Professional Documents

Culture Documents

Tsurumi Pump Model, Model Pompa Celup

Tsurumi Pump Model, Model Pompa Celup

Uploaded by

arfan rijalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tsurumi Pump Model, Model Pompa Celup

Tsurumi Pump Model, Model Pompa Celup

Uploaded by

arfan rijalCopyright:

Available Formats

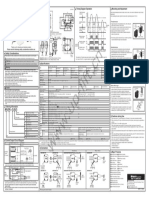

Submersible Wastewater Pumps

PN

Printed on recycled paper with soy ink - Amenities from Technology

Evidence of our commitment to the environment for People and the Earth

Being made of stainless steel and special resin, the PN-series is not only lightweight

but corrosion-resistant as well. The semi-vortex pump design with moderate impeller

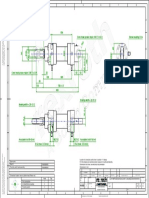

Technical Data PN

■ Performance Curves

S.S. 3000 min-1 S.S. 3600 min-1

passage provides efficient performance for versatile applications. 30 30

25

50 25

60

Hz Hz

① Cable Entry ② Motor ③ Motor Protector 6

20 6 20

Every cabtyre cable has The motor is a dry-type, squirrel-cage induction A built-in thermal motor protection device

Total Head (m)

Total Head (m)

an anti-wicking block at motor, housed in a watertight casing, and con- reacts to the heat caused by overcurrent

the cable entry section forms to insulation class E. All standard pumps or run-dry conditions. It not only cuts off 5

5

15 15

on the pump. This mecha- can be used in ambient temperatures up to 40°C. the motor circuit automatically but also

4 4

nism is such that a part resets by itself. When the motor cools

of each conductor is down to a safe operating temperature, 3 3

10 10

stripped back and the the motor restarts. 2

2

part is sealed by molded

rubber or epoxy potting 5 5 1

1

which has flowed in

between each strand of the conductor. This

unique feature prevents wicking along the 0 0

0 0.2 0.4 0.6 0.8 1.0 0 0.2 0.4 0.6 0.8 1.0

strand of the conductor itself. ① Capacity (m3/min) Capacity (m3/min)

⑤ Mechanical Seal

The mechanical seal with two seal ■ Standard Specifications 50/60Hz

③ faces containing silicon carbide (SiC) is Curve Discharge Standard Automatic Auto-alternation Motor Phase Starting Impeller Cable Cable Dimensions L × H Dry Weight*3

No. Bore Model Model Model Output Method Passage Length Code mm kg

equipped with the oil chamber. The

② advantages of the seal are two-fold, it

Auto &

Standard Auto-alternation Auto &

Standard Auto-alternation

④ Back Pull-Out Design mm kW mm m

eliminates spring failure caused by 40 40PN2.25S 40PNA2.25S 40PNW2.25S 0.25 Single Capacitor

10 5 a 236 × 360 236 × 374 7.1 7.7

Unfastening the bolts between the oil 1

Run

corrosion, abrasion or fouling which

casing and the upper pump casing allows 40 40PN2.25 40PNA2.25 40PNW2.25 0.25 Three D.O.L. 10 6 A 236 × 349 236 × 363 6.1 6.7

prevents the seal faces from closing Capacitor

the body to be separated into the pump 50 50PN2.4S 50PNA2.4S 50PNW2.4S 0.4 Single Run 10 5 a 236 × 360 236 × 374 7.1 7.7

properly, and prevents loss of cooling to 2

section and the motor section with the 50 50PN2.4 50PNA2.4 50PNW2.4 0.4 Three D.O.L. 10 6 A 236 × 360 236 × 374 7.0 7.5

the bottom seal faces during run-dry

impeller left in position. This facilitates 50 50PN2.75S 50PNA2.75S 0.75 Single Capacitor

10 5 a (b*1) 236 × 380 236 × 394 9.0 9.5

conditions which causes the bottom 3

Run

inspections of the main portions. The pump

⑦ seal to fail. 50 50PN2.75 50PNA2.75 50PNW2.75 0.75 Three D.O.L. 10 6 A 236 × 374 236 × 388 8.3 8.8

section can be disassembled/reassembled

4 50 50PN21.5 50PNA21.5 50PNW21.5 1.5 Three D.O.L. 20 6 A 295 × 435 295 × 435 15.9 16.6

using a large Phillips screwdriver.

