Professional Documents

Culture Documents

Effect of Laser Beam Welding Parameters On Microst

Effect of Laser Beam Welding Parameters On Microst

Uploaded by

Salih HASCopyright:

Available Formats

You might also like

- B 36 - B 36M - 13Document9 pagesB 36 - B 36M - 13Ahmed BilalNo ratings yet

- Effect of Laser Beam Welding Parameters On Microstructure and Properties of Duplex Stainless SteelDocument9 pagesEffect of Laser Beam Welding Parameters On Microstructure and Properties of Duplex Stainless SteelAsif HameedNo ratings yet

- Effect of Laser Beam Welding Parameters On Microstructure and Properties of Duplex Stainless SteelDocument9 pagesEffect of Laser Beam Welding Parameters On Microstructure and Properties of Duplex Stainless Steelnaresh1272No ratings yet

- Modeling and Optimization of Tensile Shear Strength of Titanium:Aluminum Dissimilar Welded ComponentDocument11 pagesModeling and Optimization of Tensile Shear Strength of Titanium:Aluminum Dissimilar Welded Componentaw1228818No ratings yet

- E3sconf Icmed2020 01030Document6 pagesE3sconf Icmed2020 01030Isaac SimbañaNo ratings yet

- Application of Taguchi Method For Resistance Spot Welding of Galvanized SteelDocument6 pagesApplication of Taguchi Method For Resistance Spot Welding of Galvanized Steelpradipta satrio wNo ratings yet

- A11 PDFDocument15 pagesA11 PDFJunaid AkhtarNo ratings yet

- 10 1016@j Jmapro 2013 06 010Document14 pages10 1016@j Jmapro 2013 06 010SamuelshrlyNo ratings yet

- 1 s2.0 S0030399212005762 MainDocument12 pages1 s2.0 S0030399212005762 MainMochamad Iqbal GhifaryNo ratings yet

- WeldingDocument6 pagesWeldingTamal PaulNo ratings yet

- Microstructure Analysis of Arc Welded Mild Steel Plates: IOP Conference Series: Materials Science and EngineeringDocument7 pagesMicrostructure Analysis of Arc Welded Mild Steel Plates: IOP Conference Series: Materials Science and EngineeringAniekanNo ratings yet

- Latest Developments in Friction Welding - A ReviewDocument6 pagesLatest Developments in Friction Welding - A ReviewIJRASETPublicationsNo ratings yet

- The Effect of Groove Welding On Mechanical PropertDocument8 pagesThe Effect of Groove Welding On Mechanical PropertMuhammad Zuhairy jabarNo ratings yet

- Saravanan2017 Article StudiesOnMetallurgicalAndMechaDocument8 pagesSaravanan2017 Article StudiesOnMetallurgicalAndMechaPardeepNo ratings yet

- Materials Science and Engineering ADocument7 pagesMaterials Science and Engineering AДмитрий ВасилNo ratings yet

- Effect of Laser Welding Process Parameters On Mechanical P Roperties of Stainless Steel-316Document11 pagesEffect of Laser Welding Process Parameters On Mechanical P Roperties of Stainless Steel-316kamal touilebNo ratings yet

- Microstructural Characteristic of Dissimilar Welded Components (AISI 430 Ferritic-AISI 304 Austenitic Stainless Steels) by CO2 Laser Beam Welding (LBW) (#97282) - 83434Document17 pagesMicrostructural Characteristic of Dissimilar Welded Components (AISI 430 Ferritic-AISI 304 Austenitic Stainless Steels) by CO2 Laser Beam Welding (LBW) (#97282) - 83434kamal touilebNo ratings yet

- Effect of Multi-Pass SMAW Welding On The Surface HDocument7 pagesEffect of Multi-Pass SMAW Welding On The Surface HYousab CreatorNo ratings yet

- ICEE097 - Full Length Paper PDFDocument4 pagesICEE097 - Full Length Paper PDFWeld TechNo ratings yet

- A Review of Friction Stirs WeldingDocument6 pagesA Review of Friction Stirs WeldingEditor IJTSRDNo ratings yet

- Impact of Process Parameters of Laser Welding On The Mechanical Properties of Ti6Al4V A ReviewDocument9 pagesImpact of Process Parameters of Laser Welding On The Mechanical Properties of Ti6Al4V A ReviewbalamuruganNo ratings yet

- Weld Quality Analysis of Tig, Laser and Electron Beam Welded Ss 304 and 316 Materials With NDT TechniquesDocument4 pagesWeld Quality Analysis of Tig, Laser and Electron Beam Welded Ss 304 and 316 Materials With NDT TechniquesИлгар НахматовNo ratings yet

- Previous Paper - EditedDocument7 pagesPrevious Paper - EditedNaveen KumarNo ratings yet

- Study and Analysis of Spot Welding of Dissimilar Material 1008 Low Carbon Steel-5052 Aluminum AlloyDocument17 pagesStudy and Analysis of Spot Welding of Dissimilar Material 1008 Low Carbon Steel-5052 Aluminum AlloyIJRASETPublicationsNo ratings yet

- 1 s2.0 S1006706X12600508 MainDocument7 pages1 s2.0 S1006706X12600508 MainMochamad Iqbal GhifaryNo ratings yet

- Optics and Laser Technology: Nikhil Kumar, Manidipto Mukherjee, Asish BandyopadhyayDocument14 pagesOptics and Laser Technology: Nikhil Kumar, Manidipto Mukherjee, Asish BandyopadhyaykaelcorbettNo ratings yet

- Impact Toughness of High Strength Low AlloyDocument7 pagesImpact Toughness of High Strength Low AlloySPINHRNo ratings yet

- Materials Today: Proceedings: U.S. Patil, M.S. KadamDocument6 pagesMaterials Today: Proceedings: U.S. Patil, M.S. KadamSREEJITH S NAIRNo ratings yet

- Eperimental Investigation of Effects of Welding Current and Elektrode AngleDocument3 pagesEperimental Investigation of Effects of Welding Current and Elektrode AngleMuizz AbdullahNo ratings yet

- Investigation of Mechanical Properties and Microstructure of GTAW On Dissimilar MetalsDocument3 pagesInvestigation of Mechanical Properties and Microstructure of GTAW On Dissimilar Metalskamal touilebNo ratings yet

- Calik PDFDocument5 pagesCalik PDFmarceloNo ratings yet

- CalikDocument5 pagesCalikmarceloNo ratings yet

- 1 s2.0 S2214785319343834 Main PDFDocument6 pages1 s2.0 S2214785319343834 Main PDFJohnny VillarroelNo ratings yet

- The Effect of Current On SMAW Welding To Tensile Strength and Micro Structure of Low Carbon SteelDocument5 pagesThe Effect of Current On SMAW Welding To Tensile Strength and Micro Structure of Low Carbon Steelmade dwi payanaNo ratings yet

- LBW OptimizationDocument11 pagesLBW Optimizationfathi.alfazaniNo ratings yet

- Study On laser-MIG Hybrid Welding Characteristics of A7N01-T6 Aluminum AlloyDocument2 pagesStudy On laser-MIG Hybrid Welding Characteristics of A7N01-T6 Aluminum Alloysreejith2786No ratings yet

- Comparative Analysis of Pulsed ND - YAG Laser Welding of 304L and 904L Stainless Steel (Materials Today - Proceedings) (2020)Document5 pagesComparative Analysis of Pulsed ND - YAG Laser Welding of 304L and 904L Stainless Steel (Materials Today - Proceedings) (2020)MahnooshNo ratings yet

- Constantin 2017 IOP Conf. Ser. Mater. Sci. Eng. 252 012038 PDFDocument9 pagesConstantin 2017 IOP Conf. Ser. Mater. Sci. Eng. 252 012038 PDFMeet PatelNo ratings yet

- Teklas 0A - PROPERTIESDocument7 pagesTeklas 0A - PROPERTIESMudzakkir DioktyantoNo ratings yet

- 45 - 5 - Taban (Butt Joint FSW Better Than Mig)Document8 pages45 - 5 - Taban (Butt Joint FSW Better Than Mig)Amar DJEDIDNo ratings yet

- 1 s2.0 S003039921830104X MainDocument8 pages1 s2.0 S003039921830104X MainMochamad Iqbal GhifaryNo ratings yet

- Failure Behavior of Resistance Spot Welded Low CarDocument10 pagesFailure Behavior of Resistance Spot Welded Low CarLuis Allan GarciaNo ratings yet

