Professional Documents

Culture Documents

Conventional Brake System Location Index: Ac5uuw00008268

Conventional Brake System Location Index: Ac5uuw00008268

Uploaded by

chí công lêOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conventional Brake System Location Index: Ac5uuw00008268

Conventional Brake System Location Index: Ac5uuw00008268

Uploaded by

chí công lêCopyright:

Available Formats

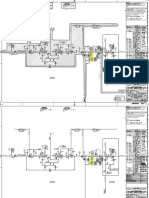

■ CONVENTIONAL BRAKE SYSTEM LOCATION INDEX

id041100800100

id041100800100

Vehicle Front Side

ac5uuw00008268

© 2018 Mazda Motor Corporation.

Vacuum line

(See VACUUM LINE INSPECTION [SKYACTIV-G 2.0, SKYACTIV-G 2.5 (WITHOUT CYLINDER

DEACTIVATION)].)

(See VACUUM LINE INSPECTION [SKYACTIV-G 2.5 (WITH CYLINDER DEACTIVATION)].)

(See VACUUM LINE INSPECTION [SKYACTIV-D 2.2].)

1 (See VACUUM HOSE REMOVAL/INSTALLATION [SKYACTIV-G 2.0, SKYACTIV-G 2.5 (WITHOUT

CYLINDER DEACTIVATION)].)

(See VACUUM HOSE REMOVAL/INSTALLATION [SKYACTIV-G 2.5 (WITH CYLINDER

DEACTIVATION)].)

(See VACUUM HOSE REMOVAL/INSTALLATION [SKYACTIV-D 2.2].)

Brake fluid

(See BRAKE FLUID INSPECTION.)

2

(See BRAKE FLUID AIR BLEEDING.)

Master cylinder

(See MASTER CYLINDER REMOVAL/INSTALLATION.)

3

(See BRAKE FLUID LEVEL SENSOR INSPECTION.)

Power brake unit

(See POWER BRAKE UNIT INSPECTION.)

4

(See POWER BRAKE UNIT REMOVAL/INSTALLATION.)

Brake switch

5

(See BRAKE SWITCH INSPECTION.)

Brake pedal

(See BRAKE PEDAL INSPECTION.)

6

(See BRAKE PEDAL REMOVAL/INSTALLATION.)

© 2018 Mazda Motor Corporation.

Front brake

(See FRONT BRAKE INSPECTION.)

(See FRONT BRAKE DISC REMOVAL/INSTALLATION [WITH SINGLE PISTON FLOATING CALIPER].)

(See FRONT BRAKE DISC REMOVAL/INSTALLATION [WITH 2-PISTON FLOATING CALIPER].)

(See FRONT BRAKE DISC PAD REMOVAL/INSTALLATION [WITH SINGLE PISTON FLOATING

CALIPER].)

(See FRONT BRAKE DISC PAD REMOVAL/INSTALLATION [WITH 2-PISTON FLOATING CALIPER].)

(See FRONT BRAKE CALIPER REMOVAL/INSTALLATION [WITH SINGLE PISTON FLOATING

7 CALIPER].)

(See FRONT BRAKE CALIPER REMOVAL/INSTALLATION [WITH 2-PISTON FLOATING CALIPER].)

(See FRONT BRAKE CALIPER DISASSEMBLY/ASSEMBLY [WITH SINGLE PISTON FLOATING

CALIPER].)

(See FRONT BRAKE CALIPER DISASSEMBLY/ASSEMBLY [WITH 2-PISTON FLOATING CALIPER].)

(See FRONT BRAKE HOSE REMOVAL/INSTALLATION [WITH SINGLE PISTON FLOATING CALIPER].)

(See FRONT BRAKE MOUNTING SUPPORT REMOVAL/INSTALLATION [WITH 2-PISTON FLOATING

CALIPER].)

Front brake hose

(See FRONT BRAKE HOSE REMOVAL/INSTALLATION [WITH SINGLE PISTON FLOATING CALIPER].)

8

(See FRONT BRAKE HOSE REMOVAL/INSTALLATION [WITH 2-PISTON FLOATING CALIPER].)

Vacuum pump

(See VACUUM PUMP INSPECTION.)

(See VACUUM PUMP REMOVAL/INSTALLATION [SKYACTIV-G 2.0, SKYACTIV-G 2.5 (WITHOUT

CYLINDER DEACTIVATION)].)

9

(See VACUUM PUMP REMOVAL/INSTALLATION [SKYACTIV-G 2.5 (WITH CYLINDER

DEACTIVATION)].)

(See VACUUM PUMP REMOVAL/INSTALLATION [SKYACTIV-D 2.2].)

Vehicle Rear Side

© 2018 Mazda Motor Corporation.

ac5uuw00004286

Rear brake hose

1

(See REAR BRAKE HOSE REMOVAL/INSTALLATION.)

Rear brake

(See REAR BRAKE INSPECTION.)

(See REAR BRAKE DISC REMOVAL/INSTALLATION.)

(See REAR BRAKE DISC PAD REMOVAL/INSTALLATION.)

2

(See REAR BRAKE CALIPER REMOVAL/INSTALLATION.)

(See REAR BRAKE CALIPER DISASSEMBLY/ASSEMBLY.)

(See REAR BRAKE MOUNTING SUPPORT REMOVAL/INSTALLATION.)

© 2018 Mazda Motor Corporation.

■ VACUUM PUMP REMOVAL/INSTALLATION [SKYACTIV-G 2.5 (WITH

CYLINDER DEACTIVATION)]

id0411008036x5

id0411008036x5

Replacement Part

O-ring

Quantity: 1

Location of use: Vacuum pump

Warning

• A hot engine and intake air system can cause severe burns. Turn off the engine and wait until they

are cool before removing the intake air system.

1.Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL

DISCONNECTION/CONNECTION.)

2.Remove the plug hole plate. (See PLUG HOLE PLATE REMOVAL/INSTALLATION [SKYACTIV-G 2.5

(WITH CYLINDER DEACTIVATION)].)

3.Remove the battery. (See BATTERY REMOVAL/INSTALLATION [SKYACTIV-G 2.5 (WITH CYLINDER

DEACTIVATION)].)

4.Remove the following parts as a single unit. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION

[SKYACTIV-G 2.5 (WITH CYLINDER DEACTIVATION)].)

• Air hose

• Air cleaner cover

• Air cleaner element

• Fresh-air duct

• Air cleaner case

5.Disconnect the clip from the bracket.

© 2018 Mazda Motor Corporation.

ac5wzw00010542

6.Remove the bolts

7.Move the battery tray, PCM and wiring harness toward the front of the vehicle to the position where the

vacuum pump can be removed.

8.Pinch open the clamp using pliers and disconnect the vacuum hose from the vacuum pump. (See

VACUUM HOSE REMOVAL/INSTALLATION [SKYACTIV-G 2.5 (WITH CYLINDER DEACTIVATION)].)

9.Remove in the order indicated in the table.

10.Install in the reverse order of removal.

© 2018 Mazda Motor Corporation.

ac5wzw00011209

1 Bolt

Vacuum pump

(See Vacuum Pump Removal Note.)

2

(See Vacuum Pump and O-ring Installation Note.)

O-ring

3

(See Vacuum Pump and O-ring Installation Note.)

Vacuum Pump Removal Note

1.When removing the vacuum pump, set a cloth to the underside of the vacuum pump installation surface

so that engine oil does not adhere to other parts.

2.Remove the vacuum pump.

Vacuum Pump and O-ring Installation Note

© 2018 Mazda Motor Corporation.

1.Rotate the vacuum pump by hand to drain the remainder of the engine oil in the vacuum pump.

2.Degrease the O-ring installation groove and installation surface.

3.Install the new O-ring to the vacuum pump.

4.Install the vacuum pump.

© 2018 Mazda Motor Corporation.

■ VACUUM PUMP INSPECTION

id041100811000

id041100811000

SKYACTIV-G 2.0, SKYACTIV-G 2.5

1.Pinch open the clamp using pliers and disconnect the vacuum hose from the vacuum pump. (See

VACUUM HOSE REMOVAL/INSTALLATION [SKYACTIV-G 2.0, SKYACTIV-G 2.5 (WITHOUT

CYLINDER DEACTIVATION)].) (See VACUUM HOSE REMOVAL/INSTALLATION [SKYACTIV-G 2.5

(WITH CYLINDER DEACTIVATION)].)

2.Install the vacuum gauge.

ac5uuw00007502

3.Warm up the engine.

4.Switch the ignition off.

5.Depress the brake pedal several times and decrease the vacuum of the vacuum gauge to 0 kPa {0

mmHg, 0 inHg}.

6.Switch the ignition ON (engine on).

Caution

• If the brake pedal is released after switching the ignition ON (engine on), the vacuum in the vacuum

pump may decrease and result in an incorrect reading when performing the inspection for the degree

of vacuum in the vacuum pump. Depress and hold the brake pedal after switching the ignition ON

(engine on).

7.Perform the inspection for the degree of vacuum in the vacuum pump.

(1)Measure the time from the measurement-start vacuum to the measurement-stop vacuum while

taking readings on the vacuum gauge.

© 2018 Mazda Motor Corporation.

Degree of vacuum in vacuum pump standard (reference)

Measurement condition Specification

Brake Measurement- Measurement-

Engine rotation speed

pedal start vacuum stop vacuum

While idling

(See ENGINE TUNE-UP

[SKYACTIV-G 2.0, SKYACTIV-G 2.5

60 kPa

(WITHOUT CYLINDER

{450 67 kPa {503

DEACTIVATION)].) Depressed Within 8 s

mmHg, 18 mmHg, 20 inHg}

inHg}

(See ENGINE TUNE-UP

[SKYACTIV-G 2.5 (WITH CYLINDER

DEACTIVATION)].)

