Professional Documents

Culture Documents

SD 1552

SD 1552

Uploaded by

Usamah TOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SD 1552

SD 1552

Uploaded by

Usamah TCopyright:

Available Formats

STANDARD TEST METHOD FOR

SULFUR IN PETROLEUM PRODUCTS

(HIGH-TEMPERATURE METHOD)

SD-1552

(Identical with ASTM D 1552-95)

1. Scope 3. Summary of Test Method

1.1 This test method covers three procedures for the 3.1 Iodate Detection System — The sample is burned

determination of total sulfur in petroleum products in a stream of oxygen at a sufficiently high temperature

including lubricating oils containing additives, and in to convert about 97% of the sulfur to sulfur dioxide.

additive concentrates. This test method is applicable to A standardization factor is employed to obtain accurate

samples boiling above 177°C (350°F) and containing results. The combustion products are passed into an

not less than 0.06 mass % sulfur. Two of the three absorber containing an acid solution of potassium iodide

procedures use iodate detection; one employing an and starch indicator. A faint blue color is developed

induction furnace for pyrolysis, the other a resistance in the absorber solution by the addition of standard

furnace. The third procedure uses IR detection following potassium iodate solution. As combustion proceeds,

pyrolysis in a resistance furnace. bleaching the blue color, more iodate is added. The

amount of standard iodate consumed during the combus-

1.2 Petroleum coke containing up to 8 mass % sulfur tion is a measure of the sulfur content of the sample.

can be analyzed.

3.2 IR Detection System — The sample is weighed

into a special ceramic boat which is then placed into

1.3 This standard may involve hazardous materials, a combustion furnace at 1371°C (2500°F) in an oxygen

operations, and equipment. This standard does not atmosphere. Most sulfur present is combusted to SO2

purport to address all of the safety concerns, if any, which is then measured with an infrared detector after

associated with its use. It is the responsibility of the moisture and dust are removed by traps. A microproces-

user of this standard to establish appropriate safety sor calculates the mass percent sulfur from the sample

and health practices and determine the applicability weight, the integrated detector signal, and a predeter-

of regulatory limitations prior to use. mined calibration factor. Both the sample identification

number and mass percent sulfur are then printed out.

The calibration factor is determined using standards

approximating the material to be analyzed.

2. Referenced Documents

4. Significance and Use

2.1 ASTM Standards:

D 1193 Specification for Reagent Water 4.1 This test method provides a means of monitoring

D 1266 Test Method for Sulfur in Petroleum Products the sulfur level of various petroleum products and

(Lamp Method) additives. This knowledge can be used to predict per-

D 4057 Practice for Manual Sampling of Petroleum and formance, handling, or processing properties. In some

Petroleum Products cases the presence of sulfur compounds is beneficial

457

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

SD-1552 2001 SECTION V

to the product and monitoring the depletion of sulfur

can provide useful information. In other cases the

presence of sulfur compounds is detrimental to the

processing or use of the product.

5. Interferences

5.1 For the iodate systems, chlorine in concentrations

less than 1 mass % does not interfere. The IR system

can tolerate somewhat higher concentrations. Nitrogen

when present in excess of 0.1 mass % may interfere

with the iodate systems; the extent of such interference

may be dependent on the type of nitrogen compound

as well as the combustion conditions. Nitrogen does

not interfere with the IR system. The alkali and alkaline

earth metals, as well as zinc, phosphorus, and lead,

do not interfere with either system.

FIG. 1 COMBUSTION TUBE

6. Apparatus

6.1 Combustion and Iodate Detection System

6.1.1 Furnaces — Two major types are available,

the primary difference being the manner in which the

necessary high temperatures are obtained. These two NOTE 2 — Also suitable for use with either type of furnace is an

types are as follows: automatic titrator, specifically designed for iodometry. This combines

the functions of absorption and titration to a predetermined end point.

6.1.1.1 Induction Type, which depends upon the

high-frequency electrical induction method of heating.

This assembly shall be capable of attaining a temperature

of at least 1482°C (2700°F) in the sample combustion 6.1.3 Buret, standard 25-mL or automatic types

zone, under the conditions set forth in Section 10 and available from the manufacturers of the specific combus-

shall be equipped with an additional induction coil tion units, are suitable (Note 2).

located above the combustion zone, substantially as

shown in Fig. 1.

6.2 Combustion and IR Detection System, comprised

6.1.1.2 The furnace work coil should have a of automatic balance, oxygen flow controls, drying

minimum output of 500 W; the minimum input rating tubes, combustion furnace, infrared detector and micro-

of the furnace must be 1000 W. With the correct processor. The furnace shall be capable of maintaining

amount of iron chips, weighed to ±0.05 g, the maximum a nominal operating temperature of 1350°C (2460°F).

plate current will be between 350 and 450 mA.