- Chiong 2019 IOP Conf. Ser. Mater. Sci. Eng. 495 012093Document10 pagesChiong 2019 IOP Conf. Ser. Mater. Sci. Eng. 495 012093Plentys KWNo ratings yet

- Welding Research PaperDocument7 pagesWelding Research Paperkifmgbikf100% (1)

- Effect of Welding Process and Post Weld Heat Treatments On Microstructure and Mechanical Properties of Aisi 431 Martensitic Stainless SteelDocument6 pagesEffect of Welding Process and Post Weld Heat Treatments On Microstructure and Mechanical Properties of Aisi 431 Martensitic Stainless SteelInternational Jpurnal Of Technical Research And ApplicationsNo ratings yet

- Microstructure and Alloy Element Distribution of Dissimilar Joint 316L and EH36 in Laser WeldingDocument9 pagesMicrostructure and Alloy Element Distribution of Dissimilar Joint 316L and EH36 in Laser WeldingPardeepNo ratings yet

- Nd-Yag Laser Beam and Gta Welding of Ti-6Al-4V Alloy: Abdel-Monem El-Batahgy, Tarasankar DebroyDocument8 pagesNd-Yag Laser Beam and Gta Welding of Ti-6Al-4V Alloy: Abdel-Monem El-Batahgy, Tarasankar DebroyerpublicationNo ratings yet

- Wang 2011Document7 pagesWang 2011wallisonkennedy014No ratings yet

- Microstructural Characterization and Its Effect On Mechanical Properties of Fiber Laser Beam Welded Ti6Al4V (2017)Document4 pagesMicrostructural Characterization and Its Effect On Mechanical Properties of Fiber Laser Beam Welded Ti6Al4V (2017)adnan domlogeNo ratings yet

- 39IJMPERDAPR201939Document8 pages39IJMPERDAPR201939TJPRC PublicationsNo ratings yet

- Evaluation of Bond Quality and Corrosion Resistance of Stainless Steel-Low Carbon Steel Friction Surfaced DepositDocument10 pagesEvaluation of Bond Quality and Corrosion Resistance of Stainless Steel-Low Carbon Steel Friction Surfaced DepositTJPRC PublicationsNo ratings yet

- Effect of Welding Process and Post Weld Heat Treatments On Microstructure and Mechanical Properties of Aisi 431 Martensitic Stainless SteelDocument6 pagesEffect of Welding Process and Post Weld Heat Treatments On Microstructure and Mechanical Properties of Aisi 431 Martensitic Stainless SteelwangpengstpNo ratings yet

- ETJ - Volume 41 - Issue 7 - Pages 1-9 NewDocument9 pagesETJ - Volume 41 - Issue 7 - Pages 1-9 Newhameed.laftaNo ratings yet

- Prediction of Mechanical Properties As A Function of Welding Variables in Robotic Gas Metal Arc Welding of Duplex Stainless Steels Saf 2205 Welds Through Artificial Neural NetworksDocument16 pagesPrediction of Mechanical Properties As A Function of Welding Variables in Robotic Gas Metal Arc Welding of Duplex Stainless Steels Saf 2205 Welds Through Artificial Neural NetworksDhruv PatelNo ratings yet

- Abrasive Wear Behaviour of Heat Treated En31 Steel: ISIJ International January 2013Document9 pagesAbrasive Wear Behaviour of Heat Treated En31 Steel: ISIJ International January 2013NABIL HUSSAINNo ratings yet

- NosaDocument9 pagesNosaosaroboNo ratings yet

- Strenx 700Document15 pagesStrenx 700SameerNo ratings yet

- 1 s2.0 S0308016120302015 MainDocument11 pages1 s2.0 S0308016120302015 MainKAVINNo ratings yet

- Review Paper On Optimization of Metal Inert Gas Welding On Stainless Steel AISI 410by Taguchi MethodDocument8 pagesReview Paper On Optimization of Metal Inert Gas Welding On Stainless Steel AISI 410by Taguchi MethodIJRASETPublicationsNo ratings yet

- Microstructure, Properties and Corrosion Characterization of Welded Joint For Composite Pipe Using A Novel Welding ProcessDocument12 pagesMicrostructure, Properties and Corrosion Characterization of Welded Joint For Composite Pipe Using A Novel Welding ProcessRami GhorbelNo ratings yet

- EBY Fasteners Product Range Aug 2020Document2 pagesEBY Fasteners Product Range Aug 2020Mark KNo ratings yet

- Cutting Data Milling Boring 2019 ITL E LowDocument60 pagesCutting Data Milling Boring 2019 ITL E LowRoberto RosasNo ratings yet

- Roller Campacted Concrete Pavements by Robert R.Thompson, Columbus, OhioDocument133 pagesRoller Campacted Concrete Pavements by Robert R.Thompson, Columbus, Ohiooscargon19100% (1)

- Belzona 1591 (Ceramic XHT) PDFDocument2 pagesBelzona 1591 (Ceramic XHT) PDFANIBALLOPEZVEGANo ratings yet

- Properties and Thermal Degradation Studies of Gelatin Based Film - Exploring The Biopolymer For Plastic AdvancementDocument5 pagesProperties and Thermal Degradation Studies of Gelatin Based Film - Exploring The Biopolymer For Plastic AdvancementKate DauNo ratings yet

- Compaign-Style: Tool CabinetDocument3 pagesCompaign-Style: Tool CabinetAlex TorresNo ratings yet

- Weld DefectsDocument43 pagesWeld Defectsraju100% (1)

- Wrought Nickel-Iron Soft Magnetic Alloys (UNS K94490, K94840, N14076, N14080)Document6 pagesWrought Nickel-Iron Soft Magnetic Alloys (UNS K94490, K94840, N14076, N14080)Tomy lee youngNo ratings yet

- DR Fixit Roofseal ClassicDocument5 pagesDR Fixit Roofseal ClassicNitin GuptaNo ratings yet

- W1 - 2 Lecture 1 - 2 Fe3C Digram and IT CCT Diagram PDFDocument61 pagesW1 - 2 Lecture 1 - 2 Fe3C Digram and IT CCT Diagram PDFYota KimireNo ratings yet

- SemDocument138 pagesSemasmjewelNo ratings yet

- Lecture 6 Azo DyesDocument23 pagesLecture 6 Azo DyesQuratul AinNo ratings yet

- Glo Backfill TBM Tunnel Boring MachinesDocument8 pagesGlo Backfill TBM Tunnel Boring Machinesjpantazis1975No ratings yet

- 02 Semi Continuous DeodorizingDocument8 pages02 Semi Continuous DeodorizingMaicon Espindola Dos SantosNo ratings yet

- MiraTEC Trim Provides Green Building BenefitsDocument2 pagesMiraTEC Trim Provides Green Building BenefitsCMI CompanyNo ratings yet

- HFY-3800-0000-GEN-PD-0013 - 0 Welding and Welding Consumable Control Procedure-Code ADocument14 pagesHFY-3800-0000-GEN-PD-0013 - 0 Welding and Welding Consumable Control Procedure-Code ANashaat DhyaaNo ratings yet

- Concrete Pipe Brochure WebDocument1 pageConcrete Pipe Brochure Webbirendra1970No ratings yet

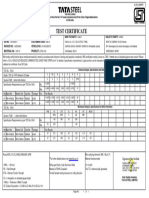

- Test Certificate: Signature Not VerifiedDocument1 pageTest Certificate: Signature Not Verifiedreportdaily819No ratings yet

- Ams 2451 Rev. DDocument9 pagesAms 2451 Rev. DJorge Luis Gonzalez Gonzalez100% (1)

- Copy of Pending Pos MetalDocument112 pagesCopy of Pending Pos MetalVijay OfficialNo ratings yet

- Utp Af Robotic 600 Brochure 2018.12Document2 pagesUtp Af Robotic 600 Brochure 2018.12Claude BouillotNo ratings yet

- Casa de Madeira Technical-GuideDocument16 pagesCasa de Madeira Technical-GuideJoaquim ArezNo ratings yet

- NemoDocument18 pagesNemoApoorva Gowda100% (2)

- Engineering Failure Analysis: Khlefa A. Esaklul, Tawfik M. AhmedDocument8 pagesEngineering Failure Analysis: Khlefa A. Esaklul, Tawfik M. AhmedMatheus Paes PeçanhaNo ratings yet

- MSM Unit 4 Chap 2 (Ferrous Materials and Non-Ferrous Materials)Document15 pagesMSM Unit 4 Chap 2 (Ferrous Materials and Non-Ferrous Materials)rakeshpatkar332No ratings yet

