Professional Documents

Culture Documents

Effective Preparation For Turnarounds

Effective Preparation For Turnarounds

Uploaded by

reguiiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effective Preparation For Turnarounds

Effective Preparation For Turnarounds

Uploaded by

reguiiCopyright:

Available Formats

Effective preparation for turnarounds

Defining the objectives, planning thoroughly and ensuring operator readiness will

increase the likelihood of a successful turnaround

LEE WILLIAMSON

T.A. Cook Consultants

W

hen preparation and exe- • The enhanced quality of work to planning for an event. It appears

cution of shutdown, turn- will lead to increased productivity. that there are silos that exist. Part of

around, and outage (STO) • The STO schedule will be more via- it has to do with area of focus and

becomes second nature, the scales ble regarding equipment availability. expertise. The key here is to engage

will tip in your favour. For oper- • Progress reporting will be clear operations early in this process and

ations, a shift of focus from pro- and accurate. gain buy-in. Within that blueprint

duction to STO preparation does We all can agree that, in some are guidelines, targets and deliver-

not happen overnight, however. cases, preparing for a unit shut- ables that govern how to effectively

For every hour when production is down is widely viewed as an ad strategise, plan, and execute an

offline, there is a major impact on hoc process, with preparation and event regardless of complexity. This

business performance due to lost training as needed and when nec- article will focus on highlighting

revenue. If not thoroughly planned, essary. Understandably, operations those deliverables that are specific

the transition from operating the typically focuses on meeting pro- to operations during the prepara-

plant to clearing the plant in prepa- duction targets at the proper run tion and execution stages of an STO.

ration for a turnaround will lead to rates and within strict quality and This, in turn, will boost the engage-

prominent failure. regulatory guidelines. Thus, when ment of operations and ensure

Resource requirements not being an STO comes around every four that accountability is maintained

identified, operator experience lev- or five years, preparedness is not throughout the process.

els being below expectations, key necessarily on the ‘high priority’ There are four key phases for

roles and responsibilities not being list. In order to change this ad hoc operations planning: define, plan,

clearly defined, and the shutdown way of doing business, operations readiness, and execution:

and start-up timeline not commu- should start preparing for the next 1. Define: develop the SD/SU strat-

nicated to the STO team are just STO as soon as the most recent one egy and V-plan, organisation roles

a few issues that will negatively has completed. The first step would and responsibilities, section and

impact the schedule. It is essen- be to review the lessons learned, system blinding programme for

tial that operations managers are implement the recommendations, equipment isolation and the permit

committed to implementing best and address what did not go so process

practices for STO preparation as well. In order to do that, operations 2. Plan: lock out tag out (LOTO)

well as production. With the guid- managers must commit to driving procedure, SD/SU procedure

ance of an effective milestone productivity and efficiency, whether review and system packages,

planning process, efficiency can be the plant is running at full capacity resource planning and equipment

maintained when the time comes or preparing and executing a pro- isolation documentation (blind list)

to take the unit down for an STO. cedure to shut the unit down and 3. Readiness: operator training, pro-

Adhering to the milestone process bring it back up after all mechanical cedure training, SD/SU schedule,

helps ensure that operations is in work has been completed. ISO and P&ID mark-up, mobile

alignment with the STO team and Operations is in the business of equipment lists, checklists and per-

delivers an efficient and optimised producing a quality product. The mit preparation

event. Following this approach, transition from production to shut- 4. Execution: progress reporting,

your organisation will yield many down and start-up must go more modify staffing plan, permit issu-

benefits: smoothly. And yes, there is a way to ing, system QA/QC and field

• Standardisation of processes will bring about this smooth transition. support

be implemented across all areas This all begins with a blueprint for

within an organisation. a successful STO. A well defined Commitment and engagement

• Well defined resource require- milestone process outlines those Preparedness is a way of life, not

ments will deliver an effective utili- deliverables for which operations is something that happens instantly.

sation of staff. accountable for completing. I bring In the world of maintenance turna-

• Operators are more prepared to this up because I have experienced rounds, this statement is especially

execute tasks during shutdown and misalignment between the STO true. Developing a good strategy,

start-up of the plant. team and operations when it comes planning, and organising ensures

www.digitalrefining.com/article/1002564 Revamps 2020 5

readiness and sets the stage for the because the operations manager overall objectives. A facilitator from

successful execution of an STO. But failed to have the equipment avail- outside of the organisation will be

what is essential is the commitment able on the first day. For this rea- more effective at this, as they will

and engagement of the operations son, it is very important to ensure not make assumptions of the knowl-

staff throughout all phases of the that operations are staffed to effec- edge of any one participant, thus

turnaround management process. tively manage the SD/SU phases. In ensuring that no participant is left

As owners of the asset, operations order to accomplish this, a thorough behind.

