Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

17 views3 Laminated Safety Glass

3 Laminated Safety Glass

Uploaded by

Zhy RazalasThis document discusses laminated glass and its manufacturing process and applications. It begins by describing the accidental discovery of laminated glass and its use in car windshields after WWII. It then explains the lamination process involving washing glass, sandwiching a PVB interlayer between glasses, and heating under pressure. Key benefits of laminated glass are safety from broken glass bonding, sound reduction from the interlayer, UV elimination, security, and heat/glare control. Applications include overhead glazing, balustrades, mirrors, blast resistance, and anti-bandit protection. Specialized laminates are discussed for cyclone resistance and high impact performance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- GUMMIDIPOONDIDocument9 pagesGUMMIDIPOONDIAshwin Krishnamurthy83% (6)

- Building Materials: Glass & Plastics: by Sanjula Maheshwari ARC048Document20 pagesBuilding Materials: Glass & Plastics: by Sanjula Maheshwari ARC048Sanjula MaheshwariNo ratings yet

- glass-BMCT FINALDocument19 pagesglass-BMCT FINALAishwarya ChauhanNo ratings yet

- Unit 1 Manufactured Building MaterialsDocument37 pagesUnit 1 Manufactured Building MaterialssamairaNo ratings yet

- 4.glass - Module 4Document47 pages4.glass - Module 4aqsam aliNo ratings yet

- Lecture 09-10 - Division 08 - Division 09Document126 pagesLecture 09-10 - Division 08 - Division 09Via AnapiNo ratings yet

- Glass As A BLDG MaterialDocument21 pagesGlass As A BLDG Materialmegha rajNo ratings yet

- Part 2 GlassDocument13 pagesPart 2 GlassLenard UsonNo ratings yet

- Materiale Sunworker CristalDocument6 pagesMateriale Sunworker Cristalaurelian paiusNo ratings yet

- Designing The Grand Canyon's New Laminated Glass Walkway: 2.2 InterlayersDocument3 pagesDesigning The Grand Canyon's New Laminated Glass Walkway: 2.2 InterlayersPaloma ValeNo ratings yet

- GlassDocument32 pagesGlassSakshi Pawar50% (2)

- Material, Techniques AND Processess: Group - 1Document18 pagesMaterial, Techniques AND Processess: Group - 1Kavya SharmaNo ratings yet

- 9999 112 32 Glass NotesDocument39 pages9999 112 32 Glass NotesDheeshna DileepNo ratings yet

- Glass and GlazingDocument8 pagesGlass and GlazingAnna KateurinaNo ratings yet

- PVB Laminated Glass & Tempered GlassDocument14 pagesPVB Laminated Glass & Tempered GlassSamantha Lim Ai PeiNo ratings yet

- 5.0 Windows and Window FramesDocument29 pages5.0 Windows and Window FramesvictorNo ratings yet

- Glass and Glazing BMCDocument13 pagesGlass and Glazing BMCSarangi NairNo ratings yet

- Glass PresentationDocument67 pagesGlass PresentationLKP GhNo ratings yet

- Types of GlassDocument15 pagesTypes of Glassiqmalharith1401No ratings yet

- MMBC Mod1 GlasssssDocument44 pagesMMBC Mod1 GlasssssNiveditha BalachandranNo ratings yet

- Toughened Glass - WikipediaDocument5 pagesToughened Glass - Wikipediaramthecharm_46098467No ratings yet

- World-Leading Skylights and Roof Windows: Product Information and Price List 1st April 2020Document16 pagesWorld-Leading Skylights and Roof Windows: Product Information and Price List 1st April 2020Toni Rose Peliño CaNo ratings yet

- High Voltage InsulatorsDocument13 pagesHigh Voltage InsulatorsDebojyotiMukherjeeNo ratings yet

- Product Elastakote Oct18Document1 pageProduct Elastakote Oct18DWI RAHMASARI FATMAWATINo ratings yet

- Waterproofing, Bitumen, GlazingDocument19 pagesWaterproofing, Bitumen, GlazingShubhani ChandraNo ratings yet

