Professional Documents

Culture Documents

F 8-13. Typical Muffler Wall Fatigue Failure at Ex-: Igure

F 8-13. Typical Muffler Wall Fatigue Failure at Ex-: Igure

Uploaded by

Jose Tomaylla QuispeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F 8-13. Typical Muffler Wall Fatigue Failure at Ex-: Igure

F 8-13. Typical Muffler Wall Fatigue Failure at Ex-: Igure

Uploaded by

Jose Tomaylla QuispeCopyright:

Available Formats

9/8/98 AC 43.

13-1B

SECTION 3. EXHAUST SYSTEMS

8-45. GENERAL. Any exhaust system fail-

ure should be regarded as a severe hazard.

Depending upon the location and type of fail-

ure, it can result in carbon monoxide (CO) poi-

soning of crew and passengers, partial or com-

plete engine power loss, or fire. Exhaust sys-

tem failures generally reach a maximum rate of

occurrence at 100 to 200 hours’ operating

time, and over 50 percent of the failures occur

within 400 hours.

8-46. MUFFLER/HEAT EXCHANGER

FAILURES. Approximately one-half of all

exhaust system failures are traced to cracks or

ruptures in the heat exchanger surfaces used

for cabin and carburetor air heat sources.

a. Failures in the heat exchanger’s sur-

face (usually the muffler’s outer wall) allow

exhaust gases to escape directly into the cabin

heat system. The failures are, for the most

part, attributed to thermal and vibration fatigue

cracking in the areas of stress concentration;

e.g., tailpipe and stack, inlet-attachment areas.

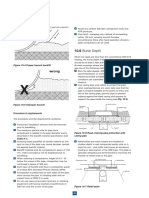

(See figures 8-13 through 8-16.) FIGURE 8-13. Typical muffler wall fatigue failure at ex-

haust outlet. (A. Complete muffler assembly with heat

b. Failures of the spot welds which at- shroud removed; B. Detail view of failure.)

tach heat transfer pins, as shown in fig-

ure 8-14A, can result in exhaust gas leakage. enter the cabin via defective or inadequate

In addition to the CO hazard, failure of heat seals at firewall openings, wing strut fittings,

exchanger surfaces can permit exhaust gases to doors, and wing root openings. Mani-

be drawn into the engine induction system and fold/stack failures, which account for ap-

cause engine overheating and power loss. proximately 20 percent of all exhaust system

failures, reach a maximum rate of occurrence

8-47. MANIFOLD/STACK FAILURES. at about 100 hours’ operating time. Over

Exhaust manifold and stack failures are also 50 percent of the failures occur within

usually fatigue-type failures which occur at 300 hours.

welded or clamped joints; e.g., stack-to-flange,

stack-to-manifold, muffler connections, or 8-48. INTERNAL MUFFLER FAIL-

crossover pipe connections. Although these URES. Internal failures (baffles, diffusers,

failures are primarily a fire hazard, they also etc.) can cause partial or complete engine

present a CO problem. Exhaust gases can power loss by restricting the flow of the ex-

haust gases. (See figures 8-17 through 8-20.)

Par 8-45 Page 8-23

AC 43.13-1B 9/8/98

FIGURE 8-14. Typical muffler wall failure. (A. Complete muffler assembly with heat shroud removed; B.

Detail view of failure; C. Cross section of failed muffler.)

As opposed to other failures, erosion and car- expected, the time required for these failures to

bonizing caused by the extreme thermal con- develop is longer than that for fatigue failures.

ditions are the primary causes of internal fail- Internal muffler failures account for nearly

ures. Engine after-firing and combustion of 20 percent of the total number of exhaust sys-

unburned fuel within the exhaust system are tem failures.

probable contributing factors.

b. The highest rate of internal muffler

a. In addition, local hot spot areas failures occurs between 500 and 750 hours of

caused by uneven exhaust gas flow, result in operating time. Engine power loss and exces-

burning, bulging, and rupture of the outer muf- sive back-pressure caused by exhaust outlet

fler wall. (See figure 8-14.) As might be blockage may be averted by the installation

Page 8-24 Par 8-48

9/8/98 AC 43.13-1B

FIGURE 8-17. Section of a muffler showing typical

internal baffle failure.

