Professional Documents

Culture Documents

Multiple Compressors With ES 6 Ed00

Multiple Compressors With ES 6 Ed00

Uploaded by

Anie EkpenyongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multiple Compressors With ES 6 Ed00

Multiple Compressors With ES 6 Ed00

Uploaded by

Anie EkpenyongCopyright:

Available Formats

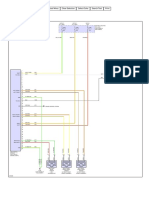

Mixed Machine Schematic With ES 6 Control

Basic Information

Description

This schematic shows a typical layout of a multi compressor system controlled by the ES 6, machines are connected

to the ES 6 via both the CAN network and through digital I/O (volt free contacts).

ES 6 – Installation Possibilities

A maximum of 6 machines can be controlled by the ES 6, 1 of which can be a VSD. Pressure is measured

downstream of all equipment using a transmitter. As standard, up to 5 machines can be controlled via digital I/O.

Remote system start/stop is also provided as standard.

Digital outputs required on each compressor:

• Stopped/running status

• Unload/load status

Unlike transducers, pressure transmitters can work over long

distances, 200m between the sensor and ES is no problem.

Remote

Digital inputs required on each compressor: pressure

• Local/remote control transmitter

(included)

• Unload/load control

CAN Network

The optimum way to connect machines to Placing The Pressure Transmitter

the ESE 6 is via the CAN network, as it The most common place to install the pressure transmitter is in the air

enables the closest and most accurate receiver. However, for a totally stable system pressure, regardless of

control. the changing pressure drop across filters and other equipment, the

sensor should be placed after all the installed equipment, as shown

above.

Edition 0 September 2006

Mixed Machine Schematic With An ES 6 & CANBox Interface

Basic Information

Description

This schematic shows a typical layout of a multi compressor system controlled by the ES 6, machines are connected

to the ES 6 via both the CAN network and through digital I/O (volt free contacts).

ES 6 – Installation Possibilities

A maximum of 6 machines can be controlled by the ES 6, 1 of which can be a VSD. Pressure is measured

downstream of all equipment using a transmitter. As standard, up to 5 machines can be controlled via digital I/O.

Remote system start/stop is also provided as standard.

Using a CANBox means that non Mk4 machines can

be added to the CAN network, reducing wiring

complexity and improving control possibilities

Unlike transducers, pressure transmitters can work over long

distances, 200m between the sensor and ENERGON is no problem.

Remote

pressure

transmitter

(included)

CAN Network

The optimum way to connect machines to Placing The Pressure Transmitter

the ES 6 is via the CAN network, as it The most common place to install the pressure transmitter is in the air

enables the closest and most accurate receiver. However, for a totally stable system pressure, regardless of

control. the changing pressure drop across filters and other equipment, the

sensor should be placed after all the installed equipment, as shown

above.

Edition 0 September 2006

You might also like

- CAT G3516 Generator Maintenance ManualDocument70 pagesCAT G3516 Generator Maintenance ManualAnie Ekpenyong88% (43)

- KNX Vragen ExDocument5 pagesKNX Vragen ExkloesNo ratings yet

- Atlas Copco SF 11 FF Parts List NEWDocument128 pagesAtlas Copco SF 11 FF Parts List NEWAnie Ekpenyong100% (1)

- BiffiDocument12 pagesBiffiMiko RokkoNo ratings yet

- Sc-Eq Communication Card: Installation InstructionsDocument40 pagesSc-Eq Communication Card: Installation InstructionsHectorFalconLlenderrozosNo ratings yet

- Pneumatech Sequence Master ControllerDocument4 pagesPneumatech Sequence Master ControllerFlo RinNo ratings yet

- Air Managment ModuleDocument12 pagesAir Managment ModuleemiljanlazeNo ratings yet

- Enviromux Series: Quick Installation GuideDocument2 pagesEnviromux Series: Quick Installation GuideDiana LopezNo ratings yet

- ES 6 - FAQs Ed02Document1 pageES 6 - FAQs Ed02Adeel SajjadNo ratings yet

- Lighting Controls: LCP3000EZ PanelsDocument1 pageLighting Controls: LCP3000EZ PanelsAg Oe NgNo ratings yet

- What Is Clipsal CDocument4 pagesWhat Is Clipsal CmarbyNo ratings yet

- Ethernet Intelligent Pressure Scanner: Netscanner™ SystemDocument8 pagesEthernet Intelligent Pressure Scanner: Netscanner™ SystemljboorNo ratings yet

