Professional Documents

Culture Documents

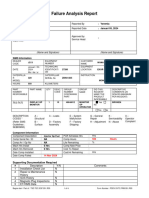

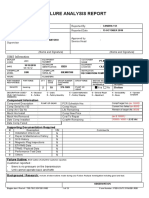

Failure Analysis and Learning Report

Failure Analysis and Learning Report

Uploaded by

AnbarasanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Failure Analysis and Learning Report

Failure Analysis and Learning Report

Uploaded by

AnbarasanCopyright:

Available Formats

Doc Ref No: ESCC/RP/2021/001Rev:01

ENGINEERING SERVICES, Page No:- 1

Document Orissa/AMNS/

No:- Trans/001

FAILURE ANALYSIS LEARNING AND CAPA* Date:- 24/12/2021

Report Header Information

VOLVO Equipment L220G Equipment 0015

Equipment Make

Model serial No

Component

Equipment HMR 24738 Component Transmission Volvo/HTL306

Make / Model

22575 10255 Component 24738 HRS 2nd Hand Purchase

Component Serial No Component type

Life

Failures observed:

1. Gear Shifting Problem found.

First information of failure/ Observations:

Gear shifting Problem

Spares changed History:

Sl.No Parts Description Part No Qty If Known source Remarks

Note:Not changed.(Scope: Inspection & testing)

Team who attended:

1. Mr.Amarjith – Sr.Engineer (Scope: Inspection and testing).

2. Mr.Aditiya- Service Engineer (Calibiration).

3. Subburaja Sethuraman- Sr. Enginner ( Engine Sec).

Team who observed failure:

1. Mr. Amarjith & Mr. Subburaja

Team who did failure analysis:

Where was failure observed:

1. Gear shift problem at mines.

Failure Analysis Steps:

1. Transmission gear shifting problem found.

2. Checked Error codes & electrical side-No abnormalities.

3. Carried out Transmission pressure test, Found pressure low for convertor &

lubrication.

4. Checked strainer found minor metal particles.

5. Stopped the machine & removed the transmission for overhauling purpose.

State facts, History & Observation:

1. No previous gear shifting issue found.

List of possible causes for this failure:

Investigation steps:

a) Summary of Facts gathered that eliminates each Possible root cause

b) Summary of facts gathered that supports each possible root cause

Is it a Repeated failure:( If yes ,1st.2nd,3rd …..with dates & HMR

1. Not known (Old & purchased)

Spares consumed to attend failure:

Is there further scope to investigate failure:

Share any documents related to this failure:

Digital images related to this failure:

Cost of failure:

Final learning from failure:

File Note:

a) Conclusion of root cause analysis

b) Scope of work carried out to recondition the sub assembly

c) Caution to be adopted to avoid repeated failure:

Prepared By:

Validated By:

You might also like

- CUMMINS 6BT5.9 Manuals: CUMMINS 6BT5.9 Shop Manual (462 Pages) (/manual/1201997/Cummins-5-9.html#product-6BT5.9)Document4 pagesCUMMINS 6BT5.9 Manuals: CUMMINS 6BT5.9 Shop Manual (462 Pages) (/manual/1201997/Cummins-5-9.html#product-6BT5.9)Anbarasan63% (8)

- Workshop, Repair and Service Manuals, Wiring Diagrams, Fault Codes PDF - More Than 1000+ Truck Manuals Are Available For Free Download!Document12 pagesWorkshop, Repair and Service Manuals, Wiring Diagrams, Fault Codes PDF - More Than 1000+ Truck Manuals Are Available For Free Download!Anbarasan0% (1)

- The Cubonomicon v1Document43 pagesThe Cubonomicon v1javandarNo ratings yet

- Parameter List MCS - RCB2Document34 pagesParameter List MCS - RCB2FazilNo ratings yet

- Coastal Engineering Manual: Overview And Coastal HydrodynamicsFrom EverandCoastal Engineering Manual: Overview And Coastal HydrodynamicsNo ratings yet

- Volvo L220G Wheel Loader Service Repair Manual - Service Manual DownloadDocument3 pagesVolvo L220G Wheel Loader Service Repair Manual - Service Manual DownloadAnbarasan25% (4)