- Lecture 2 TCP 1 2015Document89 pagesLecture 2 TCP 1 2015Muhammad ZohaibNo ratings yet

- Handwritten Notes - Chemical Reactions and Equations - Chemical HandwrittenDocument16 pagesHandwritten Notes - Chemical Reactions and Equations - Chemical HandwrittenisharNo ratings yet

- PMA 600 H Datenblatt Renitherm enDocument3 pagesPMA 600 H Datenblatt Renitherm enMuhammad ArslanNo ratings yet

- Design of RCC StructureDocument14 pagesDesign of RCC Structuremark bingNo ratings yet

Effect of Laser Beam Welding Parameters On Microst

Effect of Laser Beam Welding Parameters On Microst

Uploaded by

Salih HASOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Laser Beam Welding Parameters On Microst

Effect of Laser Beam Welding Parameters On Microst

Uploaded by

Salih HASCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/276541373

Effect of Laser Beam Welding Parameters on Microstructure and Properties of

Duplex Stainless Steel

Article in Materials Sciences and Applications · January 2011

DOI: 10.4236/msa.2011.210195

CITATIONS READS

47 2,534

3 authors, including:

A. M. El-Batahgy Abdelfattah Khourshid

Central Metallurgical Research and Development Institute faculty of engineering, Tanta university, Egypt

55 PUBLICATIONS 444 CITATIONS 20 PUBLICATIONS 218 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Laser assisted machining of tool steel View project

Welding 9% Nickel steels View project

All content following this page was uploaded by A. M. El-Batahgy on 19 November 2015.

The user has requested enhancement of the downloaded file.

Materials Sciences and Applications, 2011, 2, 1443-1451 1443

doi:10.4236/msa.2011.210195 Published Online October 2011 (http://www.SciRP.org/journal/msa)

Effect of Laser Beam Welding Parameters on

Microstructure and Properties of Duplex

Stainless Steel

Abdel-Monem El-Batahgy1, Abdel-Fattah Khourshid2, Thoria Sharef2

1

Manufacturing Technology Department, Central Metallurgical Research and Development Institute, Cairo, Egypt; 2Mechanical De-

sign and Production Department, Faculty of Engineering, Tanta University, Tanta, Egypt.

Email: elbatahgy@yahoo.com

Received June 26th, 2011; revised July 19th, 2011; accepted August 25th, 2011.

ABSTRACT

The present study is concerned with laser beam welding and its effect on size and microstructure of fusion zone then, on

mechanical and corrosion properties of duplex stainless steel welded joints. In this regard, influence of different laser

welding parameters was clarified. Both bead-on-plate and autogenously butt welded joints were made using carbon

dioxide laser with a maximum output of 9 kW in the continuous wave mode. Welded joints were subjected to visual, dye

penetrant and radiography tests before sectioning it for different destructive tests. Accelerated corrosion test was car-

ried out based on tafel plot technique. The results achieved in this investigation disclosed that welding parameters play

an important role in obtaining satisfactory properties of welded joint. High laser power and/or high welding speed to-

gether with adjusting laser focused spot at specimen surface have produced welded joints with a remarkable decrease

in fusion zone size and an acceptable weld profile with higher weld depth/width ratio. Besides, acceptable mechanical

and corrosion properties were obtained. Using nitrogen as a shielding gas has resulted in improving mechanical and

corrosion properties of welded joints in comparison with argon shielding. This is related to maintaining proper fer-

rite/austenite balance in both weld metal and HAZ in case of nitrogen shielding. As a conclusion, laser power, welding

speed, defocusing distance and type of shielding gas combination have to be optimized for obtaining welded joints with

acceptable profile as well as mechanical and corrosion properties.

Keywords: Duplex Stainless Steel, Laser Beam Welding, Laser Power, Welding Speed, Defocusing Distance, Shielding

Gas Type, Fusion Zone, Microstructure, Mechanical Properties, Corrosion Resistance

1. Introduction ties of duplex stainless steels [6,7]. The optimum proper-

ties of duplex stainless steels are achieved when nearly

The duplex stainless steels have been developed to pro- equal proportions of austenite and ferrite are present in

vide a combination of strength and resistance to pitting the microstructure. In base metals, this phase balance is

and stress corrosion cracking in comparison with the obtained by an appropriate combination of composition

300-series austenitic stainless steels [1-3]. These unique and solution heat treatment. However, control of the fer-

properties of the duplex stainless steels have resulted in rite/austenite balance in welds is not as straightforward

their use in a variety of industrial applications, including as in the base metals [8-11].

chemical process plant piping, oil and gas transmission Previous investigations have demonstrated that micro-

lines, and structures for use in marine environments [4,5]. structure of both weld and heat affected zones is a func-

Since welding is widely used in these applications, un- tion of the cooling rate from peak temperature [12-15].

derstanding the factors which affect the weldability of Consequently, it is expected that the ferrite/austenite

duplex stainless steels is critical to the successful imple- balance in fusion zone is affected by laser power and

mentation of these engineering materials. welding speed. However, this research area has received

Generally, the ferrite/austenite balance has a remark- comparatively little investigations and more work is re-

able influence on both mechanical and corrosion proper- quired for deep understanding the effect of different laser

Copyright © 2011 SciRes. MSA

1444 Effect of Laser Beam Welding Parameters on Microstructure and Properties of Duplex Stainless Steel

welding parameters on properties of duplex stainless lyzed included both ferrite and austenite stabilizing ele-

steels. The present study is concerned with laser beam ments.

welding and its effect on size and microstructure of fu- Mechanical tests including tensile, bending and hard-

sion zone then, on mechanical and corrosion properties ness were performed for laser beam butt welded joints

of duplex stainless steel welded joints. having complete penetration. These tests were performed

at room temperature according to relevant standards.

2. Experimental Procedure

Tensile test was performed for three samples in each

The used steel is a commercial duplex stainless steel; condition and the data reported are the average of the

2205 with 6.4 mm plate thickness. Its chemical composi- three individual results. The given hardness values are

tion and mechanical properties are given in Table 1. the average of five readings. Regarding corrosion test,

Both bead-on-plate and autogenously single pass square selected laser beam welded samples were subjected to

butt welds were made using CO2 laser beam welding accelerated corrosion test based on tafel plot technique

process. Schematic illustration of laser butt welding joint where corrosion rate was measured using Potentio-

is shown in Figure 1. Weld specimens (150 × 100 × 6.4 stat—Auto Lab PGSTAT 30 device.

mm) were prepared as square butt joints with machined

3. Results and Discussion

surfaces and were held firmly using fixture to prevent

distortion. Laser beam welding parameters studied are 3.1. Effect of Laser Power

given in Table 2.

The effect of laser power was clarified using 0.5m/min

The used laser was a carbon dioxide with a maximum

welding speed, 0.0 and −2.0 mm defocusing distances.

output power of 9 kW in the continuous wave mode. Af-

Figure 2 shows macrographs of cross sections of laser

ter welding, the specimens were visually inspected, ra-

bead-on-plate welds made using 0.5 m/min welding

diographed then, sectioned transverse to the welding di-

rection where it were subjected to metallographic ex-

aminations as well as mechanical and corrosion tests. For

metallographic examination, the specimens were pre-

pared using standard techniques. The size and micro-

structure of fusion zone were examined using optical

microscope. Compositional variations across welded

joints were determined in scanning electron microscope

equipped with an energy dispersive spectrometer (EDS)

at an accelerating voltage of 30 kV. The elements ana- Figure 1. Schematic illustration of laser butt welding joint.

Table 1. Chemical composition (wt%) and mechanical properties of used base metal.

Chemical composition

Cr Ni Mn C Si P S Mo Cu N

21.9 4.70 1.71 0.03 0.50 0.03 0.002 2.60 0.20 0.17

Mechanical properties

Tensile strength (MPa) Yield strength (MPa) Elongation (%)

730 685 30

Table 2. Laser beam welding parameters.

Weld type P (kW) S (m/min) △Z (mm) Shielding gas/ Flow rate (l/min)

Bead-on-plate 4, 5, 6, 7, 7.5, 8 0.5 −2, 0 Argon/20

Bead-on-plate 7 0.25, 0.4, 0.5, 1, 2, 3, 4, 5, 6 −2, 0 Argon/20

Bead-on-plate 7 0.5 3, 2, 1, 0, −1, −2, −3, −4 Argon/20

Butt joint 8 0.25, 0.5 −2 Nitrogen/20

P: Power; S: Speed; △Z: Defocusing distance.