- 8 - Glass and TimberDocument17 pages8 - Glass and TimberSyed Muzamil AhmedNo ratings yet

- Glass Properties FinalDocument13 pagesGlass Properties FinalSAURABH KUMAR SINGHNo ratings yet

- Chapter 4: Advantages and Disadvantages of The ProcessDocument8 pagesChapter 4: Advantages and Disadvantages of The ProcessAida SuhanumNo ratings yet

- Lecture 2 - EIFS - SmallerDocument89 pagesLecture 2 - EIFS - SmallertrungNo ratings yet

- 1 Getting To Know GlassDocument47 pages1 Getting To Know GlassZhy RazalasNo ratings yet

- Thermal Insulation: Akanksha Bhakare Sy. B.VocDocument14 pagesThermal Insulation: Akanksha Bhakare Sy. B.VocAkanksha BhakareNo ratings yet

- 1 GlassDocument45 pages1 GlassIkhwan BudimanNo ratings yet

- Selection of Right Cladding Material For PolyhouseDocument45 pagesSelection of Right Cladding Material For Polyhousepink girlNo ratings yet

- Types of Glass and Its Engineering Properties For Use in ConstructionDocument10 pagesTypes of Glass and Its Engineering Properties For Use in ConstructionKristineNo ratings yet

- Building Construction ArchitectureDocument5 pagesBuilding Construction ArchitectureRHYME KIDSNo ratings yet

- Report 2 Glass and Glazing PDFDocument76 pagesReport 2 Glass and Glazing PDFJerome DacasinNo ratings yet

- Hardware For GlassesDocument11 pagesHardware For GlassesSarinNo ratings yet

- Saint Gobain Glass Protection PDFDocument20 pagesSaint Gobain Glass Protection PDFAnonymous t83HjAvXNo ratings yet

- Professional Silicone Sealants: Dow CorningDocument4 pagesProfessional Silicone Sealants: Dow CorninggabyorNo ratings yet

- GLASSDocument21 pagesGLASSSachin Kumar PatelNo ratings yet

- Nitocote Wall Guard: Elastomeric & Decorative Acrylic Waterproof-Ing Coating For Exterior WallsDocument4 pagesNitocote Wall Guard: Elastomeric & Decorative Acrylic Waterproof-Ing Coating For Exterior Wallsaneesh kapaNo ratings yet

- 02 PGBC - Chapter 2.1Document82 pages02 PGBC - Chapter 2.1Klyo NismalNo ratings yet

- Glass: Construction & MaterialsDocument7 pagesGlass: Construction & MaterialsRachit AgarwalNo ratings yet

- Open Your Webcams Upon Entering The Online ClassDocument24 pagesOpen Your Webcams Upon Entering The Online ClassXyra Airysh InandanNo ratings yet

- Design Consideration of Facade Wall SystemDocument5 pagesDesign Consideration of Facade Wall SystemPrantik Adhar SamantaNo ratings yet

- Building Construction: Report OnDocument15 pagesBuilding Construction: Report Ony2kareinNo ratings yet

- Glasses in ConstructionDocument18 pagesGlasses in Constructionanasali786mughalaliNo ratings yet

- GlassDocument14 pagesGlassJithendra Jagadish22No ratings yet

- Which Interlayer For Which Glazing Application - Bjo RN SandenDocument5 pagesWhich Interlayer For Which Glazing Application - Bjo RN SandenKrzysztof HarasimowiczNo ratings yet

- BMC Unit1Document59 pagesBMC Unit1Mythili MadhusudhanNo ratings yet

- Information Sheet 6 - Heat Soak Tested Thermally Toughened Glass - April 2016Document2 pagesInformation Sheet 6 - Heat Soak Tested Thermally Toughened Glass - April 2016Khurshed Alam IndiaNo ratings yet

- I. Module 1 Title: Glass and Glazing Building TechnologyDocument9 pagesI. Module 1 Title: Glass and Glazing Building Technologydee jay100% (1)

- TDS Decofill India3Document2 pagesTDS Decofill India3omkarborde2313No ratings yet

- World-Leading Skylights and Roof Windows: Product Information and Price List 2018Document16 pagesWorld-Leading Skylights and Roof Windows: Product Information and Price List 2018nick rourkeNo ratings yet

