Professional Documents

Culture Documents

Lean Manufacturing

Lean Manufacturing

Uploaded by

Paula GarzaCopyright:

Available Formats

You might also like

- Activity A8. America BarriosDocument2 pagesActivity A8. America BarriosamericaNo ratings yet

- Quality Assurance,: A Systemic Approach For Effective ComplianceDocument73 pagesQuality Assurance,: A Systemic Approach For Effective ComplianceHemanth PanasaNo ratings yet

- Activity A8. Synoptic PictureDocument1 pageActivity A8. Synoptic PictureJoanna HerreraNo ratings yet

- Top 25 Lean ToolsDocument4 pagesTop 25 Lean ToolsMamun IENo ratings yet

- Manufacturing Scheduling and Workflow AutomationDocument7 pagesManufacturing Scheduling and Workflow AutomationMAMTANo ratings yet

- Lean Manufacturing Tools: EdifymindsDocument3 pagesLean Manufacturing Tools: EdifymindsKomal TagraNo ratings yet

- Pom Reviewer PrelimsDocument7 pagesPom Reviewer Prelimshiraeth.naharaNo ratings yet

- Business & Management Mind Map - W4Document1 pageBusiness & Management Mind Map - W4Diva Tertia AlmiraNo ratings yet

- MANMGT2 First Grading ReviewerDocument5 pagesMANMGT2 First Grading Reviewerpout poutNo ratings yet

- Modul 11Document23 pagesModul 11Reynaldi MaintokNo ratings yet

- Production and Operations Management (Finished)Document12 pagesProduction and Operations Management (Finished)kingfearless27No ratings yet

- Production ManagementDocument39 pagesProduction Managementonly_vimaljoshi80% (5)

- MGMT Unit 1Document12 pagesMGMT Unit 15461 VINAYAK HANDENo ratings yet

- Top 25 Lean Tools White PaperDocument2 pagesTop 25 Lean Tools White PaperVelu KaruppiahNo ratings yet

- Kanban System Analysis and Improvement of The Supply Carset in BMW Logistics at Jakarta Plant Using Just in Time (JIT) MethodDocument9 pagesKanban System Analysis and Improvement of The Supply Carset in BMW Logistics at Jakarta Plant Using Just in Time (JIT) MethodInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Chapter-1 Introduction To Production and Operations ManagementDocument20 pagesChapter-1 Introduction To Production and Operations Managementllpud229.karrthikhNo ratings yet

- Productivity Improvement of AutomotiveDocument26 pagesProductivity Improvement of AutomotivechetanNo ratings yet

- Time For Lean ThinkingDocument2 pagesTime For Lean ThinkingBrendan CrowleyNo ratings yet

- PDPP - Presentation.2.Four Plane Concept of Manufacturing - January.2021Document12 pagesPDPP - Presentation.2.Four Plane Concept of Manufacturing - January.2021Ashish Kumar100% (1)

- Just in TimeDocument56 pagesJust in TimeJuvi CruzNo ratings yet

- IntroductionDocument30 pagesIntroductionNandini SuriNo ratings yet

- Introduction To Production and Operations ManagementDocument30 pagesIntroduction To Production and Operations ManagementReigneir PatotoyNo ratings yet

- What Is TPMDocument10 pagesWhat Is TPMmouNo ratings yet

- Cbac101 ReviewerDocument7 pagesCbac101 ReviewerJeca AranaNo ratings yet

- Lean Synchronization: Key QuestionsDocument31 pagesLean Synchronization: Key QuestionsQuốc PhạmNo ratings yet

- Contemporary Issues in MADocument1 pageContemporary Issues in MAGlydel B. MatayaNo ratings yet

- M Business 4th Edition Ferrell Solutions Manual Full Chapter PDFDocument43 pagesM Business 4th Edition Ferrell Solutions Manual Full Chapter PDFjamesstokesmfyqdrocjp100% (15)

