Professional Documents

Culture Documents

Side Facing

Side Facing

Uploaded by

Chiller PartyCopyright:

Available Formats

You might also like

- Iveco - Eurocargo 12-26t - Repair ManualDocument1,690 pagesIveco - Eurocargo 12-26t - Repair ManualSan Juam Contratistas100% (2)

- Iveco Daily Euro 4Document1,132 pagesIveco Daily Euro 4roney83% (18)

- F2be0681a F3a F3beDocument478 pagesF2be0681a F3a F3bejvega_534120100% (2)

- Iveco - Daily 2000my - Repair ManualDocument1,654 pagesIveco - Daily 2000my - Repair Manualjuan100% (2)

- Flange FacingDocument1 pageFlange FacingChiller PartyNo ratings yet

- Mounting Face TappingDocument1 pageMounting Face TappingChiller PartyNo ratings yet

- CNC MachiningDocument1 pageCNC MachiningChiller PartyNo ratings yet

- Oil Filter Body0Document1 pageOil Filter Body0Chiller PartyNo ratings yet

- C13 Service Manual - 1Document180 pagesC13 Service Manual - 1mes100% (1)

- Alignment & LevellingDocument4 pagesAlignment & LevellingyuwantoniNo ratings yet

- Actividad de DurezaDocument7 pagesActividad de DurezaMartin Fibela EsparzaNo ratings yet

- Cm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)Document1 pageCm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)ali morisyNo ratings yet

- Cm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)Document1 pageCm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)ali morisyNo ratings yet

- DET ReviewDocument2 pagesDET ReviewBasanta RoyNo ratings yet

- Maintenance Prescription: Analysis Integrated With Accuracy and MeaningDocument1 pageMaintenance Prescription: Analysis Integrated With Accuracy and MeaningVic AnaboNo ratings yet

- 3 WH Drum Process ProjectDocument28 pages3 WH Drum Process ProjectBrandvision AdvertisementNo ratings yet

- PPM Checklist - Air Circuit Breaker (Acb)Document1 pagePPM Checklist - Air Circuit Breaker (Acb)Mohamed Firdaus Bin ZakariaNo ratings yet

- Checkpont of Tyre Building ORPDocument3 pagesCheckpont of Tyre Building ORPDilnesa EjiguNo ratings yet

- Lube Oil Cooler: PT Sks Listrik Kalimantan Kalteng 1Document21 pagesLube Oil Cooler: PT Sks Listrik Kalimantan Kalteng 1Muhammad AbyNo ratings yet

- 297 FlywheelDocument10 pages297 FlywheelChellaPandianNo ratings yet

- Control (Quality) PlanDocument1 pageControl (Quality) PlanRabia ZulqarnainNo ratings yet

- Lembar 1Document1 pageLembar 1saepudin 40No ratings yet

- Control Plan H.TDocument1 pageControl Plan H.TABHISHEK PANDEYNo ratings yet

- Ih Setup 38tDocument1 pageIh Setup 38tmuthuselvanNo ratings yet

- 3 WH Drum Process ProjectDocument28 pages3 WH Drum Process ProjectBrandvision AdvertisementNo ratings yet

- Line Balance 059Document39 pagesLine Balance 059smitaNo ratings yet

- Mechtek Laboratory: Raw Data Sheet For Vernier CaliperDocument3 pagesMechtek Laboratory: Raw Data Sheet For Vernier CaliperMechtek LabNo ratings yet

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedureAnand KesarkarNo ratings yet

- In Process InspectionDocument4 pagesIn Process InspectionSuraj RawatNo ratings yet

- Iveco Daily 2000Document13 pagesIveco Daily 2000Alberto Piosa OlivaresNo ratings yet

- Production ReportDocument1 pageProduction ReportbhuvaneshNo ratings yet

- OPRAF01 Service Activity Report V2Document1 pageOPRAF01 Service Activity Report V2BollywoodRevival SongsNo ratings yet