- CaseStudy - Hudson - 98 0150 0813 3Document2 pagesCaseStudy - Hudson - 98 0150 0813 3IhabNo ratings yet

- GlassDocument5 pagesGlassmaggy mamdouhNo ratings yet

- Market SurveyDocument29 pagesMarket SurveyreetNo ratings yet

- Laboratory Manual of Glass-BlowingFrom EverandLaboratory Manual of Glass-BlowingRating: 5 out of 5 stars5/5 (1)

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet

- 5 Curved Toughened GlassDocument5 pages5 Curved Toughened GlassZhy RazalasNo ratings yet

- 4 Heat Treated GlassDocument13 pages4 Heat Treated GlassZhy RazalasNo ratings yet

- 2 Float GlassDocument3 pages2 Float GlassZhy RazalasNo ratings yet

- 1 Getting To Know GlassDocument47 pages1 Getting To Know GlassZhy RazalasNo ratings yet

- AISI 1045 Medium Carbon SteelDocument3 pagesAISI 1045 Medium Carbon SteelDodi SuhendraNo ratings yet

- MTH - Spec Cross-Ref Chartr1Document1 pageMTH - Spec Cross-Ref Chartr1RamuAlagappanNo ratings yet

- A Presentation ON: Study of Effect of Silica Fume & Nano Silica On Mechanical Properties of High Performance ConcreteDocument7 pagesA Presentation ON: Study of Effect of Silica Fume & Nano Silica On Mechanical Properties of High Performance ConcretePrathamesh MoreNo ratings yet

- 2 Concrete (Hand Mixed)Document10 pages2 Concrete (Hand Mixed)Cloud NyeinNo ratings yet

- DIV-07 Labor (Thermal - Moisture Protection)Document13 pagesDIV-07 Labor (Thermal - Moisture Protection)Ajaya KumarNo ratings yet

- Cojet-Installation-At-Sumikin-Steel PraxairDocument12 pagesCojet-Installation-At-Sumikin-Steel PraxairDanilo HoskenNo ratings yet

- Tds Dexcoat 1 (En)Document2 pagesTds Dexcoat 1 (En)Phuong The NguyenNo ratings yet

- High Performance Laminated GlassDocument8 pagesHigh Performance Laminated GlassRafael de OliveiraNo ratings yet

- Full Download Biochemistry 4th Edition Mathews Test BankDocument5 pagesFull Download Biochemistry 4th Edition Mathews Test Bankaydynkaoh100% (44)

- Design of Column Base Plate: COLUMN 1 (C-1) COLUMN 1a (C-1')Document6 pagesDesign of Column Base Plate: COLUMN 1 (C-1) COLUMN 1a (C-1')andre villanuevaNo ratings yet

- 2016 BASF ArchitecturalCoatingsBrochure ELDocument64 pages2016 BASF ArchitecturalCoatingsBrochure ELLong An DoNo ratings yet

- Attachment 3. Unit RateDocument2 pagesAttachment 3. Unit RateMuhamad AlfarisiNo ratings yet

- Gulf Perlite Ready Mixed Perlite ConcreteDocument4 pagesGulf Perlite Ready Mixed Perlite Concreteosama feilatNo ratings yet

- Adva Antislip TdsDocument2 pagesAdva Antislip TdsMohammed AbugharbiehNo ratings yet

- ProjectDocument34 pagesProjectfaisalmir27100% (1)

- Whatman Uniflo Syringe Filters: Consistent Performance. Maximum ValueDocument7 pagesWhatman Uniflo Syringe Filters: Consistent Performance. Maximum ValueKarinNo ratings yet

- Ice Melt Buyer'S Guide Ice Melt Buyer'S GuideDocument7 pagesIce Melt Buyer'S Guide Ice Melt Buyer'S GuidelyndondrNo ratings yet

- Mind Mapping of WeldingDocument8 pagesMind Mapping of WeldingFadlanbunglonNo ratings yet

- Silicone Fluids Stable Inert MediaDocument32 pagesSilicone Fluids Stable Inert MediachayanunNo ratings yet

