Professional Documents

Culture Documents

US7594780B2

US7594780B2

Uploaded by

Ashen0 ratings0% found this document useful (0 votes)

11 views5 pagesdsvsd

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdsvsd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

11 views5 pagesUS7594780B2

US7594780B2

Uploaded by

Ashendsvsd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 5

(2)

6

os,

wy

w

an

@

ws)

(60)

on

(2)

68)

36)

United States Patent

Bull

DAMPING PLATES.

Inventor: Diana Bull, Philadelphia, PA (US)

Assignee: Ocean Power Technologies, Inc.

Pennington, ND (US)

Notice: Subject to any disclaimer, the term ofthis

patent is extended of adjusted under 35

USC. 154(b) by O days

Appl. No 11/799,138

Filed: May 1, 2007

Prior Publication Data

US 200810131208 AT Jun, 5, 2008,

Related US. Application Data

Provisional aplication No. 60°796,388, filed on May

1.2006,

1c,

Base 2200 (2006.01)

us.cl. 405/198.1; 441/22; 114/258,

Fleld of Classification Search +405/195.1

‘405/205; 114/258

‘See pplication file for complete search history.

USS. PATENT DOCUMENTS

2892862 A T1944 Rabuse ans

BIDESRR A * 611965 Liwig ‘wosi97

342538 A * 21969 Scherer 114282

100

PTO

34

'US007594780B2

US 7,594,780 B2

Sep. 29, 2009

(10) Patent No.

4s) Date of Patent:

350078 A S97 Johan Jeeta oon 8268

RISS36 A$ 91973 Milazo 4

ROMS A$ L1976 Wainwright Tae.

a0 S41 4 * 91981 Bionic etal ot

SA7AL29 8 ¢ 1DI981 Watkins eal has

5132850 A + 71902 MeCabe 200'53

Sio2707 A * M1908 Hono. a0s224

6102825 A * 82000 Olsen cal “os9s..

8718130 B2* 42004 Grober 396/55

FowtIS B2* 42005 Huang etal. 405-206

200410061338 A1* 42004 Woodbridge 29083

2040181812 AL* 72004 Base 05203

ao040208707 AL* 102004 Hang eal 405 206,

2006 0120809 A1* "63005 Ingram et al “os'19s1

Sou7io0s9108 A1* 33007 Chang 40819511

* cited by examiner

Tara Mayo-Pinnoek

‘or Firm-—Ulengy |, Scbanzer, Es

Primary Examiner

(18) Attorney, Agent,

on ABSTRACT

A damping (or heave) plate comprises a generally fat plate

‘attached, beneath the strface of @ sea, a in horizontal or

fnlaton, to a structural member subject to being vertically

moved in response to passing surface waves. The plate tends

toresist vertical movements and has the elec of adding mass

‘o the structure, A vertically extending structure is added 10

both major surfaces of the heave plate for increasing the

volume of water moved by the plate, For minimizing drag

forces generally created by use of the damping plate, the

verically extending structure is shaped to inchide curved

fnydodynamic surfaces for minimizing turbulence in the sur

rounding water,

32

30

U.S, Patent

100

Sep. 29, 2009

20.

US 7,594,780 B2

Pro ry #022

a

ui FIG.1

32

34 pales

FIG.2 on woFtS-4

30 32 20

40 059 30 o

o—

34

FIG.3

FIG.7

FIG.5 20 68 20 74 20

66 70 Dn

30 ge 3 aa

66 70

FIG.6

20, 84 20

30 30

FIG.8 & FIG.9

US 7,594,780 B2

1

DAMPING PLATES.

‘This invention claims priority from provisional application

Ser. No. 60/796388 filed May 1, 2006 for Wave Energy

Converter (WEC) with Heave Plates whose contents are

‘incomporated herein by reference.

BACKGROUND OF THE INVENTION

‘This invention relates to improvements in damping plates

(elso known as heave plates) and, while not so limited, relates

particularly to damping plates use in apparatus for conver-

Ing energy contained in waves on the surface of bodies of

water to useful energy.