- Iveco Euro Cargo 6 10t Repair ManualDocument20 pagesIveco Euro Cargo 6 10t Repair ManualAntoinette100% (66)

- G69173-D1001-Y756 - Protocolo SAT CCM Tiastar - REV2Document5 pagesG69173-D1001-Y756 - Protocolo SAT CCM Tiastar - REV2Adriana UstarizNo ratings yet

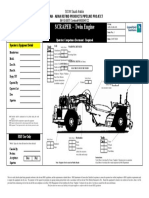

- UC Inspection Sheet Volvo A SeriesDocument7 pagesUC Inspection Sheet Volvo A SeriesLuis BertaoNo ratings yet

- Standard Work Instruction Sheet: Work Description Key PointsDocument2 pagesStandard Work Instruction Sheet: Work Description Key PointsPauline KangNo ratings yet

- LNV Technology (P) LTD ACC LTD, Tikaria Expansion Project: Daily Crane Inspection Checklist - Format / CraneDocument1 pageLNV Technology (P) LTD ACC LTD, Tikaria Expansion Project: Daily Crane Inspection Checklist - Format / CraneRajuNo ratings yet

- Two Post LifterDocument1 pageTwo Post LifterAde JulianiNo ratings yet

- JAPL-F-HE-019 Scraper CheckDocument1 pageJAPL-F-HE-019 Scraper CheckAli HassanNo ratings yet

- Pm-Clinic Service: PMED100800Document2 pagesPm-Clinic Service: PMED100800Naughty VongNo ratings yet

- Sahyog Engineering Industries: Isc Inprocess/Production/Rejection & P.P.M ReportDocument3 pagesSahyog Engineering Industries: Isc Inprocess/Production/Rejection & P.P.M ReportPrakash kumarTripathiNo ratings yet

- 01/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectDocument2 pages01/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectdaemsalNo ratings yet

- Field Service Report: Trip Dispatch Arrival at Jobsite Travel Hour Mileage Date Time Date Time 1 2 3Document2 pagesField Service Report: Trip Dispatch Arrival at Jobsite Travel Hour Mileage Date Time Date Time 1 2 3Henny Komala Sari SibaraniNo ratings yet

- F2be0685a F3ae0687a B CDocument552 pagesF2be0685a F3ae0687a B Cjvega_534120100% (1)

- 16 INSP 0016 One Engine Scraper CheckDocument1 page16 INSP 0016 One Engine Scraper CheckBarock NaturelNo ratings yet

- Pm-Clinic Service: SEPD308400Document5 pagesPm-Clinic Service: SEPD308400Naughty VongNo ratings yet

- UC Inspection Sheet Volvo D Series - 2Document15 pagesUC Inspection Sheet Volvo D Series - 2Juan Carlos ParedesNo ratings yet

- Iveco Trakker Euro 4 5 Repair ManualDocument20 pagesIveco Trakker Euro 4 5 Repair Manualjason100% (54)

- 1 Paut ReportDocument1 page1 Paut ReportAhmedNo ratings yet

- Control Plan FormatDocument1 pageControl Plan FormatMagesh WaranNo ratings yet

- Alpha Engineers: Patroling SheetDocument2 pagesAlpha Engineers: Patroling SheetHarsh KachhawaNo ratings yet

- PM Clinic Pc200-8m0Document10 pagesPM Clinic Pc200-8m0phengNo ratings yet

- Torrent G.I Job CardDocument5 pagesTorrent G.I Job Cardshanivi vrindavanNo ratings yet

- Mechtek Laboratory: Raw Data Sheet For Vernier CaliperDocument1 pageMechtek Laboratory: Raw Data Sheet For Vernier CaliperMechtek LabNo ratings yet

- 60393391C Rep. Manual EuroCargo 12-26 TonDocument1,700 pages60393391C Rep. Manual EuroCargo 12-26 TonEmad M. Naguib100% (3)

- Principles and Applications of Thermal AnalysisFrom EverandPrinciples and Applications of Thermal AnalysisPaul GabbottRating: 4 out of 5 stars4/5 (1)