5 80 80PN22.2 80PNA22.2 80PNW22.2 2.2 Three D.O.L. 20 6 A (C*2) 311 × 559 311 × 559 22.0 23.0

6 80 80PN23.7 80PNA23.7 80PNW23.7 3.7 Three D.O.L. 20 6 C (E*2) 311 × 594 311 × 594 27.0 28.0

⑦ Oil Lifter (Pat. Pending) 1 2 3

* 110~120V * 200~240V * All weights excluding cable

The Oil Lifter was developed as a

lubricating device for the mechanical

seal. Utilizing the centrifugal force of the

shaft seal, the Oil Lifter forcibly supplies

lubricating oil to the mechanical seal ■ Cabtyre Cable Code Reference

H

and continues to supply the oil to the Single-Phase Three-Phase

⑥ ⑤ ④ upper seal faces even if lubricant falls Code Pcs/unit Cores × mm2 Dia. mm Material Code Pcs/unit Cores × mm2 Dia. mm Material

below the rated volume. This amazingly

a 1 3 × 1.25 10.1 A 1 4 × 1.25 11.1

simple device is not only reliably PVC

⑥ Impeller lubricates and cools down, but also

b 1 3 × 2.0 10.9 C 1 4 × 2.0 11.8 PVC

E 1 4 × 3.5 13.9 L

Equipped with a vortex retains the stable shaft seal effect and

impeller with high-gap struc- extends the inspection term.

ture which has a good pas-

sage characteristic and high

pumping performance, these

Optional Accessory

pumps are ideal to transfer

or discharge wastewater con-

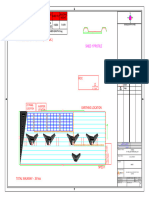

TOK Guide Rail Fitting System

taining impurities. Tsurumi provides TOK-type guide rail fitting system for all PN-series pumps. The fittings connect a pump to, or

separate it from, piping only by lifting the pump up/down. No need to enter in the pump sump for maintenance.

Advantages TOK Application Table

MODEL NUMBER DESIGNATION No Water Leak TOK Model

TOK4-P

Applicable Pump Models

0.25 to 0.75kW Models

Rubber bellows attached to the guide hook are

50 PN A 2 .4 S inverted to the duckfoot bend when the pump starts TOK2-65 Model 50PN21.5

operation. The bellows are kept inverted while the TOK2-65T 2.2 to 3.7kW Models

Discharge bore in millimeters Phase

pump is stopped. This eliminates leaks even if a Contents of TOK

None : Three-phase

Name of the series lightweight pump is connected with the guide hook. • Guide Support with Bolts & Nuts

S : Single-phase

Immune to Rust • Guide Hook

Operation sub code The guide hook, guide support and duckfoot bend are • Duckfoot Bend

None : None automatic operation Rated motor output in kilowatts made of high-quality resin and secured in position with • Lifting Chain with Shackles

A : Automatic operation stainless steel bolts and washers. This prevents (4m for TOK4-P, 5m for TOK2-65 / 65T)

W : Auto-alternation operation Number of poles of the motor corrosion completely.

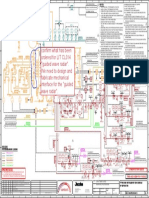

Automatic Model Auto-Alternation Model

Tsurumi automatic models have an Tsurumi also offers auto-alternation model for dual automatic

integral control circuit and two float operations using two pumps at a time. Just combine an ordinary

switches operated at low voltages. automatic model (2 floats) to an auto-alternation model (3 floats).