(2)Verify that the measured time matches the standard.

• If they do not match, repair or replace the following malfunctioning locations.

― Vacuum pump malfunction

― Engine oil pressure decrease

• If they match, go to the next step.

8.Perform the inspection for the degree of maximum attained vacuum in the vacuum pump.

Note

• The inspection for the degree of maximum attained vacuum in the vacuum pump can be performed

normally even if the brake pedal is released.

(1)Read the vacuum on the vacuum gauge.

Degree of maximum attained vacuum in vacuum pump standard (reference)

Measurement condition Specification

Engine rotation speed Measurement time

While idling

(See ENGINE TUNE-UP [SKYACTIV-G 2.0, SKYACTIV-

G 2.5 (WITHOUT CYLINDER DEACTIVATION)].) No time 93.3 kPa {700 mmHg,

designation 27.6 inHg} or more

(See ENGINE TUNE-UP [SKYACTIV-G 2.5 (WITH

CYLINDER DEACTIVATION)].)

(2)Verify that the measured vacuum matches the standard.

• If they do not match, repair or replace the following malfunctioning locations.

― Vacuum pump malfunction

© 2018 Mazda Motor Corporation.

― Engine oil pressure decrease

SKYACTIV-D 2.2

1.Remove the engine cover. (See ENGINE COVER REMOVAL/INSTALLATION [SKYACTIV-D 2.2].)

2.Pinch open the clamp using pliers and disconnect the vacuum hose from the vacuum pump. (See

VACUUM HOSE REMOVAL/INSTALLATION [SKYACTIV-D 2.2].)

3.Install the vacuum gauge.

ac5wzw00009822

4.Warm up the engine.

5.Switch the ignition off.

6.Depress the brake pedal several times and decrease the vacuum of the vacuum gauge to 0 kPa {0

mmHg, 0 inHg}.

7.Switch the ignition ON (engine on).

Caution

• If the brake pedal is released after switching the ignition ON (engine on), the vacuum in the vacuum

pump may decrease and result in an incorrect reading when performing the inspection for the degree

of vacuum in the vacuum pump. Depress and hold the brake pedal after switching the ignition ON

(engine on).

8.Perform the inspection for the degree of vacuum in the vacuum pump.

(1)Measure the time from the measurement-start vacuum to the measurement-stop vacuum while

taking readings on the vacuum gauge.

Degree of vacuum in vacuum pump maximum (reference)

© 2018 Mazda Motor Corporation.

Measurement condition Maximum value

Measurement-start Measurement-stop

Engine rotation speed Brake pedal

vacuum vacuum

While idling

0 kPa {0

67 kPa {503 mmHg, 15 s + Engine

Depressed mmHg, 0

(See ENGINE TUNE- 20 inHg} completely warmed up

inHg}

UP [SKYACTIV-D 2.2].)

(2)Verify if the measured time is the maximum value or less.

• If it exceeds the maximum value, repair or replace the following malfunctioning locations.

― Vacuum pump malfunction

― Engine oil pressure decrease

© 2018 Mazda Motor Corporation.

■ VACUUM LINE INSPECTION [SKYACTIV-G 2.5 (WITH CYLINDER

DEACTIVATION)]

id0411008015x5

id0411008015x5

Airflow Inspection

Between intake manifold and vacuum pump

1.Remove the plug hole plate. (See PLUG HOLE PLATE REMOVAL/INSTALLATION [SKYACTIV-G 2.5

(WITH CYLINDER DEACTIVATION)].)

2.Remove the vacuum hose. (See VACUUM HOSE REMOVAL/INSTALLATION [SKYACTIV-G 2.5

(WITH CYLINDER DEACTIVATION)].)

3.Blow air into the vacuum hose from the vacuum pump side using your mouth and verify that the air

flows to the intake manifold side, then blow air from the intake manifold side and verify that the air does

not flow to the vacuum pump side.

ac5uuw00007493

• If there is any malfunction of the inner check valve, replace it together with the vacuum hose as a

single unit. (SeeVACUUM HOSE REMOVAL/INSTALLATION [SKYACTIV-G 2.5 (WITH CYLINDER

DEACTIVATION)].)

Between vacuum pump and power brake unit

1.Remove the vacuum hose on the vacuum pump side. (See VACUUM HOSE

REMOVAL/INSTALLATION [SKYACTIV-G 2.5 (WITH CYLINDER DEACTIVATION)].)

2.Blow air into the vacuum hose from the power brake unit side using your mouth and verify that the air

flows to the vacuum pump side, then blow air from the vacuum pump side and verify that the air does not

flow to the power brake unit side.

© 2018 Mazda Motor Corporation.

ac5uuw00008269

• If there is any malfunction of the inner check valve, replace it together with the vacuum hose as a

single unit. (SeeVACUUM HOSE REMOVAL/INSTALLATION [SKYACTIV-G 2.5 (WITH CYLINDER

DEACTIVATION)].)

© 2018 Mazda Motor Corporation.

■ REAR BRAKE MOUNTING SUPPORT REMOVAL/INSTALLATION

id041100001300

id041100001300

Replacement Part

Dust boot

Quantity: 2

Location of use: Rear brake mounting support

Oil and Chemical Type

Rubber grease (Orange)

Type: NIGLUBE RX-2

Note

• When in maintenance mode, the clearance between the disc pad and the disc plate expands.

• When the maintenance mode is completed, perform the electric parking brake automatic

adjustment.

• With the electric parking brake automatic adjustment, the electric parking brake motor gear unit

operation time is longer than normal.

1.Switch to the maintenance mode. (See MAINTENANCE MODE.)

2.Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL

DISCONNECTION/CONNECTION.)

3.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

4.Disconnect the electric parking brake motor gear unit connector.

© 2018 Mazda Motor Corporation.

ac5uuw00007480

5.Remove in the order indicated in the table.

6.Install in the reverse order of removal.

7.End the maintenance mode. (See MAINTENANCE MODE.)

8.After installation, add brake fluid, bleed the air, and inspect for fluid leakage. (See BRAKE FLUID AIR

BLEEDING.)

9.After installation, pump the brake pedal a few times and inspect the following:

― Disc pad projection does not contact piston and caliper

― Brake drag

© 2018 Mazda Motor Corporation.

ac5uuw00007481

1 Bolt

Rear brake caliper, Electric parking brake motor gear unit

2

(See Rear Brake Caliper, Electric Parking brake motor gear unit Removal Note.)

3 Slide pin (main)

4 Slide pin (sub)

5 Dust boot

6 Disc pad component

7 Guide plate

8 Bolt

9 Mounting support

© 2018 Mazda Motor Corporation.

Rear Brake Caliper, Electric Parking brake motor gear unit Removal Note

1.Remove the rear brake caliper and electric parking brake motor gear unit as a single unit, and suspend

them in a place out of the way using a cable.

ac5jjw00011374

© 2018 Mazda Motor Corporation.

■ VACUUM HOSE REMOVAL/INSTALLATION [SKYACTIV-G 2.5 (WITH

CYLINDER DEACTIVATION)]

id0411008016x5

id0411008016x5

Between Intake Manifold and Vacuum Pump

1.Remove the plug hole plate. (See PLUG HOLE PLATE REMOVAL/INSTALLATION [SKYACTIV-G 2.5

(WITH CYLINDER DEACTIVATION)].)

2.Disconnect the vacuum hose from the clip.

ac5wzw00011205

3.Pinch open the clamps using pliers and disconnect the vacuum hose.

4.Install in the reverse order of removal. (See Vacuum hose (between intake manifold and vacuum pump)

installation note.)

Vacuum hose (between intake manifold and vacuum pump) installation note

© 2018 Mazda Motor Corporation.

1.Install the vacuum hose as shown in the figure.

ac5wzw00011206

Between Vacuum Pump and Power Brake Unit

1.Pinch open the clamps using pliers and disconnect the vacuum hose.

© 2018 Mazda Motor Corporation.

ac5wzw00011207

2.Install in the reverse order of removal. (See Vacuum hose (between vacuum pump and power brake

unit) installation note.)

Vacuum hose (between vacuum pump and power brake unit) installation note

1.Install the vacuum hose as shown in the figure.

© 2018 Mazda Motor Corporation.

ac5wzw00011208

© 2018 Mazda Motor Corporation.

■ REAR BRAKE INSPECTION

id041100000800

id041100000800

Brake Judder Repair Hints

Description

1.Brake judder concern has the following 3 characteristics:

Steering wheel vibration

1.The steering wheel vibrates in the rotation direction. This characteristic is most noticeable when

applying brakes at a vehicle speed of 100—140 km/h {62.2—86.9 mph}.

Floor vibration

1.When applying the brakes, the vehicle body shakes back and forth. The seriousness of the shaking is

not influenced by vehicle speed.

Brake pedal vibration

1.When applying the brakes, a pulsating force tries to push the brake pad back. The pulsation is

transmitted to the brake pedal.

2.The following are the main possible causes of brake judder:

Due to an excessive runout (side-to-side wobble) of the disc plate, the thickness of the disc plate is

uneven.

1.If the runout is more than 0.1 mm {0.004 in} at the position 10 mm {0.39 in} from the disc plate edge,

uneven wear occurs on the disc plate because the pad contacts the plate unevenly.

2.If the runout is less than 0.1 mm {0.004 in}, uneven wear does not occur.