- M18 DrillingDocument1 pageM18 DrillingChiller PartyNo ratings yet

- Flange FacingDocument1 pageFlange FacingChiller PartyNo ratings yet

- Oil Filter Body0Document1 pageOil Filter Body0Chiller PartyNo ratings yet

- Mounting Face TappingDocument1 pageMounting Face TappingChiller PartyNo ratings yet

- CNC MachiningDocument1 pageCNC MachiningChiller PartyNo ratings yet

- RDSO - PE - SPEC - AC - 0177 (Rev-1) 2013 Dated 29-11-2021Document124 pagesRDSO - PE - SPEC - AC - 0177 (Rev-1) 2013 Dated 29-11-2021Chiller PartyNo ratings yet

- RCF - EL - 0020 - REV - A STR For Jumper Cable With Connector 2 2 2022Document8 pagesRCF - EL - 0020 - REV - A STR For Jumper Cable With Connector 2 2 2022Chiller PartyNo ratings yet

- Scorecard Mar 20Document3 pagesScorecard Mar 20Chiller PartyNo ratings yet

- STR - Uic SOCKET 2 2 2022Document10 pagesSTR - Uic SOCKET 2 2 2022Chiller PartyNo ratings yet

- Elecronics MCQDocument7 pagesElecronics MCQNikhil BhaleraoNo ratings yet

- MFL37562519 English PDFDocument21 pagesMFL37562519 English PDFCărunta-Crista CristinaNo ratings yet

- Permutations CombinationsDocument8 pagesPermutations CombinationsaryanmcywaliaNo ratings yet

- Bivariate Analysis in SPSS - ANOVADocument6 pagesBivariate Analysis in SPSS - ANOVAAndra HuleaNo ratings yet

- Anatomy and Physiology Transes ReviewerDocument14 pagesAnatomy and Physiology Transes ReviewerYsa Mae Lomibao VillanuevaNo ratings yet

- Exploring Design Elements and PrinciplesDocument6 pagesExploring Design Elements and PrinciplesKkanjiNo ratings yet

- Santafe 2.7L 2009Document1,926 pagesSantafe 2.7L 2009Joe TateauNo ratings yet

- HHSM ZG513Document3 pagesHHSM ZG513Satain Bhat0% (1)

- Switch-Mode DC-AC Inverters: Converters For Ac Motor Drives and Uninterruptible Power SuppliesDocument19 pagesSwitch-Mode DC-AC Inverters: Converters For Ac Motor Drives and Uninterruptible Power SuppliesHartoyo MpNo ratings yet

- MLX90614 Rev001 PDFDocument35 pagesMLX90614 Rev001 PDFBrian AguirreNo ratings yet

- MEC69 - Design & Fabrication of Mini Hydraulic JackDocument25 pagesMEC69 - Design & Fabrication of Mini Hydraulic JackTejas Hambir75% (4)

- Fea MCQ AllDocument151 pagesFea MCQ AllAMOL JAGTAP100% (1)

- Modelling and Simulation of Absorption Solar Air Conditioning SystemDocument20 pagesModelling and Simulation of Absorption Solar Air Conditioning SystemShadi KarkabaNo ratings yet

- Student Exploration Element BuilderDocument5 pagesStudent Exploration Element BuilderFelix ZununNo ratings yet

- Iso 7721 1983Document8 pagesIso 7721 1983techlibrary072023No ratings yet

- Coding Module ProsesDocument4 pagesCoding Module ProsesEliana Putri NNo ratings yet

- Development of A Validated RP HPLC DAD MDocument8 pagesDevelopment of A Validated RP HPLC DAD Medlyntonic2No ratings yet

- Coronel PPT Ch03 ModifiedDocument50 pagesCoronel PPT Ch03 Modifiedaki8aNo ratings yet

- Logarithm: Meaning of Logarithm: Exponential FormDocument40 pagesLogarithm: Meaning of Logarithm: Exponential Formpurandar puneetNo ratings yet