This enables the two pumps to operate alternately without control

The automatic models are indicated panel.

by the symbol, A, added to the

series name in the model code. The auto-alternation models are identified by the symbol, W, added

They are available in all sizes of to the series name in the model code. They are available in the same

the series. output ranges as those of the ordinary automatic models.

How the Auto-alternation Model Works

● Operation is enabled by merely connecting the power supply.

Primary Operation Secondary Operation

5 4 5

4 3 3

A 1 W 2 A 1 W 2

1. Float 3 operates, and pump W starts to 1. Start float 4 of pump A operates to start

discharge water. water discharge. The pump ends primary

operation, and stops operating.

5 5

4 3 4 3

A 1 W 2 A 1 W 2

2. Water is discharged (water level falls). 2. Water is discharged (water level falls).

5 5

4 4

3 3

A W A W

1 2 1 2

3. Stop float 2 of pump W operates to end 3. Stop float 1 of pump A operates to end

water discharge. At this time, altemation water discharge. At the same time, start

start float 3 of pump W rests for one float 3 of pump W becomes ready for

discharge operation. operation.

※Primary operation and secondary operation are repeated alternately.

※Both primary and secondary operations are performed simultaneously when

water has risen to an abnormal level.

We reserve the right to change the specifications and designs for improvement without prior notice.

Your Dealer

CAT. IA115-F Printed in Japan

DC/NZ-D-L-O

You might also like

- CES Wrong Answer Summary PDFDocument6 pagesCES Wrong Answer Summary PDFAllen Wrench100% (7)

- Reference - Beach-Russ Vacuum Pump OperationDocument2 pagesReference - Beach-Russ Vacuum Pump Operationtpplant100% (2)

- SG6427 Na4030 01 602 N0gad001 092Document2 pagesSG6427 Na4030 01 602 N0gad001 092umer hayatNo ratings yet

- 1-CMZ900 Series-En PDFDocument9 pages1-CMZ900 Series-En PDFDblogic GatesNo ratings yet

- Somoil - Soyo Processing Facilities Debottlenecking - FinalDocument33 pagesSomoil - Soyo Processing Facilities Debottlenecking - FinalHedi Ben MohamedNo ratings yet

- Distributed By: Pt. Elang Mas IndoasiaDocument3 pagesDistributed By: Pt. Elang Mas IndoasiaMuizti RimadhonaNo ratings yet

- ERA Mono PERC 325W 60cDocument1 pageERA Mono PERC 325W 60cAngel M Granados EscalonaNo ratings yet

- NTE Series Electric Actuator Catalogo 2019Document10 pagesNTE Series Electric Actuator Catalogo 2019zcgarciaNo ratings yet

- EPROM Catalogo AiSA D (EN)Document1 pageEPROM Catalogo AiSA D (EN)LeandroNo ratings yet

- gn4000 PsDocument1 pagegn4000 Pszahramtk23No ratings yet

- New Plate 4 Solar 3Document1 pageNew Plate 4 Solar 3yalunglioleiNo ratings yet

- Non-Inverter Ceiling Ducted Spec DimensionDocument1 pageNon-Inverter Ceiling Ducted Spec DimensionrheriNo ratings yet

- Software Tool - Moeller Curveselect: Tripping DiagramDocument5 pagesSoftware Tool - Moeller Curveselect: Tripping DiagramTaner ErtürkNo ratings yet

- 13-NTE Electric Actuator-ENDocument9 pages13-NTE Electric Actuator-ENJennerousNo ratings yet

- ERA 340w PDFDocument1 pageERA 340w PDFSimon Aguado100% (1)

- Design of Solar PVFuel Cell Hybrid Microgrid Power SystemDocument1 pageDesign of Solar PVFuel Cell Hybrid Microgrid Power Systemlaithismail200018No ratings yet

- Tank Datasheet - CS-8000KL - RADocument1 pageTank Datasheet - CS-8000KL - RASumantrra ChattopadhyayNo ratings yet