- Volvo L220G Wheel Loaders Service Manual - A++ Repair Manual StoreDocument22 pagesVolvo L220G Wheel Loaders Service Manual - A++ Repair Manual StoreAnbarasan50% (2)

- Dokumen - Tips Toyota BT Lpe200 Electric Pallet Truck Service Repair Manual1Document23 pagesDokumen - Tips Toyota BT Lpe200 Electric Pallet Truck Service Repair Manual1Kadir Türksoy67% (3)

- Component Maintenance Manual Cargo Hook Suspension SystemDocument30 pagesComponent Maintenance Manual Cargo Hook Suspension SystemAlireza Samavati.H100% (1)

- 2015-LMFP-016 Guide For U1-2115 Error and Abnormal Noise SL-M437x 537x SeriesDocument4 pages2015-LMFP-016 Guide For U1-2115 Error and Abnormal Noise SL-M437x 537x SeriesAntonio HerreraNo ratings yet

- Far ZBN41205Document4 pagesFar ZBN41205yeremia kristianNo ratings yet

- Report JLG E450AJ - B300017885Document4 pagesReport JLG E450AJ - B300017885Agung SantosoNo ratings yet

- C15 Additional Part Bushing Cam ShaftDocument7 pagesC15 Additional Part Bushing Cam ShaftYeremiaNo ratings yet

- Eo Atr42-72-21001 R00 Ata 72 - Engine - Igniter Plug With Incorrect Terminal - Inspection ofDocument7 pagesEo Atr42-72-21001 R00 Ata 72 - Engine - Igniter Plug With Incorrect Terminal - Inspection ofVince Renier RamosNo ratings yet

- Anant Corr. MOM 7-08-18Document4 pagesAnant Corr. MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- Failure Analysis and Learning ReportDocument5 pagesFailure Analysis and Learning ReportAsim GhoshNo ratings yet

- FAR D6R LH Final Drive FailureDocument9 pagesFAR D6R LH Final Drive Failurealisa alainaNo ratings yet

- Document Review Sheet: (Refer To Transmittal For Return Date)Document4 pagesDocument Review Sheet: (Refer To Transmittal For Return Date)BalasubramanianNo ratings yet

- Failure Analysis Report: SIMS InformationDocument13 pagesFailure Analysis Report: SIMS InformationHasby PotterNo ratings yet

- Vdb016 Ar4000 IronDocument297 pagesVdb016 Ar4000 IronBruno MapurungaNo ratings yet

- 19.10.2005 SSVV-IN: Date SignDocument33 pages19.10.2005 SSVV-IN: Date SignNguyen binhNo ratings yet

- Parts Manual Service Manual: Serial Number Range Serial Number RangeDocument183 pagesParts Manual Service Manual: Serial Number Range Serial Number Rangejamalhabbas742No ratings yet

- Technical Analysis Report: Pt. Putra Perkasa AbadiDocument2 pagesTechnical Analysis Report: Pt. Putra Perkasa Abadiainul arifNo ratings yet

- Kobelco Service Bulletin Posting Notification: - Important InformationDocument10 pagesKobelco Service Bulletin Posting Notification: - Important InformationJuan Carlos Moncada PáezNo ratings yet

- Trouble Shooting Hydrolik pc210Document5 pagesTrouble Shooting Hydrolik pc210jajajaparudinNo ratings yet

- Delivery Programme: IVS Mounting Rail Adapter Part No. M22-IVS Article No. 216400 Catalog No. M22-IVSQDocument1 pageDelivery Programme: IVS Mounting Rail Adapter Part No. M22-IVS Article No. 216400 Catalog No. M22-IVSQRamius HamdaniNo ratings yet

- 007-Equipment Utilization ReportDocument1 page007-Equipment Utilization ReportNATLUS AGNo ratings yet

- Failure Analysis Report AFA 1Document5 pagesFailure Analysis Report AFA 1bartanto59No ratings yet

- IMIRDocument10 pagesIMIRvizagnucalcuttaNo ratings yet

- Service Air Comp MAS G250 - Spare PartsDocument87 pagesService Air Comp MAS G250 - Spare PartsecrNo ratings yet

