Professional Documents

Culture Documents

Topic: Personal Protective Equipment (PPE) : Sample Lesson Plan Construction Training Program (10-Hour)

Topic: Personal Protective Equipment (PPE) : Sample Lesson Plan Construction Training Program (10-Hour)

Uploaded by

consulting2Copyright:

Available Formats

You might also like

- NUR 146 MCN2 RLE P2 ExamDocument22 pagesNUR 146 MCN2 RLE P2 ExamMarga WreatheNo ratings yet

- Checklist Pencil GrinderDocument1 pageChecklist Pencil Grinderrexivy100% (1)

- Electronic Products Assembly and Servicing Grade 11: 1 Semester - Quarter 1 Module 1 Week 1-2Document42 pagesElectronic Products Assembly and Servicing Grade 11: 1 Semester - Quarter 1 Module 1 Week 1-2CHESTER ALLAN MENDEZNo ratings yet

- PPEDocument3 pagesPPEanninalongalongNo ratings yet

- TLE-TE-10 Q1 W3 Mod3 ICT-CSSDocument23 pagesTLE-TE-10 Q1 W3 Mod3 ICT-CSSMarlon Sevilla100% (1)

- An Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleFrom EverandAn Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleNo ratings yet

- No Entry SignDocument1 pageNo Entry SignrexivyNo ratings yet

- Checklist VibratorDocument1 pageChecklist VibratorrexivyNo ratings yet

- Checklist Jack HamerDocument1 pageChecklist Jack Hamerrexivy100% (1)

- Global Animal Feed Additives MarketDocument18 pagesGlobal Animal Feed Additives MarketSanjay MatthewsNo ratings yet

- Chapter 5, PPEDocument43 pagesChapter 5, PPEAnne LeighNo ratings yet

- (PPE) Awareness Training: Personal Protective EquipmentDocument11 pages(PPE) Awareness Training: Personal Protective EquipmentEmind Annamalai JPNagarNo ratings yet

- Osha30 Ppe V6 SGDocument189 pagesOsha30 Ppe V6 SGTyler HagemoNo ratings yet

- EPAS 11 - Q1 - W1 - Mod1Document45 pagesEPAS 11 - Q1 - W1 - Mod1Alberto A. FugenNo ratings yet

- Masonry FinalDocument121 pagesMasonry FinalMeltezen B. PantocNo ratings yet

- Practice Occupational Health and Safety ProceduresDocument8 pagesPractice Occupational Health and Safety ProceduresCelNo ratings yet

- Agtech PpeDocument27 pagesAgtech PpeNakimera JosephineNo ratings yet

- Vehicle Servicing: Unit of CompetenceDocument69 pagesVehicle Servicing: Unit of CompetencetselothaiilemariamNo ratings yet

- Unit - 2Document6 pagesUnit - 2محمد محمدNo ratings yet

- Vehicle Servicing: Unit of CompetenceDocument70 pagesVehicle Servicing: Unit of Competenceabel assefaNo ratings yet

- Personal Protective Equipment: OSHA Office of Training and EducationDocument36 pagesPersonal Protective Equipment: OSHA Office of Training and EducationWaseem YounisNo ratings yet

- Worksite Safety 05: OSHA Personal Protective Equipment: Course DescriptionDocument21 pagesWorksite Safety 05: OSHA Personal Protective Equipment: Course Descriptionraimundo.ojeda.12No ratings yet

- Job Safety Personal Protective EquipmentDocument4 pagesJob Safety Personal Protective EquipmenttmamputsiNo ratings yet

- Control of Workplace HazardsDocument12 pagesControl of Workplace HazardsMichael WambuaNo ratings yet

- Tab 5 - Ins 1 - PPE - G (Prosafe)Document48 pagesTab 5 - Ins 1 - PPE - G (Prosafe)Islam GadNo ratings yet

- Personal Protective EquipmentDocument3 pagesPersonal Protective EquipmentgagsvashNo ratings yet

- Safety 2 PpeDocument34 pagesSafety 2 PpeRamNo ratings yet

- Personal Protective Equipment ProgramDocument8 pagesPersonal Protective Equipment ProgramMostafizur Rahman SobujNo ratings yet

- PPE .PPT ConstructionDocument39 pagesPPE .PPT Constructiondrnzyme100% (14)

- Risk Control: OSHA Office of Training and EducationDocument60 pagesRisk Control: OSHA Office of Training and EducationAhmed Hassan Sabry100% (1)

- PPE Program...Document13 pagesPPE Program...Maryan Aybee Dabuet100% (1)

- Accident Prevention Manual For Business & Industry:: Engineering & Technology 13th EditionDocument48 pagesAccident Prevention Manual For Business & Industry:: Engineering & Technology 13th EditionAmeerUlHaqNo ratings yet

- NVQDocument20 pagesNVQAlexandru100% (1)

- Common Sulphur ProjectDocument40 pagesCommon Sulphur ProjectAkhilNo ratings yet