- CE6 Accessories - IngDocument24 pagesCE6 Accessories - IngRoberto MerizaldeNo ratings yet

- Aeroflex Land ApplicationNote 2945B EDACS RepeaterDocument8 pagesAeroflex Land ApplicationNote 2945B EDACS RepeaterStephen PANNo ratings yet

- Data Sheet T 8384-3 EN: Type 3730-3 Electropneumatic Positioner With HART CommunicationDocument12 pagesData Sheet T 8384-3 EN: Type 3730-3 Electropneumatic Positioner With HART CommunicationThiago Rodrigo Oliveira SantosNo ratings yet

- Samson 3730 DatasheetDocument12 pagesSamson 3730 DatasheetGabriel DpdNo ratings yet

- Power Management-SENTRON PAC3200Document8 pagesPower Management-SENTRON PAC3200JeyakumarNo ratings yet

- Pmma 3Document8 pagesPmma 3MancamiaicuruNo ratings yet

- Architen ETFE Data Sheet AHUDocument2 pagesArchiten ETFE Data Sheet AHUmichal.d.siwinskiNo ratings yet

- Tender Document 2Document368 pagesTender Document 2Anonymous 70lCzDJvNo ratings yet

- Control Software DC SourcesDocument4 pagesControl Software DC SourcesppNo ratings yet

- PM0021e ACE100Document4 pagesPM0021e ACE100Imran TajNo ratings yet

- Dkg-329 Automatic Transfer Switch Controller: With Uninterrupted Transfer and Multiple Genset SupportDocument2 pagesDkg-329 Automatic Transfer Switch Controller: With Uninterrupted Transfer and Multiple Genset SupportJermaine PeñaNo ratings yet

- Manual HorschDocument74 pagesManual HorschFabiano100% (1)

- Piu deDocument5 pagesPiu demonurahulNo ratings yet

- "In Sync" Parallel Control Panel: Main FeaturesDocument3 pages"In Sync" Parallel Control Panel: Main FeaturesArrammah AlkamelNo ratings yet

- Unisab III SB3296 Nov 2012PrtDocument2 pagesUnisab III SB3296 Nov 2012PrtMinerba ValiehereNo ratings yet

- Main Report DCSDocument26 pagesMain Report DCSjoymotiNo ratings yet

- ST260 ManualDocument24 pagesST260 Manualdr.khaidangNo ratings yet

- AKCP Power Monitor Sensor User ManualDocument23 pagesAKCP Power Monitor Sensor User Manualabdelouahab.lbachir.icosnetNo ratings yet

- PSCS Communication SoftwareDocument19 pagesPSCS Communication Softwarepankajsoni90No ratings yet

- Siemens Pac3200 4200Document12 pagesSiemens Pac3200 4200Anonymous Y6Mrs88No ratings yet

- DC-DST4601PX Dichron Eng PDFDocument4 pagesDC-DST4601PX Dichron Eng PDFMarco GardinaliNo ratings yet

- Phoenix Xt150 PsDocument2 pagesPhoenix Xt150 PsJavier Alfonso Fernandez100% (1)

- In Sa2 Ac2 enDocument8 pagesIn Sa2 Ac2 encapry_cornio@yahoo.comNo ratings yet

- Elum ePowerControl HFS Datasheet 102019Document4 pagesElum ePowerControl HFS Datasheet 102019CyrilColin100% (1)

- Air Handling Unit ControllerDocument13 pagesAir Handling Unit ControllerDina AlhossienNo ratings yet

- ECAS Trailer 3Document36 pagesECAS Trailer 3Константин ДубенкоNo ratings yet

- Sentry Hps HT 10-80kvaDocument14 pagesSentry Hps HT 10-80kvaCONTROL ROOM ALL INDIA RADIO HYDERABADNo ratings yet

- Compressor AntiSurge ControlDocument9 pagesCompressor AntiSurge ControlMowaten MasryNo ratings yet

- Sequencer Compressor Module (STD) - 100016166 & ZS1066046Document9 pagesSequencer Compressor Module (STD) - 100016166 & ZS1066046abdur rohman100% (1)

- 01-EDN - Tech Write Up - Valmet DNA PDFDocument16 pages01-EDN - Tech Write Up - Valmet DNA PDFguptakomal08No ratings yet