FIGURE 8-15. Typical muffler wall fatigue failure. (A.

Complete muffler assembly with heat shroud partially

removed; B. Detailed view of failure.)

FIGURE 8-16. Typical fatigue failure of muffler end

plate at stack inlet. FIGURE 8-18. Loose pieces of a failed internal baffle.

Par 8-48 Page 8-25

AC 43.13-1B 9/8/98

of an exhaust outlet guard as shown in fig- b. Remove or loosen all exhaust shields,

ures 8-21a and 8-21b. The outlet guard may carburetor and cabin heater muffs, shrouds,

be fabricated from a 3/16-inch stainless steel heat blankets, etc., required to permit inspec-

welding rod. tion of the complete system.

Form the rod into two “U” shaped segments, c. Perform necessary cleaning opera-

approximately 3 inches long and weld onto the tions and inspect all external surfaces of the

exhaust tail pipe as shown in figure 8-21b so exhaust system for cracks, dents, and missing

that the guard will extend 2 inches inside the parts. Pay particular attention to welds,

exhaust muffler outlet port. Installation of an clamps, supports and support attachment lugs,

exhaust outlet guard does not negate the im- bracing, slip joints, stack flanges, gaskets,

portance of thorough inspection of the internal flexible couplings, and etc. (See figures 8-22

parts of the muffler or the necessity of replac- and 8-23.) Examine the heel of each bend, ar-

ing defective mufflers. eas adjacent to welds, any dented areas, and

low spots in the system for thinning and pitting

8-49. INSPECTION. Inspect exhaust sys- due to internal erosion by combustion products

tems frequently to ascertain complete system or accumulated moisture. An ice pick (or

integrity. similar pointed instrument) is useful in probing

suspected areas. Disassemble the system as

CAUTION: Marking of exhaust sys- necessary to inspect internal baffles or diffus-

tem parts. Never use lead pencils, ers.

carbon based pencils, etc., to mark

exhaust system parts. Carbon depos- d. Should a component be inaccessible

ited by those tools will cause cracks for a thorough visual inspection or hidden by

from heat concentration and carboni- non-removable parts, remove the component

zation of the metal. If exhaust system and check for possible leaks by plugging its

parts must be marked, use chalk, openings, applying approximately 2 psi inter-

Prussian blue, India ink, or a grease nal pressure, and submerging it in water. Any

pencil that is carbon-free. leaks will cause bubbles that can be readily

detected. Dry thoroughly before reinstallation.

a. Before any cleaning operation, re-

move the cowling as required to expose the 8-50. REPAIRS. It is generally recom-

complete exhaust system. Examine cowling mended that exhaust stacks, mufflers, tail-

and nacelle areas adjacent to exhaust system pipes, and etc., be replaced with new or recon-

components for telltale signs of exhaust gas ditioned components rather than repaired.

soot indicating possible leakage points. Check Welded repairs to exhaust systems are compli-

to make sure no portion of the exhaust system cated by the difficulty of accurately identifying

is being chafed by cowling, engine control ca- the base metal so that the proper repair materi-

bles, or other components. The exhaust sys- als can be selected. Changes in composition

tem often operates at red-hot temperatures of and grain structure of the original base metal

1,000 °F or more; therefore, parts such as ig- further complicates the repair. However, when

nition leads, hoses, fuel lines, and flexible air welded repairs are necessary, follow the gen-

ducts, should be protected from radiation and eral procedures outlined in Chapter 4; Metal

convection heating by heat shields or adequate Structure, Welding, and Brazing; of this AC.

clearance. Retain the original contours and make sure that

Page 8-26 Par 8-48

9/8/98 AC 43.13-1B

FIGURE 8-19. Failed internal baffle partially obstructing

the muffler outlet.