- Personal Protective Equipment Policy - FinalDocument6 pagesPersonal Protective Equipment Policy - FinalmarkalvinbonNo ratings yet

- Personal Protective Equipment (PPE) ProgramDocument18 pagesPersonal Protective Equipment (PPE) ProgramKrishna KumarNo ratings yet

- Engineering Workshop Safety ManualDocument12 pagesEngineering Workshop Safety Manualsph_ertNo ratings yet

- Systematized Instruction: Prepared By: Mr. Ryan Custodio Mr. Vincent M. Gonzaga Ms. Kimberly P. Ratonel TCP-BDocument18 pagesSystematized Instruction: Prepared By: Mr. Ryan Custodio Mr. Vincent M. Gonzaga Ms. Kimberly P. Ratonel TCP-BKimberly P. RatonelNo ratings yet

- Individual OSH ReportDocument9 pagesIndividual OSH Reportanis izzatyNo ratings yet

- Personal Protective Equipment (PPE) ProgramDocument18 pagesPersonal Protective Equipment (PPE) ProgramIssac JohnNo ratings yet

- Personal Protective Equipment: For General IndustryDocument26 pagesPersonal Protective Equipment: For General IndustryZhedriex EspirituNo ratings yet

- 1 Chapter One Engine FundamentalDocument25 pages1 Chapter One Engine FundamentalGebisa TamiruNo ratings yet

- Learning Guide Learning Guide - 3: Vehicle Servicing Vehicle Servicing NTQF Level IDocument82 pagesLearning Guide Learning Guide - 3: Vehicle Servicing Vehicle Servicing NTQF Level Iabel assefaNo ratings yet

- EGN3333 Lab1Document7 pagesEGN3333 Lab1AhmedNo ratings yet

- Assingment No. 3.4Document3 pagesAssingment No. 3.4Training Cell ChhaparaNo ratings yet

- Personal Protective Equipment: Albert L. Asprec, M.D., M.O.HDocument33 pagesPersonal Protective Equipment: Albert L. Asprec, M.D., M.O.HAHLGEE BULALACAONo ratings yet

- Lab 1 Particulate Technology LabDocument52 pagesLab 1 Particulate Technology Labahmadayub2908No ratings yet

- Module 9 - Personal Protective EquipmentDocument11 pagesModule 9 - Personal Protective EquipmentSamNo ratings yet

- Administrative Controls 2Document16 pagesAdministrative Controls 2Christo GeorgeNo ratings yet

- Faculty of EngineeringDocument13 pagesFaculty of EngineeringSaliya SamarajeevaNo ratings yet

- REVIEWER For MTF INTERVIEW and WRITTEN EXAMDocument5 pagesREVIEWER For MTF INTERVIEW and WRITTEN EXAMMARJORIE BIBONNo ratings yet

- Lesson Plan: Personal Protective Equipment ''Document7 pagesLesson Plan: Personal Protective Equipment ''Mary Jane T. EspinoNo ratings yet

- Chapter 3 Workshop TechnologyDocument69 pagesChapter 3 Workshop TechnologyPeter KathuvihNo ratings yet

- M4C FF Safety Tech ProcDocument11 pagesM4C FF Safety Tech ProcFallucky SantiagoNo ratings yet

- Safety QP 3Document16 pagesSafety QP 3printermech2022No ratings yet

- Personal Protective Equipment: For General IndustryDocument28 pagesPersonal Protective Equipment: For General IndustryXozanNo ratings yet

- Course Content: Education 261 (Laboratory Techniques and Procedures) Topics: Chemistry/PhysicsDocument5 pagesCourse Content: Education 261 (Laboratory Techniques and Procedures) Topics: Chemistry/PhysicsMelmar ReverenteNo ratings yet

- BTEC Level 3 National Engineering Teaching Resource Pack Unit 1Document30 pagesBTEC Level 3 National Engineering Teaching Resource Pack Unit 1princedotty0% (1)

- This Course Provides The KnowledgeDocument3 pagesThis Course Provides The KnowledgemdelacruzNo ratings yet

- Safety Introduction: Health and Safety and YOU!Document22 pagesSafety Introduction: Health and Safety and YOU!Umer ChaudharyNo ratings yet

- Sop Template OperationsDocument2 pagesSop Template OperationsAlex BetancaNo ratings yet

- Personal Protective EquipmentDocument23 pagesPersonal Protective EquipmentShe LiedNo ratings yet

- 20 Safety Training Topics For Your Workplace - HSDocument2 pages20 Safety Training Topics For Your Workplace - HSiqceastNo ratings yet

- Protocall 934 Hazardous Materials Technician: Ten Fingers and Ten ToesFrom EverandProtocall 934 Hazardous Materials Technician: Ten Fingers and Ten ToesNo ratings yet

- The Construction Safety Guide: Injury and Illness Prevention through DesignFrom EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignRating: 4 out of 5 stars4/5 (6)

- No AccessDocument1 pageNo AccessrexivyNo ratings yet

- Heat Stress Management Inspection ChecklistDocument1 pageHeat Stress Management Inspection ChecklistrexivyNo ratings yet