‘The use of damping plates, eg. a horizontally oriented Mat

plate atached to a submerged vertical spar of a floating oil

Platform, is generally known. The plates have the effect of

‘nereasng the mass and the viscous rag of the members 10

‘which they are attached, thus making the members less likely

to be driven into destructive movements by excessively high

surface waves and winds,

‘Such damping plates are also useful in certain wypes of

‘apparatus, kaawn as wave enengy converters (WECS), for

‘converting energy in surface waves on bodies of water 10

Useful energy. One lype of such WEC comprises « pair of

oats which bob up an dowsn in response to passing surface

‘waves, Relative movements between the floats are used for

diving an energy converter, for example, an electrical gen-

‘erator connected between the oats for generating electrical

‘or any useful energy.

The amount of energy produced by a given WEC is a

fanetion of, among other things the mass of the floats driven

‘nto motion by the passing waves. For increasing the elfective

mass of atleast one of the floats, a practice isto suspend a

submerged damping or heave plate from the foat. The efle-

tive mass ofthe flat from which the damping plat is sus-

pended is increased due to the fact that the aeveleration and

‘deceleration ofthe plate through the water requires: move

‘mens of some volume of water around the plate, The greater

the amount of water moved by the plate, the greater is the

increase of the at mass,

‘The amount of water moved by a given damping plate isa

funetion of the size ofthe plate. Also, as disclosed in co-

pending patent applications, tiled “Heave Plate. with

Improved Charactristies” bearing Set. No. 1/796,851, and

“Wave Energy Converter (WEC) with Have Plates bearing

Ser. No. 11/706,852, assigned tothe asignee ofthe present

‘application, an dhe subject matter of which is incorporsed

herein by reference as though fll st forth herein, the addi

tion of a vertically extending stricture, eg. a lip along the

‘edges af the heave plat, significantly increases the amount of

water moved by the plate, hence the amount of mass added t0

the float.

‘While useful foradding effective mass oa float, a problem

associated with the use of damping plates, at least in connec

tion with WEC, is thatthe viscous drag forces associated

with the plates tends to impede relative movements, thus

tending to negatively affect poser generation. The present

Jnvention provides means for minimizing the drag forces

‘ypically associated with theuseofdamping plates the type

described,

SUMMARY OF THE INVENTION

A damping (heave) plate, of peneally fat configuration,

includes projecting structure, typically inthe form ofaledge

‘rlipalong the plate edges, for increasing the volume of water

0

o

2

nove by the plate, In accordance with he present invention,

the projecting structure has a streamlined configuration,

inching curved hydrodynamic surfeces, for minimizing tur

bulene inthe surrounding water and atendant drag forces

[BRIEF DESCRIPTION OF THE DRAWINGS.

‘The drawings are schematic and not to scale,

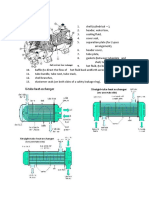

PIG. Lis aside view of a wave energy coaverter of knowa,

{ype including an elongated “spar” float having a damping

plate attached to the lower end thereof

PIG. 2 shows the lower end ofthe spar f

1 but with a known mosiieation ofthe d

PIGS, 3 through 9 are similar o FIG. 2

ts according tothe instant invention

shown in FIG.

ing plate; and

show daraping

P

DETAILED DESCRIPTION OF THE INVENTION

As show schematically in FIG. 1, preferred WEC com-

pris frst annular float 10 of a wenerally at configuration,

and second, elongated float 20, refered o a a “spat” oat,

extending drough an opening 22 though te annular Noat 10.

In accordance with known technology, the two floats are

configured to bob up and down in generally out of phase

relationship in response to passing surface waves. A poser

‘ake off device (PTO) 100 is connected between the float and

spar to coment ther relative motion int useful energy (©.

electrical

A damping plate 30 is disposed at the lower endof the spar

float 20 for increasing its effective mass. As illastated, the

damping plate comprises an essentially fat plate having

‘major surfaces 32 and 34 extending transversely to the dinee-

‘ions of motion ofthe plate 30 through the water.