NOTE 1: Warning — This type of furnace is capable of inflicting 6.3 Miscellaneous Apparatus — Specific combustion

high-frequency burns and high-voltage shocks. In addition to other

precautions, maintain all guards properly. Precaution — Disconnect assemblies require additional equipment such as cruci-

the furnace from the power line whenever electrical repairs or bles, combustion boats, crucible lids, boat pushers,

adjustments are made. separator disks, combustion tubes, sample inserters,

oxygen flow indicator, and oxygen drying trains. The

6.1.1.3 Resistance Type, capable of maintaining additional equipment required is dependent on the type

a temperature of at least 1371°C (2500°F). of furnace used and is available from the manufacturer

of the specific combustion unit. To attain the lower

6.1.2 Absorber, as described in Test Method sulfur concentration given in Section 1, the ceramics

D 1266. used with the induction furnace assembly shall be

458

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ARTICLE 24 — LIQUID PENETRANT STANDARDS SD-1552

ignited in a muffle furnace at 1371°C (2500°F) for at 7.11 Potassium Iodate, Standard Solution (0.01248

least 4 h before use. M, 1 mL p 0.2 mg S) — Measure exactly 200 mL

of KIO3 solution (0.06238 M, 1 mL p 1 mg S) into

6.4 Sieve, 60-mesh (250-mm).

a 1-L volumetric flask and dilute to volume with water.

Thoroughly mix the solution.

7. Reagents and Materials 7.12 Ascarite, 8 to 20 mesh.

7.1 Purity of Reagents — Reagent grade chemicals 7.13 Special Materials for Induction-Type Furnaces:

shall be used in all tests. Unless otherwise indicated,

it is intended that all reagents shall conform to the 7.13.1 Tin (20 to 30-mesh).

specifications of the Committee on Analytical Reagents

of the American Chemical Society, where such specifi- 7.13.2 Iron-Chip Accelerator having a sulfur con-

cations are available. Other grades may be used, pro- tent of not more than 0.005 mass %.

vided it is first ascertained that the reagent is of

7.14 Standard Sample — Potassium alum [AlK(SO4)2

sufficiently high purity to permit its use without less-

· 12H2O].

ening the accuracy of the determination.

7.2 Purity of Water — Unless otherwise indicated, 7.15 Starch-Iodide Solution — Make a paste by

references to water shall be understood to mean reagent adding 9 g of soluble starch to 15 mL of water. Add

water as defined by Type II or III of Specification this mixture, with stirring, to 500 mL of boiling water.

D 1193. Cool the mixture, add 15 g of potassium iodide (KI),

and dilute to 1 L with water.

7.3 Alundum (Al2O3) or Magnesium Oxide (Com-

Aid). 7.16 Sulfuric Acid (relative density 1.84) — Concen-

trated sulfuric acid (H2SO4).

7.4 Anhydrone (Magnesium Perchlorate).

NOTE 3: Precaution — In addition to other precautions, handle NOTE 6: Warning — Poison. Corrosive. Strong oxidizer.

magnesium perchlorate with care. Avoid contacting it with acid and

organic materials. Reactions with fuel may be violent. 7.17 Vanadium Pentoxide, anhydrous, powdered

V2O5.

7.5 Hydrochloric Acid (3 + 197) — Dilute 30 mL

of concentrated hydrochloric acid (HCl, relative density

1.19) to 2 L with water.

NOTE 4: Warning — Poison. Corrosive. May be fatal if swallowed. 8. Sampling

Liquid and vapor cause severe burns.

8.1 Take samples in accordance with the instructions

7.6 Oxygen (Extra Dry) — The oxygen shall be at in Practice D 4057.

least 99.5% pure and show no detectable sulfur by

blank determination.

NOTE 5: Warning — Oxygen vigorously accelerates combustion.

9. Preparation of Apparatus

7.7 Phosphorus Pentoxide (P2O5).

9.1 Induction-Type Furnace — Assemble the appara-

7.8 Potassium Alum (Aluminum Potassium Sulfate). tus according to the instructions furnished by the manu-

facturer. Purify the oxygen by passing it through (1)

7.9 Potassium Iodate, Standard Solution (0.06238

H2SO4 (relative density 1.84), (2) Ascarite, and (3)

M, 1 mL p 1 mg S) — Dissolve 2.225 g of potassium

magnesium perchlorate [Mg(ClO4)2] or phosphorus

iodate (KIO3) that has been dried at about 180°C to

pentoxide (P2O5) (Precaution — see Note 3). Connect

constant weight, in water and dilute to 1 L. Thoroughly

a rotameter between the purifying train and the furnace.

mix the solution.