- Operation, Installation, Maintenance Manual Air Intake Silencer Item: 02D001 Ton: 1021D001Document6 pagesOperation, Installation, Maintenance Manual Air Intake Silencer Item: 02D001 Ton: 1021D001Arun KarthikeyanNo ratings yet

- WCR For Canon Motor Relay FailureDocument1 pageWCR For Canon Motor Relay FailureIqmal WahabNo ratings yet

- Solar Power System ManualDocument184 pagesSolar Power System ManualChanuka JayamalNo ratings yet

- Maintenance Transaction Record: Aircraft Identification and StatusDocument1 pageMaintenance Transaction Record: Aircraft Identification and StatusAlejandro BarradasNo ratings yet

- C 051 390 MCC TR2!01!0002 Rev.1 DRS MCC Condensate RecyclingDocument4 pagesC 051 390 MCC TR2!01!0002 Rev.1 DRS MCC Condensate RecyclingBalasubramanianNo ratings yet

- Cover Sheet: Zapsib-2 ProjectDocument12 pagesCover Sheet: Zapsib-2 ProjectAkhtar AnsariNo ratings yet

- Eg5007 0 1Document2 pagesEg5007 0 1Victor SanchezNo ratings yet

- Win Progress Co., LTD.: Technical Service BulletinDocument2 pagesWin Progress Co., LTD.: Technical Service BulletinKhincho ayeNo ratings yet

- GIR-TVI-002 - NDE Inner Enclosure Missing Bolts Report - R1Document19 pagesGIR-TVI-002 - NDE Inner Enclosure Missing Bolts Report - R1junclarcNo ratings yet

- Failure Analysis Report DT2327 EngineDocument11 pagesFailure Analysis Report DT2327 EngineEng PLM ACPNo ratings yet

- FAR Transmission PEX 3030 300 766Document4 pagesFAR Transmission PEX 3030 300 766yohanes moningkaNo ratings yet

- Anant SPG MOM 7-08-18Document4 pagesAnant SPG MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- A-4 Calibration Check ReportDocument2 pagesA-4 Calibration Check ReportheikelNo ratings yet

- Service Bulletin Trucks: Special Tools, Group 7Document8 pagesService Bulletin Trucks: Special Tools, Group 7mattkidoNo ratings yet

- MSC Circ980a2Document313 pagesMSC Circ980a2Pradyumna SahooNo ratings yet

- Win Progress Co., LTD.: Technical Service BulletinDocument2 pagesWin Progress Co., LTD.: Technical Service BulletinKo ZayNo ratings yet

- Planos Top Drive TDS11 Ideal PDFDocument890 pagesPlanos Top Drive TDS11 Ideal PDFpablo100% (3)

- RecafcoDocument1 pageRecafcom.aliNo ratings yet

- Ta Cece JuniDocument2 pagesTa Cece JuniAsram HasanNo ratings yet

- CN202400-8002 On/ Off Valves: C/o Chemetics IncDocument2 pagesCN202400-8002 On/ Off Valves: C/o Chemetics IncImam Zulfir RamandhaNo ratings yet

- DIR-CT-030-140 Bellow Falier .Document1 pageDIR-CT-030-140 Bellow Falier .Service CoatechNo ratings yet

- SR 8500070836 GOH Engine Rig Maera 3516 73Z00324 PT ApexindoDocument45 pagesSR 8500070836 GOH Engine Rig Maera 3516 73Z00324 PT ApexindoRachmad HidayatNo ratings yet

- WS 004 Capability Change RequestDocument2 pagesWS 004 Capability Change RequestsamyghallabNo ratings yet

- T-4, F- 14, 15 U.T ProtocalDocument2 pagesT-4, F- 14, 15 U.T ProtocaltrivikramraoNo ratings yet

- C 051 390 MCC TR2!02!001 Rev.1 DRS Gas SweeteringDocument6 pagesC 051 390 MCC TR2!02!001 Rev.1 DRS Gas SweeteringBalasubramanianNo ratings yet

- Analisa GMT John Deere PDFDocument8 pagesAnalisa GMT John Deere PDFHidayatNo ratings yet

- ATP IndexDocument2,352 pagesATP IndexRicardo zafra100% (1)