The disc plate is deformed by heat.

1.Repeated panic braking may raise the temperature in some portions of the disc plate by approx.

1,000 °C {1,832 °F}. This results in a deformed disc plate.

Due to corrosion, the thickness and friction coefficient of the disc plate change.

1.If the vehicle is parked in damp conditions for a long time, corrosion occurs on the friction surface of the

disc plate.

© 2018 Mazda Motor Corporation.

2.The thickness of corrosion is uneven and sometimes appears like a wave pattern, which changes the

friction coefficient and causes a reaction force.

Inspection and repair procedure

ac5uuw00007531

Lateral runout inspection

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Remove the rear brake caliper component and suspend it out of the way using a cable. (See REAR

BRAKE DISC REMOVAL/INSTALLATION.)

© 2018 Mazda Motor Corporation.

ac5uuw00008040

3.To secure the disc plate and the hub, insert the washer (thickness 10 mm {0.39 in}, inner diameter more

than 12 mm {0.47 in}) between each hub bolt and the hub nut, then tighten all the hub nuts.

Note

• The component parts of theSST(49 B017 001 or 49 G019 003) can be used as a suitable washer.

4.After tightening all the hub nuts to the same torque, put the dial gauge on the friction surface of the disc

plate 10 mm {0.39 in} from the disc plate edge.

ac5jjw00010808

5.Rotate the disc plate one time and measure the runout.

Rear disc plate runout limit

0.1 mm {0.004 in}

Thickness variation inspection

© 2018 Mazda Motor Corporation.

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Clean the disc plate-to-pad friction surface using a brake cleaner.

3.Measure the points indicated in the illustration using a caliper (micrometer).

ac5uuw00007532

4.Subtract the minimum value from the maximum, and if the result is not within the specification, machine

the disc plate using a lathe.

Thickness variation limit

0.015 mm {0.00059 in}

Warning

• Do not exceed minimum disc plate thickness.

Disc Plate Thickness Inspection

Caution

• Excessive runout may result if the disc plate is removed from the vehicle then machined. Machine

the disc plate while installed on the vehicle.

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Measure the thickness of the disc plate.

Minimum rear disc plate thickness

8.0 mm {0.3 in}

Minimum rear disc plate thickness after machining using a brake lathe on-vehicle

8.8 mm {0.35 in}

• If the thickness is not within the specification, replace the disc plate. (SeeREAR BRAKE DISC

REMOVAL/INSTALLATION.)

Disc Pad Thickness Inspection

1.Jack up the front of the vehicle and support it with safety stands.

2.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

© 2018 Mazda Motor Corporation.

3.Verify the remaining thickness of the pads.

ac5jjw00011142

Minimum rear disc pad thickness

2.0 mm {0.079 in}

• Replace the pads as a set (right and left wheels) if either one is at or less than the minimum

thickness. (SeeREAR BRAKE DISC PAD REMOVAL/INSTALLATION.)

© 2018 Mazda Motor Corporation.

■ REAR BRAKE HOSE REMOVAL/INSTALLATION

id041100001400

id041100001400

Replacement Part

Gasket

Quantity: 2

Location of use: Rear brake hose

Oil and Chemical Type

Brake fluid type

Type: SAE J1703 or FMVSS116 DOT-3

Caution

• Brake fluid will damage painted surfaces. Be careful not to spill any on painted surfaces. In addition,

if there is any brake fluid on the wiring harness, the wire insulation may corrode causing a malfunction

such as a short circuit. If brake fluid gets on a painted surface or wiring harness, wash and flush it off

completely with water immediately.

Note

• Tighten the brake pipe flare nut using any commercially available flare nut wrench.

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Remove in the order indicated in the table.

3.Install in the reverse order of removal.

4.After installation, add brake fluid, bleed the air, and inspect for fluid leakage. (See BRAKE FLUID AIR

BLEEDING.)

© 2018 Mazda Motor Corporation.

ac5uuw00007482

1 Brake pipe

Clip

2

(See Clip Installation Note.)

3 Bolt

4 Brake hose

Clip Installation Note

1.Install a clip to the position shown in the figure.

© 2018 Mazda Motor Corporation.

ac5uuw00007483

© 2018 Mazda Motor Corporation.

■ REAR BRAKE DISC REMOVAL/INSTALLATION

id041100000900

id041100000900

Note

• When in maintenance mode, the clearance between the disc pad and the disc plate expands.

• When the maintenance mode is completed, perform the electric parking brake automatic

adjustment.

• With the electric parking brake automatic adjustment, the electric parking brake motor gear unit

operation time is longer than normal.

1.Switch to the maintenance mode. (See MAINTENANCE MODE.)

2.Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL

DISCONNECTION/CONNECTION.)

3.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

4.Disconnect the electric parking brake motor gear unit connector.

ac5uuw00007463

5.Remove in the order indicated in the table.

6.Install in the reverse order of removal.

7.End the maintenance mode. (See MAINTENANCE MODE.)

8.After installation, pump the brake pedal a few times and inspect the following:

― Disc pad projection does not contact piston and caliper

― Brake drag

© 2018 Mazda Motor Corporation.

ac5uuw00007464

1 Bolt

Rear brake caliper component

(See Rear Brake Caliper Component Removal Note.)

2

(See Rear Brake Caliper Component Installation Note.)

3 Disc plate

Rear Brake Caliper Component Removal Note

1.Remove the rear brake caliper component and suspend it in a place out of the way using a cable.

© 2018 Mazda Motor Corporation.

ac5uuw00007465

Rear Brake Caliper Component Installation Note

1.Push the piston in using the commercially available disc brake expand tool.

ac5uuw00007466

2.Install the rear brake caliper component.

© 2018 Mazda Motor Corporation.

■ REAR BRAKE CALIPER REMOVAL/INSTALLATION

id041100001100

id041100001100

Special Service Tool (SST)

49 F043 002

Wrench

Replacement Part

Bolt O-ring Gasket

Quantity: 2 Quantity: 1 Quantity: 2

Location of use: Electric parking Location of use: Electric parking Location of use: Rear

brake motor gear unit brake motor gear unit brake hose

Note

• When in maintenance mode, the clearance between the disc pad and the disc plate expands.

• When the maintenance mode is completed, perform the electric parking brake automatic

adjustment.

• With the electric parking brake automatic adjustment, the electric parking brake motor gear unit

operation time is longer than normal.

1.Switch to the maintenance mode. (See MAINTENANCE MODE.)

2.Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL

DISCONNECTION/CONNECTION.)

3.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

4.Disconnect the electric parking brake motor gear unit connector.

© 2018 Mazda Motor Corporation.

ac5uuw00007471

5.Remove in the order indicated in the table.

6.Install in the reverse order of removal.

7.End the maintenance mode. (See MAINTENANCE MODE.)

8.After installation, add brake fluid, bleed the air, and inspect for fluid leakage. (See BRAKE FLUID AIR

BLEEDING.)

9.After installation, pump the brake pedal a few times and inspect the following:

― Disc pad projection does not contact piston and caliper

― Brake drag

© 2018 Mazda Motor Corporation.

ac5uuw00007472

1 Bolt

2 Electric parking brake motor gear unit

3 Bolt

4 Brake hose

5 Bolt

Rear brake caliper

6

(See Rear Brake Caliper Installation Note.)

Rear Brake Caliper Installation Note

1.Clean the exposed area of the piston.

© 2018 Mazda Motor Corporation.

Caution

• When pressing the piston into the rear brake caliper, the rear brake caliper internal parts could be

damaged while rotating and pressing the piston. Be careful not to rotate the piston when pressing the

piston into the rear brake caliper.

2.Press in the piston using a commercially available disc brake expander tool.

ac5uuw00007473

3.Verify that the piston grooves are at the positions shown in the figure.

ac5uuw00007474

• If the piston grooves are not at the positions shown in the figure, rotate the piston clockwise slowly

using theSSTand adjust the piston grooves at the positions shown in the figure.

© 2018 Mazda Motor Corporation.

ac5uuw00007475

4.Install the rear brake caliper.

© 2018 Mazda Motor Corporation.

■ REAR BRAKE DISC PAD REMOVAL/INSTALLATION

id041100001000

id041100001000

Special Service Tool (SST)

49 F043 002

Wrench

Note

• When in maintenance mode, the clearance between the disc pad and the disc plate expands.

• When the maintenance mode is completed, perform the electric parking brake automatic

adjustment.

• With the electric parking brake automatic adjustment, the electric parking brake motor gear unit

operation time is longer than normal.

1.Switch to the maintenance mode. (See MAINTENANCE MODE.)

2.Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL

DISCONNECTION/CONNECTION.)

3.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

4.Disconnect the electric parking brake motor gear unit connector.

ac5uuw00007467

5.Remove in the order indicated in the table.

6.Install in the reverse order of removal.

7.End the maintenance mode. (See MAINTENANCE MODE.)

8.After installation, pump the brake pedal a few times and inspect the following:

© 2018 Mazda Motor Corporation.

― Disc pad projection does not contact piston and caliper

― Brake drag

ac5uuw00008102

Rear brake caliper

(See Caliper Removal Note.)

1

(See Rear Brake Caliper Installation Note.)

2 Disc pad

3 Shim

4 Guide plate

Caliper Removal Note

© 2018 Mazda Motor Corporation.

1.Remove the bolt shown in the figure and lift up the rear brake caliper.

ac5jjw00011152

Rear Brake Caliper Installation Note

1.Clean the exposed area of the piston.

Caution

• When pressing the piston into the rear brake caliper, the rear brake caliper internal parts could be

damaged while rotating and pressing the piston. Be careful not to rotate the piston when pressing the

piston into the rear brake caliper.