Insert a small glass-wool plug in the upper end of the

7.10 Potassium Iodate, Standard Solution (0.006238 glass tubing connecting the furnace with the absorber

M, 1 mL p 0.1 mg S) — Measure exactly 100 mL to catch oxides of tin. Connect the exit end of the

of KIO3 solution (0.06238 M, 1 mL p 1 mg S) into combustion tube to the absorber with glass tubing,

a 1-L volumetric flask, and dilute to volume with water. using gum rubber tubing to make connections. Position

Thoroughly mix the solution. the absorber so as to make this delivery line as short as

459

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

SD-1552 2001 SECTION V

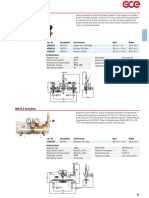

FIG. 3 SCHEMATIC ILLUSTRATION OF

FIG. 2 SCHEMATIC ILLUSTRATION OF RESISTANCE-TYPE FURNACE

INDUCTION-TYPE FURNACE

TABLE 2

SAMPLE WEIGHT FOR RESISTANCE FURNACE

TABLE 1 Normality of Standard

SAMPLE WEIGHT FOR INDUCTION FURNACE Weight of Sample KIO3 Solution for

Normality of Standard Sulfur Content, % to Be Taken, mg Titration

Weight of Sample KIO3 Solution for 0 to 2 100 to 200 0.006238

Sulfur Content, % to Be Taken, mg Titration 2 to 5 100 to 200 0.01248

5 to 10 100 to 200 0.06238

0 to 2 90A 0.006238

Over 10 (Note 7) (Note 7)

2 to 4 50 to 90 0.006238

4 to 10 50 to 90 0.01248

Over 10 12.1.1 (Note 7)

A

Approximate.

drops of the appropriate standard KIO3 solution (Table

2) to produce a faint blue color. Adjust the buret to zero.

9.3 Resistance-Type Furnace-IR Detection — Assem-

possible. Figure 2 illustrates schematically the assembled ble and adjust apparatus according to manufacturer’s

apparatus. Adjust the oxygen flow to 1 ± 0.05 L/min. instructions. Initialize microprocessor, check power sup-

Add 65 mL of HCl (3 + 197) and 2 mL of starch- plies, set oxygen pressure and flows and set furnace

iodide solution to the absorber. Add a sufficient amount temperature to 1371°C (2500°F).

of the appropriate standard KIO3 solution (Table 1) to

9.3.1 Condition a fresh anhydrone scrubber with

produce a faint blue color. This color will serve as

four coal samples.

the end point for the titration. Adjust the buret to zero.

Turn on the furnace filament switch and allow at least 9.3.2 Calibrate the automatic balance according to

1 min warm-up before running samples (Precaution — manufacturer’s instructions.

see Note 3).

9.2 Resistance-Type Furnace — Assemble the appara-

10. Standardization

tus according to the instructions furnished by the manu-

facturer. Purify the oxygen by passing it through (1) 10.1 For Iodate Methods:

H2SO4 (relative density 1.84), (2) Ascarite, and (3)

10.1.1 Determination of Alum Factor:

Mg(ClO4)2 or P2O5 (Precaution — see Note 3). Connect

a rotameter between the purifying train and the furnace. 10.1.1.1 Because these rapid combustion meth-

Figure 3 illustrates schematically the assembled appara- ods involve the reversible reaction 2SO2 + O2 p 2SO3,

tus. Turn on the current and adjust the furnace control it is not possible to evolve all the sulfur as SO2. The

to maintain a constant temperature of 1316 ± 14°C equilibrium of the reaction is temperature dependent

(2400 ± 25°F). Adjust the oxygen flow rate to 2 ± and, in an oxygen atmosphere above 1316°C, about

0.1 L/min. Add 65 mL of HCl (3 ± 197) and 2 mL 97% of the sulfur is present as SO2. To assure that

of starch-iodide solution to the absorber. Add a few the furnace is in proper adjustment and that its operation

460

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ARTICLE 24 — LIQUID PENETRANT STANDARDS SD-1552

produces acceptably high temperature, potassium alum Standardization factor (Fs) p (Ss × Ws)/[100 (Vs (2)

is employed for standardizing the apparatus. Depending − Vb) × C]

on the type of combustion equipment used, proceed as

described in Sections 10 to 13 to determine the alum where:

factor. Use 15 mg weighed to ±0.1 mg of potassium Ssp mass percent sulfur in standardization sample

alum for this determination. Use the same materials in used,

the determination of the alum and standardization factors Wsp milligrams of standardization sample used,

as for the unknown samples. For example, V2O5 has Vbp millilitres of standard KIO3 solution used in the

a definite effect and should be included if used for blank determination,

unknowns as recommended in the procedure with the Vsp millilitres of standard KIO3 solution used in

resistance-type furnace (Note 10). determining the standardization factor, and

Cp sulfur equivalent of the standard KIO3 solution

10.1.1.2 Calculate the alum factor as follows:

used in determining the standardization factor,

mg/mL.

Alum factor (AF) p (SA × WA)/[100 (Va − Vb) (1)

× C1] 10.1.3 Quality Control — Run a suitable analytical

quality control sample several times daily. When the

where: observed value lies between acceptable limits on a

SAp mass percent sulfur in potassium alum used, quality control chart, proceed with sample determina-

WAp milligrams of potassium alum used, tions.

Vap millilitres of standard KIO3 solution used in

determining the alum factor,

Vbp millilitres of standard KIO3 solution used in the 11. Preparation of Coke

blank determination, and

C1p sulfur equivalent of the standard KIO3 solution 11.1 It is assumed that a representative sample has

used in determining the alum factor, mg/mL. been received for analysis.