Copyright © 2011 SciRes. MSA

Effect of Laser Beam Welding Parameters on Microstructure and Properties of Duplex Stainless Steel 1445

(a) 2mm (b) 2mm (c) 2mm (d) 2mm

Figure 2. Macrographs of cross sections of laser bead-on-plate welds made using 0.5 m/min speed, −2 mm defocusing dis-

tance, 20 l/min Ar and different laser powers. (a) 4 kW; (b) 5 kW; (c) 7 kW; (d) 8 kW.

speed, −2 mm defocusing distance, 20 l/min Ar and dif- 5

ferent laser powers. It is clear that penetration depth in- 4.5

creases with increasing laser power. The weld bead

Depth, mm

showed a characteristic of laser welding where the de- 4

velopment of the weld is essentially symmetrical about 3.5

the axis of the laser beam. No welding cracks or porosity

3

were found and this could be partly due to the good crack

0.5m/min, -2.0mm, 20l/min Ar

resistance of the base metal and the welding conditions 2.5

provided. Figure 3 summarizes the results of penetration 2

depth measurements as a function of laser power. It can 3 4 5 6 7 8 9

be noticed that penetration depth is sharply increasing

Power, kW

with the increase of laser power. It increased from

3.4mm to 4.7mm with increasing power from 4 to 8 kW. Figure 3. Effect of laser power on weld depth of laser bead-

on-plate welds made using 0.5 m/min speed and −2 mm

3.2. Effect of Laser Welding Speed defocusing distance and 20 l/min Ar shielding.

Macrographs of cross sections of laser bead-on-plate

welds made using 8 kW laser power, –2 mm defocusing penetration at the root side was observed particularly at

lower welding speed suggesting an unsteady fluid flow.

distance, 20 l/min Ar and different welding speeds are

This is due to the presence of two strong and opposing

shown in Figure 4. It is noteworthy that the fusion zone

forces, namely, the electromagnetic and the surface ten-

is symmetrical about the axis of the laser beam. However,

sion gradient forces. At these locations, the electromag-

size and depth/width ratio of fusion zone are significantly

netic force may have overcome the surface tension force,

affected by welding speed. A lower welding speed re-

thereby, influencing convective heat transfer. As a result,

sulted in a remarkable increase in the fusion zone size.

any local perturbation in the over weld can cause the

Also, weld depth/width ratio was remarkably increased

flow field to change dramatically, resulting in the ob-

with decreasing welding speed. Consequently, acceptable served increased penetration.

weld profile was obtained where the fusion zone inter- It can be noticed that no welding cracks or porosity

face is a smooth curve with no inflections. Complete were found and this could be partly due to the good crack

penetration with relatively acceptable fusion zone size resistance of base metal and the welding conditions pro-

for the 6.4 mm base metal thickness was obtained at vided. Figure 5 summarizes the results of weld depth

welding speed of 0.25 m/min (Figure 4(d)). In other measurements as a function of welding speed. Weld

words, 0.25 m/min is considered as the optimum welding depth is decreased with the increase in welding speed. It

speed at 8kW laser power since it resulted in fusion zone decreased from 7.4mm to 1.9mm with increasing weld-

with a slight taper configuration. This fusion zone shows ing speed from 0.25 to 6 m/min.

a characteristic of laser welding with an acceptable weld

depth/width ratio. At low welding speed, attenuation of 3.3. Effect of Defocusing Distance

beam energy by plasma is less significant. This results in Defocusing distance, focus position, is the distance be-

relatively more exposure of the laser beam on the sample tween specimen surface and optical focal point. In order

surface. Consequently, the depth/width ratio would be to study its effect on both penetration depth and weld

decreased and the fusion zone would be increased. profile, bead-on-plate was made with changing defocus-

Inspite of the development of the weld is essentially ing distance of −4.0 mm up to 3.0 mm. Welding condi-

symmetrical about the axis of the laser beam, increase tions were selected to obtain incomplete penetration.

Copyright © 2011 SciRes. MSA

1446 Effect of Laser Beam Welding Parameters on Microstructure and Properties of Duplex Stainless Steel

(a) 2mm (b) 2mm (c) (d)

2mm 2mm

Figure 4. Macrographs of cross sections of laser bead-on-plate welds made using 8 kW laser power, –2 mm defocusing dis-

tance, 20 l/min Ar and different welding speeds. (a) 5 m/min; (b) 1 m/min; (c) 0.5 m/min; (d) 0.25 m/min.

10 graphic tests confirmed that laser butt welded joint is free

8kW, 0.0mm, 20l/min Ar from both external and internal defects. Then, welded

8 joint was sectioned for metallographic examinations.

Figure 8(a) shows macrograph of a cross section of laser

Depth, mm

6

butt welded joints made using 8 kW power, 0.5 m/min

4

speed, 0.0mm defocusing distance and 20 l/min argon.

Fusion zone shows a characteristic of laser welding with

2 complete penetration and acceptable weld profile where

the fusion zone interface is a smooth curve with no in-

0 flections.

0 1 2 3 4 5 6 7 In order to clarify the effect of shielding gas type, ar-

Speed, m/min gon was replaced by nitrogen with other welding condi-

tions kept constant. Figure 8(b) shows macrograph of a

Figure 5. Effect of welding speed on weld depth of laser

bead-on-plate welds made using 8 kW power, −2 mm defo- cross section of laser butt welded joint made using 8 kW

cusing distance and 20 l/min Ar shielding. power, 0.5 m/min speed, 0.0 mm defocusing distance and

20 l/min nitrogen. It can be noticed that typical laser

Examples of macrographs of cross sections of laser weld with complete penetration and acceptable weld pro-

bead-on-plate welds made using 8 kW power, 0.5 m/min file, similar to that of argon shielding, was obtained.

welding speed, 20 l/min argon shielding and different

3.5. Microstructure of Laser Butt Welds

defocusing distances are shown in Figure 6. No cracking

or porosity was observed in all welds. Figure 7 summa- The microstructure of the used 2205 duplex stainless

rizes results of weld bead depth/width ratio as a function steel base metal is shown in Figure 9. It can be noticed

of defocused distance of laser bead-on-plate welds made that this microstructure is duplex with approximately

using 8 kW power, 0.5 m/min welding speed and 20 l/min equal volumes of both ferrite and austenite phases. Since

Ar. Changing defocusing distance from zero to either hot working of duplex stainless steel is normally per-

minus or plus values has resulted in decrease in depth/ formed in the austenite-ferrite, two phase region, the re-

width ratio. In other words, shifting the focused beam sultant microstructure tends to be strongly oriented along

position to either below or above specimen surface re- the working direction. An average hardness value of

sults in decrease in depth/width ratio. However, shifting about 305 Hv was obtained for this microstructure.

the focused beam position above the specimen surface Optical micrographs of laser butt welded joint made

results in much decrease in depth/width ratio in com- using 8 kW power, 0.5 m/min speed, 0.0 mm defocusing

parison with shifting it below specimen surface. This is distance and 20 l/min of argon and nitrogen shielding are

related to decrease in laser beam density in case of shift- shown in Figures 10 and 11 respectively. The noticeable

ing the focused beam position above specimen surface. feature is the highly directional nature of the microstruc-

The above results are in good agreement with other re- ture around the axis of the laser beam in both cases. This

search work [16]. is due to solidification of the weld metal at high cooling

rate. No solidification cracking was found in the weld

3.4. Effect of Type of Shielding Gas structure. Structures of weld metal in both joints were

Based on results obtained from above experiments, op- almost similar. For weld metal, a dendritic microstructure

timum welding parameters were obtained and imple- was developed at fusion boundary due to fast cooling

mented for welding square butt joints. Nondestructive conditions (Figures 10(c), 11(c)). More globular struc-

investigations including visual, dye penetrant and radio- tures were observed at weld metal center that exposed to

Copyright © 2011 SciRes. MSA

Effect of Laser Beam Welding Parameters on Microstructure and Properties of Duplex Stainless Steel 1447

(a) (c) (d) 2mm

2mm (b) 2mm 2mm

Figure 6. Macrographs of cross sections of laser bead-on-plate welds made using 8 kW power, 0.5 m/min speed, 20 l/min Ar

with difference defocusing distances. (a) Dd = −4 mm; (b) Dd = −1 mm; (c) Dd = 0.0 mm; (d) Dd = +3 mm.