- Starrt Card RevisedDocument1 pageStarrt Card RevisedrexivyNo ratings yet

- Jsa For Tie-In Tp-950Document11 pagesJsa For Tie-In Tp-950rexivyNo ratings yet

- HSE TBT TopicDocument3 pagesHSE TBT TopicrexivyNo ratings yet

- Electrical Drill ChecklistDocument1 pageElectrical Drill ChecklistrexivyNo ratings yet

- Aspects and ImpactsDocument3 pagesAspects and Impactsrexivy100% (1)

- ForkliftDocument4 pagesForkliftrexivyNo ratings yet

- Checklist For VibratorDocument1 pageChecklist For VibratorrexivyNo ratings yet

- Checklist Hand ToolsDocument1 pageChecklist Hand ToolsrexivyNo ratings yet

- Checklist Cement MixerDocument1 pageChecklist Cement MixerrexivyNo ratings yet

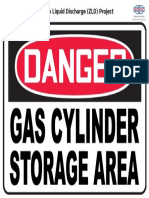

- Danger - Gas Cylinder Storage AreaDocument1 pageDanger - Gas Cylinder Storage ArearexivyNo ratings yet

- Danger - Electrical Hazard Authorized Personnel OnlyDocument1 pageDanger - Electrical Hazard Authorized Personnel OnlyrexivyNo ratings yet

- Danger - High VoltageDocument1 pageDanger - High VoltagerexivyNo ratings yet

- Danger - Hot Work Are in ProgressDocument1 pageDanger - Hot Work Are in ProgressrexivyNo ratings yet

- Danger - Hazardous MaterialsDocument1 pageDanger - Hazardous MaterialsrexivyNo ratings yet

- Caution - Chemical HazardDocument1 pageCaution - Chemical HazardrexivyNo ratings yet

- Caution - Flammable MaterialDocument1 pageCaution - Flammable MaterialrexivyNo ratings yet

- Fire Prevention - Empty Cylinder Storage AreaDocument1 pageFire Prevention - Empty Cylinder Storage ArearexivyNo ratings yet

- Safe - Smoking ShelterDocument1 pageSafe - Smoking ShelterrexivyNo ratings yet

- Danger - Gas Cylinder Storage AreaDocument1 pageDanger - Gas Cylinder Storage ArearexivyNo ratings yet

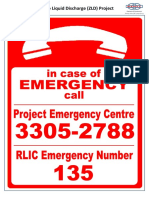

- LR Zero Liquid Discharge (ZLD) ProjectDocument1 pageLR Zero Liquid Discharge (ZLD) ProjectrexivyNo ratings yet

- Safe Condition - Emergency Exit DirectionDocument2 pagesSafe Condition - Emergency Exit DirectionrexivyNo ratings yet

- Toilet Checklist IMS-QK-HSE-3-0077-1Document1 pageToilet Checklist IMS-QK-HSE-3-0077-1rexivyNo ratings yet

- Emergency Contact Number 2Document1 pageEmergency Contact Number 2rexivyNo ratings yet

- Danger - Gas Cylinder Storage AreaDocument1 pageDanger - Gas Cylinder Storage ArearexivyNo ratings yet

- The Analysis of Pharmaceutical MarketDocument10 pagesThe Analysis of Pharmaceutical MarketAnamaria BejenariuNo ratings yet

- Data Privacy and SecurityDocument25 pagesData Privacy and SecurityBridgette MontizoNo ratings yet

- Peripheral NeuropathyDocument30 pagesPeripheral NeuropathyLyn LynNo ratings yet

- Healthy Childhood Development Through Outdoor Risky Play - Navigating The Balance With Injury Prevention - Canadian Paediatric SocietyDocument8 pagesHealthy Childhood Development Through Outdoor Risky Play - Navigating The Balance With Injury Prevention - Canadian Paediatric SocietyKatrina LoweNo ratings yet

- Breast MassDocument38 pagesBreast MassLester Paul SivilaNo ratings yet

- Initial Full-Dose Heparin For Adult: 1-Venous Thromboembolism (DVT/PE), TreatmentDocument3 pagesInitial Full-Dose Heparin For Adult: 1-Venous Thromboembolism (DVT/PE), TreatmentLamNo ratings yet

- A Century After Yehidar-Beshita (The Spanish U in Ethiopia) : Are We Prepared For The Next Pandemic?Document5 pagesA Century After Yehidar-Beshita (The Spanish U in Ethiopia) : Are We Prepared For The Next Pandemic?Yalew MekonnenNo ratings yet

- 中药复方治疗单纯性肥胖症有效性和安全性的系统评价Document5 pages中药复方治疗单纯性肥胖症有效性和安全性的系统评价wanglongcNo ratings yet

- Unit Plan-Health Healthy Eating and Habits January 5th-31stDocument22 pagesUnit Plan-Health Healthy Eating and Habits January 5th-31stapi-534505202No ratings yet