10.1.1.3 The alum factor should be in the range 11.2 Grind and sieve the sample received so as to

from 1.02 to 1.08. If values smaller than 1.02 are pass a 60-mesh (250-mm) sieve.

observed, confirm independently the sulfur content of 11.3 Dry the sieved material to constant weight at

the alum and the sulfur equivalent of the KIO3 solution 105 to 110°C.

before repeating the alum factor determination. If values

larger than 1.08 are observed, make adjustments in

the equipment in accordance with the manufacturer’s 12. Procedure With Induction-Type Furnace

recommendation and repeat the alum factor determi-

nation. 12.1 Sample Preparation — Add a 3.2 to 4.8-mm

(1⁄8 to 3⁄16-in.) layer of alundum or magnesium oxide

10.1.2 Determination of Standardization Factor: to a sample crucible. Make a depression in the bed

with the end of a stirring rod. Weigh the crucible to

10.1.2.1 Because effects such as sample volatility

0.1 mg. Weigh into the depression the proper amount

can also affect the relative recovery as SO2 of the

of sample according to Table 1 (12.1.1) (Note 7). Cover

sulfur originally present in the sample, it is necessary

the sample with a separator disk (Note 8. Place on

to determine a standardization factor. Proceed as de-

the separator disk the predetermined amount of iron

scribed in Sections 10 to 13, using an oil sample of

chips necessary to obtain the required temperature

similar type to the unknown sample and of accurately

(6.1.1.2). This is usually between 1.2 and 2.0 g, but

known sulfur content.

should be held constant with ±0.05 g. Sprinkle about

10.1.2.2 For IR detection, determine and load 0.1 g of tin on the iron. Cover the crucible with a lid

the microprocessor with the calibration factor for the and place on the furnace pedestal.

particular type of sample to be analyzed (lubricating 12.1.1 Under no conditions shall an organic sample

oil, petroleum coke, residual fuel) as recommended by larger than 100 mg be burned in an induction-type

the manufacturer. furnace.

10.1.2.3 Calculate the standardization factor as NOTE 7 — More concentrated KIO3 solutions, such as the 0.06238

follows: N solution, may be found more convenient for samples containing

461

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

SD-1552 2001 SECTION V

more than 10% sulfur, The sample size and KIO3 concentration 14. Procedure With Resistance Furnace-

should be chosen so that not more than 25 mL of titrant is needed.

IR Detection

NOTE 8 — The use of the separator disk is optional.

14.1 Allow the system to warm up and the furnace

12.2 Combustion and Titration — Turn on the plate to reach operating temperature.

current switch. After about 1 min for warm-up, raise

14.2 After homogeneity of the sample is assured,

the pedestal and lock into position. The plate current

select the sample size as follows: for liquid samples,

will fluctuate for a few seconds and should gradually

take up to 0.13 g for analysis and for solid samples,

rise to a maximum value. Add the appropriate standard

take up to 0.4 g for analysis. In each case, mass percent

KIO3 solution (Table 1) to the absorber to maintain

sulfur times weight of sample must be less than or

the blue color. Should the absorber solution become

equal to four in the case of the SC32 instrument, and

completely colorless, discard the determination. Make

two in the case of the SC132 instrument. For other

KIO3 additions as the rate of evolution of SO2 dimin-

instruments, consult the manufacturer’s instructions.

ishes such that, when combustion is completed, the

intensity of the blue color is the same as the initial 14.3 Determine and store the system blank value.

intensity. Combustion is complete when this color re-

mains for at least 1 min and the plate current has 14.4 Weigh the samples into combustion boats and

dropped considerably. Record the volume of KIO3 record the net weights. It is possible to weigh and

solution required to titrate the SO2 evolved. store several weights in the microprocessor before

beginning a series of burns.

12.3 Blank Determination — Make a blank determina-

tion whenever a new supply of crucibles, materials, or 14.4.1 Fill the combustion boat to one-third capac-

reagents is used. Follow the preceding procedure, but ity with evenly spread MgO powder.

omit the sample.

14.4.2 Form a slight trench in the MgO powder

with a scoop.

13. Procedure With Resistance-Type Furnace 14.4.3 Place the combustion boat on the balance

and weigh an appropriate amount of the sample into

13.1 Sample Preparation — Weigh into a combustion the trench in the MgO powder. Enter the weight.

boat the proper amount of sample according to Table

2. Add 100 ± 5 mg of vanadium pentoxide and com- 14.4.4 Remove the combustion boat from the

pletely cover the mixture with Alundum. balance and add MgO powder until the combustion

boat is filled to two-thirds capacity.