Depth/Width Ratio

1.2

0.8

0.6

0.4

0.2

0

4 2 0 -2 -4 -6

Defocusing Distance, mm 50 µm

Figure 7. Weld bead depth/width ratio versus defocusing Figure 9. Optical micrographs of base metal of duplex stain-

distance of laser bead-on-plate welds made using 8 kW less steel used.

power, 0.5 m/min speed and 20 l/min Ar.

Regarding heat affected zone, its microstructure is

critical for welded joint properties. In general, narrow

HAZ of about 400 - 500 µm was observed for the exam-

ined welds (Figures 10(a), 11(a)). The heat affected

zone is consisting firstly of a grain growth zone charac-

terized by coarse α-ferrite grains decorated with al-

(a) 3mm lotriomorphic layers of austenite, some austenite plates

and some intra-granularly nucleated particles formed on

inclusions where the volume fraction of austenite in this

region is low compared with the base metal. Beyond this

partially ferritised zone, the major difference being the

spacing of the grains which is a function of the distance

from the fusion zone and the peak temperature reached

(b)

during heating. In other words, the coarse grained region

3mm

adjacent to the fusion line could be resulted from nearly

Figure 8. Macrographs of cross sections of laser butt welded complete austenite dissolution on heating and subsequent

joints made using 8 kW power, 0.5 m/min speed, 0.0 mm ferrite grain growth. Higher magnifications for HAZ mi-

defocusing distance and 20 l/min of (a) argon; (b) nitrogen. crostructure are shown in color etching in Figure 12 and

hardness measurements allowed a clear distinction be-

lower cooling rates and with a less pronounced heat flow tween the ferrite and austenite in both weld metal and

direction. During solidification of duplex weld metal an HAZ. The ferrite content in both weld metal and HAZ

almost completely ferrite structure is formed. Further was relatively higher in comparison to base metal. This

cooling initiates the formation of the austenite phase nu- has been confirmed using energy dispersive X-ray (EDX)

cleating at the ferrite grain boundaries. In other words, technique. Results showed that the concentrations of

duplex stainless steel weld metal solidifies completely to elements; such as Cr and Mn in ferrite phase is higher,

α-ferrite and the volume fraction of austenite is deter- while Ni concentration is lower than in austenitic phase.

mined by subsequent solid state phase transformation The element partitioning between ferritic and austenitic

(17). phase is consistent with the stabilizing effect of each

Copyright © 2011 SciRes. MSA

1448 Effect of Laser Beam Welding Parameters on Microstructure and Properties of Duplex Stainless Steel

BM

BM

WM

WM

HAZ HAZ

(a) (b) 100 µm (c)

400 µm 50 µm

Figure 10. Optical micrographs of laser butt welded joint made using 8 kW power, 0.5 m/min speed, 0.0 mm defocusing dis-

tance and 20 l/min argon shielding.

BM

BM

WM

HAZ HAZ

WM

(a) 400 µm (b) 100 µm (c) 50 µm

Figure 11. Optical micrographs of laser butt welded joint made using 8 kW power, 0.5 m/min speed, 0.0 mm defocusing dis-

tance and 20 l/min nitrogen shielding.

in ferrite/austenite balance among different heat input of

laser welds can be rationalized using a constant iron sec-

WM

HAZ

tion of a Fe-Cr-Ni ternary phase diagram. The composition

band superimposed on the 60% constant iron section is

representative of the range of duplex stainless steel con-

sidered in this investigation. The diagram predicts that

primary solidification of this alloy occurs as delta ferrite

and that the structure is completely ferritic at completion

(a) 100 µm of solidification. On cooling in the solid state, partial trans-

formation of ferrite to austenite occurs at temperatures

below the ferrite solves. The austenite content formed

WM

during cooling in solid state is depended on cooling rate.

The higher the laser power and/or the lower welding speed,

HAZ the coarser is the dendritic structure due to decreasing

cooling rate. However, the effect of laser power was rela-

tively less than that of welding speed.

3.6. Mechanical Properties of Laser Butt Welds

(b) 100 µm Hardness profile through weld metal, HAZ and base

metal of welded joint made using 8 kW power, 0.5

Figure 12. Color etched optical micrographs of HAZ of

m/min speed, 0.0 mm defocusing distance and 20 l/min

laser butt welded joint made using 8 kW power, 0.5 m/min

speed, 0.0 mm defocusing distance and 20 l/min of (a) argon argon is shown in Figure 13. It can be noticed that no

shielding; (b) nitrogen shielding. significant difference in hardness values of weld metal,

HAZ and base metal was obtained. Similar hardness pro-

element on the respective phase. file was obtained in case of nitrogen shielding.

Generally, laser weld results in a rapid cooling rate The bending test at room temperature showed good

through the transformation temperature range which in ductility for all joints where no cracks were found after

turn resulted in decreasing austenite content and this U-bends made. Results of tensile test of laser butt welded

agreed qualitatively with optical metallography. Variation joint, made using 8 kW power, 0.5 m/min speed, 0.0 mm

Copyright © 2011 SciRes. MSA

Effect of Laser Beam Welding Parameters on Microstructure and Properties of Duplex Stainless Steel 1449

350 Table 3. Tensile properties of laser butt welded joint made

Hardness, HV (200g)

using 8 kW power, 0.5 m/min speed, 0.0 mm defocusing

distance and 20 l/min argon, as well as that of base metal.

300

Tensile Tensile strength Yield strength Elongation

WM HAZ BM

specimen (MPa) (MPa) (%)

250

Welded joint 713 669 25

200 Base metal 730 685 30

0 1 2 3 4 5

Distance from Weld Centerline, mm

3.7. Corrosion Properties of Laser Butt Welds

Figure 13. Hardness profile through weld metal, HAZ and

base metal of welded joint made using 8 kW power, 0.5 The effect of both heat input, as a function of welding

m/min speed, 0.0 mm defocusing distance and 20 l/min ar- speed, and shielding gas type on corrosion resistance of

gon. laser butt welded joints are shown in Table 4 and Figure

14. It is found that corrosion rate of welded joint de-

defocusing distance and 20 l/min argon, as well as that of creases with the increase in welding speed that means

base metal are shown in Table 3. Tensile tested welded with the decrease in heat input. This effect of heat input

specimens were failed outside weld zone. Tensile proper- can be rationalized in terms of cooling rate. For the low

ties of welded specimens are very close to that of base heat input of laser welds, the fast cooling rate resulted in

metal. Only, ductility or elongation of welded joint is insufficient amount of austenite and significant chro-

slightly lower than that of base metal. This is related to mium nitride precipitation. This could lead to depletion

decreasing austenite volume fraction of welded joint in of chromium around these precipitates which in turn

comparison with base metal. could have a deleterious effect on the pitting resistance.

The obtained mechanical properties, in general, are It is found also that using nitrogen as a shielding gas to

correlated to microstructure that was affected by shield- replace argon, under same flow condition, has resulted in

ing gas type. In other words, mechanical properties of a remarkable decrease in corrosion rate of welded joint

welds made using nitrogen shielding are relatively im- (Figure 14). Again, improvement in corrosion properties

proved in comparison with that of welds made using ar- of laser beam welded joints made using nitrogen as a

gon shielding. This could be related to better balancing shielding gas is related to improvement in ferrite-auste-

of ferrite-austenite phases in both weld metal and heat nite balance in both weld metal and heat affected zone, as

affected zone since nitrogen is austenite stabilizer and is has been reported by other research works [19,20].

of great importance in the reforming of austenite that in

turn could result in structure with approximately equal

4. Conclusions

amounts of ferrite and austenite, similar to that of base Based on the results achieved in this study, it can be con-

metal. This is conformed to results of other researchers’ cluded that laser power, welding speed, defocusing dis-

work [18]. tance and type of shielding gas combinations have to be

It should be reported that tensile elongation of laser optimized for obtaining welded joints with acceptable

welded joint was not remarkably affected by increasing fusion zone size, weld profile as well as mechanical and

heat input as a function of higher laser power and/or corrosion properties.

lower welding speed inspite of higher austenite volume The minimum fusion zone produced by laser beam is

fraction in this case. This could be related to larger fusion depended on heat input as a function of laser power and

zone size in case of higher heat input. In other words, the welding speed. High laser power and high welding speed

effect of fusion zone size to decrease tensile elongation is together with adjusting laser focused spot at specimen

higher than the effect of austenite volume fraction to in- surface have produced welded joint with a remarkable

crease it. decrease in fusion zone size and an acceptable weld profile

Table 4. Corrosion rate of laser beam welded joints made using different welding speeds and different shielding gases.