2.Press in the piston using a commercially available disc brake expander tool.

ac5uuw00007468

3.Verify that the piston grooves are at the positions shown in the figure.

© 2018 Mazda Motor Corporation.

ac5uuw00007469

• If the piston grooves are not at the positions shown in the figure, rotate the piston clockwise slowly

using theSSTand adjust the piston grooves at the positions shown in the figure.

ac5uuw00007470

4.Return the rear brake caliper to the original position and install the bolt.

ac5jjw00011154

© 2018 Mazda Motor Corporation.

■ REAR BRAKE CALIPER DISASSEMBLY/ASSEMBLY

id041100001200

id041100001200

Special Service Tool (SST)

49 F043 002

Wrench

Replacement Part

Dust seal Piston seal

Quantity: 1 Quantity: 1

Location of use: Caliper body Location of use: Piston

Oil and Chemical Type

Brake fluid type Rubber grease (Pink)

Type: SAE J1703 or FMVSS116 DOT-3 Type: RENOLIT RUBBER GREASE JP

Caution

• Brake fluid will damage painted surfaces. Be careful not to spill any on painted surfaces. In addition,

if there is any brake fluid on the wiring harness, the wire insulation may corrode causing a malfunction

such as a short circuit. If brake fluid gets on a painted surface or wiring harness, wash and flush it off

completely with water immediately.

1.Remove in the order indicated in the table.

© 2018 Mazda Motor Corporation.

ac5uuw00007476

1 Bleeder cap

2 Bleeder screw

Piston

(See Piston Disassembly Note.)

3

(See Dust Seal, Piston Assembly Note.)

Dust seal

4

(See Dust Seal, Piston Assembly Note.)

5 Piston seal

6 Caliper body

2.Install in the reverse order of removal.

Piston Disassembly Note

Warning

• When compressed air is blown into the caliper body, injury to a finger or other part from pinching

could result from the piston springing up. When blowing in compressed air, do not place your fingers

between the piston and caliper body when performing the work.

Caution

© 2018 Mazda Motor Corporation.

• The piston could be damaged if blown out with great force. Blow the compressed air slowly to

prevent the piston from suddenly popping out.

1.Insert a piece of wood in the caliper as shown in the figure and blow compressed air through the hole to

remove the piston from the caliper body.

ac5jjw00006613

Caution

• If the piston is removed from the caliper while rotating the piston, the caliper internal parts could be

damaged. Be careful not to rotate the piston when removing the piston from the caliper.

Dust Seal, Piston Assembly Note

1.Assemble the dust seal to the piston.

2.Assemble the lip of the dust seal to the groove of the caliper body with the dust seal is assembled to the

piston as shown in the figure.

ac5uuw00007477

Caution

• If the piston is pushed into the caliper while rotating the piston, the caliper internal parts could be

damaged. Be careful not to rotate the piston when pushing the piston into the caliper.

© 2018 Mazda Motor Corporation.

3.Align the head of the spindle nut with the inner shape of the piston and press the piston into the caliper

body completely.

4.Verify that the dust seal is installed into the caliper body groove.

5.Verify that the piston grooves are at the positions shown in the figure.

ac5uuw00007478

• If the piston grooves are not at the positions shown in the figure, rotate the piston clockwise slowly

using theSSTand adjust the piston grooves at the positions shown in the figure.

ac5uuw00007479

© 2018 Mazda Motor Corporation.

■ POWER BRAKE UNIT REMOVAL/INSTALLATION

id041100801800

id041100801800

Replacement Part

Gasket Brake switch

Quantity: 1 Quantity: 1

Location of use: Power brake unit Location of use: Brake pedal

Oil and Chemical Type

Brake fluid type

Type: SAE J1703 or FMVSS116 DOT-3

Caution

• Once the brake switch clearance has automatically been adjusted, it cannot be adjusted again.

Therefore, replace the switch with a new one when replacing the power brake unit or performing any

procedure that changes the pedal stroke.

• Brake fluid will damage painted surfaces. Be careful not to spill any on painted surfaces. In addition,

if there is any brake fluid on the wiring harness, the wire insulation may corrode causing a malfunction

such as a short circuit. If brake fluid gets on a painted surface or wiring harness, wash and flush it off

completely with water immediately.

Note

• Tighten the brake pipe flare nut using any commercially available flare nut wrench.

1.Disconnect the negative battery terminal.(See NEGATIVE BATTERY TERMINAL

DISCONNECTION/CONNECTION.)

2.Remove the battery. (See BATTERY REMOVAL/INSTALLATION [SKYACTIV-G 2.0, SKYACTIV-G 2.5

(WITHOUT CYLINDER DEACTIVATION)].) (See BATTERY REMOVAL/INSTALLATION [SKYACTIV-G

2.5 (WITH CYLINDER DEACTIVATION)].) (See BATTERY REMOVAL/INSTALLATION [SKYACTIV-D

2.2].)

3.Remove the following parts:

(1)Windshield wiper arm and brade (See WINDSHIELD WIPER ARM AND BLADE

REMOVAL/INSTALLATION.) (2)Cowl grille (See COWL GRILLE REMOVAL/INSTALLATION.)

(3)Windshield wiper motor and link (See WINDSHIELD WIPER MOTOR AND LINK

© 2018 Mazda Motor Corporation.

REMOVAL/INSTALLATION.) (4)Keyless beeper (With advanced keyless entry system) (See

KEYLESS BEEPER REMOVAL/INSTALLATION.) (5)Cowl panel (See COWL PANEL

REMOVAL/INSTALLATION.)

4.Remove the master cylinder. (See MASTER CYLINDER REMOVAL/INSTALLATION.)

5.For SKYACTIV-D 2.2 vehicles, remove the following parts:

• Air inlet pipe (SeeINTAKE-AIR SYSTEM REMOVAL/INSTALLATION [SKYACTIV-D 2.2].)

• Battery tray (SeeBATTERY REMOVAL/INSTALLATION [SKYACTIV-D 2.2].)

6.Remove in the order indicated in the table.

7.Install in the reverse order of removal.

8.After installation, add brake fluid, bleed the air, and inspect for fluid leakage. (See BRAKE FLUID AIR

BLEEDING.)

9.Remove the brake switch. (See BRAKE PEDAL REMOVAL/INSTALLATION.)

10.Inspect the brake pedal. (See BRAKE PEDAL INSPECTION.)

11.Install a new brake switch. (See BRAKE PEDAL REMOVAL/INSTALLATION.)

ac5uuw00007499

© 2018 Mazda Motor Corporation.

Vacuum hose

(See VACUUM HOSE REMOVAL/INSTALLATION [SKYACTIV-G 2.0, SKYACTIV-G 2.5 (WITHOUT

CYLINDER DEACTIVATION)].)

1 (See VACUUM HOSE REMOVAL/INSTALLATION [SKYACTIV-G 2.5 (WITH CYLINDER

DEACTIVATION)].)

(See VACUUM HOSE REMOVAL/INSTALLATION [SKYACTIV-D 2.2].)

2 Snap pin

3 Clevis pin

4 Nut

5 Power brake unit

6 Gasket

© 2018 Mazda Motor Corporation.

■ POWER BRAKE UNIT INSPECTION

id041100883000

id041100883000

Special Service Tool (SST)

49 U043 49 U043 49 U043

004A 005 006

Oil pressure Joint Hose

gauge

(Part of 49 (Part of 49

(Part of 49 U043 U043

U043 0A0A) 0A0A) 0A0A)

Caution

• Brake fluid will damage painted surfaces. Be careful not to spill any on painted surfaces. In addition,

if there is any brake fluid on the wiring harness, the wire insulation may corrode causing a malfunction

such as a short circuit. If brake fluid gets on a painted surface or wiring harness, wash and flush it off

completely with water immediately.

Note

• The following inspection methods are simple inspection methods to judge the function of the power

brake unit.

• If there is any malfunction in the power brake unit, replace the power brake unit as a single unit.

(SeePOWER BRAKE UNIT REMOVAL/INSTALLATION.)

• Tighten the brake pipe flare nut using any commercially available flare nut wrench.

Without Using SST

Operation inspection

1.With the engine stopped, pump the pedal a few times.

2.With the pedal depressed, start the engine.

3.If the pedal moves down slightly immediately after starting the engine, the unit is normal.

Vacuum function inspection

1.Start the engine.

2.Stop the engine after driving the vehicle for 1—2 min.

3.Depress the pedal with normal force.

© 2018 Mazda Motor Corporation.

4.If the first pedal stroke is long and becomes shorter with subsequent strokes, the unit is normal.

• If a problem is found, inspect for damage to or improper installation of the check valve and vacuum

hose. After repairing, inspect again.

Vacuum loss function inspection

1.Start the engine.

2.Depress the pedal with normal force.

3.With the pedal depressed, stop the engine.

4.Hold the pedal depressed for approx. 30 s.

5.If the pedal height does not change during this time, the unit is normal.

Using SST

Note

• When performing the inspection using the SST, inspect the brake pipe on the left or right front

wheel.

• The following procedure and figures show the inspection for the brake pipe on the left front wheel.

Pre-inspection preparation

1.Remove the clips.

ac5uuw00007503

2.Set the splash shield out of the way.

3.Disconnect the brake pipe from the brake hose.

© 2018 Mazda Motor Corporation.

ac5uuw00007504

4.Remove the clip.

5.Remove the brake hose from the bracket.