- M Business 4th Edition Ferrell Solutions ManualDocument22 pagesM Business 4th Edition Ferrell Solutions Manualmouldywolves086ez100% (28)

- Value Streams: Fundamentals of Manufacturing Excellence ProgramDocument30 pagesValue Streams: Fundamentals of Manufacturing Excellence ProgramTuan AnhNo ratings yet

- Online NotebookDocument32 pagesOnline NotebookRanveer GurjarNo ratings yet

- Chapter 7 - Conversion Cycle P4Document26 pagesChapter 7 - Conversion Cycle P4Joana TrinidadNo ratings yet

- JITfinalDocument32 pagesJITfinalPradeepNo ratings yet

- Production Notes (Summary)Document2 pagesProduction Notes (Summary)NeenaNo ratings yet

- Maintenance Management Assignment 1: Total Productive Maintenance in RMG IndustryDocument15 pagesMaintenance Management Assignment 1: Total Productive Maintenance in RMG IndustryPrakritiNo ratings yet

- Introduction To Lean ManufacturingDocument37 pagesIntroduction To Lean ManufacturingSubash DhakalNo ratings yet

- Mod 1Document39 pagesMod 1Aitesham JamadarNo ratings yet

- Cost Management For Just-in-Time Environments: Financial and Managerial Accounting 8th Edition Warren Reeve FessDocument57 pagesCost Management For Just-in-Time Environments: Financial and Managerial Accounting 8th Edition Warren Reeve FessRETNO KURNIAWANNo ratings yet

- Simulation of Lean Assembly LineDocument6 pagesSimulation of Lean Assembly Linekarthik_avadiNo ratings yet

- TPM - Key To EfficiencyDocument14 pagesTPM - Key To EfficiencyahmedNo ratings yet

- BPMS Implementation Approach - Elab2007 - Week 7Document44 pagesBPMS Implementation Approach - Elab2007 - Week 7Rommel Risco100% (1)

- Quantity of Products: Part Two: Process SelectionDocument8 pagesQuantity of Products: Part Two: Process SelectionCrestinaNo ratings yet

- 00 Lean ManufacturingDocument12 pages00 Lean ManufacturingErnesto Rascon Basaldua0% (1)

- Lean Tool PDFDocument2 pagesLean Tool PDFTuong Tan100% (1)

- Reducing Turn Around Time in Laboratory Using Value Stream MappingDocument6 pagesReducing Turn Around Time in Laboratory Using Value Stream MappingOussama ElbattatNo ratings yet

- UNIT-1 Production & Operation MGT 2023Document10 pagesUNIT-1 Production & Operation MGT 2023Karan DhiverNo ratings yet

- Clase - Lean ManufacturingDocument12 pagesClase - Lean ManufacturingPaula Andrea SanabriaNo ratings yet

- Cbac101 ReviewerDocument7 pagesCbac101 ReviewerJecaNo ratings yet

- SMT 1Document12 pagesSMT 1scrt-mNo ratings yet

- Production Planning PresentationDocument7 pagesProduction Planning PresentationAnand KumarNo ratings yet

- Anufacturing Perations Anagement: Enterprise Sof T Ware ForDocument7 pagesAnufacturing Perations Anagement: Enterprise Sof T Ware ForPedroNo ratings yet

- Materials Today: Proceedings: C. Hemalatha, K. Sankaranarayanasamy, N. DurairaajDocument5 pagesMaterials Today: Proceedings: C. Hemalatha, K. Sankaranarayanasamy, N. DurairaajNICHOLAS BINSARPANDAPOTANNo ratings yet

- Managing Production and Service OperationsDocument41 pagesManaging Production and Service OperationsJomari GaliasNo ratings yet

- Lesson1 Introduction of Production and Operation ManagementDocument25 pagesLesson1 Introduction of Production and Operation ManagementRJ 1No ratings yet