- Medical Reimbursement AptranscoDocument13 pagesMedical Reimbursement AptranscopenusilaNo ratings yet

- Acupuncture Valkai Ariviyal EnglishDocument12 pagesAcupuncture Valkai Ariviyal Englishcradha736No ratings yet

- MRCPCH TipsDocument19 pagesMRCPCH TipsBernice LimNo ratings yet

- Kuliah ATLSDocument63 pagesKuliah ATLSDwianggriany Adhetia Piesca Widoretno100% (1)

- Vitamin D SupplementsDocument11 pagesVitamin D SupplementsPetra JobovaNo ratings yet

- President Kaguta Museveni's Speech On Covid-19 As of 18 June 2021Document26 pagesPresident Kaguta Museveni's Speech On Covid-19 As of 18 June 2021The Campus TimesNo ratings yet

- 9396 02 WT Indcandrecform)Document2 pages9396 02 WT Indcandrecform)Zetsu RedNo ratings yet

- Capinpin Research PaperDocument16 pagesCapinpin Research Paperfrancine.malit24No ratings yet

- Nishtha Annual Report 2014-15Document32 pagesNishtha Annual Report 2014-15Sunny DuggalNo ratings yet

- Psychotic DisordersDocument28 pagesPsychotic DisordersGlessica YouNo ratings yet

- Practical Review of Diagnosis and Management of Cutaneous Tuberculosis in IndonesiaDocument6 pagesPractical Review of Diagnosis and Management of Cutaneous Tuberculosis in IndonesiaAde Afriza FeraniNo ratings yet

- Panduan Intermediate CycleDocument17 pagesPanduan Intermediate CyclemuhammadridhwanNo ratings yet

- OET Test 5 Listening Answers - Part A and BDocument9 pagesOET Test 5 Listening Answers - Part A and Bjeet meharNo ratings yet

- Effects of Social Media On The Mental Health of Grade 12 Students of Aclc College of TaclobanDocument24 pagesEffects of Social Media On The Mental Health of Grade 12 Students of Aclc College of TaclobanAron JaroNo ratings yet

- iRECIST: Guidelines For Response Criteria For Use in Trials Testing Immunotherapeutics AuthorsDocument30 pagesiRECIST: Guidelines For Response Criteria For Use in Trials Testing Immunotherapeutics AuthorsNguyenthanh DuongNo ratings yet

- EbpDocument29 pagesEbpapi-383975697No ratings yet

- Informed Consent Form For The Astrazeneca Covid-19 VaccineDocument1 pageInformed Consent Form For The Astrazeneca Covid-19 VaccineGodfrey Loth Sales Alcansare Jr.No ratings yet

- Health Infrastructure and Economic Development in IndiaDocument9 pagesHealth Infrastructure and Economic Development in IndiaAkanksha PalNo ratings yet

- Mapeh 8health q3 Summative TestDocument3 pagesMapeh 8health q3 Summative TestJanmae ImperialNo ratings yet

Topic: Personal Protective Equipment (PPE) : Sample Lesson Plan Construction Training Program (10-Hour)

Topic: Personal Protective Equipment (PPE) : Sample Lesson Plan Construction Training Program (10-Hour)

Uploaded by

consulting2Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Topic: Personal Protective Equipment (PPE) : Sample Lesson Plan Construction Training Program (10-Hour)

Topic: Personal Protective Equipment (PPE) : Sample Lesson Plan Construction Training Program (10-Hour)

Uploaded by

consulting2Copyright:

Available Formats

Sample Lesson Plan

Construction Training Program (10-hour)

Topic: Personal Protective Equipment (PPE)

Overview

OSHA requires employers to protect their employees from workplace hazards

through the use of engineering or work practice controls. When these controls are not

feasible or do not provide sufficient protection, the use of personal protective equipment

(PPE) is required.

Employers are required to assess the workplace to determine if hazards are

present, or are likely to be present, which necessitates the use of PPE. If employees use

PPE, employers must establish general procedures, called a PPE program, to give

employees necessary protective equipment and to train them to use it properly. The

program should explain when to use PPE and how to select, maintain and evaluate it.

Step 1: Planning the Lesson

• Instructional Materials.

1. PowerPoint presentation.

2. Instructor notes.

3. Other materials.

• Instructional Objectives.

1. Complete the required topics for the OSHA 10-hour course.

2. Complete the following optional topics:

a.

b.

c.

3. Present Personal Protective Equipment (PPE) to [number] participants.

4. Incorporate active participation in each lesson.

5. Provide a quiz or short evaluation at the end of the course.

6. Ensure feedback from participants at various points in the training.

• Guest Speakers/Presenters and Topics/Responsibilities.

Step 2: Presenting the Lesson

• Lesson Introduction.

Introductory remarks or transition from previous lesson.

• Learning Objectives/Outcomes.

Upon completion of the lesson, participants will be able to:

1. Describe the two primary means of protecting employees from workplace

hazards, prior to considering personal protective equipment (PPE).