Caution

• When removing the brake pipe, the pipe holder may detach from the body. Remove the brake pipe

while pressing the pipe holder to prevent it from detaching from the body. The pipe holder cannot be

reused if it detaches from the body.

6.Detach the brake pipe from the pipe holder.

7.Install the SSTs to the brake pipe as shown in the figure.

ac5jjw00010685

8.Bleed the brake line and the SSTs of air. Bleed the air form the SSTs using bleeder screw A.

9.Install the pedal force gauge to the brake pedal.

10.Connect the vacuum gauge to the vacuum line.

Vacuum loss inspection

1.Start the engine.

2.Depress the brake pedal with a force of 200 N {20.4 kgf, 45.0 lbf}.

© 2018 Mazda Motor Corporation.

3.Stop the engine when the vacuum gauge reading reaches 68 kPa {510 mmHg, 20 inHg} with the pedal

depressed.

4.With the engine off, observe the vacuum gauge for 15 s.

5.If the gauge has dropped 3.3 kPa {25 mmHg, 0.97 inHg} or less, the unit is normal.

Lack of hydraulic pressure inspection

1.If the pedal force and fluid pressure correlation is within the specification with the engine stopped and a

vacuum amount of 0 kPa {0 mmHg, 0 inHg}, the system is normal.

Master cylinder fluid pressure (SKYACTIV-G 2.0, SKYACTIV-G 2.5)

Vacuum amount at 0 kPa {0 mmHg, 0 inHg}

Pedal force Fluid pressure

2

200 N {20.4 kgf, 45.0 lbt} 890 kPa {9.08 kgf/cm , 129 psi} or more

Master cylinder fluid pressure (SKYACTIV-D 2.2)

Vacuum amount at 0 kPa {0 mmHg, 0 inHg}

Pedal force Fluid pressure

2

200 N {20.4 kgf, 45.0 lbf} 770 kPa {7.85 kgf/cm , 112 psi} or more

Hydraulic pressure inspection

1.Start the engine. Depress the brake pedal when the vacuum reaches 66.7 kPa {500 mmHg, 19.7 inHg}.

2.At this time, apply the indicated pedal force and if the fluid pressure is within the specification, the unit is

normal.

Master cylinder fluid pressure (SKYACTIV-G 2.0, SKYACTIV-G 2.5)

Vacuum amount at 66.7 kPa {500 mmHg, 19.7 inHg}

Pedal force Fluid pressure

2

200 N {20.4 kgf, 45.0 lbt} 6,810 kPa {69.44 kgf/cm , 987.7 psi} or more

Master cylinder fluid pressure (SKYACTIV-D 2.2)

Vacuum amount at 66.7 kPa {500 mmHg, 19.7 inHg}

Pedal force Fluid pressure

2

200 N {20.4 kgf, 45.0 lbf} 6,710 kPa {68.42 kgf/cm , 973.2 psi} or more

After-inspection procedure

© 2018 Mazda Motor Corporation.

1.After the inspection, remove the SSTs, install the brake hose, clamp, and brake pipe to the original

positions, and then bleed the air from the brake line. (See FRONT BRAKE HOSE

REMOVAL/INSTALLATION [WITH SINGLE PISTON FLOATING CALIPER].) (See FRONT BRAKE

HOSE REMOVAL/INSTALLATION [WITH 2-PISTON FLOATING CALIPER].) (See BRAKE FLUID AIR

BLEEDING.)

© 2018 Mazda Motor Corporation.

■ FRONT BRAKE MOUNTING SUPPORT REMOVAL/INSTALLATION [WITH

SINGLE PISTON FLOATING CALIPER]

id0411000005w4

id0411000005w4

Replacement Part

Dust boot

Quantity: 2

Location of use: Front brake mounting support

Oil and Chemical Type

Rubber grease (Orange) Brake grease (Brown)

Type: NIGLUBE RX-2 Type: Molykote 7439

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Remove in the order indicated in the table.

3.Install in the reverse order of removal.

4.Depress the brake pedal a few times, rotate the wheel by hand, and verify that the brake does not drag.

© 2018 Mazda Motor Corporation.

ac5uuw00007458

© 2018 Mazda Motor Corporation.

1 Bolt

Front brake caliper

2

(See Front Brake Caliper Removal Note.)

3 Slide pin (main)

4 Slide pin (sub)

5 Dust boot

6 Disc pad component

Guide plate

7

(See Guide Plate Installation Note.)

8 Bolt

9 Mounting support

Front Brake Caliper Removal Note

1.Remove the front brake caliper and suspend it in a place out of the way using a cable.

ac5uuw00007459

Guide Plate Installation Note

© 2018 Mazda Motor Corporation.

Caution

• When assembling the guide plates to the mounting support, securely assemble them on the leading

side and trailing side to each position shown in the figure. If the guide plates are assembled to the

incorrect positions, it could become a source of noise.

1.Install the guide plate as shown in the figure.

ac5uuw00007460

© 2018 Mazda Motor Corporation.

■ MASTER CYLINDER REMOVAL/INSTALLATION

id041100801300

id041100801300

Replacement Part

Nut Set bolt Bush

Quantity: 2 Quantity: 1 Quantity: 2

Location of use: Cylinder Location of use: Brake fluid Location of use: Cylinder

component reserve tank component

O-ring

Quantity: 1

— —

Location of use: Cylinder

component

Oil and Chemical Type

Brake fluid type

Type: SAE J1703 or FMVSS116 DOT-3

Caution

• Brake fluid will damage painted surfaces. Be careful not to spill any on painted surfaces. In addition,

if there is any brake fluid on the wiring harness, the wire insulation may corrode causing a malfunction

such as a short circuit. If brake fluid gets on a painted surface or wiring harness, wash and flush it off

completely with water immediately.

Note

• Tighten the brake pipe flare nut using any commercially available flare nut wrench.

1.Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL

DISCONNECTION/CONNECTION.)

2.Remove the battery. (See BATTERY REMOVAL/INSTALLATION [SKYACTIV-G 2.0, SKYACTIV-G 2.5

(WITHOUT CYLINDER DEACTIVATION)].) (See BATTERY REMOVAL/INSTALLATION [SKYACTIV-G

© 2018 Mazda Motor Corporation.

2.5 (WITH CYLINDER DEACTIVATION)].) (See BATTERY REMOVAL/INSTALLATION [SKYACTIV-D

2.2].)

3.For SKYACTIV-D 2.2 vehicles, remove the following parts:

(1)Windshield wiper arm and blade (See WINDSHIELD WIPER ARM AND BLADE

REMOVAL/INSTALLATION.) (2)Cowl grille (See COWL GRILLE REMOVAL/INSTALLATION.)

(3)Windshield wiper motor and link (See WINDSHIELD WIPER MOTOR AND LINK

REMOVAL/INSTALLATION.) (4)Keyless beeper (With advanced keyless entry system) (See

KEYLESS BEEPER REMOVAL/INSTALLATION.) (5)Cowl panel (See COWL PANEL

REMOVAL/INSTALLATION.)

4.Remove in the order indicated in the table.

5.Install in the reverse order of removal.

6.After installation, add brake fluid, bleed the air, and inspect for fluid leakage. (See BRAKE FLUID AIR

BLEEDING.)

ac5uuw00007491

© 2018 Mazda Motor Corporation.

1 Brake fluid level sensor connector

Clutch reserve hose (MTX)

(See Clutch Reserve Hose Removal Note (MTX).)

2

(See Clutch Reserve Hose Installation Note (MTX).)

3 Hose holder

4 Brake pipe

5 Nut

6 Bracket

7 Master cylinder

8 Cap

9 Brake fluid reserve tank

10 Cylinder component

Clutch Reserve Hose Removal Note (MTX)

1.Disconnect the clutch reserve hose in the order shown in the figure.

ac5uuw00007492

Clutch Reserve Hose Installation Note (MTX)

1.Insert the clutch reserve hose into the master cylinder.

2.Pull the clutch reserve hose to verify that it does not come off, and reinsert it completely.

© 2018 Mazda Motor Corporation.

■ FRONT BRAKE MOUNTING SUPPORT REMOVAL/INSTALLATION [WITH 2-

PISTON FLOATING CALIPER]

id0411000005w5

id0411000005w5

Replacement Part

Dust boot

Quantity: 2

Location of use: Front brake mounting support

Oil and Chemical Type

Rubber grease (Pink)

Type: Cosmo rubber grease

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Remove in the order indicated in the table.

3.Install in the reverse order of removal.

4.Depress the brake pedal a few times, rotate the wheel by hand, and verify that the brake does not drag.

© 2018 Mazda Motor Corporation.

ac5wzw00009652

© 2018 Mazda Motor Corporation.

1 Bolt (main)

2 Bolt (sub)

Front brake caliper

3

(See Front Brake Caliper Removal Note.)

4 Dust boot

5 Disc pad component

6 Guide plate

7 Bolt

8 Mounting support

Front Brake Caliper Removal Note

1.Remove the front brake caliper and suspend it in a place out of the way using a cable.

ac5wzw00009828

© 2018 Mazda Motor Corporation.

■ FRONT BRAKE INSPECTION

id041100000000

id041100000000

Brake Judder Repair Hints

Description

1.Brake judder concern has the following 3 characteristics:

Steering wheel vibration

1.The steering wheel vibrates in the rotation direction. This characteristic is most noticeable when

applying brakes at a vehicle speed of 100—140 km/h {62.2—86.9 mph}.

Floor vibration

1.When applying the brakes, the vehicle body shakes back and forth. The seriousness of the shaking is

not influenced by vehicle speed.

Brake pedal vibration

1.When applying the brakes, a pulsating force tries to push the brake pad back. The pulsation is

transmitted to the brake pedal.