- I Construction of 1 No. RCC Reservoir) With Connections of GI Pipes &Document47 pagesI Construction of 1 No. RCC Reservoir) With Connections of GI Pipes &yamanta_rajNo ratings yet

- Nickel Iron BatteryDocument229 pagesNickel Iron Batterygunawansigi36No ratings yet

- Water ProofDocument3 pagesWater ProofMohamed KhanNo ratings yet

- Evolen B80 C EN - GBDocument3 pagesEvolen B80 C EN - GBchrisNo ratings yet

- Iron - Direct Reduction ProcessDocument39 pagesIron - Direct Reduction ProcessSheila Mae GardonNo ratings yet

- Humes ConcretePipeManualDocument67 pagesHumes ConcretePipeManualKhusairy AhmadNo ratings yet

- Lecture 1Document22 pagesLecture 1Amit Narayan RaiNo ratings yet

- SpecialChem - Coalescing Agents in Coatings - Definition, Types & PropertiesDocument5 pagesSpecialChem - Coalescing Agents in Coatings - Definition, Types & Propertiesichsan hakimNo ratings yet

- Rolled Zinc: Standard Specification ForDocument4 pagesRolled Zinc: Standard Specification ForAadhya engineering ServicesNo ratings yet

- Reverse OsmosisDocument131 pagesReverse OsmosisTaufiqTaufiq100% (6)

3 Laminated Safety Glass

3 Laminated Safety Glass

Uploaded by

Zhy Razalas0 ratings0% found this document useful (0 votes)

17 views4 pagesThis document discusses laminated glass and its manufacturing process and applications. It begins by describing the accidental discovery of laminated glass and its use in car windshields after WWII. It then explains the lamination process involving washing glass, sandwiching a PVB interlayer between glasses, and heating under pressure. Key benefits of laminated glass are safety from broken glass bonding, sound reduction from the interlayer, UV elimination, security, and heat/glare control. Applications include overhead glazing, balustrades, mirrors, blast resistance, and anti-bandit protection. Specialized laminates are discussed for cyclone resistance and high impact performance.

Original Description:

Original Title

3 LAMINATED SAFETY GLASS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses laminated glass and its manufacturing process and applications. It begins by describing the accidental discovery of laminated glass and its use in car windshields after WWII. It then explains the lamination process involving washing glass, sandwiching a PVB interlayer between glasses, and heating under pressure. Key benefits of laminated glass are safety from broken glass bonding, sound reduction from the interlayer, UV elimination, security, and heat/glare control. Applications include overhead glazing, balustrades, mirrors, blast resistance, and anti-bandit protection. Specialized laminates are discussed for cyclone resistance and high impact performance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

17 views4 pages3 Laminated Safety Glass

3 Laminated Safety Glass

Uploaded by

Zhy RazalasThis document discusses laminated glass and its manufacturing process and applications. It begins by describing the accidental discovery of laminated glass and its use in car windshields after WWII. It then explains the lamination process involving washing glass, sandwiching a PVB interlayer between glasses, and heating under pressure. Key benefits of laminated glass are safety from broken glass bonding, sound reduction from the interlayer, UV elimination, security, and heat/glare control. Applications include overhead glazing, balustrades, mirrors, blast resistance, and anti-bandit protection. Specialized laminates are discussed for cyclone resistance and high impact performance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

3.1 INTRODUCTION G.

James produce laminated glass

covering the full spectrum from basic 2 ply

• In 1903 French chemist Edward Benedictus

clear laminates, through tinted, reflective to

accidentally broke a bottle of cellulose acetate

multiply, bandit and bullet resistant, and

in his laboratory. As a result, he discovered that

very high impact performance products.

the cellulose, on hardening, held the fragments

of glass together.

• Further development by Dupont and Monsanto

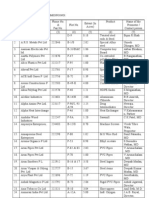

led to the use of laminated windscreens in cars Table 3.2a: Manufacturing Capabilities

after the Second World War.