FIGURE 8-21a. Example of exhaust outlet guard.

FIGURE 8-21b. Example of exhaust outlet guard

installed.

FIGURE 8-20. Failed internal baffle completely ob- temperature self-locking nuts for brass or spe-

structing the muffler outlet. cial high-temperature locknuts used by the

manufacturer. Never reuse old gaskets or old

the completed repair has not warped or other- star lock washers. When disassembly is neces-

wise affected the alignment of the exhaust sary replace gaskets with new ones of the same

system. Repairs or sloppy weld beads, which type provided by the manufacturer.

protrude internally, are not acceptable since

they cause local hotspots and may restrict ex- 8-51. TURBO-SUPERCHARGER. When

haust gas flow. All repairs must meet the a turbo-supercharger is included, the exhaust

manufacturer’s specifications. When repairing system operates under greatly-increased pres-

or replacing exhaust system components, be sure and temperature conditions. Extra pre-

sure that the proper hardware and clamps are cautions should be taken in the exhaust

used. Do not substitute steel or low- system’s care and maintenance. During

Par 8-50 Page 8-27

AC 43.13-1B 9/8/98

FIGURE 8-22. Effect of improperly positioned exhaust

pipe/muffler clamp.

high-altitude operation, the exhaust system

pressure is maintained at, or near, sea level

values. Due to the pressure differential, any

leaks in the system will allow the exhaust

gases to escape with a torch-like intensity that

can severely damage adjacent structures. A

common cause of turbo-supercharger mal-

function is coke deposits (carbon buildup) in

the waste gate unit causing erratic system op-

eration. Excessive deposit buildups may cause

the waste gate valve to stick in the closed po-

sition, causing an overboost condition. Coke

deposit buildup in the turbo-supercharger itself FIGURE 8-23. Primary inspection areas.

will cause a gradual loss of power in flight and

low deck pressure reading before takeoff. Ex- overall condition. Regardless of whether or

perience has shown that periodic decoking, or not the augmentor tubes contain heat ex-

removal of carbon deposits, is necessary to changer surfaces, they should be inspected for

maintain peak efficiency. Clean, repair, over- cracks along with the remainder of the exhaust

haul, and adjust turbo-supercharger system system. Cracks can present a fire or CO haz-

components and controls in accordance with ard by allowing exhaust gases to enter nacelle,

the applicable manufacturer’s instructions. wing, or cabin areas.

8-52. AUGMENTOR SYSTEMS. Inspect 8-70. [RESERVED.]

8-53.

augmentor tubes periodically for proper align-

ment, security of attachment, and general

Page 8-28 Par 8-51

9/27/01 AC 43.13-1B CHG 1

SECTION 4. REPAIR OF METAL PROPELLERS

8-71. GENERAL. Reject damaged blades removal of an excessive amount of metal, local

with model numbers which are on the manu- etching should be accomplished at intervals

facturer’s list of blades that cannot be repaired. during the process of removing suspected

Follow the propeller manufacturer’s recom- scratches. Upon completion of the repair,

mendations in all cases, and make repairs in carefully inspect the entire blade by etching or

accordance with latest techniques and best in- anodizing. Remove all effects of the etching

dustry practices. process with fine emery paper. Blades identi-

fied by the manufacturer as being cold-worked

NOTE: Title 14 of the Code of Fed- (shot-blasted or cold-rolled) may require

eral Regulations, 14 CFR, part 65 does peening after repair. Accomplish repair and

not allow an airframe and power peening operations on this type of blade in ac-

plant mechanic to perform major re- cordance with the manufacturer’s instructions.

pairs to propellers. However, it is not permissible in any case to

peen down the edges of any injury wherein the

8-72. STEEL BLADES. Due to the critical operation will lap metal over the injury.