- Quizlet Unit1Document6 pagesQuizlet Unit1Mohamed AhmedNo ratings yet

- POM Unit 1Document8 pagesPOM Unit 1charith sai t 122013601002No ratings yet

- Kalbe FarmaDocument5 pagesKalbe FarmaRafi WardanaNo ratings yet

- Unit - IDocument29 pagesUnit - Ivikaskumar1986No ratings yet

- POM Midterm ReviewerDocument8 pagesPOM Midterm ReviewerDaniel HunksNo ratings yet

- Om Chap 1-5Document16 pagesOm Chap 1-5cathmarquez0023No ratings yet

- 58IJMPERDFEB201958Document12 pages58IJMPERDFEB201958TJPRC PublicationsNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Background of CompanyDocument8 pagesBackground of CompanyValiant ParaPluieNo ratings yet

- Lesson 2.5 - Self-InspectionDocument3 pagesLesson 2.5 - Self-InspectionMark Harold GonzalesNo ratings yet

- HLS EU Q 47 CalculationDocument23 pagesHLS EU Q 47 CalculationAfri Kesling Document'sNo ratings yet

- Operation Management: Topic: Total Quality Management-TQMDocument20 pagesOperation Management: Topic: Total Quality Management-TQM버니 모지코No ratings yet

- Ishikawa - Juhee, ReenaDocument18 pagesIshikawa - Juhee, ReenaVanshika JainNo ratings yet

- Competitive Manufacturing ManagementDocument3 pagesCompetitive Manufacturing ManagementMBA HODNo ratings yet

- History of Iso9100Document3 pagesHistory of Iso9100dea ortega100% (1)

- (32"-Sawl Bare Pipe) : Quality Assurance Plan / Inspection Test Plan (For Sour Service Application)Document18 pages(32"-Sawl Bare Pipe) : Quality Assurance Plan / Inspection Test Plan (For Sour Service Application)Gordon LongforganNo ratings yet

- Quality Management in Construction Projects L1 PDFDocument40 pagesQuality Management in Construction Projects L1 PDFJamsheedNo ratings yet

- APQP Sample FormatDocument32 pagesAPQP Sample FormatManigandan RNo ratings yet

- CM Chapetr 3Document60 pagesCM Chapetr 3AsisGtNo ratings yet

- Pharmaceutical Manufacturing (With QA With GMP) Lecture: Activity 7Document4 pagesPharmaceutical Manufacturing (With QA With GMP) Lecture: Activity 7Rona MalagambaNo ratings yet

- FDA Good Manufacturing Practices ManualDocument3 pagesFDA Good Manufacturing Practices ManualDanielNo ratings yet

- Worksheet 8 - Interview QuestionsDocument4 pagesWorksheet 8 - Interview QuestionsAR_writing_samplesNo ratings yet

- 40522L22 Article-Rotaru Rev IV PDFDocument9 pages40522L22 Article-Rotaru Rev IV PDFMariana VictoriaNo ratings yet

- Compare ISO 9001 AS9110 RevBDocument1 pageCompare ISO 9001 AS9110 RevBislam_shafik8820No ratings yet

- ECX5267 Answer Guide Unit1-4Document64 pagesECX5267 Answer Guide Unit1-4Jineth C. HettiarachchiNo ratings yet

- Haccp 5.0, 5.1.2.4Document2 pagesHaccp 5.0, 5.1.2.4LIN TCTEMASEKNo ratings yet

- Ramasamy Subburaj Detailed Table of ContentsDocument8 pagesRamasamy Subburaj Detailed Table of ContentsAnand Mosum100% (1)

- Kaoru Ishikawa: One Step FurtherDocument2 pagesKaoru Ishikawa: One Step FurtherRafael De La CruzNo ratings yet

- Quality Management System in The Pharmaceutical Industry: A ReviewDocument8 pagesQuality Management System in The Pharmaceutical Industry: A ReviewAdvanced Research PublicationsNo ratings yet

