Professional Documents

Culture Documents

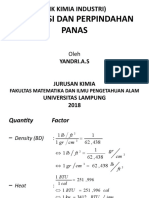

Conversion Factors 21

Conversion Factors 21

Uploaded by

Andri MPCopyright:

Available Formats

You might also like

- ASTM D3359-22 Standard Test Methods For Rating Adhesion by Tape TestDocument8 pagesASTM D3359-22 Standard Test Methods For Rating Adhesion by Tape TestManuela Castañeda100% (4)

- To Calculate A Quick Budget Price For A Stainless Steel Tank That Includes The FollowingDocument18 pagesTo Calculate A Quick Budget Price For A Stainless Steel Tank That Includes The Followingjayvijay009No ratings yet

- Magnetic ORMUS Vortex TrapDocument10 pagesMagnetic ORMUS Vortex TrapZach Royer100% (2)

- WWW - Duchesne.ca: 1. ManufacturerDocument2 pagesWWW - Duchesne.ca: 1. ManufacturerKen ShackelNo ratings yet

- Conversion FactorDocument2 pagesConversion FactorLea Gerelyn DucayNo ratings yet

- Conversion FactorsDocument1 pageConversion FactorsLea Gerelyn DucayNo ratings yet

- Convert in ExcelDocument8 pagesConvert in ExcelMadhuNo ratings yet

- Calculation For Steam Blow Rev03Document6 pagesCalculation For Steam Blow Rev03tauqeerNo ratings yet

- Mass Pressure: Physical Quantity Conversion FactorDocument2 pagesMass Pressure: Physical Quantity Conversion FactorGeorina Lycon TubieraNo ratings yet

- Process and Mechanical Standard Table: Appendix ADocument11 pagesProcess and Mechanical Standard Table: Appendix AGiovanniNo ratings yet

- Tablas de ConversionDocument5 pagesTablas de ConversionFisicoquimica ULSNo ratings yet

- Tabla de Conversión - 2022Document5 pagesTabla de Conversión - 2022benja navarreteNo ratings yet

- Fundamental Constants and Conversion Factors Gas Law Constant RDocument9 pagesFundamental Constants and Conversion Factors Gas Law Constant RyusefriNo ratings yet

- Conversion FactorsDocument2 pagesConversion FactorsKathleen May BarrilNo ratings yet

- Thermodynamics Topic 1Document11 pagesThermodynamics Topic 1Sunshine FelongcoNo ratings yet

- Sedco Forex - Drilling Operations: Conversion FactorsDocument1 pageSedco Forex - Drilling Operations: Conversion FactorsAlex SpanacheNo ratings yet

- En - Hydraulic CoursesDocument47 pagesEn - Hydraulic CoursesAhmed MoustafaNo ratings yet

- ReviewerDocument2 pagesReviewerNeo GarceraNo ratings yet

- Factores Conversión de UnidadesDocument4 pagesFactores Conversión de UnidadesCristobal OlguinNo ratings yet

- Fundamental Constants and Conversion FactorsDocument4 pagesFundamental Constants and Conversion FactorsSagitaa DwiiNo ratings yet

- Unit Conversion Table.Document1 pageUnit Conversion Table.muthukumarm4023No ratings yet

- Multiple by To Get Inch 2.54 CM This Can Also Be Written As: 1 Inch 2.54 CM ADocument1 pageMultiple by To Get Inch 2.54 CM This Can Also Be Written As: 1 Inch 2.54 CM ANoé Mayor HernándezNo ratings yet

- Unit ConversionDocument2 pagesUnit ConversionBoy BangusNo ratings yet

- Unit ConversionDocument2 pagesUnit Conversionma.shaheNo ratings yet

- Measurement ConversionsDocument1 pageMeasurement ConversionsgsbkgpymopaybcqiqcNo ratings yet

- Conversion FactorsDocument1 pageConversion Factorsuetian729No ratings yet

- Fluid Mechanics - Needed Units and ConversionsDocument2 pagesFluid Mechanics - Needed Units and ConversionsMista LuaiNo ratings yet