effects of surface injuries and their repair on

the fatigue life of steel blades, all repairs must a. Flaws in Edges. Round out nicks,

be made in accordance with the manufacturer’s scars, cuts, etc., occurring on the leading edge

instructions. of aluminum-alloy blades as shown in fig-

ure 8-24 (view B). Blades that have the lead-

8-73. ALUMINUM PROPELLER RE- ing edges pitted from normal wear in service

PAIRS. Aluminum-alloy propellers and may be reworked by removing sufficient mate-

blades with dents, cuts, scars, scratches, nicks, rial to eliminate the pitting. In this case, re-

leading-edge pitting, etc., may be repaired, move the metal by starting a sufficient distance

provided the removal or treatment does not from the edge, as shown in figure 8-25, and

materially affect the strength, weight, or per- working forward over the edge in such a way

formance of the blade. Remove these damages that the contour will remain substantially the

or otherwise treat as explained below, unless it same, avoiding abrupt changes in contour.

is contrary to the manufacturer’s instructions Trailing edges of blades may be treated in sub-

or recommendations. More than one injury is stantially the same manner. On the thrust and

not sufficient cause alone for rejection of a camber face of blades, remove the metal

blade. A reasonable number of repairs per around any dents, cuts, scars, scratches, nicks,

blade may be made and not necessarily result and pits to form shallow saucer-shaped depres-

in a dangerous condition, unless their location sions as shown in figure 8-24 (view C). Exer-

with respect to each other is such to form a cise care to remove the deepest point of the

continuous line of repairs that would materi- injury and also remove any raised metal

ally weaken the blade. Suitable sandpaper or around the edges of the injury as shown in fig-

fine-cut files may be used for removing the ure 8-24 (view A). When repairing blades,

necessary amount of metal. In each case, the figures 8-26 and 8-27 show the maximum re-

area involved will be smoothly finished with duction in width and thickness that is allow-

#00 sandpaper or crocus cloth, and each blade able below the minimum dimensions required

from which any appreciable amount of metal by the blade drawing and blade manufacturing

has been removed will be properly balanced specification. Beyond the 90

before it is used. Etch all repairs. To avoid

Par 8-71 Page 8-29

You might also like

- Unvented Indirect Hot Water Cylinders Systemfit: Megaflo Product GuideDocument40 pagesUnvented Indirect Hot Water Cylinders Systemfit: Megaflo Product GuideaaneezNo ratings yet

- Bushing Failures in Medium VoltageDocument4 pagesBushing Failures in Medium VoltageDunstan Amaratunga100% (1)

- Boeing 777 Amm Refrences 2Document7 pagesBoeing 777 Amm Refrences 2tauqir73100% (1)

- EAF BasicsDocument29 pagesEAF BasicsAndavilli Srihari KumarNo ratings yet

- Examples of Premature Stator Winding Failure in Recently Manufactured Motors and GeneratorsDocument4 pagesExamples of Premature Stator Winding Failure in Recently Manufactured Motors and GeneratorsstarkopeteNo ratings yet

- Troubleshooting Steam EjectorsDocument6 pagesTroubleshooting Steam EjectorsGabriel Eduardo Contreras PerozoNo ratings yet

- Inst Manual CeilingFloorDocument16 pagesInst Manual CeilingFloorANDERSON HERRERANo ratings yet

- ES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Document10 pagesES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Nikki RobertsNo ratings yet

- Unique Online Leak Repair TechniquesDocument8 pagesUnique Online Leak Repair TechniquesMario Alfredo MunafóNo ratings yet

- Specification For Jackets: Rev. Date Revision Description Issued by Checked by Approved byDocument14 pagesSpecification For Jackets: Rev. Date Revision Description Issued by Checked by Approved byvishal bhamreNo ratings yet

- Project Standards and Specifications Steam Jacketing of Piping Rev01Document4 pagesProject Standards and Specifications Steam Jacketing of Piping Rev01Vijay AnandNo ratings yet