The effet of the damping plate 30 is to add mass signi

cantly greater than tht of the plate itselr wo the spar Nout 20.

Such added mass is due tothe fact thatthe acceleration oF

deceleration ofthe plate requires movement of some volume

‘of fluid around the plate as it moves. It has heen established

that the volume offuid that the plate will move, by itselfand

‘without the added strctne herein disclosed, is proportional

{o the equivalent volume of the plate times some experimen-

tally determined factor |see, Chakrabarti, S. K. (1987),

“Hydrodynamics of Offshore Structures”, WET Press and

(Computational Mechanies Publications] The volume of fuk

moved isalso function ofthe frequency with whieh the plate

js moving. This parameter is nat discussed hercin,

‘The equivalent volume of the plate depends upon the

geometry ofthe plate, and the general ule thst the equiva

Tent volume is equal to the area ofthe plate multiplied by «

height dimension equal toa lateral dimension ofthe plate; for

‘example, the width ofa rectangular plate, the side ofa square

plate, or the diameter of circular pate.

"The aovelerated flow inertia force caused by the damping

plate isthe added mass of the system (he density of water

fimes the equivalent volume times the experimentally deter

mined factor) times the aceleration of the system, oF

where, is the experimentally determined f$010" Vega

is the eqhvalent volume defined above, pis the densiy of

water, and a isthe acceleration, Note thatthe added mass

‘erm, with units of mass, i the combination ofthe variables

inside ofthe parethesis.

For purposes of analysis, the viscous drag can be separated

into feo components known as skin friction dag and form

dag. Skin feetion drag arses from the fiietion of a fluid

US 7,594,780 B2

3

‘ainst the surface ("skin") of the object that is moving

through the fad, Form (or profile or pressure) drag is mainly

‘due to boundary ayer separation ofthe uid due tothe form,

i. shape, of theobject. Form drag varies (non-linear) 3s the

square of velocity: thus the viscous drag of the system is

rhon-zer> only when there isa non-zero velocity.

‘A boundary layer of fiuid is ereated around an abject dueto

the fietion of the sid agains the surface of the objec. Flow

separation, or boundary layer separation, occurs when this

boundary layer of uid detaches from the surfice of the

cobject. When separation oecurs the fluid forms eddies and

vortices (spinning and often turbulent flow). Flow separation

‘can (and in the ease of damping plates does) result in

‘increased drag as the object moves through the Maid. Aa

‘experimentally determined drag coefficient relates the

strength of the viseous drag force 10 relative flow velocity.

‘When there is no flow separation the dag coefficient will be

lower than when vortices are formed. The thinness othe plate

and porosity of he plate are important factors for the dre

‘cellent since they ereate a series of sharp angles from

‘which the flowing water can separate (soe, Chua, K. HL,

Celland, D. Huang, Sand Sworn, (2005) “Model Experi

‘ments of LIydradynamic Forces on Heave Plates”, Procecd-

ings of 24th Intemational Conference on Offshore Mechanies

and Artic Engineering, Halkidiki, Greece]. Thos, when the

Spae damping plate uit is moving ia heave the lw of Water

past these sharp edges has a tendency 10 ereate vortices,

‘reating a turbulent boundary layer, henee increasing the

‘damping ofthe system, In contrast o sharp edges, the ow

‘around blunt shaped stetues without sharp corners, sch as

‘jlinders or spheres, can exhibit no flow separation, separa

tion with no vortex shedding, and separation with vortex

shedding coinciding with an increase in heave amplitude

(often evaluated nomalized by the diameter ofthe object

heave; se, Faltinsen, 0. M. 1990; “Sea Loads on Ships and

Offshore Structures”; Cambridge University Press, Cam-

bridge). Thus fablunt shaped objects moved only a action

ofits diameter no low separation occurs,

Returning to the matter of adding mass to the system, «|

vertical sieetire, suchas shown in FIGS. 2, is addled wo the

‘damping plates for increasing the valume af Bui moved by

the plates. Bac figure shows te lower end ofa spar float 20

to which a known type of damping plate 30s attached. The

figures are only schematic and its possible o have a spar”