- 1083appa - 2 - A.2 Engineering Conversion FactorsDocument22 pages1083appa - 2 - A.2 Engineering Conversion FactorsNurdeny Hidayanto PribadiNo ratings yet

- Tabel FAKTOR KONVERSIDocument1 pageTabel FAKTOR KONVERSIFattaNo ratings yet

- Konversi Dan Perpindahan Panas (Yandri)Document16 pagesKonversi Dan Perpindahan Panas (Yandri)Merry YantiNo ratings yet

- Tabela de Conversão de UnidadesDocument1 pageTabela de Conversão de UnidadesrobertaNo ratings yet

- Conversion Factors - 2014 - Process Heat TransferDocument2 pagesConversion Factors - 2014 - Process Heat TransferBryanNo ratings yet

- Practical Units For Fps Mks and Cgs SystDocument2 pagesPractical Units For Fps Mks and Cgs SystRohail HussainNo ratings yet

- Pressur Drop Calculation For DS Unit Vessels With F ProductsDocument9 pagesPressur Drop Calculation For DS Unit Vessels With F ProductsMaryam vafaee.nNo ratings yet

- Conversion FactorsDocument1 pageConversion FactorsDiana AmadoNo ratings yet

- Conversion of Units LengthDocument4 pagesConversion of Units LengthRoscarl GorospeNo ratings yet

- Acacia Pure Spec (Nov 2016)Document1 pageAcacia Pure Spec (Nov 2016)Adriel KurniawanNo ratings yet

- Station 0 - Freestream (Compresser Inlet) DescriptionDocument6 pagesStation 0 - Freestream (Compresser Inlet) DescriptionBonaventure Mills-DadsonNo ratings yet

- 01 General FormulaeDocument10 pages01 General FormulaenelsonhugoNo ratings yet

- Calculos TFDocument8 pagesCalculos TFJUAN PABLO DIAZ CANDELERONo ratings yet

- Halliburton Main Menu Ver 3Document83 pagesHalliburton Main Menu Ver 3Alejandro RivasNo ratings yet

- Appendix (Steam Tabel,.Etc)Document43 pagesAppendix (Steam Tabel,.Etc)Akun RPNo ratings yet

- Introduction To Fluid Mechanics, Eighth EditionDocument2 pagesIntroduction To Fluid Mechanics, Eighth EditionAnonymous JN21JYuMhcNo ratings yet

- Formulas in PhysicsDocument2 pagesFormulas in PhysicsChristine Irish Yebes MacaliNo ratings yet

- Conversion FactorsDocument2 pagesConversion FactorsThiago Rocha GomesNo ratings yet

- h-101 TwiceDocument20 pagesh-101 TwiceAdela ShofiaNo ratings yet

- Book 2Document15 pagesBook 2futhanul weweNo ratings yet

- Part 4 - Conversion FactorsDocument4 pagesPart 4 - Conversion FactorsCarlo Ray SelabaoNo ratings yet

- Gas Flow Rate Mass Flow Mol Flow Gas Volume FlowDocument9 pagesGas Flow Rate Mass Flow Mol Flow Gas Volume FlownivethithaNo ratings yet

- Unit ConversionDocument1 pageUnit ConversionfkpcwNo ratings yet

- Casing Data Bit Data Mud Data: Hours RemarksDocument8 pagesCasing Data Bit Data Mud Data: Hours RemarksdiegoNo ratings yet

- 1986 Bookmatter PetroleumEngineering Units ConversionDocument105 pages1986 Bookmatter PetroleumEngineering Units ConversionRosana da CunhaNo ratings yet

- Anchor LengthDocument1 pageAnchor LengthSaqib LaeeqNo ratings yet

- Cálculo Selección Molinos 11.10.19Document24 pagesCálculo Selección Molinos 11.10.19Edgardo Soto HermenegildoNo ratings yet

- Practica Post CyO 2Document11 pagesPractica Post CyO 2eljerrymoonNo ratings yet

- Design of Slab BridgesDocument12 pagesDesign of Slab BridgesEna Mie CambaNo ratings yet

