet

- Quick Term III 3MDocument11 pagesQuick Term III 3MGRUPO GENELCONo ratings yet

- 15kV Indoor Termination - KSU - 500sq - MMDocument6 pages15kV Indoor Termination - KSU - 500sq - MMabd elmohsen saedNo ratings yet

- YW-4500 Wall-Mounted Wireless Antenna: WarningDocument20 pagesYW-4500 Wall-Mounted Wireless Antenna: WarningTito SetiajiNo ratings yet

- Cable Gland Installation InstructionsDocument2 pagesCable Gland Installation InstructionsJairo WilchesNo ratings yet

- Distribution Plastic TiesDocument4 pagesDistribution Plastic TiesanonymousNo ratings yet

- HVT Series Terminations 15-35kV Class High Voltage Termination For LC Shield CableDocument6 pagesHVT Series Terminations 15-35kV Class High Voltage Termination For LC Shield Cable20353124No ratings yet

- Cat6 /6A Modular Plug: 3 Prong 50U" Gold PlatedDocument2 pagesCat6 /6A Modular Plug: 3 Prong 50U" Gold PlatedAndrés CisnerosNo ratings yet

- Terminal Con Copa 3M Cold Shrink QT-III 769X-S-4 KitsDocument20 pagesTerminal Con Copa 3M Cold Shrink QT-III 769X-S-4 KitsEnrique G.No ratings yet

- SF6170 K VDocument8 pagesSF6170 K VMuchlis AlatasNo ratings yet

- Sitesgfilescozyhq596files2020 093300XL20Transducer20Accessories20Datasheet20 20145668.pDocument15 pagesSitesgfilescozyhq596files2020 093300XL20Transducer20Accessories20Datasheet20 20145668.pqdzungNo ratings yet

- Toshiba TV 20AF45 - 20AF45C - SVM PDFDocument50 pagesToshiba TV 20AF45 - 20AF45C - SVM PDFcarlos avilaNo ratings yet

- 15kV Outdoor Termination - KSU - 500sq - MMDocument5 pages15kV Outdoor Termination - KSU - 500sq - MMabd elmohsen saedNo ratings yet

- 005 038Document11 pages005 038shaicoNo ratings yet

- KAT0815-0001-E Single Pole Insulated Conductor RailDocument36 pagesKAT0815-0001-E Single Pole Insulated Conductor RailirinaNo ratings yet

- WAGO For Network RailDocument14 pagesWAGO For Network Railgrilleflapper.00No ratings yet

- Tricks For Cable Accessories InstallationDocument30 pagesTricks For Cable Accessories InstallationcxfuentesNo ratings yet

- Installation Instructions For General Duty Safety Switches Directives D'installation Pour Interrupteurs de Sécurité UniverselsDocument6 pagesInstallation Instructions For General Duty Safety Switches Directives D'installation Pour Interrupteurs de Sécurité UniverselscarteauNo ratings yet

- Nordmende n2121cb Chassis Giii-08Document34 pagesNordmende n2121cb Chassis Giii-08PE TruNo ratings yet

- p220 en Inb43Document10 pagesp220 en Inb43Sambit MohapatraNo ratings yet

- 114-6053 High-Performance Modular Plug ConnectorsDocument10 pages114-6053 High-Performance Modular Plug ConnectorsDiegoNo ratings yet

- PII 1C 17.5kV CWS HKOTDocument6 pagesPII 1C 17.5kV CWS HKOTDaniel GarciaNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- J6182FDocument5 pagesJ6182FHelar Armejo VasquezNo ratings yet

- G H J K: Edyce Arrigoni Edyce ArrigoniDocument1 pageG H J K: Edyce Arrigoni Edyce ArrigoniHelar Armejo VasquezNo ratings yet

- Edr 5253Document10 pagesEdr 5253Helar Armejo VasquezNo ratings yet

- BQ5477Document10 pagesBQ5477Helar Armejo VasquezNo ratings yet

- HVS-S-1520S-M Series: Suggested Installation Equipment (Not Supplied With Kit) Recommended Tyco Electronics TorchesDocument6 pagesHVS-S-1520S-M Series: Suggested Installation Equipment (Not Supplied With Kit) Recommended Tyco Electronics TorchesHelar Armejo VasquezNo ratings yet

- Gelcap Insulating Splice Cover For 600V CableDocument2 pagesGelcap Insulating Splice Cover For 600V CableHelar Armejo VasquezNo ratings yet

- Gelport Sealed Bus Connector P/N Gp-350-Xx-Connscrew Gp-500-Xx-Connscrew 502-47264 (I) Rev. 0Document19 pagesGelport Sealed Bus Connector P/N Gp-350-Xx-Connscrew Gp-500-Xx-Connscrew 502-47264 (I) Rev. 0Helar Armejo VasquezNo ratings yet

- Engineering Test Report: Test Laboratory Markham, OntarioDocument22 pagesEngineering Test Report: Test Laboratory Markham, OntarioHelar Armejo VasquezNo ratings yet