2.The following are the main possible causes of brake judder:

Due to an excessive runout (side-to-side wobble) of the disc plate, the thickness of the disc plate is

uneven.

1.If the runout is more than 0.04 mm {0.002 in} at the position 10 mm {0.39 in} from the disc plate edge,

uneven wear occurs on the disc plate because the pad contacts the plate unevenly.

2.If the runout is less than 0.04 mm {0.002 in}, uneven wear does not occur.

The disc plate is deformed by heat.

1.Repeated panic braking may raise the temperature in some portions of the disc plate by approx.

1,000 °C {1,832 °F}. This results in a deformed disc plate.

Due to corrosion, the thickness and friction coefficient of the disc plate change.

1.If the vehicle is parked in damp conditions for a long time, corrosion occurs on the friction surface of the

disc plate.

© 2018 Mazda Motor Corporation.

2.The thickness of corrosion is uneven and sometimes appears like a wave pattern, which changes the

friction coefficient and causes a reaction force.

Inspection and repair procedure

ac5uuw00007446

Lateral runout inspection

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Remove the front brake caliper component and suspend it in a place out of the way using a cable. (See

FRONT BRAKE DISC REMOVAL/INSTALLATION [WITH SINGLE PISTON FLOATING CALIPER].) (See

FRONT BRAKE DISC REMOVAL/INSTALLATION [WITH 2-PISTON FLOATING CALIPER].)

© 2018 Mazda Motor Corporation.

ac5uuw00007447

3.To secure the disc plate and the hub, insert the washer (thickness 10 mm {0.39 in}, inner diameter more

than 12 mm {0.47 in}) between each hub bolt and the hub nut, then tighten all the hub nuts.

Note

• The component parts of theSST(49 B017 001 or 49 G019 003) can be used as a suitable washer.

4.After tightening all the hub nuts to the same torque, put the dial gauge on the friction surface of the disc

plate 10 mm {0.39 in} from the disc plate edge.

ac5wzw00000197

5.Rotate the disc plate one time and measure the runout.

Front disc plate runout limit

0.04 mm {0.002 in}

Thickness variation inspection

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

© 2018 Mazda Motor Corporation.

2.Clean the disc plate-to-pad friction surface using a brake cleaner.

3.Measure the points indicated in the illustration using a caliper (micrometer).

ac5uuw00007448

4.Subtract the minimum value from the maximum, and if the result is not within the specification, machine

the disc plate using a lathe.

Thickness variation limit

0.015 mm {0.00059 in}

Warning

• Do not exceed minimum disc plate thickness.

Disc Plate Thickness Inspection

Caution

• Excessive runout may result if the disc plate is removed from the vehicle then machined. Machine

the disc plate while installed on the vehicle.

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Measure the thickness of the disc plate.

Minimum front disc plate thickness

26.0 mm {1.02 in}

Minimum front disc plate thickness after machining using a brake lathe on-vehicle

26.8 mm {1.06 in}

• If the thickness is not within the specification, replace the disc plate. (SeeFRONT BRAKE DISC

REMOVAL/INSTALLATION [WITH SINGLE PISTON FLOATING CALIPER].) (SeeFRONT BRAKE

DISC REMOVAL/INSTALLATION [WITH 2-PISTON FLOATING CALIPER].)

Disc Pad Thickness Inspection

1.Jack up the front of the vehicle and support it with safety stands.

2.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

© 2018 Mazda Motor Corporation.

3.Verify the remaining thickness of the pads.

ac5wzw00009643

Minimum front disc pad thickness

2.0 mm {0.079 in}

• Replace the pads as a set (right and left wheels) if either one is at or less than the minimum

thickness.(SeeFRONT BRAKE DISC REMOVAL/INSTALLATION [WITH SINGLE PISTON

FLOATING CALIPER].) (SeeFRONT BRAKE DISC REMOVAL/INSTALLATION [WITH 2-PISTON

FLOATING CALIPER].)

© 2018 Mazda Motor Corporation.

■ FRONT BRAKE HOSE REMOVAL/INSTALLATION [WITH SINGLE PISTON

FLOATING CALIPER]

id0411000006w4

id0411000006w4

Replacement Part

Gasket

Quantity: 2

Location of use: Front brake hose

Oil and Chemical Type

Brake fluid type

Type: SAE J1703 or FMVSS116 DOT-3

Caution

• Brake fluid will damage painted surfaces. Be careful not to spill any on painted surfaces. In addition,

if there is any brake fluid on the wiring harness, the wire insulation may corrode causing a malfunction

such as a short circuit. If brake fluid gets on a painted surface or wiring harness, wash and flush it off

completely with water immediately.

Note

• Tighten the brake pipe flare nut using any commercially available flare nut wrench.

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Remove in the order indicated in the table.

3.Install in the reverse order of removal.

4.After installation, add brake fluid, bleed the air, and inspect for fluid leakage. (See BRAKE FLUID AIR

BLEEDING.)

© 2018 Mazda Motor Corporation.

ac5uuw00007461

1 Brake pipe

Clip

2

(See Clip Installation Note.)

3 Bolt

4 Brake hose

Clip Installation Note

1.Install a clip to the position shown in the figure.

© 2018 Mazda Motor Corporation.

ac5uuw00007462

© 2018 Mazda Motor Corporation.

■ FRONT BRAKE DISC REMOVAL/INSTALLATION [WITH SINGLE PISTON

FLOATING CALIPER]

id0411000001w4

id0411000001w4

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Remove in the order indicated in the table.

3.Install in the reverse order of removal.

4.Depress the brake pedal a few times, rotate the wheel by hand, and verify that the brake does not drag.

ac5uuw00007449

© 2018 Mazda Motor Corporation.

1 Bolt

Front brake caliper component

(See Front Brake Caliper Component Removal Note.)

2

(See Front Brake Caliper Component Installation Note.)

3 Disc plate

Front Brake Caliper Component Removal Note

1.Remove the front brake caliper component and suspend it in a place out of the way using a cable.

ac5uuw00007450

Front Brake Caliper Component Installation Note

1.Push the piston in using the commercially available disc brake expand tool.

© 2018 Mazda Motor Corporation.

ac5uuw00007451

2.Install the front brake caliper component.

© 2018 Mazda Motor Corporation.

■ FRONT BRAKE HOSE REMOVAL/INSTALLATION [WITH 2-PISTON FLOATING

CALIPER]

id0411000006w5

id0411000006w5

Replacement Part

Gasket

Quantity: 2

Location of use: Front brake hose

Oil and Chemical Type

Brake fluid type

Type: SAE J1703 or FMVSS116 DOT-3

Caution

• Brake fluid will damage painted surfaces. Be careful not to spill any on painted surfaces. In addition,

if there is any brake fluid on the wiring harness, the wire insulation may corrode causing a malfunction

such as a short circuit. If brake fluid gets on a painted surface or wiring harness, wash and flush it off

completely with water immediately.

Note

• Tighten the brake pipe flare nut using any commercially available flare nut wrench.

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Remove in the order indicated in the table.

3.Install in the reverse order of removal.

4.After installation, add brake fluid, bleed the air, and inspect for fluid leakage. (See BRAKE FLUID AIR

BLEEDING.)

© 2018 Mazda Motor Corporation.

ac5wzw00009653

1 Brake pipe

Clip

2

(See Clip Installation Note.)

3 Bolt

4 Brake hose

Clip Installation Note

1.Install a clip to the position shown in the figure.

© 2018 Mazda Motor Corporation.

ac5uuw00007462

© 2018 Mazda Motor Corporation.

■ FRONT BRAKE DISC REMOVAL/INSTALLATION [WITH 2-PISTON FLOATING

CALIPER]

id0411000001w5

id0411000001w5

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Remove in the order indicated in the table.

3.Install in the reverse order of removal.

4.Depress the brake pedal a few times, rotate the wheel by hand, and verify that the brake does not drag.

ac5wzw00009644

© 2018 Mazda Motor Corporation.

1 Bolt

Front brake caliper component

(See Front Brake Caliper Component Removal Note.)

2

(See Front Brake Caliper Component Installation Note.)

3 Disc plate

Front Brake Caliper Component Removal Note

1.Remove the front brake caliper component and suspend it in a place out of the way using a cable.

ac5wzw00009645

Front Brake Caliper Component Installation Note

1.Push the piston in using the commercially available disc brake expand tool.

© 2018 Mazda Motor Corporation.

ac5wzw00009646

2.Install the front brake caliper component.

© 2018 Mazda Motor Corporation.

■ FRONT BRAKE DISC PAD REMOVAL/INSTALLATION [WITH SINGLE PISTON

FLOATING CALIPER]

id0411000002w4

id0411000002w4

Oil and Chemical Type

Brake grease (Brown) Brake grease (Black)

Type: Molykote 7439 Type: AS880N

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Remove in the order indicated in the table.

3.Install in the reverse order of removal.

4.Depress the brake pedal a few times, rotate the wheel by hand, and verify that the brake does not drag.

ac5uuw00007452

© 2018 Mazda Motor Corporation.

1 Bolt

2 Caliper

Disc pad

3

(See Disc Pad, Bolt Installation Note.)

4 Shim

Guide plate

5

(See Guide Plate Installation Note.)

Guide Plate Installation Note

Caution

• When assembling the guide plates to the mounting support, securely assemble them on the leading

side and trailing side to each position shown in the figure. If the guide plates are assembled to the

incorrect positions, it could become a source of noise.