Minimum Maximum

3.2 PROCESS

Thickness 5.38mm 50mm

• The glass being thoroughly

washed and dried before passing into an

Size 100mm x 100mm 2440mm x 3660mm

airconditioned ‘clean room’.

• A PVB interlayer, initially translucent in

appearance, is sandwiched between the

glass(es) which then pass through pressurised

rollers and heating ovens

• The glass is then autoclaved where it is again

heated and subjected to extreme pressure

3.3 BENEFITS

SAFETY SOUND REDUCTION UV ELIMINATION

• The glass and interlayer combine to absorb • For most applications, laminated glass • The PVB interlayer filters the

the force of the impact Should the impact provides an effective, low cost method sun eliminating up to 99% of

be sufficient to break the glass, the of reducing the transmission of noise UV rays while allowing the

resulting fragments typically remain intact, through the glass

important visible light to

firmly adhered to the PVB interlayer. • Achieved through the ‘viscoelastic’

• This important characteristic significantly properties of the PVB interlayer which pass through.

reduces the likelihood of serious injury dampens the coincidence dip (See

qualifying laminated glass as a Grade A Section 1.14) in the mid to high

safety glass. frequency range (1000 - 2000 Hz)

SECURITY HEAT AND GLARE CONTROL LOW VISIBLE DISTORTION

• The interlayer will resist penetration • Can reduce heat gain by absorbing this • Facades glazed with

ensuring any attempt to enter the premises radiated heat while simultaneously cutting laminated, annealed glass avoid

will be slow and noisy. down the amount of glare that occurs with the risk of visible distortions,

• Also, if attacked the glass will tend to remain high levels of natural light. providing significantly sharper

in the opening, keeping wind and rain out of • Lower costs associated with cooling the

reflections.

the building until it can be replaced at a interior.

convenient time.

3.5 OPTILIGHT

3.4 APPLICATIONS • Offer optimum light transmission, reduced

solar heat gain/loss and minimum

The many features and possible configurations reflectance while maintaining the natural

of laminated glass combine to provide a toning of the glass.

product that has a wide and varied range of • Optilight provides a cost-effective

applications: product with proven durability, reliability

• Overhead glazing, skylights and rooflights and service ability.

• Glazed areas surrounding gymnasiums • Suitable for vision

and swimming pools and overhead glazing applications

• Glass balustrading and lift wells

• Shower screens, mirrors, sliding doors

and sidelights

• Shopping centers, offices and banks

• Hospitals, schools and libraries

• Aquariums and zoos

• Jails, embassies and security vehicles

• Blast resistant glazing

3.4 CYCLONE RESISTANT LAMINATE 3.7 ANTI-BANDIT GLASS

• Designed to resist penetration of flying • Increased thickness of

debris and maintain clear vision interlayer which foil attacks from

(dependent on glass configuration) in the such items as bricks, hammers and

event of breakage. axes

• Held captive in a suitable framing system • Held captive in a suitable framing

to prevent the glass from evacuating the system to prevent

building when subjected to severe storm the glass evacuating the building

and cyclone conditions. when subjected to an attack.

• Meets the requirement of resisting

penetration from impact of a 4kg, 50mm x

100mm timber plank on end, travelling at

3.8 CHARACTERISTICS

15mtrs/sec. This is equivalent to an impact • Edge Delamination

Energy of 450J. the glass edges are exposed,

delamination is the result of a

breakdown in the bond between

the polyvinyl butyral interlayer and

the glass

You might also like

- GUMMIDIPOONDIDocument9 pagesGUMMIDIPOONDIAshwin Krishnamurthy83% (6)

- Building Materials: Glass & Plastics: by Sanjula Maheshwari ARC048Document20 pagesBuilding Materials: Glass & Plastics: by Sanjula Maheshwari ARC048Sanjula MaheshwariNo ratings yet

- glass-BMCT FINALDocument19 pagesglass-BMCT FINALAishwarya ChauhanNo ratings yet

- Unit 1 Manufactured Building MaterialsDocument37 pagesUnit 1 Manufactured Building MaterialssamairaNo ratings yet