13.2 Combustion and Titration — Place the boat in

the cool portion of the combustion tube, near the NOTE 9 — If unacceptable repeatability is encountered for particular

entrance. To proceed with the combustion, push the oil samples, combustion promoter such as V2O5 or the LECO product

Com-Aid can be substituted for the MgO.

boat containing the sample progressively into the hotter

zone of the combustion tube using the equipment NOTE 10 — Caution — V2O5 can cause deterioration of the furnace

provided by the manufacturers. The boat should be ceramics so use it with care.

advanced as rapidly as possible consistent with the rate

of evolution of SO2. Add the appropriate standard KIO3 14.5 Initiate oxygen flow and load boat into furnace.

solution (Table 2) to the absorber to maintain the blue 14.6 When the analysis is complete, read the result

color. Should the absorber solution become completely from the microprocessor.

colorless, discard the determination. Make KIO3 addi-

tions as the rate of evolution of SO2 diminishes such 14.7 Remove the expended combustion boat from

that, when combustion is completed, the intensity of the furnace.

the blue color is the same as the initial intensity.

14.8 Make repeated runs until two results differ by

Combustion is complete when this color remains for

less than the repeatability of the method.

at least 1 min. Record the volume of KIO3 solution

required to titrate the SO2 evolved.

13.3 Blank Determination — Make a blank determina-

15. Calculation

tion whenever a new supply of combustion boats,

materials, or reagents is used. Follow the above proce- 15.1 Calculation for Iodate Detection — Calculate

dure, but omit the sample. the sulfur content of the sample as follows:

462

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ARTICLE 24 — LIQUID PENETRANT STANDARDS SD-1552

Sulfur, mass % p [100 (V − Vb) × Fs × C]/W (3) operators working in different laboratories on identical

test material would, in the long run, in the normal and

where: correct operation of the test method, exceed the follow-

Vp standard KIO3 solution, mL, used in the ing values in only one case in twenty:

analysis, Sulfur, Mass, % Reproducibility

Vbp standard KIO3 solution, mL, used in the blank Range Iodate IR8

determination, 0.0 to 0.5 0.08 0.13

Fsp standardization factor (see 10.1.2), 0.5 to 1.0 0.11 0.21

Cp sulfur equivalent of the standard KIO3 solution 1.0 to 2.0 0.17 0.27

used in the analysis, mg/mL, and 2.0 to 3.0 0.26 0.38

3.0 to 4.0 0.40 0.44

Wp milligrams of sample used in the analysis. 4.0 to 5.0 0.54 0.49

15.2 Calculation for IR Detection: 17.2 For Petroleum Cokes by Iodate and IR Meth-

15.2.1 Report all results using the microprocessor. ods — The precision of the test method as determined

by statistical examination of interlaboratory results is

15.2.2 Report the average of two results. as follows:

17.2.1 Repeatability — The difference between

16. Report two test results obtained by the same operator with

the same apparatus under constant operating conditions

16.1 In the range from 0.05 to 5.00 mass % sulfur, on identical test material would, in the long run, in

report to the nearest 0.01 mass %. In the range from the normal and correct operation of the test method,

5 to 30 mass % sulfur, report to the nearest 0.1 mass %. exceed the following values in only one case in twenty:

r p 0.05X

17. Precision and Bias

17.1 For Petroleum Products by Iodate and IR where X is the average of the two test results.

Methods — The precision of this test method as deter-

17.2.2 Reproducibility — The difference between

mined by statistical examination of interlaboratory re-

two single and independent results obtained by different

sults is as follows:

operators working in different laboratories on identical

17.1.1 Repeatability — The difference between test material could, in the long run, in the normal and

two test results obtained by the same operator with correct operation of the test method, exceed the follow-

the same apparatus under constant operating conditions ing values in only one case in twenty:

on identical test material would, in the long run, in

the normal and correct operation of the test method, R p 0.22X

exceed the following values in only one case in twenty:

Sulfur, Mass, % Repeatability

where X is the average of the two test results.

8

Range Iodate IR 17.3 Bias — The bias of the procedure in this test

0.0 to 0.5 0.05 0.04 method is being determined.

0.5 to 1.0 0.07 0.07

1.0 to 2.0 0.10 0.09

2.0 to 3.0 0.16 0.12

3.0 to 4.0 0.22 0.13 18. Keywords

4.0 to 5.0 0.24 0.16

18.1 furnace; high temperature; induction furnace;

17.1.2 Reproducibility — The difference between iodate titration; IR detection; petroleum; resistance;

two single and independent results obtained by different sulfur; titration

463

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

You might also like

- Post Laboratory Discussion PrelimDocument84 pagesPost Laboratory Discussion PrelimRichel Silao73% (15)

- D6722-Standard Testing Method For Total Mercury in Coal and Coal Combustion Residues by Direct Combustion AnalysisDocument4 pagesD6722-Standard Testing Method For Total Mercury in Coal and Coal Combustion Residues by Direct Combustion AnalysisWelsinsin Kevin SinNo ratings yet

- Astm D4239 18 SulphurDocument8 pagesAstm D4239 18 SulphurMd Naseem Javed100% (4)