- Failure of Modern GeneratorsDocument6 pagesFailure of Modern GeneratorsJose Calvo100% (1)

- Boiler OverhaulDocument9 pagesBoiler OverhaulHemant PatilNo ratings yet

- Large Grilles Multiple SectionsDocument46 pagesLarge Grilles Multiple SectionsFaquruddin AliNo ratings yet

- Water Cooled Fcu Piping DetailsDocument14 pagesWater Cooled Fcu Piping Detailsfernandoreyes893No ratings yet

- Isophase Condition EvaluationDocument9 pagesIsophase Condition Evaluationdinesh_rajan1986No ratings yet

- Format Sime Boiler ManualDocument21 pagesFormat Sime Boiler Manualadysanro100% (1)

- 09 Oct 17 3317 16 Generator Field Windings Moisture EffectsDocument9 pages09 Oct 17 3317 16 Generator Field Windings Moisture EffectsAhemadNo ratings yet

- 18 Ah41d1 2 - 1206Document8 pages18 Ah41d1 2 - 1206scribdquyNo ratings yet

- PANEADocument20 pagesPANEAAndrey TazNo ratings yet

- TM 07-08 12 PDFDocument1 pageTM 07-08 12 PDFjoymotiNo ratings yet

- H Im 68Document12 pagesH Im 68Maria DazaNo ratings yet

- 2.1 Ducts and Pipes Sizing and Insulation Specification 2.5.1 Duct Size CalculationDocument28 pages2.1 Ducts and Pipes Sizing and Insulation Specification 2.5.1 Duct Size CalculationAllanNo ratings yet

- Goodman Ductos - Inst OperaciónDocument8 pagesGoodman Ductos - Inst OperaciónlafsNo ratings yet

- Stack SpecDocument10 pagesStack SpecHoney TiwariNo ratings yet

- DLU TechDocument20 pagesDLU Techqwerty_conanNo ratings yet

- 70.00.00 Standard Practices - RepairDocument8 pages70.00.00 Standard Practices - RepairTimoteo Molina RomeroNo ratings yet

- SB 7-1-108Document6 pagesSB 7-1-108jussmeeeNo ratings yet

- Holtop XHBQ-D40GF With HDK-09 ControllerDocument14 pagesHoltop XHBQ-D40GF With HDK-09 ControllerarminsarajevoNo ratings yet

- STC Sa02816ch In50000k33 CD 1Document9 pagesSTC Sa02816ch In50000k33 CD 1mecarservices1No ratings yet

- Holtop XHBQ-D40GF With HDK-19D ControllerDocument16 pagesHoltop XHBQ-D40GF With HDK-19D ControllerarminsarajevoNo ratings yet

- GSLN Advisory Plat Reactor External Nozzle 20161128 Rev1Document30 pagesGSLN Advisory Plat Reactor External Nozzle 20161128 Rev1SagarBabuNo ratings yet

- HP Fan Coil Guide Specifications: ©november, 2019 Johnson Controls, Inc. - Page 1 of 4Document4 pagesHP Fan Coil Guide Specifications: ©november, 2019 Johnson Controls, Inc. - Page 1 of 4Jesse TarrNo ratings yet

- H Im 65BDocument16 pagesH Im 65BMaria DazaNo ratings yet

- Analysis of Leak and Water Absorption Test Results For Water-Cooled Generator Stator WindingsDocument6 pagesAnalysis of Leak and Water Absorption Test Results For Water-Cooled Generator Stator WindingsHeryanto SyamNo ratings yet

- Pattern Failures: Plagued With Problems by DesignDocument2 pagesPattern Failures: Plagued With Problems by DesignavinashjhamechxNo ratings yet

- MEPF BOQ - AZURE TargetDocument33 pagesMEPF BOQ - AZURE TargetUpendra ChariNo ratings yet

- 88 Series 2 Boiler: Suggested SpecificationsDocument4 pages88 Series 2 Boiler: Suggested SpecificationsAdam Bin Abu BakarNo ratings yet