- GMP FinalDocument37 pagesGMP FinalekramNo ratings yet

- Trainingfacts: Fs 132 - Functional Safety Engineer (Tüv Rheinland)Document1 pageTrainingfacts: Fs 132 - Functional Safety Engineer (Tüv Rheinland)faisal84inNo ratings yet

- ROP Handbook enDocument65 pagesROP Handbook enJoanna AngelopoulouNo ratings yet

- QMS - of A CompanyDocument172 pagesQMS - of A CompanyAvinash ShrivastavaNo ratings yet

- TQM MCQsDocument8 pagesTQM MCQsrattan billawaria100% (1)

- Ameriforge ISO 9001 CERT ANABDocument2 pagesAmeriforge ISO 9001 CERT ANABAkshay RaskarNo ratings yet

- 1 Introduction To Statistical Quality ControlDocument20 pages1 Introduction To Statistical Quality Controljher18No ratings yet

- AS9100 Mandatory RecordsDocument3 pagesAS9100 Mandatory Recordsocardenas9160No ratings yet

Lean Manufacturing

Lean Manufacturing

Uploaded by

Paula GarzaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lean Manufacturing

Lean Manufacturing

Uploaded by

Paula GarzaCopyright:

Available Formats

LEAN MANUFACTURING

LEAN MANUFACTURING

Operations management is

one step ahead of

Production management

production management, or

refers to managing the

it can be said that

activities related to the

production management is a

production of goods

part of operational

management.

Just-In-Time (JIT)

Continuous Flow

Just-in-time is pulling parts through

Continuous Flow is manufacturing production based on customer demand

where work-in-process smoothly flows instead of pushing parts through production

through production with minimal (or based on projected demand. It relies on

no) buffers between steps of the many lean tools, such as Continuous Flow,

manufacturing process. Heijunka, Kanban, Standardized Work and

Takt Time.

Standardized Work

Kaizen (Continuous Improvement)

Standardized Work is documented

procedures for manufacturing that Kaizen is a strategy where employees work

capture best practices (including the together proactively to achieve regular,

time to complete each task). It must be incremental improvements in the

manufacturing process.

“living” documentation that is easy to

change.

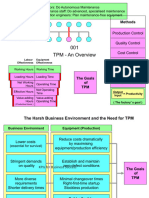

Total Productive Maintenance (TPM)

Kanban (Pull System)

Total Productive Maintenance is a holistic

approach to maintenance that focuses on Kanban is a method of regulating the flow of

proactive and preventative maintenance to goods both within the factory and with

maximize the operational time of outside suppliers and customers. Based on

equipment. TPM blurs the distinction automatic replenishment through signal

between maintenance and production by cards that indicate when more goods are

placing a strong emphasis on empowering needed.

operators to help maintain their equipment.

Toyota Production System (TPS)

Toyota Production System is a

manufacturing strategy developed by

Toyota Motor Corporation of Japan over a

period of many years. TPS focuses on the

complete elimination of waste from the

manufacturing process, and is the

progenitor of lean manufacturing.

Referencia

Vorne Industries Inc – 2011 - 2021. https://www.leanproduction.com/lean-

glossary.html. Lean Production.

You might also like

- Activity A8. America BarriosDocument2 pagesActivity A8. America BarriosamericaNo ratings yet

- Quality Assurance,: A Systemic Approach For Effective ComplianceDocument73 pagesQuality Assurance,: A Systemic Approach For Effective ComplianceHemanth PanasaNo ratings yet

- Activity A8. Synoptic PictureDocument1 pageActivity A8. Synoptic PictureJoanna HerreraNo ratings yet

- Top 25 Lean ToolsDocument4 pagesTop 25 Lean ToolsMamun IENo ratings yet

- Manufacturing Scheduling and Workflow AutomationDocument7 pagesManufacturing Scheduling and Workflow AutomationMAMTANo ratings yet

- Lean Manufacturing Tools: EdifymindsDocument3 pagesLean Manufacturing Tools: EdifymindsKomal TagraNo ratings yet