- CCR JN 5646488-Sis-C9 Engine en Mbd09063-High BlowbyDocument15 pagesCCR JN 5646488-Sis-C9 Engine en Mbd09063-High Blowbyahmat ramadaniNo ratings yet

- Ear - Eng.002.2015 Mpi Machine r1Document3 pagesEar - Eng.002.2015 Mpi Machine r1galihteaNo ratings yet

- Ups Train3Document157 pagesUps Train3Younes SaifiNo ratings yet

- SurfaceDocument3 pagesSurfacedhaninurhidayat1933No ratings yet

- SDV TSB 079 May 2011Document2 pagesSDV TSB 079 May 2011Khincho ayeNo ratings yet

- WI-TC-020 Landing Gear Overhaul & RepairDocument14 pagesWI-TC-020 Landing Gear Overhaul & RepairwildanmuhammadnajmiNo ratings yet

- Checklist Fire StopDocument9 pagesChecklist Fire StopAnonymous DMdGdsOENo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Grader 4Document10 pagesGrader 4AnbarasanNo ratings yet

- Tata LPT 1613 SpecificationsDocument4 pagesTata LPT 1613 SpecificationsAnbarasanNo ratings yet

- Grader 3Document5 pagesGrader 3AnbarasanNo ratings yet

- Grader 1Document6 pagesGrader 1AnbarasanNo ratings yet

- KleemannDocument1 pageKleemannAnbarasanNo ratings yet

- Wheel Loaders Specs and ChartsDocument3 pagesWheel Loaders Specs and ChartsAnbarasanNo ratings yet

- Thermostats: What Is A Thermostat?Document7 pagesThermostats: What Is A Thermostat?AnbarasanNo ratings yet

- Grader 2Document2 pagesGrader 2AnbarasanNo ratings yet

- Fhewoighwr 2Document6 pagesFhewoighwr 2AnbarasanNo ratings yet

- DGMS5Document2 pagesDGMS5AnbarasanNo ratings yet

- Specifications: TATA SK 1613Document3 pagesSpecifications: TATA SK 1613AnbarasanNo ratings yet

- DGMS1Document11 pagesDGMS1AnbarasanNo ratings yet

- DGMS7Document3 pagesDGMS7AnbarasanNo ratings yet

- Lem1 4Document2 pagesLem1 4AnbarasanNo ratings yet

- Part No Details of FMPLDocument117 pagesPart No Details of FMPLAnbarasanNo ratings yet

- SyllabusDocument4 pagesSyllabusAnbarasanNo ratings yet

- D1105 BG2 1500RPMDocument2 pagesD1105 BG2 1500RPMAnbarasanNo ratings yet

- OBD2 Scanner, Car Code Reader, TOPDON AL400 Check Engine Light Scan Tool, Car Scanner With O2 Sensor/Freeze Frame/I/M Readiness/Smog Check/DTC Lookup, CAN Diagnostic Scanner For All OBDII CarsDocument3 pagesOBD2 Scanner, Car Code Reader, TOPDON AL400 Check Engine Light Scan Tool, Car Scanner With O2 Sensor/Freeze Frame/I/M Readiness/Smog Check/DTC Lookup, CAN Diagnostic Scanner For All OBDII CarsAnbarasanNo ratings yet

- AL3Document5 pagesAL3AnbarasanNo ratings yet

- Owner's Manual Owner's Manual: All AllDocument6 pagesOwner's Manual Owner's Manual: All AllAnbarasanNo ratings yet

- 6BTA 5.9 G2-1 Cummins Engine Performance and Emission Tests Using Methyl Ester Mahua (Madhuca Indica) Oil - Diesel Blends - ScienceDirectDocument3 pages6BTA 5.9 G2-1 Cummins Engine Performance and Emission Tests Using Methyl Ester Mahua (Madhuca Indica) Oil - Diesel Blends - ScienceDirectAnbarasanNo ratings yet

- Tata Truck Service Manual PDF - : PinterestDocument2 pagesTata Truck Service Manual PDF - : PinterestAnbarasan100% (1)

- Shanghai Client Diesel Engine Co., LTD.: CategoriesDocument11 pagesShanghai Client Diesel Engine Co., LTD.: CategoriesAnbarasanNo ratings yet