that is comprised of multiple components, « truss spe

Because the spar flat oseilates in the vertical cretion, the

‘added structure encompasses both the upper and lower sur-

faces ofthe damping lates,

"As previously’ described, the damping plate 30, by itself

aves a volume of fuid proportional to the “equivalent vole

tume” of the plate, determined primarily by the area of the

plato. With the added vertical structure, an additional amount

‘of uid is moved as a finetion ofthe volume enclosed by the

plate and the added surtounding strctur, i. the height of

theadded structure multiplied by the area ofthe plate. Also, in

some instances, the added stricture functions to inerease the

‘effective area of the plate thereby’ furher increasing the

amount of fluid moved by the plate

In FIG, 2 the added structure comprises a numberof th

plates 40 secured to and extending completely around the

‘edge ofthe damping plate 30 and perpendicular thereto, The

plates can be edge-joined 4 one another, thus comprising @

‘ylinder enclosing the plate 30. The additional added mass

achieved by the vertical plates is, for movements in either the

Uupor down direction, proportional othe vertical height ofthe

plates 4 above orbelow the plate 30, respectively. multiplied

by the area ofthe plate 30, The structure shown in FIG. 2is

o

4

disclosed inthe previously cited provisional application See

‘No. 60/796,388. A problem associated with the FIG. 2 damp-

ing plate 30, however is that te plates 40 terminate in sharp

tedges which tend to generate undesimably high drag fares.

Conversely inthe strctites shown in FIGS. 3-9, sharp edges

are avoided and! lower dmg forces are present.

TInFIG. 3 the added structure comprises a tube 50 of cite

lar cross-section and outer diameter D disposed along the

cedgeof the plate 30. This results, similarly asin FIG. 2, nan

‘add mass proportional to the height of the tube 80 above

‘and below the plate 30 multiplied by the area ofthe plate 30,

‘but with the added effect that the area of the plate is inereased

by the area of the circular tube 50, An advantage of this

cembodinient is thatthe smooth eicular shape ofthe vertical

portion of the tube wall keeps the fluid flow attached to the

Structure thus decreasing the drag coefficient

TInFIG. 4, the added stecture comprises anellipticeylinder

60 (a 3-dimensional object with an oblong erose-section)

surrounding the plate 30. This results ina larger addition to

the mass added to the plate 30 then that provided by the

structure showin in FIG. 2 provided the longer sie is orients

perpendiculartothe plate 30, Thesmooth shape ofthe elit

tylinder tends to keep the fd flow attached to the structure

thus decreasing the drag evefficient

In FIG. 5, the addition comprises semi-cievlar beads or

sims 66 facing away from the plate 30 at the top and bots

eds ofa vertical eylinder 68 (as in FIG. 2). The rims 66 add

{othe area ofthe damping plate thus inreasing the equivalent

volume thereof, hence the amount of Mid moved thereby.

‘The additional added mass achieved by the vertical eylinder

68 is proportional tothe height ofthe cylinder nmap by

the area ofthe damping plate. The curved shape ofthe rims

‘keeps the Bid flow attached to the stricture thos decreasing

the drag evelicient.

TaFIG. 6 the additonal structures similartothatshowatia

FIG. $ except that the rims 70 face inwardly ofthe plate edge.

Anadvantage of thisis thatthe flu inside the rims is isolated

{rom the fui around the plate structure thus decreasing the

strength ofthe vortex shedding nd hence the drag eoeiciet.