- Astm D4929 PDFDocument8 pagesAstm D4929 PDFMarisol ColoradoNo ratings yet

- Astm d5453Document11 pagesAstm d5453Carlos PalominoNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- D4629Document5 pagesD4629Aditya Kafi Berkahsmgshop100% (1)

- ASTM D5453-16e11Document11 pagesASTM D5453-16e11Andres Muñoz Aguirre100% (2)

- Ladle Heating FurnaceDocument34 pagesLadle Heating FurnaceAnusha Rao100% (5)

- The Periodic Table: Test Yourself 16.1 and 16.2 (Page 312)Document3 pagesThe Periodic Table: Test Yourself 16.1 and 16.2 (Page 312)Jack Kowman0% (1)

- Preparation of Thiokol RubberDocument2 pagesPreparation of Thiokol RubberAwad Said70% (10)

- Sulfur in Petroleum Products (High-Temperature Method) : Standard Test Method ForDocument7 pagesSulfur in Petroleum Products (High-Temperature Method) : Standard Test Method ForMaria SoutoNo ratings yet

- Sulfur in Petroleum Products (High-Temperature Method) : Standard Test Method ForDocument7 pagesSulfur in Petroleum Products (High-Temperature Method) : Standard Test Method ForArdiansyah ARNo ratings yet

- Astm D-1552Document7 pagesAstm D-1552GianfrancoNo ratings yet

- SD 1552Document8 pagesSD 1552juan ninaNo ratings yet

- ASTM 1552 Sulfur PDFDocument8 pagesASTM 1552 Sulfur PDFIka KurniatyNo ratings yet

- Astm D1552Document7 pagesAstm D1552Zein GmNo ratings yet

- D1552.24552 (1)Document4 pagesD1552.24552 (1)Luis Ernesto Marin JaimesNo ratings yet

- Astm 5453 - Stantard Test Method For Determination of Total Sulfur PDFDocument9 pagesAstm 5453 - Stantard Test Method For Determination of Total Sulfur PDFgaso99No ratings yet

- D1552.20106Document6 pagesD1552.20106Luis Ernesto Marin JaimesNo ratings yet

- Sulfur in Petroleum Products (Lamp Method) : Standard Test Method ForDocument12 pagesSulfur in Petroleum Products (Lamp Method) : Standard Test Method ForLucía MontalvoNo ratings yet

- Astm D5453-93Document6 pagesAstm D5453-93nardeneNo ratings yet

- D2784-11 Azufre Oxy HidrógenoDocument7 pagesD2784-11 Azufre Oxy HidrógenoKALATUSNo ratings yet

- Trace Nitrogen in Liquid Petroleum Hydrocarbons by Syringe/Inlet Oxidative Combustion and Chemiluminescence DetectionDocument5 pagesTrace Nitrogen in Liquid Petroleum Hydrocarbons by Syringe/Inlet Oxidative Combustion and Chemiluminescence Detectiontribo technicalNo ratings yet

- D5762.9657Document7 pagesD5762.9657Luis Ernesto Marin JaimesNo ratings yet

- Trace Quantities of Sulfur in Light Liquid Petroleum Hydrocarbons by Oxidative MicrocoulometryDocument6 pagesTrace Quantities of Sulfur in Light Liquid Petroleum Hydrocarbons by Oxidative MicrocoulometryyuliaNo ratings yet

- D 6920 - 03Document5 pagesD 6920 - 03David CazorlaNo ratings yet

- ASTMDocument7 pagesASTMPaul SunnyNo ratings yet

- D4629.40802 (2)Document5 pagesD4629.40802 (2)Luis Ernesto Marin JaimesNo ratings yet

- Astmd7622 10Document5 pagesAstmd7622 10moh_ichwanuddinNo ratings yet

- D4239 8862 PDFDocument7 pagesD4239 8862 PDFKarol Giraldo DelgadoNo ratings yet

- Major and Minor Elements in Combustion Residues From Coal Utilization ProcessesDocument7 pagesMajor and Minor Elements in Combustion Residues From Coal Utilization ProcessesNghia PhamNo ratings yet

- D 4239 - 18e1 SulfurDocument8 pagesD 4239 - 18e1 Sulfurfatmachemist1No ratings yet

- Determination of Organic Chloride Content in Crude Oil: Standard Test Methods ForDocument8 pagesDetermination of Organic Chloride Content in Crude Oil: Standard Test Methods ForJl BorrazNo ratings yet

- Astm - d3682 - 01 (Reapp 2006) (Major and Minor Element in Combustion Residues)Document7 pagesAstm - d3682 - 01 (Reapp 2006) (Major and Minor Element in Combustion Residues)Dandy RizkanNo ratings yet

- Sulfur in Petroleum Products (Lamp Method) : Standard Test Method ForDocument12 pagesSulfur in Petroleum Products (Lamp Method) : Standard Test Method ForAhmedNo ratings yet

- Oxidation Characteristics of Inhibited Mineral Oils: Standard Test Method ForDocument11 pagesOxidation Characteristics of Inhibited Mineral Oils: Standard Test Method ForTarlan AllahverdiyevNo ratings yet