- Vessel NewDocument16 pagesVessel NewakshaybhuranNo ratings yet

- Halliburton CalculationsDocument71 pagesHalliburton CalculationsIGNATIUS MANOSAYNo ratings yet

- PIPE-100: Variabel Satuan Sumur HCE 29 Pad 7Document55 pagesPIPE-100: Variabel Satuan Sumur HCE 29 Pad 7Hesti Fuzi LestariNo ratings yet

- ConvertDocument4 pagesConvertHasif MohammedNo ratings yet

- SPE Nomenclature and Symbols PDFDocument105 pagesSPE Nomenclature and Symbols PDFJuan GómezNo ratings yet

- Triple Crown: - Higher Pressures - Improved Temperatures - Improved Abrasion ResistanceDocument8 pagesTriple Crown: - Higher Pressures - Improved Temperatures - Improved Abrasion ResistanceKeron TrotzNo ratings yet

- Important To Write The Correct Structure FromDocument16 pagesImportant To Write The Correct Structure FromR A V INo ratings yet

- TE - 2019 - Composite Materials With AnswerDocument38 pagesTE - 2019 - Composite Materials With AnswerAditya NanekarNo ratings yet

- Smeb MP 150 Cement Sc4000Document7 pagesSmeb MP 150 Cement Sc4000andrecormeNo ratings yet

- Alvó KutyusDocument11 pagesAlvó KutyusÁgi Markó100% (1)

- Engineering Steels PDFDocument432 pagesEngineering Steels PDFMargarita Romero EscalanteNo ratings yet

- Concrete MSDS 5 PDFDocument2 pagesConcrete MSDS 5 PDFmanil_5No ratings yet

- TDS PDF Intertherm - 751CSADocument4 pagesTDS PDF Intertherm - 751CSAwilliam sukyonoNo ratings yet

- CCS001Document5 pagesCCS001durgesh yadavNo ratings yet

- Bsi Eof DWG Cs 150 (0) - Lighting Pole 10m HeightDocument1 pageBsi Eof DWG Cs 150 (0) - Lighting Pole 10m Heightdharu100% (1)

- Pump Shaft Repair Recommendation GuidelinesDocument4 pagesPump Shaft Repair Recommendation Guidelineschiz escudero100% (2)

- Sx-70 Cover Installation Instructions: Please Remove Your Old Camera Cover. Also Remove AnyDocument1 pageSx-70 Cover Installation Instructions: Please Remove Your Old Camera Cover. Also Remove AnyAlix RâNo ratings yet

- Investigatory File On Foaming Capacity of SoapsDocument16 pagesInvestigatory File On Foaming Capacity of SoapsAditya Pratap Singh Sengar92% (13)

- EN9 Technical Data: Print Friendly Text Only Site MapDocument1 pageEN9 Technical Data: Print Friendly Text Only Site MapMari selvamNo ratings yet

- Determination of Velocity Seal Area Reduction BaseDocument5 pagesDetermination of Velocity Seal Area Reduction BaseNajem A. SakorNo ratings yet

- Bearing Steel 100Cr6 AUSA - 2Document3 pagesBearing Steel 100Cr6 AUSA - 2suresh kumarNo ratings yet

- Principle: Evaporation Loss / VolatilityDocument2 pagesPrinciple: Evaporation Loss / VolatilityMiguelNo ratings yet

- Safe Work Method Statement For Welding of Pipes WPS PQR PDFDocument3 pagesSafe Work Method Statement For Welding of Pipes WPS PQR PDFDeepak RajanNo ratings yet

- PLAS 4180 / PLAS 5180 Plastic Part Design: Other Molding ProcessesDocument15 pagesPLAS 4180 / PLAS 5180 Plastic Part Design: Other Molding ProcessesBethany SilvaNo ratings yet

- Upcycle Portfolio Lala Boria DiazDocument1 pageUpcycle Portfolio Lala Boria Diazapi-644244557No ratings yet

- Plamcor - 1: Bloating Fireproof PaintDocument2 pagesPlamcor - 1: Bloating Fireproof PainttamariNo ratings yet