- Miniwedge Gel Cover P/N 3-1199125-2 (GHFC-MW - (B10) ) 502-47233 REV. 0Document10 pagesMiniwedge Gel Cover P/N 3-1199125-2 (GHFC-MW - (B10) ) 502-47233 REV. 0Helar Armejo VasquezNo ratings yet

- Gelport Sealed Bus Connector To Accommodate 500kcmil Conductor P/N Gb-500-3P-Connscrew 502-47308 (I) Rev. 0Document19 pagesGelport Sealed Bus Connector To Accommodate 500kcmil Conductor P/N Gb-500-3P-Connscrew 502-47308 (I) Rev. 0Helar Armejo VasquezNo ratings yet

- 408 9921Document4 pages408 9921Helar Armejo VasquezNo ratings yet

- Instruction Sheet Aluminum Shearbolt ConnectorDocument2 pagesInstruction Sheet Aluminum Shearbolt ConnectorHelar Armejo VasquezNo ratings yet

- 7A784BDocument7 pages7A784BHelar Armejo VasquezNo ratings yet

- Firstlook Timing ChartDocument1 pageFirstlook Timing ChartNorman Varela SandinoNo ratings yet

- Electric Light and Power Jul-Ago PDFDocument44 pagesElectric Light and Power Jul-Ago PDFjegva7875No ratings yet

- Best Polysilicon Technologies Russ HamiltonDocument15 pagesBest Polysilicon Technologies Russ HamiltonBenYi Chou100% (1)

- CuproBraze 34Document2 pagesCuproBraze 34Vinod SaleNo ratings yet

- Circuit Elements: Unit 2Document3 pagesCircuit Elements: Unit 2duy phanNo ratings yet

- B310PDC - PDF CatalougeDocument3 pagesB310PDC - PDF CatalougeEswaranNo ratings yet

- Product Manual - AECDocument164 pagesProduct Manual - AECcristian ortegaNo ratings yet

- Nemko - Nemko India - 2019-07-15Document2 pagesNemko - Nemko India - 2019-07-15Rahul mishraNo ratings yet

- Service Schedule For All MachinesDocument47 pagesService Schedule For All MachinesGENOVIC MPEMBANo ratings yet

- FSK-628D Gobernador Electronico de MotorDocument35 pagesFSK-628D Gobernador Electronico de Motorsoldadores motoresNo ratings yet

- Steam Hydrocarbon Reforming, Hydrogen Reformer, Steam Methane Reformer - Products and Services - SELAS FLUID A Linde Engineering Division MemberDocument1 pageSteam Hydrocarbon Reforming, Hydrogen Reformer, Steam Methane Reformer - Products and Services - SELAS FLUID A Linde Engineering Division Membernizam17100% (1)

- B78417A1698A003 - EPCOS 1698 CoilDocument3 pagesB78417A1698A003 - EPCOS 1698 CoilDwp BhaskaranNo ratings yet

- 1 s2.0 S0301421516305055 MainDocument8 pages1 s2.0 S0301421516305055 MainAli AhmadNo ratings yet

- Vacuum Pump SlidesDocument19 pagesVacuum Pump SlidesABNo ratings yet

- Physics of Nuclear MedicineDocument90 pagesPhysics of Nuclear MedicineArvindhanNo ratings yet

- Qualification of Gas Turbine Engines For U. S. Navy Shipboard UseDocument5 pagesQualification of Gas Turbine Engines For U. S. Navy Shipboard Usejwpaprk1No ratings yet

- Circuit Breakers, Fuses and Switches-1Document19 pagesCircuit Breakers, Fuses and Switches-1a_mutic100% (1)

- Powerware: For Critical Power ProtectionDocument2 pagesPowerware: For Critical Power Protectionandy175No ratings yet

- Extended Response 5 QDocument3 pagesExtended Response 5 Q12-057 MOHAMMAD MUSHFIQUR RAHMAN100% (1)

- Vacon 100 HVAC Product BrochureDocument4 pagesVacon 100 HVAC Product Brochureknightfelix12No ratings yet

- Fdci222 Fdcio222 Fdcio224 DsDocument4 pagesFdci222 Fdcio222 Fdcio224 DsElisabeta StefanNo ratings yet

- Parabolic Trough Collector - MainDocument17 pagesParabolic Trough Collector - MainAbhijitNo ratings yet

- DN-X500/DN-X900: Dj Mixer / Dj-Mixer / Melangeur Dj / Dj Mixer / Dj Mixer / Dj Mixer / Dj Mixer / 混音台Document63 pagesDN-X500/DN-X900: Dj Mixer / Dj-Mixer / Melangeur Dj / Dj Mixer / Dj Mixer / Dj Mixer / Dj Mixer / 混音台Erson MarquezNo ratings yet

- Test - T NG H P Unit 6Document3 pagesTest - T NG H P Unit 6Hoàng Phi NgaNo ratings yet

- (Download PDF) Electrical Wiring Residential 19Th Edition Ray C Mullin Online Ebook All Chapter PDFDocument42 pages(Download PDF) Electrical Wiring Residential 19Th Edition Ray C Mullin Online Ebook All Chapter PDFjames.pickett954100% (15)