- Ceiling Concealed Chilled Water Fan Coil UnitDocument14 pagesCeiling Concealed Chilled Water Fan Coil UnitRodrigo Neira De FinoNo ratings yet

- Heat Exchanger Tube Plugging Relative To ASME PCC 2 2011 PDFDocument5 pagesHeat Exchanger Tube Plugging Relative To ASME PCC 2 2011 PDFNomi A100% (1)

- Installation, Operating and Maintenance Instructions For Indeeco Electric Duct HeatersDocument2 pagesInstallation, Operating and Maintenance Instructions For Indeeco Electric Duct HeatersJed DavidNo ratings yet

- Carrier 2trDocument15 pagesCarrier 2trfernandoreyes893No ratings yet

- ETA Inspection and Maintanance - ETA 10+15 - Rev - 09 - 09Document66 pagesETA Inspection and Maintanance - ETA 10+15 - Rev - 09 - 09serkalemtNo ratings yet

- MT4400 Exhaust Assembly - Heated BodyDocument5 pagesMT4400 Exhaust Assembly - Heated BodyBrian CareelNo ratings yet

- PR PYR P06-17 v1 How To Improve Fan EfficiencyDocument8 pagesPR PYR P06-17 v1 How To Improve Fan EfficiencyTamer FathyNo ratings yet

- Api 510 NotificationDocument15 pagesApi 510 NotificationAhmed ShakirNo ratings yet

- Specification For Core & Jacket: Rev. Date Revision Description Issued by Checked by Approved byDocument13 pagesSpecification For Core & Jacket: Rev. Date Revision Description Issued by Checked by Approved byvishal bhamreNo ratings yet

- HVAC Specs - ComplianceDocument32 pagesHVAC Specs - ComplianceArchanaShenoyNo ratings yet

- Split System Indoor Coils Installation InstructionsDocument8 pagesSplit System Indoor Coils Installation Instructionskhopdi_number1No ratings yet

- BPM800 BPM800 Repair - Rev 1Document7 pagesBPM800 BPM800 Repair - Rev 1api-3752216No ratings yet

- Main Group 8 Ship System: O/3175-Specification Revision 6 Date: 12.04.06 1Document55 pagesMain Group 8 Ship System: O/3175-Specification Revision 6 Date: 12.04.06 1Vladi GasperNo ratings yet

- Trane Mini Split Normal InstalacionDocument12 pagesTrane Mini Split Normal InstalacionAnonymous ApjtcZ6YT6100% (1)

- Catalogohce090 150Document18 pagesCatalogohce090 150Xol DiaMa GarciaNo ratings yet

- Steam TrapTD55Document3 pagesSteam TrapTD55Avneet MaanNo ratings yet

- Fis128 en AqDocument12 pagesFis128 en Aqjerin samNo ratings yet

- Fan Application GuidelineDocument6 pagesFan Application GuidelineEdward SabedraNo ratings yet

- Instalacion de CanatalDocument36 pagesInstalacion de Canataltecnofresh.serviciosNo ratings yet

- Elmo 2bh1 Gas Ring Vacuum PumpsDocument11 pagesElmo 2bh1 Gas Ring Vacuum PumpsAlberto Costilla GarciaNo ratings yet

- Refinery Cooling Plant SpecificationDocument8 pagesRefinery Cooling Plant SpecificationHatem ShawkiNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Demco Butterfly ValveDocument35 pagesDemco Butterfly ValveJairo PuentesNo ratings yet

- Swagelok HoseDocument28 pagesSwagelok HoseRashi Akmal0% (1)

- Protecting Insulation On Riser Pipes UnderwaterDocument2 pagesProtecting Insulation On Riser Pipes UnderwaterMazwan MansorNo ratings yet

- Zhengzhou Huitong CatalogueDocument11 pagesZhengzhou Huitong CatalogueweqefyteNo ratings yet