Sample Lesson Plan - Personal Protective Equipment (PPE) 1

• Learning Objectives/Outcomes. (Continued)

Possible responses.

• Engineering Controls. Physically change the machine or work environment

to prevent employee exposure to a potential hazard.

• Isolate the process • Change the process

• Enclose the process • Consider design specifications

• Substitute less harmful material

• Work Practice Controls. Remove employees from exposure to the potential

hazard.

• Use of wet methods to suppress dust

• Personal hygiene

• Housekeeping and maintenance

• Job rotation of workers

2. List at least four of the seven items that should be covered during PPE

training.

Possible responses.

• Why training is necessary.

• How the PPE will protect the wearer

• What the PPE’s limitations are

• When and how to wear the PPE

• How to identify signs of wear

• How to clean and disinfect the PPE

• What the useful life of the PPE is, and how to dispose of unusable equipment

3. Identify at least three elements of an appropriate PPE program.

Possible responses.

• The employer uses engineering and work practice controls to eliminate or

reduce hazards before using PPE.

• The employer assesses the workplace for hazards.

• The employer selects appropriate PPE to protect employees from hazards

that cannot be eliminated.

• Employees are informed about why the PPE is necessary and when it must

be worn.

• Employees are trained in proper use and care of the PPE.

• Employees are required to wear PPE as protection from identified and likely

hazards in their work area.

Sample Lesson Plan - Personal Protective Equipment (PPE) 2

4. Match the PPE described in this lesson to at least one hazard for which it is

appropriate protection.

Possible responses.

PPE Hazard

Safety goggles/glasses flying particles, dust, sawdust,

(eye protection) corrosives or intense light

Face shields dust, splashes or sprays of hazardous

(face protection) liquid

Welding shields radiant light, flying sparks, spatters,

(face protection) slag chips

Hard hats/helmets injury from impact, falling objects,

(head protection) flying objects, electrical shock or

burns (if helmet is insulated)

Safety shoes hot, wet or slippery surfaces; heavy

(feet protection) objects falling or rolling against the

foot; exposure to nails or molten

materials (e.g. paving materials or

metals)

Gloves and sleeves burns, bruises, abrasions, cuts,

(hand and arm protection) punctures, fractures, amputations,

chemical exposure

Vests, coveralls, body suits, aprons intense heat, splash of hot metals or

(body protection) liquids, impact from tools or

machinery, cuts, hazardous

chemicals

• Planned Activities, Discussion, or Participant Interaction

Step 3: Evaluating Student Learning and Instruction

• Lesson Evaluation and Comments.

Sample Lesson Plan - Personal Protective Equipment (PPE) 3

You might also like

- NUR 146 MCN2 RLE P2 ExamDocument22 pagesNUR 146 MCN2 RLE P2 ExamMarga WreatheNo ratings yet

- Checklist Pencil GrinderDocument1 pageChecklist Pencil Grinderrexivy100% (1)

- Electronic Products Assembly and Servicing Grade 11: 1 Semester - Quarter 1 Module 1 Week 1-2Document42 pagesElectronic Products Assembly and Servicing Grade 11: 1 Semester - Quarter 1 Module 1 Week 1-2CHESTER ALLAN MENDEZNo ratings yet

- PPEDocument3 pagesPPEanninalongalongNo ratings yet

- TLE-TE-10 Q1 W3 Mod3 ICT-CSSDocument23 pagesTLE-TE-10 Q1 W3 Mod3 ICT-CSSMarlon Sevilla100% (1)

- An Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleFrom EverandAn Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleNo ratings yet

- No Entry SignDocument1 pageNo Entry SignrexivyNo ratings yet

- Checklist VibratorDocument1 pageChecklist VibratorrexivyNo ratings yet

- Checklist Jack HamerDocument1 pageChecklist Jack Hamerrexivy100% (1)

- Global Animal Feed Additives MarketDocument18 pagesGlobal Animal Feed Additives MarketSanjay MatthewsNo ratings yet

- Chapter 5, PPEDocument43 pagesChapter 5, PPEAnne LeighNo ratings yet

- (PPE) Awareness Training: Personal Protective EquipmentDocument11 pages(PPE) Awareness Training: Personal Protective EquipmentEmind Annamalai JPNagarNo ratings yet

- Osha30 Ppe V6 SGDocument189 pagesOsha30 Ppe V6 SGTyler HagemoNo ratings yet

- EPAS 11 - Q1 - W1 - Mod1Document45 pagesEPAS 11 - Q1 - W1 - Mod1Alberto A. FugenNo ratings yet

- Masonry FinalDocument121 pagesMasonry FinalMeltezen B. PantocNo ratings yet

- Practice Occupational Health and Safety ProceduresDocument8 pagesPractice Occupational Health and Safety ProceduresCelNo ratings yet

- Agtech PpeDocument27 pagesAgtech PpeNakimera JosephineNo ratings yet

- Vehicle Servicing: Unit of CompetenceDocument69 pagesVehicle Servicing: Unit of CompetencetselothaiilemariamNo ratings yet