- Factors Affecting Durability PDFDocument5 pagesFactors Affecting Durability PDFApoorvaAppiNo ratings yet

- Harpar Group Profile New IntDocument38 pagesHarpar Group Profile New IntKrishnaRajaNo ratings yet

- Engg. Materials - Unit - 1Document13 pagesEngg. Materials - Unit - 1Satish SahuNo ratings yet

- Sand Seals Process Design OverviewDocument2 pagesSand Seals Process Design OverviewAriel VargasNo ratings yet

- 20BC0049 - 2ND Billing PCMADocument1 page20BC0049 - 2ND Billing PCMARandy Jake Calizo BaluscangNo ratings yet

- JKR PQP BP MicrosurfacingDocument9 pagesJKR PQP BP MicrosurfacinghongNo ratings yet

Conversion Factors 21

Conversion Factors 21

Uploaded by

Andri MPOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conversion Factors 21

Conversion Factors 21

Uploaded by

Andri MPCopyright:

Available Formats

Conversion Factors | Nico O.

Aspra

LINEAR

m 3.28 ft

100 cm

in 2.54 cm

yd 3 ft

mile 1.609 km

5 280 ft

n. mile 6 080 ft

league 3 n.miles

hand 4 in

span 9 in

fathom 6 ft

furlong 660 ft

cable 120 fathom

rod 16.5 ft

chain 66 ft

vara 33.33 in

mil 0.001 in

gross 144 pcs

micron 10-6 m

angstrom 10-10 m

light-yr 9.46x1012 km

par-sec 30.84x1012 km

AREA

ha 10 000 m2

100 ares

are 100 m2

acre 4 046.8 m2

section 1 sq.mile

circular mil 5.067x10-10 m2

VOLUME

m3 1 000 L

1 stere

gal 3.78 L

4 qt

8 pt

16 cup

128 oz

256 tbsp

768 tsp

UK gal 1.2009 gal

US bbl 158.99 L

42 gal

ft3 7.48 gal

ganta 3 L

8 chupas

cavan 25 ganta

cfm 7.48 gpm

L/s 15.85 gpm

MASS

kg 2.2046 lbm

slug 32.2 lbm

lbm 7 000 grain

g 6.024x1023 amu

ounce 28.35 g

kip 1 000 lbm

mtons 1 000 kg

ton 2 000 lbm

long ton 2 240 lbm

FORCE

kgf 9.80665 N

lbf 4.448 N

32.2 poundal

1 slug-ft/sec

tonf 2 000 lbf

N 100 000 dynes

WORK

BTU 1 055.0559 J

778.169 ft-lbf

cal 4.1858 J

J 1.602x10-19 eV

107 erg

erg 1 dyne-cm

chu 1.8 BTU

therm 105 BTU

POWER

hp 746 W

42.42 BTU/min

550 ft-lbf/sec

1.014 mhp

BHP 35 322 kJ/hr

ehp 1.0004 hp

TOR 3.516 kW

12 000 BTU/hr

kW 3 413 BTU/hr

PRESSURE

atm 101.325 kPa

1.01325 bar

1013250 dynes/cm2

14.7 psi

760 mmHg

bar 1x105 Pa

psi 2.307 ft H2O

ANGLE

rev 360 deg

2π rad

400 grad

400 gon

6 400 mils

deg 60 min

min 60 sec

sphere 4π steradian

SPECIFIC HEAT

BTU/lb-°F 4.1858 kJ/kg-°C

BTU/lb-°F 778 ft-lbf/lbm-°R

THERMAL CONDUCTIVITY, k

BTU/hr-ft-°F 1.73 W/m-°C

HEAT TRANSFER COEF., h

BTU/hr-ft2°F 5.67 W/m2-°C

mksq SYSTEM

volt 1 N-m/C

J 1 C-V

farad 1 C/V

amp 1 C/s

weber 1 V-s

ohm 1 V/A

henry 1 w/A

Nico Obusan Aspra

Conversion Factors | Nico O. Aspra

TEMPERATURE CHANGE, dT

9

ΔTF ΔTC

5

4

reamur (°Re) °C

5

20 ligem (°L)