- S17 2170501 CreDocument3 pagesS17 2170501 CremorganNo ratings yet

- Chapter 10 - Connect PlusDocument18 pagesChapter 10 - Connect Plushampi67% (3)

- Relative Effects of Cognitive and Behavioral Therapies On Generalized Anxiety Disorder, Social Anxiety Disorder and Panic Disorder: A Meta AnalysisDocument32 pagesRelative Effects of Cognitive and Behavioral Therapies On Generalized Anxiety Disorder, Social Anxiety Disorder and Panic Disorder: A Meta AnalysisregiaNo ratings yet

- Assignment I (Algebra)Document1 pageAssignment I (Algebra)Tushar KumarNo ratings yet

- BJT and FET Frequency ResponseDocument79 pagesBJT and FET Frequency ResponseJerc ZajNo ratings yet

- Chapter 3: Mathematical Modelling Principles: - Formulate Dynamic Models Based OnDocument40 pagesChapter 3: Mathematical Modelling Principles: - Formulate Dynamic Models Based OnJanusNo ratings yet

- The Fundamental of Leaky Wave Antenna: January 2018Document10 pagesThe Fundamental of Leaky Wave Antenna: January 2018Mohamed MOUMOUNo ratings yet

- Ase 18 2 GaDocument36 pagesAse 18 2 Gac131508No ratings yet

- C86 - Silt Pusher Inst Manual ConciseDocument35 pagesC86 - Silt Pusher Inst Manual ConciseSujeet SarukNo ratings yet

- Determinants of Brand Equity in Hair Care Products An Empirical StudyDocument20 pagesDeterminants of Brand Equity in Hair Care Products An Empirical StudychaubeydsNo ratings yet

- Pipelining Basic and Intermediate ConceptsDocument75 pagesPipelining Basic and Intermediate Conceptsjoshi.prahaldNo ratings yet

Side Facing

Side Facing

Uploaded by

Chiller PartyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Side Facing

Side Facing

Uploaded by

Chiller PartyCopyright:

Available Formats

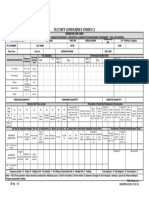

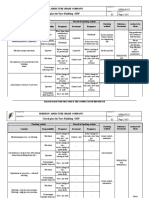

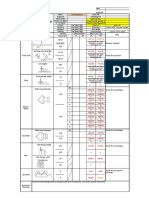

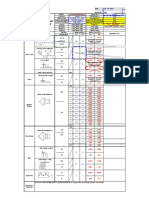

VICTORY LUMINAIRES WORKS 2

OPERATOR JOB CARD

(IN PROCESS INSPECTION REPORT / PRODUCTION REPORT / PREVENTIVE & PREDICTIVE MAINTENANCE CHECKSHEET / TOOL LIFE RECORD)

PART DESCRIPTION :- Filter head PART NO. 000016210P04 OPERATION Side Facing

NO.

M/C NUMBER M/C NAME DATE :- Shift

Time From Time To OPERATOR NAME DIE CODE

FOC READING IN PROCESS INSPECTION

Measuring

Dimension Sign After 4 After 8 After 12

PARAMETER DESCRIPTION Inst to be TIME - Sign - Sign - Sign -

& Tolerance Hours Hours Hours

used

1 2 3 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

1st Side Facing length from Centre 60 ± 0.3 Vernier

Vernier /

Total Length 121.25 ± 0.6

height

2nd Side Facing lenghtfrom Centre 60 ± 0.3 Vernier

Vernier /

Total Length 120 ± 0.6

height

PRODUCED QUANTITY REWORKED QUANTITY REJECTED QUANTITY

Machine Idle Time records Preventive & Predictive Maintenance Check points

Cleaning (Chips Checking Checking Over

Idle Oiling - Air Filter & Drying of

N1 N2 N3 N4 N5 N6 N7 N8 N9 Removal from moving

Tightness of sensing (Freq - Cooling

of level of Spindle Checking Excess heating of

Electric tool clamp

Code parts, sensors, tool coolant & Taper of oil & air vibrations motor or

dog of pallet change D)& fans sparking - / declamp

Idle Machine No magazine, pallet lubrication cleaning - leakage - of moving sliding