In FIG. 7, the added member comprises a eylinder 72

faving # wall of V-shaped eros section thus including both

vertical and horizontal components. AS in the forewoing

‘examples, the borizatal components result in added mass by

‘adding wo the equivalent volume of the plate 30, while the

added mass achieved by the vertical components isthe height

‘of such components multiplied by the area ofthe plate, FIG.

also shows the placement af smooth (blunt-shaped) objects,

here, fll cizcula tubes 74 atthe ends ofthe eylindee 72 for

Keeping the Mud flow amtached to the stractre for decreasing

the drog coefficient, Other objects, such as the semi-circular

rims 66 aid 70 shown respectively in FIGS, 8 and 6 can be

used,

TaFIGS. 8and9, theaddition of hick circular menabers 80

‘or 410 the plate 30 ith vertical dimensions curving towards

fr away from the spar 20, respectively, inerease the added

‘massa a function, asin previous examples, of the product of

the vertical dimension and the plate area. The members 80

and 84 are shown as being relatively thick and hollow. Alter

tatvely, the eircular members can comprise curved plates

‘Te smooth shapes ofthe circular members 80nd 84 help 10

Keep Mud floss ataced to the strveture,

Tn general, the elimination of sharp comers on the edges of

the plates or on vertically extending members added to the

damping plates will decrease the drag coefficient. Ths is

adntagenus for WECs since decreasing the drag coeMicient

‘ill result in lager relative motions and hence allowing fora

mon elicent capture of enerpy

US 7,594,780 B2

5

Another use ofthe invention is in industrial mixing pro-

‘cesses (Where an actuator causes a plate to oscillate in a

‘container of non-mixed liquids) in whieh it is desired 10

‘suppress (or enhance} formation of small scale vortices. This

‘can bo accomplished by the use of vertically extending. ip

Strvctures as above-described with more or les streamlining

‘of the lip structures to obtain the desired results

‘What is claimed is

1A damping plate comprising a first plate for being

attached to the submerged end ofa spar-ike float ina body of

Fiqid and said spar ike oat being subject to movement inthe

vertical directions, said fist plate of generally solid lat con-

figuration having a pair of oppositely facing major surfaces

‘extending transversely of the up down movement ofthe spar-

like float, and vertically extending structures mounted on said

major surfaces of said fist plete for inewesing the volume of

liguid pushed aside during movements ofthe plate through

the lighid said vertically’ extending stevctures defining an

‘enclosure whose sides are sold and of predetermined height,

for capturing a volume of water which is a function of the

‘enclosed surface area of the damping plate multiplied by the

height ofthe vertically extending structures fr increasing the

elfective mass of water pushed during the up down movement

fof the damping plate through the water; said vertically

‘extending structures having streamlined curved configura

tions for minimizing turbulence andthe amount of drag ene-

ated by the up down movement of the damping plate in the

body of liquid.

2.A damping plateinacconlance withelaim 1 wherein sid

vertically extending sirctures have smooth and curved sue

tices

“3. damping plate inaccordance withelaitn I wherein id

vertically extending structures have an elliptical eoss-see-

4A damping platein accordance with clan 1 wherein iid

vertically extending strictures comprise socond plates dis-

posed at edges of said first plate and terminating above and

below said firs plate in rims having curved walls

'.A damping plate inaccordance withclaitn I wherein id

vertically extending structures comprise one or more semi

circular members disposed at one or more edges of sid fis

plate.

6. A damping plate as claimed in claim 1, wherein the

Figuidis water ad the movement is oscillatory’ tesponsive 10

passing waves

7. damping platein accordance withclatn 1 wherein iid

vertically extending structures have a circular eros section

‘extending long the periphery of the first plate.