- Hebei Haihao Group - ProfileDocument6 pagesHebei Haihao Group - ProfileJesse Zhu100% (1)

- 10.1007@978 3 030 41626 3 PDFDocument136 pages10.1007@978 3 030 41626 3 PDFGalaktecos99 Galaktecos99No ratings yet

- Method Statements For Watersupply NetworkDocument19 pagesMethod Statements For Watersupply NetworkShahab KhanNo ratings yet

- Amipox - SUBMITTAL 52Document1 pageAmipox - SUBMITTAL 52norman moralesNo ratings yet

- Cox Instruments Flow StraightenersDocument8 pagesCox Instruments Flow StraightenersYasmine ياسمينNo ratings yet

- XyzDocument64 pagesXyzP S HARSHITANo ratings yet

- IAP10, IGP10, IAP20, IGP20 Pressure TransmitterDocument40 pagesIAP10, IGP10, IAP20, IGP20 Pressure TransmitterTefa SernaNo ratings yet

- Nominal Pipe Size - Wikipedia, The Free EncyclopediaDocument7 pagesNominal Pipe Size - Wikipedia, The Free EncyclopediaNaser JahangiriNo ratings yet

- STFFD-P1-006002-D10-1001 Rev B HVAC System - Piping & Instrumentation DiagramDocument4 pagesSTFFD-P1-006002-D10-1001 Rev B HVAC System - Piping & Instrumentation DiagramHiếu NguyênNo ratings yet

- The Application of Industrial Scale Ultrasonic Cleaning To Heat ExchangersDocument3 pagesThe Application of Industrial Scale Ultrasonic Cleaning To Heat Exchangersbai tap hoa vo coNo ratings yet

- Jun M. de LeonDocument5 pagesJun M. de LeonHarry DemeterioNo ratings yet

- Numerical and Experimental Thermal Analysis For A Metallic Hollow Cylinder Subjected To Step-Wise Electro-Magnetic Induction HeatingDocument12 pagesNumerical and Experimental Thermal Analysis For A Metallic Hollow Cylinder Subjected To Step-Wise Electro-Magnetic Induction HeatingOthman Ben CheikhNo ratings yet

- Marley Polyethylene ManualDocument80 pagesMarley Polyethylene ManualHamish Laing100% (1)

- SPAN MSIG - Vol.3 - Sewer Network and Pump StationDocument153 pagesSPAN MSIG - Vol.3 - Sewer Network and Pump StationkhuanozNo ratings yet

- 1690B Flow Conditioner Catalog En21.r00 WDocument7 pages1690B Flow Conditioner Catalog En21.r00 WaliNo ratings yet

- 83 FDocument134 pages83 FvinothetisNo ratings yet

- A Corrosion Risk Assessment Model For Underground PipingDocument5 pagesA Corrosion Risk Assessment Model For Underground PipingEnnSee100% (1)

- Concrete Pipes: Scib Concrete Manufacturing SDN BHDDocument4 pagesConcrete Pipes: Scib Concrete Manufacturing SDN BHDSoonHan WaiNo ratings yet

- Eastern Shipbuilding Fire CO2 System ManualDocument79 pagesEastern Shipbuilding Fire CO2 System ManualRomanPochinkovNo ratings yet

- Series 1000 Hinged ClosureDocument3 pagesSeries 1000 Hinged ClosureMurli RamchandranNo ratings yet

- Iq RMG001Document30 pagesIq RMG001Dhaval ChaplaNo ratings yet

- CHW Piping SpecsDocument42 pagesCHW Piping SpecsEugen LupanNo ratings yet

- Water Distribution SystemDocument57 pagesWater Distribution Systemamber1999588% (8)

- Gcs2 002 Gen Az7 SP 01 0 Specification For PaintingDocument31 pagesGcs2 002 Gen Az7 SP 01 0 Specification For Paintingsondk2100% (2)

- GasDocument242 pagesGasConnie RodriguezNo ratings yet