No No Fixture Inprocess Any Other changing zone) - (Freq cycle - (Freq - D) Greasing - Cleaning - (Freq - D) device -

Descriptio No Power Tool Setting Breakdow Requireme oil - (Freq (Freq - D) (Freq - D) parts - parts -

Material Operator Setting Inspection Reason (Freq - W) (Freq - W) (Freq - W)

n n nt 4 Hrs) - D) (Freq - D) (Freq - D)

TIME (in

minutes)

Job Set up Inspection Report (For nos. of equipments i.e. fixture no, tool no., etc, please refer control plan displayed at shop floor) Preventive & Predictive Maintenance Check

Fixture Availability Tightness

Check as

Fixture locating Control Inprocess of marker Availability Dirty oil in of nut

PARAMETER Fixture Clamp Fixture Working of Tool life Tool SOP Availability per SOP

Fixture No. resting point pins / Tool No. plan report for of rej / oil tank - bolts or

DESCRIPTION condition

condition

blocks

calibration pokayoke qty condition display

display availability marking of rew bin

of gauges no. 11 -

(Freq - W) missing -

(Freq - D)

condition rej (Freq - D)

Ok (a) / Not ok (x)

Remark

Availability Checked By : Approved By :

of Availability of Gauge

PARAMETER

measuring identification condition &

DESCRIPTION

instrument plates due date

s

Ok (a) / Not ok (x)

Remark

Frequency Codes - D - Daily, W - Weekly, N/A - No Activity, T - for Filling of Lubrication Oil, O - Weekly Off, H - Holiday. Tool replaced - R. Tool Regrind - G, Tool indexed - I

Note :- FOC (First operation check) should be conducted in following cases -1) Start of machine 2) Power failure 3) Operator Changed 4) Tool changed / indexed / ground 5) Fixture setting 6)

Program parameters setting

IIR No. - H1 Filter head.xlsxQC/QF/02-03(20.12.2016)

You might also like

- Iveco - Eurocargo 12-26t - Repair ManualDocument1,690 pagesIveco - Eurocargo 12-26t - Repair ManualSan Juam Contratistas100% (2)

- Iveco Daily Euro 4Document1,132 pagesIveco Daily Euro 4roney83% (18)

- F2be0681a F3a F3beDocument478 pagesF2be0681a F3a F3bejvega_534120100% (2)

- Iveco - Daily 2000my - Repair ManualDocument1,654 pagesIveco - Daily 2000my - Repair Manualjuan100% (2)

- Flange FacingDocument1 pageFlange FacingChiller PartyNo ratings yet

- Mounting Face TappingDocument1 pageMounting Face TappingChiller PartyNo ratings yet

- CNC MachiningDocument1 pageCNC MachiningChiller PartyNo ratings yet

- Oil Filter Body0Document1 pageOil Filter Body0Chiller PartyNo ratings yet

- C13 Service Manual - 1Document180 pagesC13 Service Manual - 1mes100% (1)

- Alignment & LevellingDocument4 pagesAlignment & LevellingyuwantoniNo ratings yet

- Actividad de DurezaDocument7 pagesActividad de DurezaMartin Fibela EsparzaNo ratings yet

- Cm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)Document1 pageCm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)ali morisyNo ratings yet

- Cm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)Document1 pageCm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)ali morisyNo ratings yet

- DET ReviewDocument2 pagesDET ReviewBasanta RoyNo ratings yet

- Maintenance Prescription: Analysis Integrated With Accuracy and MeaningDocument1 pageMaintenance Prescription: Analysis Integrated With Accuracy and MeaningVic AnaboNo ratings yet