Welding condition Corrosion rate, mm/year Remarks

8 kW, 0.5 m/min, 20 l/min, Nitrogen 0.001637 Weld metal-fusion line corrosion

8 kW, 0.5 m/min, 20 l/min Argon 0.05334 Weld metal-fusion line corrosion

8 kW, 0.25 m/min, 20 l/min, Argon 0.2171 Weld metal-fusion line corrosion

Copyright © 2011 SciRes. MSA

1450 Effect of Laser Beam Welding Parameters on Microstructure and Properties of Duplex Stainless Steel

Figure 14. Comparison between corrosion rate of laser beam welded joints made using different welding speeds and shielding

gases.

with higher weld depth/width ratio. The nature of ferrite to doi:10.1007/BF02484228

austenite transformation in fusion zone is strongly influ- [2] A. Poznansky, C. S. Nalbone and J. D. Crawford, “The

enced by cooling rate, which is depended on heat input as Corrosion Resistance of 25Cr-3.5Mo-6Ni and 25Cr 4.5Mo-

a function of laser power and/or welding speed. Low heat 6Ni Cast Duplex Stainless Steels,” Proceedings of Inter-

national Conference, Duplex Stainless Steels, St. Louis,

input laser welds resulted in considerable variation in the

25-28 October 1983, pp. 431-444.

ferrite/austenite balance of fusion zone relative to the base

[3] N. Lopez, M. Cid and M. Puigalli, “Influence of σ-Phase

metal as a result of high cooling rate. on Mechanical Properties and Corrosion Resistance of

Satisfactory mechanical properties including yield Duplex Steels,” Corrosion Science, Vol. 41, No. 8, 1999,

strength, tensile strength, elongation and bending were pp. 1615-1631. doi:10.1016/S0010-938X(99)00009-8

obtained for laser welds. Results indicated that heat input [4] M. Tynell, “Applicability Range for a High Strength Du-

has no remarkable effect on mechanical properties, ex- plex Stainless Steel in Deep Sour Oil and Gas Wells,”

cept elongation that was improved with either increasing Proceedings of International Conference, Duplex Stain-

laser power or decreasing welding speed that means with less Steels, St. Louis, 25-28 October 1983, pp. 283-292.

increasing heat input. This is related to maintaining pro- [5] H. Miyuki, T. Kudo, M. Koso, M. Miura and T. Moroishi,

per ferrite-austenite balance in fusion zone in this case. “25%Cr Containing Duplex Phase Stainless Steel for Hot

Using nitrogen to replace argon as a shielding gas, under Sea Water Applications,” Proceedings of International

Conference, Duplex Stainless Steels, St. Louis, 25-28

same flow rate, has resulted in remarkable decrease in October 1983, pp. 95-112.

corrosion rate and increase in ductility of welded joint.

[6] S. M. Tavares, V. F. Terra, J. M. Pardal and M. P. Fon-

Improvement in both mechanical and corrosion proper- seca, “Influence of the Microstructure on the Toughness

ties of laser beam welded joints made using nitrogen as a of a Duplex Stainless Steel UNS S31803,” Journal of

shielding gas is related to maintaining proper ferrite- Materials Science, Vol. 40, No. 1, 2005, pp. 145-154.

austenite balance in both weld metal and heat affected doi:10.1007/s10853-005-5700-7

zone. [7] L. F. Svensson and B. Gretoft, “Properties-Microstructure

Relationship for Duplex Stainless Steel Weld Metals,”

5. Acknowledgements Proceedings of International Conference, Duplex Stainless

Steel, The Hague, 27-28 October 1986, Paper 22.

The authors would like to acknowledge Libyan Research

Institute for conducting laser beam welding experiments. [8] M. Miura, T. Kudo, M. Tsuge, M. Kuso and T. Kobaya-

shi, “Effect of Chemical Composition on Microstructure,

Mechanical and Corrosion Properties of Duplex Stainless

REFERENCES Steel Weldment,” Proceedings of International Confer-

[1] B. I. Voronenko, “Austenitic-Ferritic Stainless Steels: A ence, Duplex Stainless Steel, The Hague, 27-28 October

State-of-the Art Review,” Metal Science and Heat Treat- 1986, paper 33C.

ment, Vol. 39, No. 9-10, 1997, pp. 428-437. [9] J. Dobranszky and J. Ginsztler, “Microstructural Stability

Copyright © 2011 SciRes. MSA

Effect of Laser Beam Welding Parameters on Microstructure and Properties of Duplex Stainless Steel 1451

of Duplex Stainless Steel Weldments,” Materials Science pp. 770-775. doi:10.1016/S0924-0136(96)02721-5

Forum, Vol. 561-565, 2007, pp. 2119-2122. [16] A. El-Batahgy, “Effect of Laser Beam Welding Parame-

doi:10.4028/www.scientific.net/MSF.561-565.2119 ters on Fusion Zone Shape and Microstructure of Austen-

[10] V. Muthupandi, P. B. Srinivasan, S. K. Seshadri and S. itic Stainless Steel,” Materials Letters, Vol. 32, No. 2-3,

Sundaresan, “Effect of Weld Metal Chemistry and Heat 1997, pp. 155-163. doi:10.1016/S0167-577X(97)00023-2

Input on the Structure and Properties of Duplex Stainless [17] J. Nowacki and A. Lukojc, “Microstructural Transforma-

Steels,” Materials Science Engineering: A, Vol. 358, No. tions of Heat Affected Zones in Duplex Steel Welded

1-2, 2003, pp. 9-16. doi:10.1016/S0921-5093(03)00077-7 Joints,” Materials Characterization, Vol. 56, No. 4-5,

[11] J. Honeycombe and T. G. Gooch, “Intergranular Attack in 2006, pp. 436-441. doi:10.1016/j.matchar.2006.02.007

Welded Stress-Corrosion Resistant Stainless Steels,” Weld- [18] T. Omura, T. Kushida and Y. Komizo, “Effect of Nitro-

ing Journal, Vol. 56, No. 11, 1977, pp. 339-s-353-s. gen Distribution on Rapid Solidification in Laser Welded

[12] R. Mundt and H. Hoffmeister, “Effect of Chemical Com- Duplex Stainless Steels,” Welding International, Vol. 14,

position and Weld Thermal Cycles on Phase Transforma- No. 4, 2000, pp. 288-294.

tion and Microstructures of Ferrite-Austenite Steels,” doi:10.1080/09507110009549181

Proceedings of International Conference, Stainless Steel,

[19] P. Bala Srinivasan, V. Muthupandi, W. Dietzel and V.

Gothenberg, 3-4 September 1984, pp. 315-322.

Sivan, “Microstructure and Corrosion Behavior of Shield-

[13] S. Jana, “Effect of Heat Input on HAZ Properties of Two ed Metal Arc Welded Dissimilar Joints Comprising Du-

Duplex Stainless Steels,” Journal of Materials Processing plex Stainless Steel and Low Alloy Steel,” Materials En-

Technology, Vol. 33, No. 3, 1992, pp. 247-261. gineering and Performance, Vol. 15, No. 6, 2006, p. 758.

doi:10.1016/0924-0136(92)90211-A doi:10.1361/105994906X150902

[14] B. Bonnefois, R. Blondeau and D. Catelin, “Control of [20] G. Lothongkum, P. Wongpanya, S. Morito, T. Furuhara

the Ferrite Level in Duplex Stainless Steel Welds,” Pro- and T. Maki, “Effect of Nitrogen on Corrosion Behaviour

ceedings of International Conference, Duplex Stainless of 28Cr-7Ni Duplex and Microduplex Stainless Steels in

Steel, The Hague, 27-28 October 1986, Paper 6. Air-Saturated 3.5 wt% NaCl Solution,” Corrosion Sci-

[15] J. Ku, N. Ho and S. Tjong, “Properties of Electron Beam ence, Vol. 48, No. 1, 2006, pp. 137-153.