8. Apparat including a damping plate comprising a first,

plate for being attached tothe submerged end of a sparlike

Float in a body of liguid and subject to movement in the

vertical directions, said plate having @ pair of oppositely

‘acing surfaces extending ransversely ofthe Vertical up and

‘down movement of the spar-ike float and vertically extend

jing strictures mounted on ssid surfaces for inereasing the

volume of guid pushed aside during the up dawa movements

0

6

‘ofthe plate through the Figuid suid vertically extending strve-

tures defining an enclosure whose sides are solid and of

predetermined height for capturing volume of water whieh

‘sa function ofthe enclosed surface area of the damping plate

‘multiplied hy the height of he vertically extending steutures

orincreasing the eectivemass of water pushed wp and down

during movement of the damping plate through the water

ssid vertically extending structures having. streamlined

ceurved configurations for minimizing the amount of drag

created by the up and down movement of the damping plat

9. Apparatus claimed in claim 8, further inchuding at

intended to Tie along the surface of a hody of Water and

designed to move generally in-phase with the waves present

jn the body of water: and wherein said sparlike Moat is

intended to extend vertically, generally perpendicular o the

‘eat and the surface ofthe body of water, aid spar-like float

extending below the surface ofthe body of water and being

intended to move vertically up and down generally outof-

phase with the waves; and further including a power takeoff

Geviee PTO), connected between the spar-like Not and the

Hoa, responsivetotheitrelative motion to convert the relative

motion 1 useful ener.

10, Apparatus as claimed in claim 9, wherein said vertical

structures have a circular eross section and extend coat

‘ously along the periphery of the damping pate.

11, Apparatus as claimed in elim 10, wherein said vertical

structures are symmetrically disposed above and below the

damping plate.

12, A wave energy converer (WEC) comprising: alot for

Aloating ona surface of abody of water for generally in-phase

movements with the waves present inthe body of water, an

elongated spar for foating vertically in the body of water for

‘gencmlly oitof-phase movements with the waves: poster

{ake off device (PTO), connected between the spar and the

float for converting relative motion there between to usefl

‘energy’aheave plate connected oa submerged portion ofthe

Spar, said heave plate extending in a plane perpendicular to

the spar and having a pair of oppositely facing surfaces

extending transversely tothe vertical directions af movement

‘ofthe spar, and vertical strvetires mounted on the oppositely

‘acing surfaces, said verical structures defining an enclosure

whose sides ae solid and of predetermined height foreaptur-

ing a volume of water which is a function ofthe enclosed

surface area of the damping plate multiplied by the height of

the vertically extending structures for inereasing the effective

mass of water pushed doring the up and down movement of

the damping plate through the water, said vertical structures

having curved surfaces along its edges for lowering the vi

cous drag of said heave plate

13. A WEC as claimed in claim 12, wherein said vertical

structures have one ofa generally elliptical and circular cross

section extending along the periphery ofthe heave plat.

14. WEC as claimed in claim 12, wherein said vertical

structures extend symmetrically above and below the heave

plate

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- GraphsDocument3 pagesGraphsAshenNo ratings yet

- ChemistryDocument2 pagesChemistryAshenNo ratings yet

- EquationDocument2 pagesEquationAshenNo ratings yet

- Turbo ChargersdocxDocument35 pagesTurbo ChargersdocxAshenNo ratings yet

- Fresh Water Generator or EvaporatorDocument3 pagesFresh Water Generator or EvaporatorAshenNo ratings yet

- Grade 11Document3 pagesGrade 11AshenNo ratings yet

- PlantDocument4 pagesPlantAshenNo ratings yet

- Heat Exchangers HandoutDocument9 pagesHeat Exchangers HandoutAshenNo ratings yet

- bOILERS - PPT (Compatibility Mode)Document22 pagesbOILERS - PPT (Compatibility Mode)AshenNo ratings yet

- FactorsDocument2 pagesFactorsAshenNo ratings yet

- Motor 2Document19 pagesMotor 2AshenNo ratings yet

- US10155678B2Document18 pagesUS10155678B2AshenNo ratings yet

- Lathe Maachine Theorywork ShopDocument37 pagesLathe Maachine Theorywork ShopAshenNo ratings yet

- US20080131208A1Document5 pagesUS20080131208A1AshenNo ratings yet

- Ma DPD 20Document1 pageMa DPD 20AshenNo ratings yet