- 3 WH Drum Process ProjectDocument28 pages3 WH Drum Process ProjectBrandvision AdvertisementNo ratings yet

- PPM Checklist - Air Circuit Breaker (Acb)Document1 pagePPM Checklist - Air Circuit Breaker (Acb)Mohamed Firdaus Bin ZakariaNo ratings yet

- Checkpont of Tyre Building ORPDocument3 pagesCheckpont of Tyre Building ORPDilnesa EjiguNo ratings yet

- Lube Oil Cooler: PT Sks Listrik Kalimantan Kalteng 1Document21 pagesLube Oil Cooler: PT Sks Listrik Kalimantan Kalteng 1Muhammad AbyNo ratings yet

- 297 FlywheelDocument10 pages297 FlywheelChellaPandianNo ratings yet

- Control (Quality) PlanDocument1 pageControl (Quality) PlanRabia ZulqarnainNo ratings yet

- Lembar 1Document1 pageLembar 1saepudin 40No ratings yet

- Control Plan H.TDocument1 pageControl Plan H.TABHISHEK PANDEYNo ratings yet

- Ih Setup 38tDocument1 pageIh Setup 38tmuthuselvanNo ratings yet

- 3 WH Drum Process ProjectDocument28 pages3 WH Drum Process ProjectBrandvision AdvertisementNo ratings yet

- Line Balance 059Document39 pagesLine Balance 059smitaNo ratings yet

- Mechtek Laboratory: Raw Data Sheet For Vernier CaliperDocument3 pagesMechtek Laboratory: Raw Data Sheet For Vernier CaliperMechtek LabNo ratings yet

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedureAnand KesarkarNo ratings yet

- In Process InspectionDocument4 pagesIn Process InspectionSuraj RawatNo ratings yet

- Iveco Daily 2000Document13 pagesIveco Daily 2000Alberto Piosa OlivaresNo ratings yet

- Production ReportDocument1 pageProduction ReportbhuvaneshNo ratings yet

- OPRAF01 Service Activity Report V2Document1 pageOPRAF01 Service Activity Report V2BollywoodRevival SongsNo ratings yet

- Iveco Euro Cargo 6 10t Repair ManualDocument20 pagesIveco Euro Cargo 6 10t Repair ManualAntoinette100% (66)

- G69173-D1001-Y756 - Protocolo SAT CCM Tiastar - REV2Document5 pagesG69173-D1001-Y756 - Protocolo SAT CCM Tiastar - REV2Adriana UstarizNo ratings yet

- UC Inspection Sheet Volvo A SeriesDocument7 pagesUC Inspection Sheet Volvo A SeriesLuis BertaoNo ratings yet

- Standard Work Instruction Sheet: Work Description Key PointsDocument2 pagesStandard Work Instruction Sheet: Work Description Key PointsPauline KangNo ratings yet

- LNV Technology (P) LTD ACC LTD, Tikaria Expansion Project: Daily Crane Inspection Checklist - Format / CraneDocument1 pageLNV Technology (P) LTD ACC LTD, Tikaria Expansion Project: Daily Crane Inspection Checklist - Format / CraneRajuNo ratings yet

- Two Post LifterDocument1 pageTwo Post LifterAde JulianiNo ratings yet

- JAPL-F-HE-019 Scraper CheckDocument1 pageJAPL-F-HE-019 Scraper CheckAli HassanNo ratings yet

- Pm-Clinic Service: PMED100800Document2 pagesPm-Clinic Service: PMED100800Naughty VongNo ratings yet

- Sahyog Engineering Industries: Isc Inprocess/Production/Rejection & P.P.M ReportDocument3 pagesSahyog Engineering Industries: Isc Inprocess/Production/Rejection & P.P.M ReportPrakash kumarTripathiNo ratings yet

- 01/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectDocument2 pages01/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectdaemsalNo ratings yet