DYNAMIC VISCOSITY

1 poise 0.1 Pa-s

1 dynes-s/cm2

KINEMATIC VISCOSITY

1 stoke 0.0001 m2/s

1 cm2/s

METRIC PREFIX

deka, da 101 deci, d 10-1

2

hecto, h 10 centi, c 10-2

3

kilo, k 10 mili, m 10-3

6

mega, M 10 micro, µ 10-6

9

giga, G 10 nano, n 10-9

12

tera, T 10 pico, p 10-12

15

peta, P 10 femto, f 10-15

18

exa, E 10 atto, a 10-18

21

zeta, Z 10 zepto, z 10-21

24

yotta, Y 10 yocto, y 10-24

DENSITY

water 1 kg/L

62.4 lb/ft3

8.33 lb/gal

air 1.225 kg/m3

concrete 2 406 kg/m3

steel 7 800 - 8 050 kg/m3

iron 7 200 kg/m3

leather belt 0.035 lbm/in3

fat rubber belt 0.045 bm/in3

MATERIAL steel alum iron wood

E (106 psi) 29 10 14.5 1.6

G (106 psi) 11.5-12 3.8 6 0.6

µ 0.3 0.33 0.21 0.33

note: valid within elastic range

𝐸

𝐺 = 2(1+µ)

SHEARING STRESS FOR PUNCHING (psi)

steel/iron 50 000

bronze 40 000

copper 30 000

aluminium 20 000

zinc 10 000

tin/lead 5 000

note: non circular hole

1

d= 3P

BOLT CONSTANT, c

bronze 10 000

carbon steel 5 000

alloy steel 1 500

CHEMICAL COMPOUNDS

ammonia NH3 H 1

methane CH4 He 4

ethane C2H6 C 12

propane C3H8 N 14

butane C4H10 O 16

pentane C5H12 Fl 19

hexane C6H14 Mg 24

heptane C7H16 Al 27

liquid octane C8H18 Si 28

nonane C9H20 P 31

decane C10H22 S 32

undecane C11H24 Cl 35

dodecane C12H26 Ar 40

benzene C6H6 Ca 40

methyl alcohol CH4O Ti 48

ethyl alcohol C2H6O Fe 56

APPROX. STEAM TABLE PROPERTIES

h = 2 454.5 + 2.12 𝑡°C − 50 𝑃𝑀𝑝𝑎 + 0.072 𝑡°C 𝑃𝑀𝑝𝑎 kJ/kg

hg = 2 501 + 1.84 𝑡sat kJ/kg

= 1 060.5 + 0.435 𝑡sat BTU/lb

hf = 𝑡°F − 32 BTU/lb

237.7 ln(1.638 𝑃𝑠𝑎𝑡 )

tsat = °C

17.27 − ln(1.638 𝑃𝑠𝑎𝑡 )

MAXIMUM SLOPE, 𝜃

1 1/2 *2

1/8 1/16

*3

1/6 1/24

1/24 8/360 , 7/360

MAXIMUM DEFLECTION, y

1/2 1/3 *3

5/48 1/48 1/192 7/768 *4

1/8 5/384 1/384 1/185

1/30 2.5/384 1/768

MAXIMUM MOMENT, M

1/2 1/4 1/8

1/2 1/8 1/12 1/8 *2

1/6 1/9√3 1/30 , 1/20

Nico Obusan Aspra

You might also like

- ASTM D3359-22 Standard Test Methods For Rating Adhesion by Tape TestDocument8 pagesASTM D3359-22 Standard Test Methods For Rating Adhesion by Tape TestManuela Castañeda100% (4)

- To Calculate A Quick Budget Price For A Stainless Steel Tank That Includes The FollowingDocument18 pagesTo Calculate A Quick Budget Price For A Stainless Steel Tank That Includes The Followingjayvijay009No ratings yet

- Magnetic ORMUS Vortex TrapDocument10 pagesMagnetic ORMUS Vortex TrapZach Royer100% (2)