- Unit - 2Document6 pagesUnit - 2محمد محمدNo ratings yet

- Vehicle Servicing: Unit of CompetenceDocument70 pagesVehicle Servicing: Unit of Competenceabel assefaNo ratings yet

- Personal Protective Equipment: OSHA Office of Training and EducationDocument36 pagesPersonal Protective Equipment: OSHA Office of Training and EducationWaseem YounisNo ratings yet

- Worksite Safety 05: OSHA Personal Protective Equipment: Course DescriptionDocument21 pagesWorksite Safety 05: OSHA Personal Protective Equipment: Course Descriptionraimundo.ojeda.12No ratings yet

- Job Safety Personal Protective EquipmentDocument4 pagesJob Safety Personal Protective EquipmenttmamputsiNo ratings yet

- Control of Workplace HazardsDocument12 pagesControl of Workplace HazardsMichael WambuaNo ratings yet

- Tab 5 - Ins 1 - PPE - G (Prosafe)Document48 pagesTab 5 - Ins 1 - PPE - G (Prosafe)Islam GadNo ratings yet

- Personal Protective EquipmentDocument3 pagesPersonal Protective EquipmentgagsvashNo ratings yet

- Safety 2 PpeDocument34 pagesSafety 2 PpeRamNo ratings yet

- Personal Protective Equipment ProgramDocument8 pagesPersonal Protective Equipment ProgramMostafizur Rahman SobujNo ratings yet

- PPE .PPT ConstructionDocument39 pagesPPE .PPT Constructiondrnzyme100% (14)

- Risk Control: OSHA Office of Training and EducationDocument60 pagesRisk Control: OSHA Office of Training and EducationAhmed Hassan Sabry100% (1)

- PPE Program...Document13 pagesPPE Program...Maryan Aybee Dabuet100% (1)

- Accident Prevention Manual For Business & Industry:: Engineering & Technology 13th EditionDocument48 pagesAccident Prevention Manual For Business & Industry:: Engineering & Technology 13th EditionAmeerUlHaqNo ratings yet

- NVQDocument20 pagesNVQAlexandru100% (1)

- Common Sulphur ProjectDocument40 pagesCommon Sulphur ProjectAkhilNo ratings yet

- Personal Protective Equipment Policy - FinalDocument6 pagesPersonal Protective Equipment Policy - FinalmarkalvinbonNo ratings yet

- Personal Protective Equipment (PPE) ProgramDocument18 pagesPersonal Protective Equipment (PPE) ProgramKrishna KumarNo ratings yet

- Engineering Workshop Safety ManualDocument12 pagesEngineering Workshop Safety Manualsph_ertNo ratings yet

- Systematized Instruction: Prepared By: Mr. Ryan Custodio Mr. Vincent M. Gonzaga Ms. Kimberly P. Ratonel TCP-BDocument18 pagesSystematized Instruction: Prepared By: Mr. Ryan Custodio Mr. Vincent M. Gonzaga Ms. Kimberly P. Ratonel TCP-BKimberly P. RatonelNo ratings yet

- Individual OSH ReportDocument9 pagesIndividual OSH Reportanis izzatyNo ratings yet

- Personal Protective Equipment (PPE) ProgramDocument18 pagesPersonal Protective Equipment (PPE) ProgramIssac JohnNo ratings yet

- Personal Protective Equipment: For General IndustryDocument26 pagesPersonal Protective Equipment: For General IndustryZhedriex EspirituNo ratings yet

- 1 Chapter One Engine FundamentalDocument25 pages1 Chapter One Engine FundamentalGebisa TamiruNo ratings yet

- Learning Guide Learning Guide - 3: Vehicle Servicing Vehicle Servicing NTQF Level IDocument82 pagesLearning Guide Learning Guide - 3: Vehicle Servicing Vehicle Servicing NTQF Level Iabel assefaNo ratings yet

- EGN3333 Lab1Document7 pagesEGN3333 Lab1AhmedNo ratings yet

- Assingment No. 3.4Document3 pagesAssingment No. 3.4Training Cell ChhaparaNo ratings yet

- Personal Protective Equipment: Albert L. Asprec, M.D., M.O.HDocument33 pagesPersonal Protective Equipment: Albert L. Asprec, M.D., M.O.HAHLGEE BULALACAONo ratings yet

- Lab 1 Particulate Technology LabDocument52 pagesLab 1 Particulate Technology Labahmadayub2908No ratings yet

- Module 9 - Personal Protective EquipmentDocument11 pagesModule 9 - Personal Protective EquipmentSamNo ratings yet

- Administrative Controls 2Document16 pagesAdministrative Controls 2Christo GeorgeNo ratings yet

- Faculty of EngineeringDocument13 pagesFaculty of EngineeringSaliya SamarajeevaNo ratings yet

- REVIEWER For MTF INTERVIEW and WRITTEN EXAMDocument5 pagesREVIEWER For MTF INTERVIEW and WRITTEN EXAMMARJORIE BIBONNo ratings yet