- Field Service Report: Trip Dispatch Arrival at Jobsite Travel Hour Mileage Date Time Date Time 1 2 3Document2 pagesField Service Report: Trip Dispatch Arrival at Jobsite Travel Hour Mileage Date Time Date Time 1 2 3Henny Komala Sari SibaraniNo ratings yet

- F2be0685a F3ae0687a B CDocument552 pagesF2be0685a F3ae0687a B Cjvega_534120100% (1)

- 16 INSP 0016 One Engine Scraper CheckDocument1 page16 INSP 0016 One Engine Scraper CheckBarock NaturelNo ratings yet

- Pm-Clinic Service: SEPD308400Document5 pagesPm-Clinic Service: SEPD308400Naughty VongNo ratings yet

- UC Inspection Sheet Volvo D Series - 2Document15 pagesUC Inspection Sheet Volvo D Series - 2Juan Carlos ParedesNo ratings yet

- Iveco Trakker Euro 4 5 Repair ManualDocument20 pagesIveco Trakker Euro 4 5 Repair Manualjason100% (54)

- 1 Paut ReportDocument1 page1 Paut ReportAhmedNo ratings yet

- Control Plan FormatDocument1 pageControl Plan FormatMagesh WaranNo ratings yet

- Alpha Engineers: Patroling SheetDocument2 pagesAlpha Engineers: Patroling SheetHarsh KachhawaNo ratings yet

- PM Clinic Pc200-8m0Document10 pagesPM Clinic Pc200-8m0phengNo ratings yet

- Torrent G.I Job CardDocument5 pagesTorrent G.I Job Cardshanivi vrindavanNo ratings yet

- Mechtek Laboratory: Raw Data Sheet For Vernier CaliperDocument1 pageMechtek Laboratory: Raw Data Sheet For Vernier CaliperMechtek LabNo ratings yet

- 60393391C Rep. Manual EuroCargo 12-26 TonDocument1,700 pages60393391C Rep. Manual EuroCargo 12-26 TonEmad M. Naguib100% (3)

- Principles and Applications of Thermal AnalysisFrom EverandPrinciples and Applications of Thermal AnalysisPaul GabbottRating: 4 out of 5 stars4/5 (1)

- M18 DrillingDocument1 pageM18 DrillingChiller PartyNo ratings yet

- Flange FacingDocument1 pageFlange FacingChiller PartyNo ratings yet

- Oil Filter Body0Document1 pageOil Filter Body0Chiller PartyNo ratings yet

- Mounting Face TappingDocument1 pageMounting Face TappingChiller PartyNo ratings yet

- CNC MachiningDocument1 pageCNC MachiningChiller PartyNo ratings yet

- RDSO - PE - SPEC - AC - 0177 (Rev-1) 2013 Dated 29-11-2021Document124 pagesRDSO - PE - SPEC - AC - 0177 (Rev-1) 2013 Dated 29-11-2021Chiller PartyNo ratings yet

- RCF - EL - 0020 - REV - A STR For Jumper Cable With Connector 2 2 2022Document8 pagesRCF - EL - 0020 - REV - A STR For Jumper Cable With Connector 2 2 2022Chiller PartyNo ratings yet

- Scorecard Mar 20Document3 pagesScorecard Mar 20Chiller PartyNo ratings yet

- STR - Uic SOCKET 2 2 2022Document10 pagesSTR - Uic SOCKET 2 2 2022Chiller PartyNo ratings yet

- Elecronics MCQDocument7 pagesElecronics MCQNikhil BhaleraoNo ratings yet

- MFL37562519 English PDFDocument21 pagesMFL37562519 English PDFCărunta-Crista CristinaNo ratings yet

- Permutations CombinationsDocument8 pagesPermutations CombinationsaryanmcywaliaNo ratings yet

- Bivariate Analysis in SPSS - ANOVADocument6 pagesBivariate Analysis in SPSS - ANOVAAndra HuleaNo ratings yet

- Anatomy and Physiology Transes ReviewerDocument14 pagesAnatomy and Physiology Transes ReviewerYsa Mae Lomibao VillanuevaNo ratings yet