- WWW - Duchesne.ca: 1. ManufacturerDocument2 pagesWWW - Duchesne.ca: 1. ManufacturerKen ShackelNo ratings yet

- Conversion FactorDocument2 pagesConversion FactorLea Gerelyn DucayNo ratings yet

- Conversion FactorsDocument1 pageConversion FactorsLea Gerelyn DucayNo ratings yet

- Convert in ExcelDocument8 pagesConvert in ExcelMadhuNo ratings yet

- Calculation For Steam Blow Rev03Document6 pagesCalculation For Steam Blow Rev03tauqeerNo ratings yet

- Mass Pressure: Physical Quantity Conversion FactorDocument2 pagesMass Pressure: Physical Quantity Conversion FactorGeorina Lycon TubieraNo ratings yet

- Process and Mechanical Standard Table: Appendix ADocument11 pagesProcess and Mechanical Standard Table: Appendix AGiovanniNo ratings yet

- Tablas de ConversionDocument5 pagesTablas de ConversionFisicoquimica ULSNo ratings yet

- Tabla de Conversión - 2022Document5 pagesTabla de Conversión - 2022benja navarreteNo ratings yet

- Fundamental Constants and Conversion Factors Gas Law Constant RDocument9 pagesFundamental Constants and Conversion Factors Gas Law Constant RyusefriNo ratings yet

- Conversion FactorsDocument2 pagesConversion FactorsKathleen May BarrilNo ratings yet

- Thermodynamics Topic 1Document11 pagesThermodynamics Topic 1Sunshine FelongcoNo ratings yet

- Sedco Forex - Drilling Operations: Conversion FactorsDocument1 pageSedco Forex - Drilling Operations: Conversion FactorsAlex SpanacheNo ratings yet

- En - Hydraulic CoursesDocument47 pagesEn - Hydraulic CoursesAhmed MoustafaNo ratings yet

- ReviewerDocument2 pagesReviewerNeo GarceraNo ratings yet

- Factores Conversión de UnidadesDocument4 pagesFactores Conversión de UnidadesCristobal OlguinNo ratings yet

- Fundamental Constants and Conversion FactorsDocument4 pagesFundamental Constants and Conversion FactorsSagitaa DwiiNo ratings yet

- Unit Conversion Table.Document1 pageUnit Conversion Table.muthukumarm4023No ratings yet

- Multiple by To Get Inch 2.54 CM This Can Also Be Written As: 1 Inch 2.54 CM ADocument1 pageMultiple by To Get Inch 2.54 CM This Can Also Be Written As: 1 Inch 2.54 CM ANoé Mayor HernándezNo ratings yet

- Unit ConversionDocument2 pagesUnit ConversionBoy BangusNo ratings yet

- Unit ConversionDocument2 pagesUnit Conversionma.shaheNo ratings yet

- Measurement ConversionsDocument1 pageMeasurement ConversionsgsbkgpymopaybcqiqcNo ratings yet

- Conversion FactorsDocument1 pageConversion Factorsuetian729No ratings yet

- Fluid Mechanics - Needed Units and ConversionsDocument2 pagesFluid Mechanics - Needed Units and ConversionsMista LuaiNo ratings yet

- 1083appa - 2 - A.2 Engineering Conversion FactorsDocument22 pages1083appa - 2 - A.2 Engineering Conversion FactorsNurdeny Hidayanto PribadiNo ratings yet

- Tabel FAKTOR KONVERSIDocument1 pageTabel FAKTOR KONVERSIFattaNo ratings yet

- Konversi Dan Perpindahan Panas (Yandri)Document16 pagesKonversi Dan Perpindahan Panas (Yandri)Merry YantiNo ratings yet

- Tabela de Conversão de UnidadesDocument1 pageTabela de Conversão de UnidadesrobertaNo ratings yet

- Conversion Factors - 2014 - Process Heat TransferDocument2 pagesConversion Factors - 2014 - Process Heat TransferBryanNo ratings yet