- Lever 1Document1 pageLever 1balasubramani krishnamurthiNo ratings yet

- Inclined ConveyorDocument1 pageInclined ConveyorShaiju NarayananNo ratings yet

- No Changes AA ICSDocument1 pageNo Changes AA ICSGerges RamzyNo ratings yet

- EXCAVATIONDocument1 pageEXCAVATIONSimranjot KaurNo ratings yet

- Electrical Room: 2041.44 kVA 1219.938 kVA Rated Load Peak Load 2455.471 A 1467.357 ADocument3 pagesElectrical Room: 2041.44 kVA 1219.938 kVA Rated Load Peak Load 2455.471 A 1467.357 ARodrigo Pedraza GalazNo ratings yet

- Ac Cable Length - 25 MTR (Approx.) : Shed 1 ProfileDocument1 pageAc Cable Length - 25 MTR (Approx.) : Shed 1 Profilesarukh.khanNo ratings yet

- High-Bay LED Lighting Fitting: Logistics/Warehouse AreaDocument1 pageHigh-Bay LED Lighting Fitting: Logistics/Warehouse AreaMatíasSosaNo ratings yet

- Clarifier Tank Layout - 250 CMH PDFDocument1 pageClarifier Tank Layout - 250 CMH PDFepe civil1No ratings yet

- Schéma Électrique 923043Document1 pageSchéma Électrique 923043ChriskvaNo ratings yet

- Lecture 25 Inertia Power Flow, GMD Modeling, Black Start PDFDocument55 pagesLecture 25 Inertia Power Flow, GMD Modeling, Black Start PDFManuelNo ratings yet

- 1TB02012 012C06 Acn 01 GF SDW Me 10077 10077Document1 page1TB02012 012C06 Acn 01 GF SDW Me 10077 10077Rafeeq AbdulNo ratings yet

- Pipenet - Training Guide Part 02Document67 pagesPipenet - Training Guide Part 02Michel De Souza CorreaNo ratings yet

- Cherif. Transiet Analysis of Complex Network of Gas Pipeline Compusolry in The Design by Dynamic Simulation.Document9 pagesCherif. Transiet Analysis of Complex Network of Gas Pipeline Compusolry in The Design by Dynamic Simulation.Angel HaroNo ratings yet

- Triode Electronics Aa764 Champ Layout: 5Y3GT 6V6GT 12AX7Document1 pageTriode Electronics Aa764 Champ Layout: 5Y3GT 6V6GT 12AX7Sergio RiveroNo ratings yet

- A Single-Stage Three-Phase Split-Y-Source InverterDocument1 pageA Single-Stage Three-Phase Split-Y-Source InverterManxin ChenNo ratings yet

- HGW 33 630Document1 pageHGW 33 630BAWA ALEXNo ratings yet

- ROFC065330w ADocument1 pageROFC065330w AchetanbakkerNo ratings yet

- Silicon NPN Triple Diffused Planar Transistor: (High Voltage and High Speed Switchihg Transistor)Document1 pageSilicon NPN Triple Diffused Planar Transistor: (High Voltage and High Speed Switchihg Transistor)Angel Simo MoralesNo ratings yet

- Safety Notes: 1 L+ Q M Q 4 3 2 Q 5Document2 pagesSafety Notes: 1 L+ Q M Q 4 3 2 Q 5Quý Đình Mai MaiNo ratings yet

- SBGR - Rnav Amvul 4a Rwy 10l - Sid - 20231005Document1 pageSBGR - Rnav Amvul 4a Rwy 10l - Sid - 20231005sebitadonato1No ratings yet

- Gripspan BrochureDocument12 pagesGripspan BrochureTeknik produksi wikonNo ratings yet

- 3hac042305 040Document1 page3hac042305 040Hwigeun KangNo ratings yet

- Triode Electronics Aa764 Champ Layout: 5Y3GT 6V6GT 12AX7Document1 pageTriode Electronics Aa764 Champ Layout: 5Y3GT 6V6GT 12AX7Sergio RiveroNo ratings yet

- Datasheet PDFDocument1 pageDatasheet PDFRycky de la CruzNo ratings yet

- Tabg Jec 0 000 Pro Pid 0012 - GDocument1 pageTabg Jec 0 000 Pro Pid 0012 - GAfif FadhliNo ratings yet