1.Install the guide plate as shown in the figure.

ac5uuw00007453

Disc Pad, Bolt Installation Note

1.Clean the exposed area of the piston.

© 2018 Mazda Motor Corporation.

2.Push the piston in using the commercially available disc brake expand tool.

ac5uuw00007454

3.Install the disc pads to the mounting support.

4.Return the caliper to the original position and install the bolt.

© 2018 Mazda Motor Corporation.

■ FRONT BRAKE DISC PAD REMOVAL/INSTALLATION [WITH 2-PISTON

FLOATING CALIPER]

id0411000002w5

id0411000002w5

Oil and Chemical Type

Brake grease (Black)

Type: Daikalub grease

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Remove in the order indicated in the table.

3.Install in the reverse order of removal.

4.Depress the brake pedal a few times, rotate the wheel by hand, and verify that the brake does not drag.

© 2018 Mazda Motor Corporation.

ac5wzw00009647

1 Bolt

2 Caliper

Disc pad

3

(See Disc Pad, Bolt Installation Note.)

4 Shim

5 Guide plate

Disc Pad, Bolt Installation Note

© 2018 Mazda Motor Corporation.

1.Clean the exposed area of the piston.

2.Push the piston in using the commercially available disc brake expand tool.

ac5wzw00009648

3.Install the disc pads to the mounting support.

4.Return the caliper to the original position and install the bolt.

© 2018 Mazda Motor Corporation.

■ FRONT BRAKE CALIPER REMOVAL/INSTALLATION [WITH SINGLE PISTON

FLOATING CALIPER]

id0411000003w4

id0411000003w4

Replacement Part

Gasket

Quantity: 2

Location of use: Front brake hose

Oil and Chemical Type

Brake fluid type

Type: SAE J1703 or FMVSS116 DOT-3

Caution

• Brake fluid will damage painted surfaces. Be careful not to spill any on painted surfaces. In addition,

if there is any brake fluid on the wiring harness, the wire insulation may corrode causing a malfunction

such as a short circuit. If brake fluid gets on a painted surface or wiring harness, wash and flush it off

completely with water immediately.

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Remove in the order indicated in the table.

3.Install in the reverse order of removal.

4.After installation, add brake fluid, bleed the air, and inspect for fluid leakage. (See BRAKE FLUID AIR

BLEEDING.)

5.Depress the brake pedal a few times, rotate the wheel by hand, and verify that the brake does not drag.

© 2018 Mazda Motor Corporation.

ac5uuw00007455

1 Bolt

2 Brake hose

3 Bolt

Front brake caliper

4

(See Front Brake Caliper Installation Note.)

Front Brake Caliper Installation Note

1.Clean the exposed area of the piston.

2.Push the piston in using the commercially available disc brake expand tool.

© 2018 Mazda Motor Corporation.

ac5uuw00007456

3.Install the front brake caliper component.

© 2018 Mazda Motor Corporation.

■ FRONT BRAKE CALIPER DISASSEMBLY/ASSEMBLY [WITH SINGLE PISTON

FLOATING CALIPER]

id0411000004w4

id0411000004w4

Replacement Part

Dust seal Piston seal

Quantity: 1 Quantity: 1

Location of use: Caliper body Location of use: Piston

Oil and Chemical Type

Brake fluid type Rubber grease (Pink)

Type: SAE J1703 or FMVSS116 DOT-3 Type: Oil mixed with rubber grease 3611560 and CCI#20

Caution

• Brake fluid will damage painted surfaces. Be careful not to spill any on painted surfaces. In addition,

if there is any brake fluid on the wiring harness, the wire insulation may corrode causing a malfunction

such as a short circuit. If brake fluid gets on a painted surface or wiring harness, wash and flush it off

completely with water immediately.

1.Remove in the order indicated in the table.

© 2018 Mazda Motor Corporation.

ac5uuw00007457

1 Bleeder cap

2 Bleeder screw

Piston

3

(See Piston Disassembly Note.)

4 Dust seal

5 Piston seal

6 Caliper body

2.Install in the reverse order of removal.

Piston Disassembly Note

Warning

• When compressed air is blown into the caliper body, injury to a finger or other part from pinching

could result from the piston springing up. When blowing in compressed air, do not place your fingers

between the piston and caliper body when performing the work.

Caution

© 2018 Mazda Motor Corporation.

• The piston could be damaged if blown out with great force. Blow the compressed air slowly to

prevent the piston from suddenly popping out.

1.Insert a piece of wood in the caliper as shown in the figure and blow compressed air through the hole to

remove the piston from the caliper body.

ac5wzw00000202

© 2018 Mazda Motor Corporation.

■ FRONT BRAKE CALIPER REMOVAL/INSTALLATION [WITH 2-PISTON

FLOATING CALIPER]

id0411000003w5

id0411000003w5

Replacement Part

Gasket

Quantity: 2

Location of use: Front brake hose

Oil and Chemical Type

Brake fluid type

Type: SAE J1703 or FMVSS116 DOT-3

Caution

• Brake fluid will damage painted surfaces. Be careful not to spill any on painted surfaces. In addition,

if there is any brake fluid on the wiring harness, the wire insulation may corrode causing a malfunction

such as a short circuit. If brake fluid gets on a painted surface or wiring harness, wash and flush it off

completely with water immediately.

1.Remove the wheel and tire. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

2.Remove in the order indicated in the table.

3.Install in the reverse order of removal.

4.After installation, add brake fluid, bleed the air, and inspect for fluid leakage. (See BRAKE FLUID AIR

BLEEDING.)

5.Depress the brake pedal a few times, rotate the wheel by hand, and verify that the brake does not drag.

© 2018 Mazda Motor Corporation.

ac5wzw00009649

1 Bolt

2 Brake hose

3 Bolt

Front brake caliper

4

(See Front Brake Caliper Installation Note.)

Front Brake Caliper Installation Note

1.Clean the exposed area of the piston.

2.Push the piston in using the commercially available disc brake expand tool.

© 2018 Mazda Motor Corporation.

ac5wzw00009650

3.Install the front brake caliper component.

© 2018 Mazda Motor Corporation.

■ FRONT BRAKE CALIPER DISASSEMBLY/ASSEMBLY [WITH 2-PISTON

FLOATING CALIPER]

id0411000004w5

id0411000004w5

Caution

• Brake fluid will damage painted surfaces. Be careful not to spill any on painted surfaces. In addition,

if there is any brake fluid on the wiring harness, the wire insulation may corrode causing a malfunction

such as a short circuit. If brake fluid gets on a painted surface or wiring harness, wash and flush it off

completely with water immediately.

Replacement Part

Dust seal Piston seal

Quantity: 1 Quantity: 1

Location of use: Caliper body Location of use: Piston

Oil and Chemical Type

Brake fluid type Rubber grease (Pink)

Type: SAE J1703 or FMVSS116 DOT-3 Type: Cosmo rubber grease

1.Disassemble in the order indicated in the table.

© 2018 Mazda Motor Corporation.

ac5wzw00009651

1 Bleeder cap

2 Bleeder screw

Piston

3

(See Piston Disassembly Note.)

4 Dust seal

5 Piston seal

6 Caliper body

2.Assemble in the reverse order of removal.

Piston Disassembly Note

Warning

• When compressed air is blown into the caliper body, injury to a finger or other part from pinching

could result from the piston springing up. When blowing in compressed air, do not place your fingers

between the piston and caliper body when performing the work.

Caution

© 2018 Mazda Motor Corporation.

• The piston could be damaged if blown out with great force. Blow the compressed air slowly to

prevent the piston from suddenly popping out.

1.Insert a piece of wood in the caliper as shown in the figure and blow compressed air through the hole to

remove the pistons from the caliper body.

ac9uuw00008899

© 2018 Mazda Motor Corporation.

■ BRAKE PEDAL REMOVAL/INSTALLATION

id041100801200

id041100801200

Replacement Part

Brake switch

Quantity: 1

Location of use: Brake pedal

Caution

• The clearance between the brake switch and the brake pedal is automatically adjusted to the

correct amount when the brake switch is inserted into the installation hole on the brake pedal and

rotated to fix in place. If the brake switch is not properly installed, the clearance may be incorrect,

causing a brake light malfunction. Therefore, always verify that the brake pedal is properly installed

and fully released before installing the brake switch to the pedal.

• Once the brake switch clearance has automatically been adjusted, it cannot be adjusted again.

Therefore, replace the switch with a new one when replacing the power brake unit or the pedal, or

performing any procedure that changes the pedal stroke.

1.Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL

DISCONNECTION/CONNECTION.)

2.Remove the battery. (See BATTERY REMOVAL/INSTALLATION [SKYACTIV-G 2.0, SKYACTIV-G 2.5

(WITHOUT CYLINDER DEACTIVATION)].) (See BATTERY REMOVAL/INSTALLATION [SKYACTIV-G

2.5 (WITH CYLINDER DEACTIVATION)].) (See BATTERY REMOVAL/INSTALLATION [SKYACTIV-D

2.2].)

3.For SKYACTIV-D 2.2 vehicles, remove the following parts:

(1)Windshield wiper arm and blade (See WINDSHIELD WIPER ARM AND BLADE

REMOVAL/INSTALLATION.) (2)Cowl grille (See COWL GRILLE REMOVAL/INSTALLATION.)

(3)Windshield wiper motor and link (See WINDSHIELD WIPER MOTOR AND LINK

REMOVAL/INSTALLATION.) (4)Keyless beeper (With advanced keyless entry system) (See

KEYLESS BEEPER REMOVAL/INSTALLATION.) (5)Cowl panel (See COWL PANEL

REMOVAL/INSTALLATION.)