- Determination of Total Sulfur in Aromatic Hydrocarbons and Related Chemicals by Ultraviolet FluorescenceDocument5 pagesDetermination of Total Sulfur in Aromatic Hydrocarbons and Related Chemicals by Ultraviolet Fluorescencerasool Fakhraie100% (1)

- D4239Document10 pagesD4239Timothy Ferguson100% (1)

- Astm D 3682 01 Major and Minor Elements in Combustion Residues From PDFDocument6 pagesAstm D 3682 01 Major and Minor Elements in Combustion Residues From PDFJulio AsenciosNo ratings yet

- Determination of Sludging and Corrosion Tendencies of Inhibited Mineral OilsDocument12 pagesDetermination of Sludging and Corrosion Tendencies of Inhibited Mineral OilsTarlan AllahverdiyevNo ratings yet

- Trace Quantities of Sulfur in Light Liquid Petroleum Hydrocarbons by Oxidative MicrocoulometryDocument10 pagesTrace Quantities of Sulfur in Light Liquid Petroleum Hydrocarbons by Oxidative MicrocoulometryDennise ChicaizaNo ratings yet

- ASTM D4468-85 R2015 Azufre Total en Combustibles GaseososDocument5 pagesASTM D4468-85 R2015 Azufre Total en Combustibles GaseososDiana Alejandra Castañón IniestraNo ratings yet

- Determination of Carbon Residue (Micro Method) : Standard Test Method ForDocument7 pagesDetermination of Carbon Residue (Micro Method) : Standard Test Method ForCK CkkouNo ratings yet

- In By: and ProductsDocument6 pagesIn By: and ProductscavitNo ratings yet

- D5016Sulfur in AshDocument3 pagesD5016Sulfur in AshAdam PerkasaNo ratings yet

- Determination of Sulfur Compounds in Natural Gas and Gaseous Fuels by Gas Chromatography and ChemiluminescenceDocument11 pagesDetermination of Sulfur Compounds in Natural Gas and Gaseous Fuels by Gas Chromatography and ChemiluminescenceDIAZCORDOBANo ratings yet

- Total Mercury in Coal and Coal Combustion Residues by Direct Combustion AnalysisDocument5 pagesTotal Mercury in Coal and Coal Combustion Residues by Direct Combustion AnalysisAna OchoaNo ratings yet

- Epa 7473 (Mercury in Solids and Solutions by Thermal Decomposition, Amalgamation,)Document15 pagesEpa 7473 (Mercury in Solids and Solutions by Thermal Decomposition, Amalgamation,)Osmel García MorfiNo ratings yet

- Sulfur in The Analysis Sample of Coal and Coke Using High-Temperature Tube Furnace CombustionDocument7 pagesSulfur in The Analysis Sample of Coal and Coke Using High-Temperature Tube Furnace CombustionMuhammad Syarif HidayatullahNo ratings yet

- ASTM D943-04a - Oxidation of Inhibited Mineral OilDocument10 pagesASTM D943-04a - Oxidation of Inhibited Mineral OilKamruzaman MiahNo ratings yet

- Contenido de Azufre ASTM D5453Document10 pagesContenido de Azufre ASTM D5453Coordinador LaboratorioNo ratings yet

- d5504 PDFDocument10 pagesd5504 PDFNicola MargarelliNo ratings yet

- Astm D-5453-09Document10 pagesAstm D-5453-09myriammoellermendozaNo ratings yet

- D 4239-12 Standard Test Method For Sulfur in The Analysis Sample For Coa...Document6 pagesD 4239-12 Standard Test Method For Sulfur in The Analysis Sample For Coa...sarahNo ratings yet

- Determination of Hydrocarbon Impurities in Ethylene by Gas ChromatographyDocument5 pagesDetermination of Hydrocarbon Impurities in Ethylene by Gas ChromatographyAlabbas Fadhel100% (1)

- D 5762 - 98 - Rdu3njitoDocument6 pagesD 5762 - 98 - Rdu3njitodelta lab sangliNo ratings yet

- D4809-Standard Test Method For Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb Calorimeter (Precision Method)Document10 pagesD4809-Standard Test Method For Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb Calorimeter (Precision Method)rezaNo ratings yet

- Drying of Metal Bearing Ores, Concentrates, and Related Metallurgical Materials For The Determination of MercuryDocument2 pagesDrying of Metal Bearing Ores, Concentrates, and Related Metallurgical Materials For The Determination of MercurypravkovoilaNo ratings yet

- Astm D 5504 - 01Document10 pagesAstm D 5504 - 01hopkhtn100% (1)

- Determination of Mercury in Soil Samples: Utilizing Direct Mercury Analysis in As Little As 6 Minutes Per SampleDocument3 pagesDetermination of Mercury in Soil Samples: Utilizing Direct Mercury Analysis in As Little As 6 Minutes Per SampleJorge Sierra PaezNo ratings yet

- Functionalized Inorganic Fluorides: Synthesis, Characterization and Properties of Nanostructured SolidsFrom EverandFunctionalized Inorganic Fluorides: Synthesis, Characterization and Properties of Nanostructured SolidsNo ratings yet