Welded SAF 2205 Duplex Stainless Steel,” Journal of doi:10.1016/j.corsci.2004.11.017

Materials Processing Technology, Vol. 63, No. 1-3, 1993,

Copyright © 2011 SciRes. MSA

View publication stats

You might also like

- B 36 - B 36M - 13Document9 pagesB 36 - B 36M - 13Ahmed BilalNo ratings yet

- Effect of Laser Beam Welding Parameters On Microstructure and Properties of Duplex Stainless SteelDocument9 pagesEffect of Laser Beam Welding Parameters On Microstructure and Properties of Duplex Stainless SteelAsif HameedNo ratings yet

- Effect of Laser Beam Welding Parameters On Microstructure and Properties of Duplex Stainless SteelDocument9 pagesEffect of Laser Beam Welding Parameters On Microstructure and Properties of Duplex Stainless Steelnaresh1272No ratings yet

- Modeling and Optimization of Tensile Shear Strength of Titanium:Aluminum Dissimilar Welded ComponentDocument11 pagesModeling and Optimization of Tensile Shear Strength of Titanium:Aluminum Dissimilar Welded Componentaw1228818No ratings yet

- E3sconf Icmed2020 01030Document6 pagesE3sconf Icmed2020 01030Isaac SimbañaNo ratings yet

- Application of Taguchi Method For Resistance Spot Welding of Galvanized SteelDocument6 pagesApplication of Taguchi Method For Resistance Spot Welding of Galvanized Steelpradipta satrio wNo ratings yet

- A11 PDFDocument15 pagesA11 PDFJunaid AkhtarNo ratings yet

- 10 1016@j Jmapro 2013 06 010Document14 pages10 1016@j Jmapro 2013 06 010SamuelshrlyNo ratings yet

- 1 s2.0 S0030399212005762 MainDocument12 pages1 s2.0 S0030399212005762 MainMochamad Iqbal GhifaryNo ratings yet

- WeldingDocument6 pagesWeldingTamal PaulNo ratings yet

- Microstructure Analysis of Arc Welded Mild Steel Plates: IOP Conference Series: Materials Science and EngineeringDocument7 pagesMicrostructure Analysis of Arc Welded Mild Steel Plates: IOP Conference Series: Materials Science and EngineeringAniekanNo ratings yet

- Latest Developments in Friction Welding - A ReviewDocument6 pagesLatest Developments in Friction Welding - A ReviewIJRASETPublicationsNo ratings yet

- The Effect of Groove Welding On Mechanical PropertDocument8 pagesThe Effect of Groove Welding On Mechanical PropertMuhammad Zuhairy jabarNo ratings yet

- Saravanan2017 Article StudiesOnMetallurgicalAndMechaDocument8 pagesSaravanan2017 Article StudiesOnMetallurgicalAndMechaPardeepNo ratings yet

- Materials Science and Engineering ADocument7 pagesMaterials Science and Engineering AДмитрий ВасилNo ratings yet

- Effect of Laser Welding Process Parameters On Mechanical P Roperties of Stainless Steel-316Document11 pagesEffect of Laser Welding Process Parameters On Mechanical P Roperties of Stainless Steel-316kamal touilebNo ratings yet

- Microstructural Characteristic of Dissimilar Welded Components (AISI 430 Ferritic-AISI 304 Austenitic Stainless Steels) by CO2 Laser Beam Welding (LBW) (#97282) - 83434Document17 pagesMicrostructural Characteristic of Dissimilar Welded Components (AISI 430 Ferritic-AISI 304 Austenitic Stainless Steels) by CO2 Laser Beam Welding (LBW) (#97282) - 83434kamal touilebNo ratings yet

- Effect of Multi-Pass SMAW Welding On The Surface HDocument7 pagesEffect of Multi-Pass SMAW Welding On The Surface HYousab CreatorNo ratings yet

- ICEE097 - Full Length Paper PDFDocument4 pagesICEE097 - Full Length Paper PDFWeld TechNo ratings yet

- A Review of Friction Stirs WeldingDocument6 pagesA Review of Friction Stirs WeldingEditor IJTSRDNo ratings yet

- Impact of Process Parameters of Laser Welding On The Mechanical Properties of Ti6Al4V A ReviewDocument9 pagesImpact of Process Parameters of Laser Welding On The Mechanical Properties of Ti6Al4V A ReviewbalamuruganNo ratings yet

- Weld Quality Analysis of Tig, Laser and Electron Beam Welded Ss 304 and 316 Materials With NDT TechniquesDocument4 pagesWeld Quality Analysis of Tig, Laser and Electron Beam Welded Ss 304 and 316 Materials With NDT TechniquesИлгар НахматовNo ratings yet

- Previous Paper - EditedDocument7 pagesPrevious Paper - EditedNaveen KumarNo ratings yet

- Study and Analysis of Spot Welding of Dissimilar Material 1008 Low Carbon Steel-5052 Aluminum AlloyDocument17 pagesStudy and Analysis of Spot Welding of Dissimilar Material 1008 Low Carbon Steel-5052 Aluminum AlloyIJRASETPublicationsNo ratings yet

- 1 s2.0 S1006706X12600508 MainDocument7 pages1 s2.0 S1006706X12600508 MainMochamad Iqbal GhifaryNo ratings yet

- Optics and Laser Technology: Nikhil Kumar, Manidipto Mukherjee, Asish BandyopadhyayDocument14 pagesOptics and Laser Technology: Nikhil Kumar, Manidipto Mukherjee, Asish BandyopadhyaykaelcorbettNo ratings yet

- Impact Toughness of High Strength Low AlloyDocument7 pagesImpact Toughness of High Strength Low AlloySPINHRNo ratings yet

- Materials Today: Proceedings: U.S. Patil, M.S. KadamDocument6 pagesMaterials Today: Proceedings: U.S. Patil, M.S. KadamSREEJITH S NAIRNo ratings yet

- Eperimental Investigation of Effects of Welding Current and Elektrode AngleDocument3 pagesEperimental Investigation of Effects of Welding Current and Elektrode AngleMuizz AbdullahNo ratings yet

- Investigation of Mechanical Properties and Microstructure of GTAW On Dissimilar MetalsDocument3 pagesInvestigation of Mechanical Properties and Microstructure of GTAW On Dissimilar Metalskamal touilebNo ratings yet

- Calik PDFDocument5 pagesCalik PDFmarceloNo ratings yet

- CalikDocument5 pagesCalikmarceloNo ratings yet

- 1 s2.0 S2214785319343834 Main PDFDocument6 pages1 s2.0 S2214785319343834 Main PDFJohnny VillarroelNo ratings yet

- The Effect of Current On SMAW Welding To Tensile Strength and Micro Structure of Low Carbon SteelDocument5 pagesThe Effect of Current On SMAW Welding To Tensile Strength and Micro Structure of Low Carbon Steelmade dwi payanaNo ratings yet

- LBW OptimizationDocument11 pagesLBW Optimizationfathi.alfazaniNo ratings yet

- Study On laser-MIG Hybrid Welding Characteristics of A7N01-T6 Aluminum AlloyDocument2 pagesStudy On laser-MIG Hybrid Welding Characteristics of A7N01-T6 Aluminum Alloysreejith2786No ratings yet

- Comparative Analysis of Pulsed ND - YAG Laser Welding of 304L and 904L Stainless Steel (Materials Today - Proceedings) (2020)Document5 pagesComparative Analysis of Pulsed ND - YAG Laser Welding of 304L and 904L Stainless Steel (Materials Today - Proceedings) (2020)MahnooshNo ratings yet

- Constantin 2017 IOP Conf. Ser. Mater. Sci. Eng. 252 012038 PDFDocument9 pagesConstantin 2017 IOP Conf. Ser. Mater. Sci. Eng. 252 012038 PDFMeet PatelNo ratings yet

- Teklas 0A - PROPERTIESDocument7 pagesTeklas 0A - PROPERTIESMudzakkir DioktyantoNo ratings yet

- 45 - 5 - Taban (Butt Joint FSW Better Than Mig)Document8 pages45 - 5 - Taban (Butt Joint FSW Better Than Mig)Amar DJEDIDNo ratings yet

- 1 s2.0 S003039921830104X MainDocument8 pages1 s2.0 S003039921830104X MainMochamad Iqbal GhifaryNo ratings yet

- Failure Behavior of Resistance Spot Welded Low CarDocument10 pagesFailure Behavior of Resistance Spot Welded Low CarLuis Allan GarciaNo ratings yet

- Chiong 2019 IOP Conf. Ser. Mater. Sci. Eng. 495 012093Document10 pagesChiong 2019 IOP Conf. Ser. Mater. Sci. Eng. 495 012093Plentys KWNo ratings yet

- Welding Research PaperDocument7 pagesWelding Research Paperkifmgbikf100% (1)

- Effect of Welding Process and Post Weld Heat Treatments On Microstructure and Mechanical Properties of Aisi 431 Martensitic Stainless SteelDocument6 pagesEffect of Welding Process and Post Weld Heat Treatments On Microstructure and Mechanical Properties of Aisi 431 Martensitic Stainless SteelInternational Jpurnal Of Technical Research And ApplicationsNo ratings yet