- Lesson Plan: Personal Protective Equipment ''Document7 pagesLesson Plan: Personal Protective Equipment ''Mary Jane T. EspinoNo ratings yet

- Chapter 3 Workshop TechnologyDocument69 pagesChapter 3 Workshop TechnologyPeter KathuvihNo ratings yet

- M4C FF Safety Tech ProcDocument11 pagesM4C FF Safety Tech ProcFallucky SantiagoNo ratings yet

- Safety QP 3Document16 pagesSafety QP 3printermech2022No ratings yet

- Personal Protective Equipment: For General IndustryDocument28 pagesPersonal Protective Equipment: For General IndustryXozanNo ratings yet

- Course Content: Education 261 (Laboratory Techniques and Procedures) Topics: Chemistry/PhysicsDocument5 pagesCourse Content: Education 261 (Laboratory Techniques and Procedures) Topics: Chemistry/PhysicsMelmar ReverenteNo ratings yet

- BTEC Level 3 National Engineering Teaching Resource Pack Unit 1Document30 pagesBTEC Level 3 National Engineering Teaching Resource Pack Unit 1princedotty0% (1)

- This Course Provides The KnowledgeDocument3 pagesThis Course Provides The KnowledgemdelacruzNo ratings yet

- Safety Introduction: Health and Safety and YOU!Document22 pagesSafety Introduction: Health and Safety and YOU!Umer ChaudharyNo ratings yet

- Sop Template OperationsDocument2 pagesSop Template OperationsAlex BetancaNo ratings yet

- Personal Protective EquipmentDocument23 pagesPersonal Protective EquipmentShe LiedNo ratings yet

- 20 Safety Training Topics For Your Workplace - HSDocument2 pages20 Safety Training Topics For Your Workplace - HSiqceastNo ratings yet

- Protocall 934 Hazardous Materials Technician: Ten Fingers and Ten ToesFrom EverandProtocall 934 Hazardous Materials Technician: Ten Fingers and Ten ToesNo ratings yet

- The Construction Safety Guide: Injury and Illness Prevention through DesignFrom EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignRating: 4 out of 5 stars4/5 (6)

- No AccessDocument1 pageNo AccessrexivyNo ratings yet

- Heat Stress Management Inspection ChecklistDocument1 pageHeat Stress Management Inspection ChecklistrexivyNo ratings yet

- Starrt Card RevisedDocument1 pageStarrt Card RevisedrexivyNo ratings yet

- Jsa For Tie-In Tp-950Document11 pagesJsa For Tie-In Tp-950rexivyNo ratings yet

- HSE TBT TopicDocument3 pagesHSE TBT TopicrexivyNo ratings yet

- Electrical Drill ChecklistDocument1 pageElectrical Drill ChecklistrexivyNo ratings yet

- Aspects and ImpactsDocument3 pagesAspects and Impactsrexivy100% (1)

- ForkliftDocument4 pagesForkliftrexivyNo ratings yet

- Checklist For VibratorDocument1 pageChecklist For VibratorrexivyNo ratings yet

- Checklist Hand ToolsDocument1 pageChecklist Hand ToolsrexivyNo ratings yet

- Checklist Cement MixerDocument1 pageChecklist Cement MixerrexivyNo ratings yet

- Danger - Gas Cylinder Storage AreaDocument1 pageDanger - Gas Cylinder Storage ArearexivyNo ratings yet

- Danger - Electrical Hazard Authorized Personnel OnlyDocument1 pageDanger - Electrical Hazard Authorized Personnel OnlyrexivyNo ratings yet

- Danger - High VoltageDocument1 pageDanger - High VoltagerexivyNo ratings yet

- Danger - Hot Work Are in ProgressDocument1 pageDanger - Hot Work Are in ProgressrexivyNo ratings yet

- Danger - Hazardous MaterialsDocument1 pageDanger - Hazardous MaterialsrexivyNo ratings yet

- Caution - Chemical HazardDocument1 pageCaution - Chemical HazardrexivyNo ratings yet

- Caution - Flammable MaterialDocument1 pageCaution - Flammable MaterialrexivyNo ratings yet

- Fire Prevention - Empty Cylinder Storage AreaDocument1 pageFire Prevention - Empty Cylinder Storage ArearexivyNo ratings yet

- Safe - Smoking ShelterDocument1 pageSafe - Smoking ShelterrexivyNo ratings yet

- Danger - Gas Cylinder Storage AreaDocument1 pageDanger - Gas Cylinder Storage ArearexivyNo ratings yet

- LR Zero Liquid Discharge (ZLD) ProjectDocument1 pageLR Zero Liquid Discharge (ZLD) ProjectrexivyNo ratings yet

- Safe Condition - Emergency Exit DirectionDocument2 pagesSafe Condition - Emergency Exit DirectionrexivyNo ratings yet

- Toilet Checklist IMS-QK-HSE-3-0077-1Document1 pageToilet Checklist IMS-QK-HSE-3-0077-1rexivyNo ratings yet