- 4.glass - Module 4Document47 pages4.glass - Module 4aqsam aliNo ratings yet

- Lecture 09-10 - Division 08 - Division 09Document126 pagesLecture 09-10 - Division 08 - Division 09Via AnapiNo ratings yet

- Glass As A BLDG MaterialDocument21 pagesGlass As A BLDG Materialmegha rajNo ratings yet

- Part 2 GlassDocument13 pagesPart 2 GlassLenard UsonNo ratings yet

- Materiale Sunworker CristalDocument6 pagesMateriale Sunworker Cristalaurelian paiusNo ratings yet

- Designing The Grand Canyon's New Laminated Glass Walkway: 2.2 InterlayersDocument3 pagesDesigning The Grand Canyon's New Laminated Glass Walkway: 2.2 InterlayersPaloma ValeNo ratings yet

- GlassDocument32 pagesGlassSakshi Pawar50% (2)

- Material, Techniques AND Processess: Group - 1Document18 pagesMaterial, Techniques AND Processess: Group - 1Kavya SharmaNo ratings yet

- 9999 112 32 Glass NotesDocument39 pages9999 112 32 Glass NotesDheeshna DileepNo ratings yet

- Glass and GlazingDocument8 pagesGlass and GlazingAnna KateurinaNo ratings yet

- PVB Laminated Glass & Tempered GlassDocument14 pagesPVB Laminated Glass & Tempered GlassSamantha Lim Ai PeiNo ratings yet

- 5.0 Windows and Window FramesDocument29 pages5.0 Windows and Window FramesvictorNo ratings yet

- Glass and Glazing BMCDocument13 pagesGlass and Glazing BMCSarangi NairNo ratings yet

- Glass PresentationDocument67 pagesGlass PresentationLKP GhNo ratings yet

- Types of GlassDocument15 pagesTypes of Glassiqmalharith1401No ratings yet

- MMBC Mod1 GlasssssDocument44 pagesMMBC Mod1 GlasssssNiveditha BalachandranNo ratings yet

- Toughened Glass - WikipediaDocument5 pagesToughened Glass - Wikipediaramthecharm_46098467No ratings yet

- World-Leading Skylights and Roof Windows: Product Information and Price List 1st April 2020Document16 pagesWorld-Leading Skylights and Roof Windows: Product Information and Price List 1st April 2020Toni Rose Peliño CaNo ratings yet

- High Voltage InsulatorsDocument13 pagesHigh Voltage InsulatorsDebojyotiMukherjeeNo ratings yet

- Product Elastakote Oct18Document1 pageProduct Elastakote Oct18DWI RAHMASARI FATMAWATINo ratings yet

- Waterproofing, Bitumen, GlazingDocument19 pagesWaterproofing, Bitumen, GlazingShubhani ChandraNo ratings yet

- 8 - Glass and TimberDocument17 pages8 - Glass and TimberSyed Muzamil AhmedNo ratings yet

- Glass Properties FinalDocument13 pagesGlass Properties FinalSAURABH KUMAR SINGHNo ratings yet

- Chapter 4: Advantages and Disadvantages of The ProcessDocument8 pagesChapter 4: Advantages and Disadvantages of The ProcessAida SuhanumNo ratings yet

- Lecture 2 - EIFS - SmallerDocument89 pagesLecture 2 - EIFS - SmallertrungNo ratings yet

- 1 Getting To Know GlassDocument47 pages1 Getting To Know GlassZhy RazalasNo ratings yet

- Thermal Insulation: Akanksha Bhakare Sy. B.VocDocument14 pagesThermal Insulation: Akanksha Bhakare Sy. B.VocAkanksha BhakareNo ratings yet

- 1 GlassDocument45 pages1 GlassIkhwan BudimanNo ratings yet

- Selection of Right Cladding Material For PolyhouseDocument45 pagesSelection of Right Cladding Material For Polyhousepink girlNo ratings yet

- Types of Glass and Its Engineering Properties For Use in ConstructionDocument10 pagesTypes of Glass and Its Engineering Properties For Use in ConstructionKristineNo ratings yet

- Building Construction ArchitectureDocument5 pagesBuilding Construction ArchitectureRHYME KIDSNo ratings yet