- Pom Reviewer PrelimsDocument7 pagesPom Reviewer Prelimshiraeth.naharaNo ratings yet

- Business & Management Mind Map - W4Document1 pageBusiness & Management Mind Map - W4Diva Tertia AlmiraNo ratings yet

- MANMGT2 First Grading ReviewerDocument5 pagesMANMGT2 First Grading Reviewerpout poutNo ratings yet

- Modul 11Document23 pagesModul 11Reynaldi MaintokNo ratings yet

- Production and Operations Management (Finished)Document12 pagesProduction and Operations Management (Finished)kingfearless27No ratings yet

- Production ManagementDocument39 pagesProduction Managementonly_vimaljoshi80% (5)

- MGMT Unit 1Document12 pagesMGMT Unit 15461 VINAYAK HANDENo ratings yet

- Top 25 Lean Tools White PaperDocument2 pagesTop 25 Lean Tools White PaperVelu KaruppiahNo ratings yet

- Kanban System Analysis and Improvement of The Supply Carset in BMW Logistics at Jakarta Plant Using Just in Time (JIT) MethodDocument9 pagesKanban System Analysis and Improvement of The Supply Carset in BMW Logistics at Jakarta Plant Using Just in Time (JIT) MethodInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Chapter-1 Introduction To Production and Operations ManagementDocument20 pagesChapter-1 Introduction To Production and Operations Managementllpud229.karrthikhNo ratings yet

- Productivity Improvement of AutomotiveDocument26 pagesProductivity Improvement of AutomotivechetanNo ratings yet

- Time For Lean ThinkingDocument2 pagesTime For Lean ThinkingBrendan CrowleyNo ratings yet

- PDPP - Presentation.2.Four Plane Concept of Manufacturing - January.2021Document12 pagesPDPP - Presentation.2.Four Plane Concept of Manufacturing - January.2021Ashish Kumar100% (1)

- Just in TimeDocument56 pagesJust in TimeJuvi CruzNo ratings yet

- IntroductionDocument30 pagesIntroductionNandini SuriNo ratings yet

- Introduction To Production and Operations ManagementDocument30 pagesIntroduction To Production and Operations ManagementReigneir PatotoyNo ratings yet

- What Is TPMDocument10 pagesWhat Is TPMmouNo ratings yet

- Cbac101 ReviewerDocument7 pagesCbac101 ReviewerJeca AranaNo ratings yet

- Lean Synchronization: Key QuestionsDocument31 pagesLean Synchronization: Key QuestionsQuốc PhạmNo ratings yet

- Contemporary Issues in MADocument1 pageContemporary Issues in MAGlydel B. MatayaNo ratings yet

- M Business 4th Edition Ferrell Solutions Manual Full Chapter PDFDocument43 pagesM Business 4th Edition Ferrell Solutions Manual Full Chapter PDFjamesstokesmfyqdrocjp100% (15)

- M Business 4th Edition Ferrell Solutions ManualDocument22 pagesM Business 4th Edition Ferrell Solutions Manualmouldywolves086ez100% (28)

- Value Streams: Fundamentals of Manufacturing Excellence ProgramDocument30 pagesValue Streams: Fundamentals of Manufacturing Excellence ProgramTuan AnhNo ratings yet

- Online NotebookDocument32 pagesOnline NotebookRanveer GurjarNo ratings yet

- Chapter 7 - Conversion Cycle P4Document26 pagesChapter 7 - Conversion Cycle P4Joana TrinidadNo ratings yet

- JITfinalDocument32 pagesJITfinalPradeepNo ratings yet

- Production Notes (Summary)Document2 pagesProduction Notes (Summary)NeenaNo ratings yet

- Maintenance Management Assignment 1: Total Productive Maintenance in RMG IndustryDocument15 pagesMaintenance Management Assignment 1: Total Productive Maintenance in RMG IndustryPrakritiNo ratings yet