- Practical Units For Fps Mks and Cgs SystDocument2 pagesPractical Units For Fps Mks and Cgs SystRohail HussainNo ratings yet

- Pressur Drop Calculation For DS Unit Vessels With F ProductsDocument9 pagesPressur Drop Calculation For DS Unit Vessels With F ProductsMaryam vafaee.nNo ratings yet

- Conversion FactorsDocument1 pageConversion FactorsDiana AmadoNo ratings yet

- Conversion of Units LengthDocument4 pagesConversion of Units LengthRoscarl GorospeNo ratings yet

- Acacia Pure Spec (Nov 2016)Document1 pageAcacia Pure Spec (Nov 2016)Adriel KurniawanNo ratings yet

- Station 0 - Freestream (Compresser Inlet) DescriptionDocument6 pagesStation 0 - Freestream (Compresser Inlet) DescriptionBonaventure Mills-DadsonNo ratings yet

- 01 General FormulaeDocument10 pages01 General FormulaenelsonhugoNo ratings yet

- Calculos TFDocument8 pagesCalculos TFJUAN PABLO DIAZ CANDELERONo ratings yet

- Halliburton Main Menu Ver 3Document83 pagesHalliburton Main Menu Ver 3Alejandro RivasNo ratings yet

- Appendix (Steam Tabel,.Etc)Document43 pagesAppendix (Steam Tabel,.Etc)Akun RPNo ratings yet

- Introduction To Fluid Mechanics, Eighth EditionDocument2 pagesIntroduction To Fluid Mechanics, Eighth EditionAnonymous JN21JYuMhcNo ratings yet

- Formulas in PhysicsDocument2 pagesFormulas in PhysicsChristine Irish Yebes MacaliNo ratings yet

- Conversion FactorsDocument2 pagesConversion FactorsThiago Rocha GomesNo ratings yet

- h-101 TwiceDocument20 pagesh-101 TwiceAdela ShofiaNo ratings yet

- Book 2Document15 pagesBook 2futhanul weweNo ratings yet

- Part 4 - Conversion FactorsDocument4 pagesPart 4 - Conversion FactorsCarlo Ray SelabaoNo ratings yet

- Gas Flow Rate Mass Flow Mol Flow Gas Volume FlowDocument9 pagesGas Flow Rate Mass Flow Mol Flow Gas Volume FlownivethithaNo ratings yet

- Unit ConversionDocument1 pageUnit ConversionfkpcwNo ratings yet

- Casing Data Bit Data Mud Data: Hours RemarksDocument8 pagesCasing Data Bit Data Mud Data: Hours RemarksdiegoNo ratings yet

- 1986 Bookmatter PetroleumEngineering Units ConversionDocument105 pages1986 Bookmatter PetroleumEngineering Units ConversionRosana da CunhaNo ratings yet

- Anchor LengthDocument1 pageAnchor LengthSaqib LaeeqNo ratings yet

- Cálculo Selección Molinos 11.10.19Document24 pagesCálculo Selección Molinos 11.10.19Edgardo Soto HermenegildoNo ratings yet

- Practica Post CyO 2Document11 pagesPractica Post CyO 2eljerrymoonNo ratings yet

- Design of Slab BridgesDocument12 pagesDesign of Slab BridgesEna Mie CambaNo ratings yet

- Vessel NewDocument16 pagesVessel NewakshaybhuranNo ratings yet

- Halliburton CalculationsDocument71 pagesHalliburton CalculationsIGNATIUS MANOSAYNo ratings yet

- PIPE-100: Variabel Satuan Sumur HCE 29 Pad 7Document55 pagesPIPE-100: Variabel Satuan Sumur HCE 29 Pad 7Hesti Fuzi LestariNo ratings yet

- ConvertDocument4 pagesConvertHasif MohammedNo ratings yet

- SPE Nomenclature and Symbols PDFDocument105 pagesSPE Nomenclature and Symbols PDFJuan GómezNo ratings yet

- Triple Crown: - Higher Pressures - Improved Temperatures - Improved Abrasion ResistanceDocument8 pagesTriple Crown: - Higher Pressures - Improved Temperatures - Improved Abrasion ResistanceKeron TrotzNo ratings yet