- Prsu-4 Manual v.2.3Document5 pagesPrsu-4 Manual v.2.3gilangaspNo ratings yet

- 507 ManualDocument2 pages507 ManualEsteban OrtegaNo ratings yet

- Katalog SIMEAS P enDocument9 pagesKatalog SIMEAS P eniwan.satyaNo ratings yet

- TFS 2100eDocument4 pagesTFS 2100eRoyyan Hasmi FadhillahNo ratings yet

- Dsg1611dups Ii 8-06Document47 pagesDsg1611dups Ii 8-06Giang Vuong KhaiNo ratings yet

- PC Software EddyAssist EDocument14 pagesPC Software EddyAssist EizmitlimonNo ratings yet

- Wireless Application GuideDocument16 pagesWireless Application GuideRicardo SantosNo ratings yet

- PMA KSvario Datasheet English 9498 737 47113Document8 pagesPMA KSvario Datasheet English 9498 737 47113Aadil FerozeNo ratings yet

- Tfs 2100e Tfs 2100Document4 pagesTfs 2100e Tfs 2100DucTam Nguyen100% (1)

- Recent Development in The Measurement Techniques: "Strain Gage As Usb Interface" Model 9205 Usb Interface SensorDocument11 pagesRecent Development in The Measurement Techniques: "Strain Gage As Usb Interface" Model 9205 Usb Interface SensorPruthvi CrazeNo ratings yet

- DE 3000 BrochureDocument4 pagesDE 3000 BrochureJerNo ratings yet

- 60 To 60000 Kva SiriusDocument8 pages60 To 60000 Kva SiriusAlemseged HabtamuNo ratings yet

- Powercommand Digital Master Control: FeaturesDocument12 pagesPowercommand Digital Master Control: FeaturesthainarimeNo ratings yet

- Kathrein'S Remote Electrical Tilt System: Overview of Related Products, Installation and Control PossibilitiesDocument20 pagesKathrein'S Remote Electrical Tilt System: Overview of Related Products, Installation and Control PossibilitiesVítor Lopes100% (1)

- Masimu03 SpecDocument9 pagesMasimu03 Specdplatt8162No ratings yet

- Installation GuideDocument65 pagesInstallation GuidesudheervilluriNo ratings yet

- Nuclear Lab StationDocument15 pagesNuclear Lab StationAndré ArayaNo ratings yet

- PegasusDocument3 pagesPegasusagieyogaswaraNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Mechanical Workshop Presenters: Chris Akpan & Adeboye ODocument143 pagesMechanical Workshop Presenters: Chris Akpan & Adeboye OAnie EkpenyongNo ratings yet

- Brochure Alfa Laval Compabloc Ppm00033enDocument8 pagesBrochure Alfa Laval Compabloc Ppm00033enAnie EkpenyongNo ratings yet

- Compabloc 207-235Document248 pagesCompabloc 207-235Anie EkpenyongNo ratings yet

- Compressor Instruction Manual XATS 1050 2654 5440 00 - C9 - LP - EN PDFDocument104 pagesCompressor Instruction Manual XATS 1050 2654 5440 00 - C9 - LP - EN PDFAnie EkpenyongNo ratings yet

- Airtek Preventative Maintenance Guide Rev003 NA July 2013Document81 pagesAirtek Preventative Maintenance Guide Rev003 NA July 2013Anie EkpenyongNo ratings yet

- New Compabloc IMCP0002GDocument37 pagesNew Compabloc IMCP0002GAnie Ekpenyong0% (1)

- Lifting and Mechanical Handling GuidelinesDocument26 pagesLifting and Mechanical Handling GuidelinesAnie Ekpenyong100% (1)

- G3408C and G3412C Engines Operation and Mtce ManualDocument44 pagesG3408C and G3412C Engines Operation and Mtce ManualAnie EkpenyongNo ratings yet

- Technical Information - Spiral Drill Collar SpecificationDocument1 pageTechnical Information - Spiral Drill Collar SpecificationAmirhosseinNo ratings yet

- P-TB23REAB TakeuchiDocument42 pagesP-TB23REAB TakeuchiJUAN MANUEL RUIZ BERMEJONo ratings yet

- Steps in Installing FusionComputeDocument1 pageSteps in Installing FusionComputeanniNo ratings yet

- Video Enhancement With Task-Oriented Flow: Liu and Sun 2011 Baker Et Al 2011 Liu and Freeman 2010Document20 pagesVideo Enhancement With Task-Oriented Flow: Liu and Sun 2011 Baker Et Al 2011 Liu and Freeman 2010Kamal SwamiNo ratings yet