4.Disconnect the clutch reserve hose from the master cylinder. (MTX) (See MASTER CYLINDER

REMOVAL/INSTALLATION.)

5.Disconnect the brake pipe from the master cylinder. (See MASTER CYLINDER

REMOVAL/INSTALLATION.)

6.Remove in the order indicated in the table.

7.Install in the reverse order of removal.

© 2018 Mazda Motor Corporation.

8.After installation, add brake fluid, bleed the air, and inspect for fluid leakage. (See BRAKE FLUID AIR

BLEEDING.)

ac5uuw00007486

© 2018 Mazda Motor Corporation.

1 Brake switch connector

2 Brake switch wiring harness

Brake switch

3

(See Brake Switch Installation Note.)

Snap pin

4

(See Snap Pin Installation Note.)

5 Clevis pin

Nut

6

(See Nut Installation Note.)

Brake pedal

7

(See Brake Pedal Removal Note.)

8 Pedal pad

Brake Pedal Removal Note

1.Move the power brake unit to the vehicle front where the power brake unit fork does not interfere with

the brake pedal arm.

2.Move the brake pedal in the direction of the arrow shown in the figure, and remove it while avoiding the

hook.

© 2018 Mazda Motor Corporation.

ac5uuw00007487

Nut Installation Note

1.Temporarily tighten nuts A.

ac5uuw00007488

2.Temporarily tighten nuts B.

3.Tighten nuts B to the specified torque.

Tightening torque

19—25 Nm {2.0—2.5 kgf·m, 15—18 ft·lbf}

4.Tighten nuts A to the specified torque.

Tightening torque

© 2018 Mazda Motor Corporation.

19—25 Nm {2.0—2.5 kgf·m, 15—18 ft·lbf}

Snap Pin Installation Note

1.Install the snap pin as shown in the figure.

ac5uuw00007489

Brake Switch Installation Note

1.Inspect the brake pedal. (See BRAKE PEDAL INSPECTION.)

2.With the brake pedal fully released, insert a new brake switch into the installation hole on the brake

pedal.

Caution

• If the brake pedal arm is moved when securing the brake switch, the clearance between the brake

pedal and brake switch may not be adjusted to the correct clearance. Be careful not to move the

brake pedal arm when securing the brake switch.

3.Secure the brake switch by turning it counterclockwise 45°.

© 2018 Mazda Motor Corporation.

ac5uuw00007490

© 2018 Mazda Motor Corporation.

■ BRAKE SWITCH INSPECTION

id041100801900

id041100801900

Caution

• Inspect the brake switch with it installed to the brake pedal, otherwise the brake switch may not

operate normally. If the brake switch is removed from the brake pedal, replace the brake switch with a

new one.

1.Remove the lower panel. (See LOWER PANEL REMOVAL/INSTALLATION.)

2.Remove the front heat duct (LH). (See FRONT HEAT DUCT REMOVAL/INSTALLATION.)

3.Disconnect the brake switch connector.

4.Verify that the continuity is as indicated in the table.

am3uuw00006691

• If not as indicated in the table, replace the brake switch. (SeeBRAKE PEDAL

REMOVAL/INSTALLATION.)

am3zzw00010316

© 2018 Mazda Motor Corporation.

■ BRAKE PEDAL INSPECTION

id041100801100

id041100801100

Pedal Height Inspection

1.Measure the distance from the center of the upper surface of the pedal pad to the floor covering and

verify that it is as specified.

ac5uuw00007484

Brake pedal height (reference value)

137 mm {5.39 in}

• If not within the specification, inspect the following items and repair or replace the applicable part if

there is any malfunction.

― Power brake unit installation condition

― Deformation of or damage to the power brake unit fork

― Brake pedal installation condition

― Clevis pin wear

• If there is no malfunction in the above items, replace the brake pedal. (SeeBRAKE PEDAL

REMOVAL/INSTALLATION.)

Pedal Play Inspection

1.Pump the pedal several times to release the vacuum in the power brake unit.

2.Gently depress the pedal by hand and measure the pedal play.

© 2018 Mazda Motor Corporation.

Brake pedal play

4.8 mm {0.19 in} or less

• If not within the specification, inspect the wear of the clevis pin. Replace it if there is any

malfunction. (SeeBRAKE PEDAL REMOVAL/INSTALLATION.)

• If there is no malfunction in the clevis pin, there is a possibility that the power brake unit has some

malfunction. Verify that there are no malfunctions, and replace it if necessary. (SeePOWER BRAKE

UNIT INSPECTION.) (SeePOWER BRAKE UNIT REMOVAL/INSTALLATION.)

Pedal-to-floor Clearance Inspection

1.Start the engine and depress the brake pedal with a force of 147 N {15.0 kgf, 33.0 lbf}.

2.Measure the distance from the center of the upper surface of the pedal pad to the floor covering and

verify that it is as specified.

ac5uuw00007485

Brake pedal-to-floor clearance

86 mm {3.4 in} or more

• If it is less than the specification, inspect for air in the brake line. (SeeBRAKE FLUID AIR

BLEEDING.)

© 2018 Mazda Motor Corporation.

■ BRAKE FLUID LEVEL SENSOR INSPECTION

id041100801400

id041100801400

1.Disconnect the brake fluid level sensor connector. (See MASTER CYLINDER

REMOVAL/INSTALLATION.)

2.Verify that the continuity is as indicated in the table.

ac5wzw00000247

• If not as indicated in the table, replace the master cylinder component. (SeeMASTER CYLINDER

REMOVAL/INSTALLATION.)

ac5uuw00007365

© 2018 Mazda Motor Corporation.

■ BRAKE FLUID INSPECTION

id041100815200

id041100815200

Oil and Chemical Type

Brake fluid type

Type: SAE J1703 or FMVSS116 DOT-3

Caution

• Brake fluid will damage painted surfaces. Be careful not to spill any on painted surfaces. In addition,

if there is any brake fluid on the wiring harness, the wire insulation may corrode causing a malfunction

such as a short circuit. If brake fluid gets on a painted surface or wiring harness, wash and flush it off

completely with water immediately.

1.Verify that the brake fluid level in the brake fluid reserve tank is between the MAX and MIN marks.

© 2018 Mazda Motor Corporation.

ac5uuw00008274

• If the brake fluid level is below the MIN mark, add brake fluid.

Brake fluid type

SAE J1703 or FMVSS116 DOT-3

© 2018 Mazda Motor Corporation.

■ BRAKE FLUID AIR BLEEDING

id041100815300

id041100815300

Oil and Chemical Type

Brake fluid type

Type: SAE J1703 or FMVSS116 DOT-3

Caution

• Brake fluid will damage painted surfaces. Be careful not to spill any on painted surfaces. In addition,

if there is any brake fluid on the wiring harness, the wire insulation may corrode causing a malfunction

such as a short circuit. If brake fluid gets on a painted surface or wiring harness, wash and flush it off

completely with water immediately.

Note

• Keep the fluid level in the brake fluid reserve tank at 3/4 full or more during the air bleeding.

• Begin air bleeding with the brake caliper that is furthest from the master cylinder.

Brake fluid type

SAE J1703 or FMVSS116 DOT-3

1.Switch the ignition ON (engine off).

2.Release the electric parking brake.

3.Switch the ignition off.

4.Remove the cap from the brake fluid reserved tank and add brake fluid.

5.Remove the bleeder cap on the brake caliper, and attach a vinyl tube to the bleeder screw.

6.Place the other end of the vinyl tube in a clear container and fill the container with fluid during air

bleeding.

7.Working with two people, one should pump the brake pedal several times and depress and hold the

pedal down.

© 2018 Mazda Motor Corporation.

ac4ccw00001649

8.While the brake pedal is depressed, the other should loosen the bleeder screw using a commercially

available flare nut wrench, drain out any fluid containing air bubbles, and tighten the bleeder screw.

ac4ccw00001650

Tightening torque

Front (With single piston floating caliper) : 6.9—9.8 N·m {71—99 kgf·cm, 62—86

in·lbf}Front (With 2-piston floating caliper) : 9—12 N·m {92—122 kgf·cm, 80—

106 in·lbf}Rear: 6.9—9.8 N·m {71—99 kgf·cm, 62—86 in·lbf}

9.Repeat Steps 7 and 8 until no air bubbles are seen.

10.Perform air bleeding as described in the above procedures for all brake calipers.

Note

• If the air bleed from the left/right rear calipers is insufficient, air bleeding can implemented quickly by

operating/releasing the electric parking brake several times while performing the work in Steps 7 and

8.

11.Clean the brake calipers.

12.After air bleeding, inspect the following:

• Brake operation

• Fluid leakage

© 2018 Mazda Motor Corporation.

• Fluid level

© 2018 Mazda Motor Corporation.

You might also like

- Grand Vitara 2010Document169 pagesGrand Vitara 2010CarlosAndresAguirreRiveraNo ratings yet

- 2014-16 Transmission CVT Fluid Change - Corolla (k313)Document16 pages2014-16 Transmission CVT Fluid Change - Corolla (k313)ossoski100% (7)

- J24B EngineDocument196 pagesJ24B EngineLeonel Dominguez100% (3)

- Vacuum Pump Removal - Installation (Skyactiv-D 2.2)Document3 pagesVacuum Pump Removal - Installation (Skyactiv-D 2.2)toywrc100% (2)

- Deere - trs22 UserManualDocument23 pagesDeere - trs22 UserManualcimbom1979No ratings yet

- RB 25 HeadDocument9 pagesRB 25 HeadAlexander Dominguez0% (1)