- DrawingsDocument80 pagesDrawingsQooNo ratings yet

- DrawingsDocument80 pagesDrawingsQooNo ratings yet

- 390 - SSRD2200 - GRILLAGE TYPE S1-Model PDFDocument1 page390 - SSRD2200 - GRILLAGE TYPE S1-Model PDFVictor FernandezNo ratings yet

- Specifications:: Section DDDocument1 pageSpecifications:: Section DDBharani Madamanchi100% (1)

- VR2D 245-4000 + 1xCD 101 - C25036ECDC09 - C PDFDocument6 pagesVR2D 245-4000 + 1xCD 101 - C25036ECDC09 - C PDFAhmed Nasr (By NAZRi)No ratings yet

- Schematic ElectricoDocument1 pageSchematic ElectricoberroslexNo ratings yet

- L08284eng GSDocument2 pagesL08284eng GSLuciernagaNo ratings yet

- Ultrasonic Sensor UC4000-L2-I-V15-Y263652: DimensionsDocument7 pagesUltrasonic Sensor UC4000-L2-I-V15-Y263652: DimensionsClodomiroLoboNo ratings yet

- Pacific ATEX WT470-MI 1Document3 pagesPacific ATEX WT470-MI 1Omar BouamoudNo ratings yet

- SBGR - Rnav Evneb 1a Rwy 28l - Sid - 20220908Document1 pageSBGR - Rnav Evneb 1a Rwy 28l - Sid - 20220908Douglas Souza de MatosNo ratings yet

- A1 Tee Sheet 06 PDFDocument1 pageA1 Tee Sheet 06 PDFArtieres Nataniel R. TeçariNo ratings yet

- Amarex N S 32 DataDocument2 pagesAmarex N S 32 DataRamly MyzharNo ratings yet

- Helipad Plan 1:200 Scale: Float Finished Margins To Helipad Brushed Concrete With 100MmDocument1 pageHelipad Plan 1:200 Scale: Float Finished Margins To Helipad Brushed Concrete With 100MmAhmed AsimNo ratings yet

- Autonics BEN10M-TFR Details, Control Output Circuit Diagram, Specifications, Connection - Mounting and AdjustmentDocument1 pageAutonics BEN10M-TFR Details, Control Output Circuit Diagram, Specifications, Connection - Mounting and AdjustmentRebecca DangNo ratings yet

- Operation Manual: Fieldbus DeviceDocument1 pageOperation Manual: Fieldbus DeviceRodrigo CostaNo ratings yet

- 18wattamp PDFDocument1 page18wattamp PDFleolamiaNo ratings yet

- Solenoid Valve 3V Series Air Valve 3A Series: Pneumatic PneumaticDocument8 pagesSolenoid Valve 3V Series Air Valve 3A Series: Pneumatic PneumaticVivin Welroy RodriguesNo ratings yet

- GA37 SchematicsDocument18 pagesGA37 Schematicstechbiomed100% (1)

- SGM2-450W (Rigid Panel)Document1 pageSGM2-450W (Rigid Panel)Soundar MXNo ratings yet

- 4B-33652 00 L3PD 000Document35 pages4B-33652 00 L3PD 000arfan rijalNo ratings yet

- M O IHM Digital BrochureDocument7 pagesM O IHM Digital Brochurearfan rijalNo ratings yet

- Click On Start Test.: AA) ) PROCEDURE To Complete Online TrainingDocument2 pagesClick On Start Test.: AA) ) PROCEDURE To Complete Online Trainingarfan rijalNo ratings yet

- Mengelola Pengoperasian Peralatan MesinDocument96 pagesMengelola Pengoperasian Peralatan Mesinarfan rijalNo ratings yet

- Pump Sizing Calculation SheetDocument20 pagesPump Sizing Calculation Sheetvazzoleralex6884100% (1)

- Isuzu 4JA1 Section 6Document249 pagesIsuzu 4JA1 Section 6Niti KlinKaew100% (1)