- Introduction To Lean ManufacturingDocument37 pagesIntroduction To Lean ManufacturingSubash DhakalNo ratings yet

- Mod 1Document39 pagesMod 1Aitesham JamadarNo ratings yet

- Cost Management For Just-in-Time Environments: Financial and Managerial Accounting 8th Edition Warren Reeve FessDocument57 pagesCost Management For Just-in-Time Environments: Financial and Managerial Accounting 8th Edition Warren Reeve FessRETNO KURNIAWANNo ratings yet

- Simulation of Lean Assembly LineDocument6 pagesSimulation of Lean Assembly Linekarthik_avadiNo ratings yet

- TPM - Key To EfficiencyDocument14 pagesTPM - Key To EfficiencyahmedNo ratings yet

- BPMS Implementation Approach - Elab2007 - Week 7Document44 pagesBPMS Implementation Approach - Elab2007 - Week 7Rommel Risco100% (1)

- Quantity of Products: Part Two: Process SelectionDocument8 pagesQuantity of Products: Part Two: Process SelectionCrestinaNo ratings yet

- 00 Lean ManufacturingDocument12 pages00 Lean ManufacturingErnesto Rascon Basaldua0% (1)

- Lean Tool PDFDocument2 pagesLean Tool PDFTuong Tan100% (1)

- Reducing Turn Around Time in Laboratory Using Value Stream MappingDocument6 pagesReducing Turn Around Time in Laboratory Using Value Stream MappingOussama ElbattatNo ratings yet

- UNIT-1 Production & Operation MGT 2023Document10 pagesUNIT-1 Production & Operation MGT 2023Karan DhiverNo ratings yet

- Clase - Lean ManufacturingDocument12 pagesClase - Lean ManufacturingPaula Andrea SanabriaNo ratings yet

- Cbac101 ReviewerDocument7 pagesCbac101 ReviewerJecaNo ratings yet

- SMT 1Document12 pagesSMT 1scrt-mNo ratings yet

- Production Planning PresentationDocument7 pagesProduction Planning PresentationAnand KumarNo ratings yet

- Anufacturing Perations Anagement: Enterprise Sof T Ware ForDocument7 pagesAnufacturing Perations Anagement: Enterprise Sof T Ware ForPedroNo ratings yet

- Materials Today: Proceedings: C. Hemalatha, K. Sankaranarayanasamy, N. DurairaajDocument5 pagesMaterials Today: Proceedings: C. Hemalatha, K. Sankaranarayanasamy, N. DurairaajNICHOLAS BINSARPANDAPOTANNo ratings yet

- Managing Production and Service OperationsDocument41 pagesManaging Production and Service OperationsJomari GaliasNo ratings yet

- Lesson1 Introduction of Production and Operation ManagementDocument25 pagesLesson1 Introduction of Production and Operation ManagementRJ 1No ratings yet

- Quizlet Unit1Document6 pagesQuizlet Unit1Mohamed AhmedNo ratings yet

- POM Unit 1Document8 pagesPOM Unit 1charith sai t 122013601002No ratings yet

- Kalbe FarmaDocument5 pagesKalbe FarmaRafi WardanaNo ratings yet

- Unit - IDocument29 pagesUnit - Ivikaskumar1986No ratings yet

- POM Midterm ReviewerDocument8 pagesPOM Midterm ReviewerDaniel HunksNo ratings yet

- Om Chap 1-5Document16 pagesOm Chap 1-5cathmarquez0023No ratings yet

- 58IJMPERDFEB201958Document12 pages58IJMPERDFEB201958TJPRC PublicationsNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Background of CompanyDocument8 pagesBackground of CompanyValiant ParaPluieNo ratings yet

- Lesson 2.5 - Self-InspectionDocument3 pagesLesson 2.5 - Self-InspectionMark Harold GonzalesNo ratings yet

- HLS EU Q 47 CalculationDocument23 pagesHLS EU Q 47 CalculationAfri Kesling Document'sNo ratings yet