- Report 2 Glass and Glazing PDFDocument76 pagesReport 2 Glass and Glazing PDFJerome DacasinNo ratings yet

- Hardware For GlassesDocument11 pagesHardware For GlassesSarinNo ratings yet

- Saint Gobain Glass Protection PDFDocument20 pagesSaint Gobain Glass Protection PDFAnonymous t83HjAvXNo ratings yet

- Professional Silicone Sealants: Dow CorningDocument4 pagesProfessional Silicone Sealants: Dow CorninggabyorNo ratings yet

- GLASSDocument21 pagesGLASSSachin Kumar PatelNo ratings yet

- Nitocote Wall Guard: Elastomeric & Decorative Acrylic Waterproof-Ing Coating For Exterior WallsDocument4 pagesNitocote Wall Guard: Elastomeric & Decorative Acrylic Waterproof-Ing Coating For Exterior Wallsaneesh kapaNo ratings yet

- 02 PGBC - Chapter 2.1Document82 pages02 PGBC - Chapter 2.1Klyo NismalNo ratings yet

- Glass: Construction & MaterialsDocument7 pagesGlass: Construction & MaterialsRachit AgarwalNo ratings yet

- Open Your Webcams Upon Entering The Online ClassDocument24 pagesOpen Your Webcams Upon Entering The Online ClassXyra Airysh InandanNo ratings yet

- Design Consideration of Facade Wall SystemDocument5 pagesDesign Consideration of Facade Wall SystemPrantik Adhar SamantaNo ratings yet

- Building Construction: Report OnDocument15 pagesBuilding Construction: Report Ony2kareinNo ratings yet

- Glasses in ConstructionDocument18 pagesGlasses in Constructionanasali786mughalaliNo ratings yet

- GlassDocument14 pagesGlassJithendra Jagadish22No ratings yet

- Which Interlayer For Which Glazing Application - Bjo RN SandenDocument5 pagesWhich Interlayer For Which Glazing Application - Bjo RN SandenKrzysztof HarasimowiczNo ratings yet

- BMC Unit1Document59 pagesBMC Unit1Mythili MadhusudhanNo ratings yet

- Information Sheet 6 - Heat Soak Tested Thermally Toughened Glass - April 2016Document2 pagesInformation Sheet 6 - Heat Soak Tested Thermally Toughened Glass - April 2016Khurshed Alam IndiaNo ratings yet

- I. Module 1 Title: Glass and Glazing Building TechnologyDocument9 pagesI. Module 1 Title: Glass and Glazing Building Technologydee jay100% (1)

- TDS Decofill India3Document2 pagesTDS Decofill India3omkarborde2313No ratings yet

- World-Leading Skylights and Roof Windows: Product Information and Price List 2018Document16 pagesWorld-Leading Skylights and Roof Windows: Product Information and Price List 2018nick rourkeNo ratings yet

- CaseStudy - Hudson - 98 0150 0813 3Document2 pagesCaseStudy - Hudson - 98 0150 0813 3IhabNo ratings yet

- GlassDocument5 pagesGlassmaggy mamdouhNo ratings yet

- Market SurveyDocument29 pagesMarket SurveyreetNo ratings yet

- Laboratory Manual of Glass-BlowingFrom EverandLaboratory Manual of Glass-BlowingRating: 5 out of 5 stars5/5 (1)

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet

- 5 Curved Toughened GlassDocument5 pages5 Curved Toughened GlassZhy RazalasNo ratings yet

- 4 Heat Treated GlassDocument13 pages4 Heat Treated GlassZhy RazalasNo ratings yet

- 2 Float GlassDocument3 pages2 Float GlassZhy RazalasNo ratings yet

- 1 Getting To Know GlassDocument47 pages1 Getting To Know GlassZhy RazalasNo ratings yet

- AISI 1045 Medium Carbon SteelDocument3 pagesAISI 1045 Medium Carbon SteelDodi SuhendraNo ratings yet

- MTH - Spec Cross-Ref Chartr1Document1 pageMTH - Spec Cross-Ref Chartr1RamuAlagappanNo ratings yet