- Exploring Design Elements and PrinciplesDocument6 pagesExploring Design Elements and PrinciplesKkanjiNo ratings yet

- Santafe 2.7L 2009Document1,926 pagesSantafe 2.7L 2009Joe TateauNo ratings yet

- HHSM ZG513Document3 pagesHHSM ZG513Satain Bhat0% (1)

- Switch-Mode DC-AC Inverters: Converters For Ac Motor Drives and Uninterruptible Power SuppliesDocument19 pagesSwitch-Mode DC-AC Inverters: Converters For Ac Motor Drives and Uninterruptible Power SuppliesHartoyo MpNo ratings yet

- MLX90614 Rev001 PDFDocument35 pagesMLX90614 Rev001 PDFBrian AguirreNo ratings yet

- MEC69 - Design & Fabrication of Mini Hydraulic JackDocument25 pagesMEC69 - Design & Fabrication of Mini Hydraulic JackTejas Hambir75% (4)

- Fea MCQ AllDocument151 pagesFea MCQ AllAMOL JAGTAP100% (1)

- Modelling and Simulation of Absorption Solar Air Conditioning SystemDocument20 pagesModelling and Simulation of Absorption Solar Air Conditioning SystemShadi KarkabaNo ratings yet

- Student Exploration Element BuilderDocument5 pagesStudent Exploration Element BuilderFelix ZununNo ratings yet

- Iso 7721 1983Document8 pagesIso 7721 1983techlibrary072023No ratings yet

- Coding Module ProsesDocument4 pagesCoding Module ProsesEliana Putri NNo ratings yet

- Development of A Validated RP HPLC DAD MDocument8 pagesDevelopment of A Validated RP HPLC DAD Medlyntonic2No ratings yet

- Coronel PPT Ch03 ModifiedDocument50 pagesCoronel PPT Ch03 Modifiedaki8aNo ratings yet

- Logarithm: Meaning of Logarithm: Exponential FormDocument40 pagesLogarithm: Meaning of Logarithm: Exponential Formpurandar puneetNo ratings yet

- S17 2170501 CreDocument3 pagesS17 2170501 CremorganNo ratings yet

- Chapter 10 - Connect PlusDocument18 pagesChapter 10 - Connect Plushampi67% (3)

- Relative Effects of Cognitive and Behavioral Therapies On Generalized Anxiety Disorder, Social Anxiety Disorder and Panic Disorder: A Meta AnalysisDocument32 pagesRelative Effects of Cognitive and Behavioral Therapies On Generalized Anxiety Disorder, Social Anxiety Disorder and Panic Disorder: A Meta AnalysisregiaNo ratings yet

- Assignment I (Algebra)Document1 pageAssignment I (Algebra)Tushar KumarNo ratings yet

- BJT and FET Frequency ResponseDocument79 pagesBJT and FET Frequency ResponseJerc ZajNo ratings yet

- Chapter 3: Mathematical Modelling Principles: - Formulate Dynamic Models Based OnDocument40 pagesChapter 3: Mathematical Modelling Principles: - Formulate Dynamic Models Based OnJanusNo ratings yet

- The Fundamental of Leaky Wave Antenna: January 2018Document10 pagesThe Fundamental of Leaky Wave Antenna: January 2018Mohamed MOUMOUNo ratings yet

- Ase 18 2 GaDocument36 pagesAse 18 2 Gac131508No ratings yet

- C86 - Silt Pusher Inst Manual ConciseDocument35 pagesC86 - Silt Pusher Inst Manual ConciseSujeet SarukNo ratings yet

- Determinants of Brand Equity in Hair Care Products An Empirical StudyDocument20 pagesDeterminants of Brand Equity in Hair Care Products An Empirical StudychaubeydsNo ratings yet

- Pipelining Basic and Intermediate ConceptsDocument75 pagesPipelining Basic and Intermediate Conceptsjoshi.prahaldNo ratings yet