- SPTools MayJuneDocument24 pagesSPTools MayJuneRiverland Welding and Tool SuppliesNo ratings yet

- Manual Book Gambro cp12Document104 pagesManual Book Gambro cp12Wahyu Setyo PNo ratings yet

- Training - Flowserve Apm Pump CW PumpDocument19 pagesTraining - Flowserve Apm Pump CW Pumphasan099100% (1)

- Alto Marine CatalogDocument35 pagesAlto Marine CatalogdavidNo ratings yet

- Pumps Vs AgitatorAsd F DsfsDocument5 pagesPumps Vs AgitatorAsd F DsfsMARK LESTER REALNo ratings yet

- pt3 4diaphragm DrumPumpsDocument29 pagespt3 4diaphragm DrumPumpsMatthew NievesNo ratings yet

- POY TroubleshooterDocument2 pagesPOY TroubleshooterKağan Ayşe AyanNo ratings yet

- SMC™-50 Solid-State Smart Motor Controller: Selection GuideDocument58 pagesSMC™-50 Solid-State Smart Motor Controller: Selection GuideYusef Nome C.No ratings yet

- Chapter 5 Positive Displacement MachinesDocument43 pagesChapter 5 Positive Displacement MachinesCh. Muhammad Usama50% (2)

- Presentations - DeWatering With ESPDocument31 pagesPresentations - DeWatering With ESPBambang Hadinugroho100% (1)

- Root Cause AnalysisDocument1 pageRoot Cause AnalysisSick LoveNo ratings yet

- Specification Titon 600 Bpi 0906 Acert&CumminsDocument5 pagesSpecification Titon 600 Bpi 0906 Acert&CumminsElfer Angell MllNo ratings yet

- Leybold D40B D65B 11286 11296 ManualDocument60 pagesLeybold D40B D65B 11286 11296 ManualBabak MahaniNo ratings yet

- Toma Presion de Bomba AceiteDocument1 pageToma Presion de Bomba Aceitetonomart79No ratings yet

- Two Stage High/Low Hydraulic Pumps: Concentric ABDocument8 pagesTwo Stage High/Low Hydraulic Pumps: Concentric ABZakNo ratings yet

- RR300 Recuperadora de PavimentoDocument16 pagesRR300 Recuperadora de PavimentoJulio Cesar Izquierdo MadrigalNo ratings yet

- Changes From Model 3: Overall SpecificationsDocument50 pagesChanges From Model 3: Overall SpecificationsRoyenNo ratings yet

- A4VG Series 40 Data SheetDocument72 pagesA4VG Series 40 Data SheetsalesNo ratings yet

- Residential Pool/Spa - Fact Sheet: Community Development DepartmentDocument6 pagesResidential Pool/Spa - Fact Sheet: Community Development DepartmentdapsiduNo ratings yet

- HOS - PG1028E Mar2003Document164 pagesHOS - PG1028E Mar2003David QuijanoNo ratings yet

- 3.2 Design & Procure Ment DataDocument8 pages3.2 Design & Procure Ment DataBhaumik BhuvaNo ratings yet

- 10 001 Krebs millMAX Centrifugal Slurry Pumps 2017 PDFDocument8 pages10 001 Krebs millMAX Centrifugal Slurry Pumps 2017 PDFNicolas BaquedanoNo ratings yet

- Hydraulic Brake Control Unit 3000-0100-801Document29 pagesHydraulic Brake Control Unit 3000-0100-801Freddy DenmarkNo ratings yet

- UseMaintanceManual NEF MechInjection L31900009E Oct05 PDFDocument43 pagesUseMaintanceManual NEF MechInjection L31900009E Oct05 PDFJosé David Barrios PadrónNo ratings yet

- Pre Spud Checklist 4Document2 pagesPre Spud Checklist 4Ali Alakari100% (1)

- Mix Design and Pumped ConcreteDocument13 pagesMix Design and Pumped ConcreteLimbu Niwa Lawahang100% (1)