- Operation Management: Topic: Total Quality Management-TQMDocument20 pagesOperation Management: Topic: Total Quality Management-TQM버니 모지코No ratings yet

- Ishikawa - Juhee, ReenaDocument18 pagesIshikawa - Juhee, ReenaVanshika JainNo ratings yet

- Competitive Manufacturing ManagementDocument3 pagesCompetitive Manufacturing ManagementMBA HODNo ratings yet

- History of Iso9100Document3 pagesHistory of Iso9100dea ortega100% (1)

- (32"-Sawl Bare Pipe) : Quality Assurance Plan / Inspection Test Plan (For Sour Service Application)Document18 pages(32"-Sawl Bare Pipe) : Quality Assurance Plan / Inspection Test Plan (For Sour Service Application)Gordon LongforganNo ratings yet

- Quality Management in Construction Projects L1 PDFDocument40 pagesQuality Management in Construction Projects L1 PDFJamsheedNo ratings yet

- APQP Sample FormatDocument32 pagesAPQP Sample FormatManigandan RNo ratings yet

- CM Chapetr 3Document60 pagesCM Chapetr 3AsisGtNo ratings yet

- Pharmaceutical Manufacturing (With QA With GMP) Lecture: Activity 7Document4 pagesPharmaceutical Manufacturing (With QA With GMP) Lecture: Activity 7Rona MalagambaNo ratings yet

- FDA Good Manufacturing Practices ManualDocument3 pagesFDA Good Manufacturing Practices ManualDanielNo ratings yet

- Worksheet 8 - Interview QuestionsDocument4 pagesWorksheet 8 - Interview QuestionsAR_writing_samplesNo ratings yet

- 40522L22 Article-Rotaru Rev IV PDFDocument9 pages40522L22 Article-Rotaru Rev IV PDFMariana VictoriaNo ratings yet

- Compare ISO 9001 AS9110 RevBDocument1 pageCompare ISO 9001 AS9110 RevBislam_shafik8820No ratings yet

- ECX5267 Answer Guide Unit1-4Document64 pagesECX5267 Answer Guide Unit1-4Jineth C. HettiarachchiNo ratings yet

- Haccp 5.0, 5.1.2.4Document2 pagesHaccp 5.0, 5.1.2.4LIN TCTEMASEKNo ratings yet

- Ramasamy Subburaj Detailed Table of ContentsDocument8 pagesRamasamy Subburaj Detailed Table of ContentsAnand Mosum100% (1)

- Kaoru Ishikawa: One Step FurtherDocument2 pagesKaoru Ishikawa: One Step FurtherRafael De La CruzNo ratings yet

- Quality Management System in The Pharmaceutical Industry: A ReviewDocument8 pagesQuality Management System in The Pharmaceutical Industry: A ReviewAdvanced Research PublicationsNo ratings yet

- GMP FinalDocument37 pagesGMP FinalekramNo ratings yet

- Trainingfacts: Fs 132 - Functional Safety Engineer (Tüv Rheinland)Document1 pageTrainingfacts: Fs 132 - Functional Safety Engineer (Tüv Rheinland)faisal84inNo ratings yet

- ROP Handbook enDocument65 pagesROP Handbook enJoanna AngelopoulouNo ratings yet

- QMS - of A CompanyDocument172 pagesQMS - of A CompanyAvinash ShrivastavaNo ratings yet

- TQM MCQsDocument8 pagesTQM MCQsrattan billawaria100% (1)

- Ameriforge ISO 9001 CERT ANABDocument2 pagesAmeriforge ISO 9001 CERT ANABAkshay RaskarNo ratings yet

- 1 Introduction To Statistical Quality ControlDocument20 pages1 Introduction To Statistical Quality Controljher18No ratings yet

- AS9100 Mandatory RecordsDocument3 pagesAS9100 Mandatory Recordsocardenas9160No ratings yet