- Important To Write The Correct Structure FromDocument16 pagesImportant To Write The Correct Structure FromR A V INo ratings yet

- TE - 2019 - Composite Materials With AnswerDocument38 pagesTE - 2019 - Composite Materials With AnswerAditya NanekarNo ratings yet

- Smeb MP 150 Cement Sc4000Document7 pagesSmeb MP 150 Cement Sc4000andrecormeNo ratings yet

- Alvó KutyusDocument11 pagesAlvó KutyusÁgi Markó100% (1)

- Engineering Steels PDFDocument432 pagesEngineering Steels PDFMargarita Romero EscalanteNo ratings yet

- Concrete MSDS 5 PDFDocument2 pagesConcrete MSDS 5 PDFmanil_5No ratings yet

- TDS PDF Intertherm - 751CSADocument4 pagesTDS PDF Intertherm - 751CSAwilliam sukyonoNo ratings yet

- CCS001Document5 pagesCCS001durgesh yadavNo ratings yet

- Bsi Eof DWG Cs 150 (0) - Lighting Pole 10m HeightDocument1 pageBsi Eof DWG Cs 150 (0) - Lighting Pole 10m Heightdharu100% (1)

- Pump Shaft Repair Recommendation GuidelinesDocument4 pagesPump Shaft Repair Recommendation Guidelineschiz escudero100% (2)

- Sx-70 Cover Installation Instructions: Please Remove Your Old Camera Cover. Also Remove AnyDocument1 pageSx-70 Cover Installation Instructions: Please Remove Your Old Camera Cover. Also Remove AnyAlix RâNo ratings yet

- Investigatory File On Foaming Capacity of SoapsDocument16 pagesInvestigatory File On Foaming Capacity of SoapsAditya Pratap Singh Sengar92% (13)

- EN9 Technical Data: Print Friendly Text Only Site MapDocument1 pageEN9 Technical Data: Print Friendly Text Only Site MapMari selvamNo ratings yet

- Determination of Velocity Seal Area Reduction BaseDocument5 pagesDetermination of Velocity Seal Area Reduction BaseNajem A. SakorNo ratings yet

- Bearing Steel 100Cr6 AUSA - 2Document3 pagesBearing Steel 100Cr6 AUSA - 2suresh kumarNo ratings yet

- Principle: Evaporation Loss / VolatilityDocument2 pagesPrinciple: Evaporation Loss / VolatilityMiguelNo ratings yet

- Safe Work Method Statement For Welding of Pipes WPS PQR PDFDocument3 pagesSafe Work Method Statement For Welding of Pipes WPS PQR PDFDeepak RajanNo ratings yet

- PLAS 4180 / PLAS 5180 Plastic Part Design: Other Molding ProcessesDocument15 pagesPLAS 4180 / PLAS 5180 Plastic Part Design: Other Molding ProcessesBethany SilvaNo ratings yet

- Upcycle Portfolio Lala Boria DiazDocument1 pageUpcycle Portfolio Lala Boria Diazapi-644244557No ratings yet

- Plamcor - 1: Bloating Fireproof PaintDocument2 pagesPlamcor - 1: Bloating Fireproof PainttamariNo ratings yet

- Factors Affecting Durability PDFDocument5 pagesFactors Affecting Durability PDFApoorvaAppiNo ratings yet

- Harpar Group Profile New IntDocument38 pagesHarpar Group Profile New IntKrishnaRajaNo ratings yet

- Engg. Materials - Unit - 1Document13 pagesEngg. Materials - Unit - 1Satish SahuNo ratings yet

- Sand Seals Process Design OverviewDocument2 pagesSand Seals Process Design OverviewAriel VargasNo ratings yet

- 20BC0049 - 2ND Billing PCMADocument1 page20BC0049 - 2ND Billing PCMARandy Jake Calizo BaluscangNo ratings yet

- JKR PQP BP MicrosurfacingDocument9 pagesJKR PQP BP MicrosurfacinghongNo ratings yet