- Truck Manuals PDFDocument4 pagesTruck Manuals PDFAnbarasanNo ratings yet

- GREENE AaronDocument56 pagesGREENE AaronVisnja DjordjicNo ratings yet

- G.O.Ms - No.105, Dated13.11.2015 PDFDocument4 pagesG.O.Ms - No.105, Dated13.11.2015 PDFsiddaraju krishna29gowdaNo ratings yet

- Thomas Carlyle - A Sign of The TimesDocument11 pagesThomas Carlyle - A Sign of The TimesJack ReadNo ratings yet

- Translating English Sentences To Mathematical Sentences and Vice-VersaDocument8 pagesTranslating English Sentences To Mathematical Sentences and Vice-VersaDana0% (1)

- Unit-2 Design ConceptsDocument37 pagesUnit-2 Design ConceptsNeo TarunNo ratings yet

- Tutorial Letter 101/3/2018: Basic Numeracy BNU1501 Semesters 1 and 2Document58 pagesTutorial Letter 101/3/2018: Basic Numeracy BNU1501 Semesters 1 and 2Ngoni B MakakaNo ratings yet

- Tribes in The Dark Quickstart (32317351)Document61 pagesTribes in The Dark Quickstart (32317351)jvmarron100% (1)

- Lesson - 3 Periodic TableDocument19 pagesLesson - 3 Periodic TableHeaven varghese C S C SNo ratings yet

- Leviton AppNote RetentionForceTechnologyDocument5 pagesLeviton AppNote RetentionForceTechnologySajeda M. Al-TalafhaNo ratings yet

- Tailings Filtration Using Viper Filtration TechnolDocument7 pagesTailings Filtration Using Viper Filtration TechnolNicoViljoenNo ratings yet

- Clearias Upsc Prelims Online Mock Test Series 2021 Timetable v1Document58 pagesClearias Upsc Prelims Online Mock Test Series 2021 Timetable v1Silpa KrishnaveniNo ratings yet

- Lorus Watch Manual PDFDocument2 pagesLorus Watch Manual PDFDave Long100% (1)

- Terhadap Pola Hidup Sehat Masyarakat Kecamatan PrambananDocument10 pagesTerhadap Pola Hidup Sehat Masyarakat Kecamatan PrambananNurul HidayatNo ratings yet

- Lec 3 (Linked List)Document12 pagesLec 3 (Linked List)Dr LolaNo ratings yet

- Automated Object Oriented Door BellDocument3 pagesAutomated Object Oriented Door Bellcarl eliot100% (1)

- Yg-1 V7plusa Endmill America YuDocument25 pagesYg-1 V7plusa Endmill America YuLuis CoolNo ratings yet

- Act 1Document5 pagesAct 1Yue YueNo ratings yet

- Group 3 Written Report Unit III 1Document8 pagesGroup 3 Written Report Unit III 1Almere AzurNo ratings yet

- 2000 Words EssayDocument6 pages2000 Words Essaylwfdwwwhd100% (2)

- APADocument2 pagesAPANovianto Dwi putraNo ratings yet

- Training and Development: 06/30/2022 HRM Chapter 5 - Truong Nu To Giang 1Document54 pagesTraining and Development: 06/30/2022 HRM Chapter 5 - Truong Nu To Giang 1Trần LuânNo ratings yet

- Homework 2 IENG584Document3 pagesHomework 2 IENG584Frida YoungNo ratings yet

- Challenges Faced by An Economics TeacherDocument8 pagesChallenges Faced by An Economics TeacherSanjay mehta100% (4)

- Cot1 DLPDocument11 pagesCot1 DLPNelvie DatuNo ratings yet

- BNN-Orientierungswert EN 22122021Document4 pagesBNN-Orientierungswert EN 22122021MOhamedNo ratings yet

- Overleaf Amsl Package PDFDocument44 pagesOverleaf Amsl Package PDFBruce LimNo ratings yet

- Geology For CE Module Ch2 - 2Document12 pagesGeology For CE Module Ch2 - 2Anthony LoñezNo ratings yet

- Checking of Forms Sample TemplateDocument3 pagesChecking of Forms Sample TemplateMilain NabiaNo ratings yet

- MC74VHC00 D-2315589Document9 pagesMC74VHC00 D-2315589rajabur688No ratings yet