- A Presentation ON: Study of Effect of Silica Fume & Nano Silica On Mechanical Properties of High Performance ConcreteDocument7 pagesA Presentation ON: Study of Effect of Silica Fume & Nano Silica On Mechanical Properties of High Performance ConcretePrathamesh MoreNo ratings yet

- 2 Concrete (Hand Mixed)Document10 pages2 Concrete (Hand Mixed)Cloud NyeinNo ratings yet

- DIV-07 Labor (Thermal - Moisture Protection)Document13 pagesDIV-07 Labor (Thermal - Moisture Protection)Ajaya KumarNo ratings yet

- Cojet-Installation-At-Sumikin-Steel PraxairDocument12 pagesCojet-Installation-At-Sumikin-Steel PraxairDanilo HoskenNo ratings yet

- Tds Dexcoat 1 (En)Document2 pagesTds Dexcoat 1 (En)Phuong The NguyenNo ratings yet

- High Performance Laminated GlassDocument8 pagesHigh Performance Laminated GlassRafael de OliveiraNo ratings yet

- Full Download Biochemistry 4th Edition Mathews Test BankDocument5 pagesFull Download Biochemistry 4th Edition Mathews Test Bankaydynkaoh100% (44)

- Design of Column Base Plate: COLUMN 1 (C-1) COLUMN 1a (C-1')Document6 pagesDesign of Column Base Plate: COLUMN 1 (C-1) COLUMN 1a (C-1')andre villanuevaNo ratings yet

- 2016 BASF ArchitecturalCoatingsBrochure ELDocument64 pages2016 BASF ArchitecturalCoatingsBrochure ELLong An DoNo ratings yet

- Attachment 3. Unit RateDocument2 pagesAttachment 3. Unit RateMuhamad AlfarisiNo ratings yet

- Gulf Perlite Ready Mixed Perlite ConcreteDocument4 pagesGulf Perlite Ready Mixed Perlite Concreteosama feilatNo ratings yet

- Adva Antislip TdsDocument2 pagesAdva Antislip TdsMohammed AbugharbiehNo ratings yet

- ProjectDocument34 pagesProjectfaisalmir27100% (1)

- Whatman Uniflo Syringe Filters: Consistent Performance. Maximum ValueDocument7 pagesWhatman Uniflo Syringe Filters: Consistent Performance. Maximum ValueKarinNo ratings yet

- Ice Melt Buyer'S Guide Ice Melt Buyer'S GuideDocument7 pagesIce Melt Buyer'S Guide Ice Melt Buyer'S GuidelyndondrNo ratings yet

- Mind Mapping of WeldingDocument8 pagesMind Mapping of WeldingFadlanbunglonNo ratings yet

- Silicone Fluids Stable Inert MediaDocument32 pagesSilicone Fluids Stable Inert MediachayanunNo ratings yet

- I Construction of 1 No. RCC Reservoir) With Connections of GI Pipes &Document47 pagesI Construction of 1 No. RCC Reservoir) With Connections of GI Pipes &yamanta_rajNo ratings yet

- Nickel Iron BatteryDocument229 pagesNickel Iron Batterygunawansigi36No ratings yet

- Water ProofDocument3 pagesWater ProofMohamed KhanNo ratings yet

- Evolen B80 C EN - GBDocument3 pagesEvolen B80 C EN - GBchrisNo ratings yet

- Iron - Direct Reduction ProcessDocument39 pagesIron - Direct Reduction ProcessSheila Mae GardonNo ratings yet

- Humes ConcretePipeManualDocument67 pagesHumes ConcretePipeManualKhusairy AhmadNo ratings yet

- Lecture 1Document22 pagesLecture 1Amit Narayan RaiNo ratings yet

- SpecialChem - Coalescing Agents in Coatings - Definition, Types & PropertiesDocument5 pagesSpecialChem - Coalescing Agents in Coatings - Definition, Types & Propertiesichsan hakimNo ratings yet

- Rolled Zinc: Standard Specification ForDocument4 pagesRolled Zinc: Standard Specification ForAadhya engineering ServicesNo ratings yet

- Reverse OsmosisDocument131 pagesReverse OsmosisTaufiqTaufiq100% (6)