- Emergency Contact Number 2Document1 pageEmergency Contact Number 2rexivyNo ratings yet

- Danger - Gas Cylinder Storage AreaDocument1 pageDanger - Gas Cylinder Storage ArearexivyNo ratings yet

- The Analysis of Pharmaceutical MarketDocument10 pagesThe Analysis of Pharmaceutical MarketAnamaria BejenariuNo ratings yet

- Data Privacy and SecurityDocument25 pagesData Privacy and SecurityBridgette MontizoNo ratings yet

- Peripheral NeuropathyDocument30 pagesPeripheral NeuropathyLyn LynNo ratings yet

- Healthy Childhood Development Through Outdoor Risky Play - Navigating The Balance With Injury Prevention - Canadian Paediatric SocietyDocument8 pagesHealthy Childhood Development Through Outdoor Risky Play - Navigating The Balance With Injury Prevention - Canadian Paediatric SocietyKatrina LoweNo ratings yet

- Breast MassDocument38 pagesBreast MassLester Paul SivilaNo ratings yet

- Initial Full-Dose Heparin For Adult: 1-Venous Thromboembolism (DVT/PE), TreatmentDocument3 pagesInitial Full-Dose Heparin For Adult: 1-Venous Thromboembolism (DVT/PE), TreatmentLamNo ratings yet

- A Century After Yehidar-Beshita (The Spanish U in Ethiopia) : Are We Prepared For The Next Pandemic?Document5 pagesA Century After Yehidar-Beshita (The Spanish U in Ethiopia) : Are We Prepared For The Next Pandemic?Yalew MekonnenNo ratings yet

- 中药复方治疗单纯性肥胖症有效性和安全性的系统评价Document5 pages中药复方治疗单纯性肥胖症有效性和安全性的系统评价wanglongcNo ratings yet

- Unit Plan-Health Healthy Eating and Habits January 5th-31stDocument22 pagesUnit Plan-Health Healthy Eating and Habits January 5th-31stapi-534505202No ratings yet

- Medical Reimbursement AptranscoDocument13 pagesMedical Reimbursement AptranscopenusilaNo ratings yet

- Acupuncture Valkai Ariviyal EnglishDocument12 pagesAcupuncture Valkai Ariviyal Englishcradha736No ratings yet

- MRCPCH TipsDocument19 pagesMRCPCH TipsBernice LimNo ratings yet

- Kuliah ATLSDocument63 pagesKuliah ATLSDwianggriany Adhetia Piesca Widoretno100% (1)

- Vitamin D SupplementsDocument11 pagesVitamin D SupplementsPetra JobovaNo ratings yet

- President Kaguta Museveni's Speech On Covid-19 As of 18 June 2021Document26 pagesPresident Kaguta Museveni's Speech On Covid-19 As of 18 June 2021The Campus TimesNo ratings yet

- 9396 02 WT Indcandrecform)Document2 pages9396 02 WT Indcandrecform)Zetsu RedNo ratings yet

- Capinpin Research PaperDocument16 pagesCapinpin Research Paperfrancine.malit24No ratings yet

- Nishtha Annual Report 2014-15Document32 pagesNishtha Annual Report 2014-15Sunny DuggalNo ratings yet

- Psychotic DisordersDocument28 pagesPsychotic DisordersGlessica YouNo ratings yet

- Practical Review of Diagnosis and Management of Cutaneous Tuberculosis in IndonesiaDocument6 pagesPractical Review of Diagnosis and Management of Cutaneous Tuberculosis in IndonesiaAde Afriza FeraniNo ratings yet

- Panduan Intermediate CycleDocument17 pagesPanduan Intermediate CyclemuhammadridhwanNo ratings yet

- OET Test 5 Listening Answers - Part A and BDocument9 pagesOET Test 5 Listening Answers - Part A and Bjeet meharNo ratings yet

- Effects of Social Media On The Mental Health of Grade 12 Students of Aclc College of TaclobanDocument24 pagesEffects of Social Media On The Mental Health of Grade 12 Students of Aclc College of TaclobanAron JaroNo ratings yet

- iRECIST: Guidelines For Response Criteria For Use in Trials Testing Immunotherapeutics AuthorsDocument30 pagesiRECIST: Guidelines For Response Criteria For Use in Trials Testing Immunotherapeutics AuthorsNguyenthanh DuongNo ratings yet

- EbpDocument29 pagesEbpapi-383975697No ratings yet

- Informed Consent Form For The Astrazeneca Covid-19 VaccineDocument1 pageInformed Consent Form For The Astrazeneca Covid-19 VaccineGodfrey Loth Sales Alcansare Jr.No ratings yet

- Health Infrastructure and Economic Development in IndiaDocument9 pagesHealth Infrastructure and Economic Development in IndiaAkanksha PalNo ratings yet

- Mapeh 8health q3 Summative TestDocument3 pagesMapeh 8health q3 Summative TestJanmae ImperialNo ratings yet