- Philips fwm399-21 22 25 30 Ver1.0Document82 pagesPhilips fwm399-21 22 25 30 Ver1.0JeovannyAlexanderMatamorosSanchezNo ratings yet

- Salesforce Interview QuestionsDocument59 pagesSalesforce Interview Questionskumarvicky87No ratings yet

- How To Remove VSCSI DiskDocument6 pagesHow To Remove VSCSI DiskilovedocNo ratings yet

- VIKING-Water Spray System DesignDocument16 pagesVIKING-Water Spray System Designbonaccorsokar9802100% (2)

- ATV900 CIP Safety Manual EN JYT89146 01Document84 pagesATV900 CIP Safety Manual EN JYT89146 01SándorRónyaiNo ratings yet

- Mba Report SampleDocument78 pagesMba Report Samplesayaliofficial05No ratings yet

- Cover Page Format Research PaperDocument7 pagesCover Page Format Research Paperapeuyqznd100% (1)

- ACFrOgBjzrAQREr25aCEPrVyUvX-WzmD9yYxttgsIUEeDVQVjQqb4v9tRPI1Artyazvis2U26ADZ8q4ARN3Yp 4qK-7YIEqokoCQTBN v0aqwQUmtEPIEXCYusdPwb4ej1jvCdayUdie413 wd9SDocument15 pagesACFrOgBjzrAQREr25aCEPrVyUvX-WzmD9yYxttgsIUEeDVQVjQqb4v9tRPI1Artyazvis2U26ADZ8q4ARN3Yp 4qK-7YIEqokoCQTBN v0aqwQUmtEPIEXCYusdPwb4ej1jvCdayUdie413 wd9SMartin Paul Embile GabitoNo ratings yet

- 12V 55ah 12V 64ah Solar Series: Technical Dimensions (MM)Document3 pages12V 55ah 12V 64ah Solar Series: Technical Dimensions (MM)kerigma75No ratings yet

- Malicious Behavior Detection Using Windows Audit LogsDocument10 pagesMalicious Behavior Detection Using Windows Audit LogsFrancisco BuenoNo ratings yet

- How To Write Case Study PaperDocument3 pagesHow To Write Case Study PaperafibykkhxxhdidNo ratings yet

- Eegame LogcatDocument42 pagesEegame LogcatKelvin AlexanderNo ratings yet

- L02 R02D01 Fos 00 XX DWG Ar 52004Document1 pageL02 R02D01 Fos 00 XX DWG Ar 52004Osama KheadryNo ratings yet

- Form One Bearing and Survey CompiledDocument21 pagesForm One Bearing and Survey Compiledchristinekirimi46No ratings yet

- User Manual: Geforce Gtx10 Series MXM Graphics Board Aetina M3N1050-LN Aetina M3N1050TI-LNDocument29 pagesUser Manual: Geforce Gtx10 Series MXM Graphics Board Aetina M3N1050-LN Aetina M3N1050TI-LNJovino Junior Jr.No ratings yet

- Unit III - Docx-1Document33 pagesUnit III - Docx-1shaikhsahil hafijNo ratings yet

- Chatbot White PaperDocument10 pagesChatbot White PaperVignesh GangulyNo ratings yet

- Crouse Hinds HLL Led BrochureDocument6 pagesCrouse Hinds HLL Led Brochurephúc phạm100% (1)

- MSD 252 Safety Inspection FormDocument11 pagesMSD 252 Safety Inspection FormNitin GoyalNo ratings yet

- Substation Designing BasicsDocument47 pagesSubstation Designing Basicsbhuvana_eee100% (2)

- Section AbstractsDocument35 pagesSection AbstractsAgung Satria WarmanNo ratings yet

- Continuous Dioxin/furan Emission Monitoring by Long-Term SamplingDocument2 pagesContinuous Dioxin/furan Emission Monitoring by Long-Term SamplingJuan David Muriel CastilloNo ratings yet

- Toggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintDocument2 pagesToggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintFelix VelasquezNo ratings yet

- Loop Programming Exercises and Solutions in C - CodeforwinDocument2 pagesLoop Programming Exercises and Solutions in C - CodeforwinyibewodNo ratings yet

- Broadband TransformersDocument26 pagesBroadband TransformersTNo ratings yet