- Microstructure and Alloy Element Distribution of Dissimilar Joint 316L and EH36 in Laser WeldingDocument9 pagesMicrostructure and Alloy Element Distribution of Dissimilar Joint 316L and EH36 in Laser WeldingPardeepNo ratings yet

- Nd-Yag Laser Beam and Gta Welding of Ti-6Al-4V Alloy: Abdel-Monem El-Batahgy, Tarasankar DebroyDocument8 pagesNd-Yag Laser Beam and Gta Welding of Ti-6Al-4V Alloy: Abdel-Monem El-Batahgy, Tarasankar DebroyerpublicationNo ratings yet

- Wang 2011Document7 pagesWang 2011wallisonkennedy014No ratings yet

- Microstructural Characterization and Its Effect On Mechanical Properties of Fiber Laser Beam Welded Ti6Al4V (2017)Document4 pagesMicrostructural Characterization and Its Effect On Mechanical Properties of Fiber Laser Beam Welded Ti6Al4V (2017)adnan domlogeNo ratings yet

- 39IJMPERDAPR201939Document8 pages39IJMPERDAPR201939TJPRC PublicationsNo ratings yet

- Evaluation of Bond Quality and Corrosion Resistance of Stainless Steel-Low Carbon Steel Friction Surfaced DepositDocument10 pagesEvaluation of Bond Quality and Corrosion Resistance of Stainless Steel-Low Carbon Steel Friction Surfaced DepositTJPRC PublicationsNo ratings yet

- Effect of Welding Process and Post Weld Heat Treatments On Microstructure and Mechanical Properties of Aisi 431 Martensitic Stainless SteelDocument6 pagesEffect of Welding Process and Post Weld Heat Treatments On Microstructure and Mechanical Properties of Aisi 431 Martensitic Stainless SteelwangpengstpNo ratings yet

- ETJ - Volume 41 - Issue 7 - Pages 1-9 NewDocument9 pagesETJ - Volume 41 - Issue 7 - Pages 1-9 Newhameed.laftaNo ratings yet

- Prediction of Mechanical Properties As A Function of Welding Variables in Robotic Gas Metal Arc Welding of Duplex Stainless Steels Saf 2205 Welds Through Artificial Neural NetworksDocument16 pagesPrediction of Mechanical Properties As A Function of Welding Variables in Robotic Gas Metal Arc Welding of Duplex Stainless Steels Saf 2205 Welds Through Artificial Neural NetworksDhruv PatelNo ratings yet

- Abrasive Wear Behaviour of Heat Treated En31 Steel: ISIJ International January 2013Document9 pagesAbrasive Wear Behaviour of Heat Treated En31 Steel: ISIJ International January 2013NABIL HUSSAINNo ratings yet

- NosaDocument9 pagesNosaosaroboNo ratings yet

- Strenx 700Document15 pagesStrenx 700SameerNo ratings yet

- 1 s2.0 S0308016120302015 MainDocument11 pages1 s2.0 S0308016120302015 MainKAVINNo ratings yet

- Review Paper On Optimization of Metal Inert Gas Welding On Stainless Steel AISI 410by Taguchi MethodDocument8 pagesReview Paper On Optimization of Metal Inert Gas Welding On Stainless Steel AISI 410by Taguchi MethodIJRASETPublicationsNo ratings yet

- Microstructure, Properties and Corrosion Characterization of Welded Joint For Composite Pipe Using A Novel Welding ProcessDocument12 pagesMicrostructure, Properties and Corrosion Characterization of Welded Joint For Composite Pipe Using A Novel Welding ProcessRami GhorbelNo ratings yet

- EBY Fasteners Product Range Aug 2020Document2 pagesEBY Fasteners Product Range Aug 2020Mark KNo ratings yet

- Cutting Data Milling Boring 2019 ITL E LowDocument60 pagesCutting Data Milling Boring 2019 ITL E LowRoberto RosasNo ratings yet

- Roller Campacted Concrete Pavements by Robert R.Thompson, Columbus, OhioDocument133 pagesRoller Campacted Concrete Pavements by Robert R.Thompson, Columbus, Ohiooscargon19100% (1)

- Belzona 1591 (Ceramic XHT) PDFDocument2 pagesBelzona 1591 (Ceramic XHT) PDFANIBALLOPEZVEGANo ratings yet

- Properties and Thermal Degradation Studies of Gelatin Based Film - Exploring The Biopolymer For Plastic AdvancementDocument5 pagesProperties and Thermal Degradation Studies of Gelatin Based Film - Exploring The Biopolymer For Plastic AdvancementKate DauNo ratings yet

- Compaign-Style: Tool CabinetDocument3 pagesCompaign-Style: Tool CabinetAlex TorresNo ratings yet

- Weld DefectsDocument43 pagesWeld Defectsraju100% (1)

- Wrought Nickel-Iron Soft Magnetic Alloys (UNS K94490, K94840, N14076, N14080)Document6 pagesWrought Nickel-Iron Soft Magnetic Alloys (UNS K94490, K94840, N14076, N14080)Tomy lee youngNo ratings yet

- DR Fixit Roofseal ClassicDocument5 pagesDR Fixit Roofseal ClassicNitin GuptaNo ratings yet

- W1 - 2 Lecture 1 - 2 Fe3C Digram and IT CCT Diagram PDFDocument61 pagesW1 - 2 Lecture 1 - 2 Fe3C Digram and IT CCT Diagram PDFYota KimireNo ratings yet

- SemDocument138 pagesSemasmjewelNo ratings yet

- Lecture 6 Azo DyesDocument23 pagesLecture 6 Azo DyesQuratul AinNo ratings yet

- Glo Backfill TBM Tunnel Boring MachinesDocument8 pagesGlo Backfill TBM Tunnel Boring Machinesjpantazis1975No ratings yet

- 02 Semi Continuous DeodorizingDocument8 pages02 Semi Continuous DeodorizingMaicon Espindola Dos SantosNo ratings yet

- MiraTEC Trim Provides Green Building BenefitsDocument2 pagesMiraTEC Trim Provides Green Building BenefitsCMI CompanyNo ratings yet

- HFY-3800-0000-GEN-PD-0013 - 0 Welding and Welding Consumable Control Procedure-Code ADocument14 pagesHFY-3800-0000-GEN-PD-0013 - 0 Welding and Welding Consumable Control Procedure-Code ANashaat DhyaaNo ratings yet

- Concrete Pipe Brochure WebDocument1 pageConcrete Pipe Brochure Webbirendra1970No ratings yet

- Test Certificate: Signature Not VerifiedDocument1 pageTest Certificate: Signature Not Verifiedreportdaily819No ratings yet

- Ams 2451 Rev. DDocument9 pagesAms 2451 Rev. DJorge Luis Gonzalez Gonzalez100% (1)

- Copy of Pending Pos MetalDocument112 pagesCopy of Pending Pos MetalVijay OfficialNo ratings yet

- Utp Af Robotic 600 Brochure 2018.12Document2 pagesUtp Af Robotic 600 Brochure 2018.12Claude BouillotNo ratings yet

- Casa de Madeira Technical-GuideDocument16 pagesCasa de Madeira Technical-GuideJoaquim ArezNo ratings yet

- NemoDocument18 pagesNemoApoorva Gowda100% (2)

- Engineering Failure Analysis: Khlefa A. Esaklul, Tawfik M. AhmedDocument8 pagesEngineering Failure Analysis: Khlefa A. Esaklul, Tawfik M. AhmedMatheus Paes PeçanhaNo ratings yet

- MSM Unit 4 Chap 2 (Ferrous Materials and Non-Ferrous Materials)Document15 pagesMSM Unit 4 Chap 2 (Ferrous Materials and Non-Ferrous Materials)rakeshpatkar332No ratings yet

- Lecture 2 TCP 1 2015Document89 pagesLecture 2 TCP 1 2015Muhammad ZohaibNo ratings yet

- Handwritten Notes - Chemical Reactions and Equations - Chemical HandwrittenDocument16 pagesHandwritten Notes - Chemical Reactions and Equations - Chemical HandwrittenisharNo ratings yet

- PMA 600 H Datenblatt Renitherm enDocument3 pagesPMA 600 H Datenblatt Renitherm enMuhammad ArslanNo ratings yet

- Design of RCC StructureDocument14 pagesDesign of RCC Structuremark bingNo ratings yet