- Usama Tamboli CV QDocument3 pagesUsama Tamboli CV QUsamah TNo ratings yet

- SMD 500-24Document1 pageSMD 500-24Usamah TNo ratings yet

- Art. Nr. Description Gas, Pressure Inlet Outlet 0768122 0768124 0768125 Technical DataDocument1 pageArt. Nr. Description Gas, Pressure Inlet Outlet 0768122 0768124 0768125 Technical DataUsamah TNo ratings yet

- Connector Ss-UDocument1 pageConnector Ss-UUsamah TNo ratings yet

- MaxiflowDocument1 pageMaxiflowUsamah TNo ratings yet

- Valve SDocument2 pagesValve SUsamah TNo ratings yet

- PDS Safety Cabinets CatalougeDocument2 pagesPDS Safety Cabinets CatalougeUsamah TNo ratings yet

- Justrite Page 008Document1 pageJustrite Page 008Usamah TNo ratings yet

- Justrite Page 009Document1 pageJustrite Page 009Usamah TNo ratings yet

- SD 129Document5 pagesSD 129Usamah TNo ratings yet

- 2045 Cyclect GroupDocument6 pages2045 Cyclect GroupUsamah TNo ratings yet

- ZA Gas GeneratorDocument2 pagesZA Gas GeneratorUsamah TNo ratings yet

- Coordination CompoundsDocument67 pagesCoordination CompoundsSantanu DasNo ratings yet

- Dielectric Polymers For ElectronicsDocument48 pagesDielectric Polymers For ElectronicsnadhimalkhamseenNo ratings yet

- Organic Qualitative Analysis PDFDocument54 pagesOrganic Qualitative Analysis PDFRiyan WibawaNo ratings yet

- Chemistry For IIT PreparationDocument82 pagesChemistry For IIT PreparationApex Institute50% (4)

- Volumetric AnalysisDocument47 pagesVolumetric AnalysisDinesh100% (3)

- Summative Test in Grade 10 ScienceDocument2 pagesSummative Test in Grade 10 Sciencecherry salvacion100% (2)

- UPDATED G11-Chemistry (S2) - Oral Interview Bank Questions-2020-2021Document8 pagesUPDATED G11-Chemistry (S2) - Oral Interview Bank Questions-2020-2021Samar Helmy Haj YousefNo ratings yet

- Arabian Gulf Is CorrosiveDocument5 pagesArabian Gulf Is CorrosiveJeevan Prasad JalliNo ratings yet

- Materiaux Fongiques1 00128 1Document10 pagesMateriaux Fongiques1 00128 1Yss ୪No ratings yet

- Carbohydrates: Dr. Shahab UddinDocument12 pagesCarbohydrates: Dr. Shahab UddinShahabNo ratings yet

- Bio-Based Flame Retardants When Nature Meets Fire ProtectionDocument25 pagesBio-Based Flame Retardants When Nature Meets Fire ProtectionMurillo PolettoNo ratings yet

- Chemical Constituents and Bioactive Potential of Portulaca Pilosa LDocument12 pagesChemical Constituents and Bioactive Potential of Portulaca Pilosa LCharles BritoNo ratings yet

- Chemical Kinetics Exercise SolutionsDocument98 pagesChemical Kinetics Exercise SolutionsKivilia EduventuresNo ratings yet

- Khalil M. K. KhaderDocument8 pagesKhalil M. K. KhaderajmanNo ratings yet

- DiluentsDocument15 pagesDiluentsvishnukiranniperNo ratings yet

- Chemical TestsDocument6 pagesChemical TestsAshwin UpretiNo ratings yet

- White Wine ProductionDocument3 pagesWhite Wine ProductionfikerykNo ratings yet

- Salt AnalysisDocument16 pagesSalt AnalysisAnshik BansalNo ratings yet

- Photocatalytic Degradation of LDPEDocument10 pagesPhotocatalytic Degradation of LDPErubikaNo ratings yet

- Separation of Spinach PigmentsDocument5 pagesSeparation of Spinach PigmentsFatima Saavedra0% (1)

- Coronary Stent DesignDocument79 pagesCoronary Stent DesignVickysh MevawalaNo ratings yet

- 1 s2.0 S0003267019302259 MainDocument28 pages1 s2.0 S0003267019302259 MainKelly ArrietaNo ratings yet

- Abiotic Stress ManagementDocument8 pagesAbiotic Stress ManagementMayank PandeyNo ratings yet

- Tariro Moto Project Proposal UpdatedDocument13 pagesTariro Moto Project Proposal Updatedtapiwa guy nyamukapaNo ratings yet

- Qualitative Analysis of Organic CompoundsDocument10 pagesQualitative Analysis of Organic Compoundspayal_joshi_14No ratings yet

- Aqa CHM2 W QP Jun08Document18 pagesAqa CHM2 W QP Jun08Yashoda AmarasekeraNo ratings yet