personnel shift focus from day-to- review of the current SD/SU proce-

day production to clearing and iso- dures must take place. Success story

lating the equipment in preparation Benjamin Franklin once said, One of the most important elements

for the turnaround work to begin. “By failing to prepare, you are pre- to ensure operational readiness is to

The plant is turned back over to paring to fail.” There is no better make sure that objectives are met.

operations once all planned main- example of this than the specific Achieving primary objectives deter-

tenance activities and construction preparations needed for a successful mines the success of a turnaround.

are finalised. The task for operations turnaround. Turnarounds are peri- Two key primary objectives are

is to then resume routine produc- odic events wherein processing/ the development of shutdown and

tion safely while ensuring that the production units are temporarily start-up procedures. Typically, pro-

unit is at full capacity within a short removed from service in order to cess engineers utilise operations per-

amount of time. Lost production, revamp and make improvements. sonnel to develop these procedures.

increased labour, and maintenance This pause in production has signif- Again, relying upon experience

costs negatively impact a com- icant effects on output, thus mak- and knowledge of the area is a very

pany’s profitability. When turna- ing precise turnaround planning important part of a successful turn-

rounds are managed effectively, the vital to the overall financial success around. Adherence to established

impact on the bottom line will be of the company. Given the impor- timelines is critical as well. In cases

less detrimental. Operational readi- tance and critical nature of this where the shutdown procedure was

ness is key to keeping costs within a event, operations personnel must not finalised before the start of the

specified range. be actively involved in all aspects of turnaround, delays and increased

Front-end loading (FEL) criti- the turnaround. labour costs were the result. Having

cal dimensions are scope, cost, and maintenance technicians and con-

schedule. In this phase, establish- Change in perspective tractors on hold while the plant is

ing scope is key to accomplishing A common mistake found in turn- still in the process of shutting down

favourable cost results and sched- arounds begins with the pre- is extremely expensive. Having these

ule adherence. Operations manage- planned procedures and checklists. procedures developed, approved

ment must provide input into the Often, the activities mentioned in and in place during the FEL stage

scope of work for the turnaround. them lack details on duration and can mitigate costly over-runs. Here is

Participation in scope meetings required staffing. Identifying the an actual scenario that exhibits what

during the beginning of the FEL duration of each required task and I just stated:

process is crucial. In order to avoid how many operators are required Plant A takes 21 days to shut

costly expenditures, every item in to perform the activity are both key down and seven days to start up.

the scope work list must be chal- in effective planning. The review of The mechanical window is 42 days.

lenged. Needs must take priority these procedures should be done in Plant A will be down for 70 days.

over wants. Operations personnel a group setting and include manag- Therefore, 40% of the offline time

have the working knowledge, expe- ers, supervisors, coordinators, and is directly related to operations. At

rience, and expertise to play an inte- operators. The operators involved $750 000 per day, the overall reve-

gral part in what goes into defining should have varying levels of expe- nue loss will be $52 million during

the scope. rience. A fresh perspective from the event. Of that amount, $21 mil-

A successful turnaround also less-tenured operators is just as lion is directly related to shutdown

depends on having an effective important as input from senior level and start-up.

organisational structure prepared operators. More experienced opera- What makes this significant

well before the event takes place. tors tend to rely solely on what has is that the mechanical start date

The overall STO schedule includes been done in the past. The less you depends on having the unit shut

the time it takes to shut down and hear “We’ve always done it this down, cleared, and isolated. If the

start up the unit as well as the win- way”, the better off you will be. unthinkable happened and the

dow where all maintenance work While the overall objective of shutdown took longer than the

is done. So, even if all the sched- this exercise is to develop duration scheduled 21 days, the entire STO

uled work is completed within the and staffing, it is also important to schedule would be impacted. And

set timeframe, the event will still optimise steps in the process and we all know what happens when an

be unsuccessful if the SD/SU of eliminate obsolete and ambiguous event goes on longer than expected.

the unit takes longer than planned. instructions. If the review is facil- The challenge was to thoroughly

In many instances, the start of the itated correctly, it will allow for review the shutdown and start-up

maintenance window is delayed participants to have better focus on procedures with a cross-functional

6 Revamps 2020 www.digitalrefining.com/article/1002564

team (operations, STO, safety) to Operations deliverables Conclusion

verify the duration and manpower Delegation and accountability are This article is based upon best prac-

for each step. As an added meas- also key to bringing about the suc- tice methodologies for STOs. In

ure, I wanted to challenge the team cessful completion of primary objec- many cases, I reflect on my own

to find steps that could be done tives. The list of STO milestones personal experience in working

simultaneously by dividing the can be extensive and complex. in the industry. Throughout my

plant into blocks. The objective here Operations and STO leaders can career, I have noticed that the STO

was to optimise the shutdown and become overwhelmed if these asso- team and operations are not always

start-up procedures and reduce the ciated tasks are not delegated appro- on the same page when it comes to

time from 28 days by 25%. The cli- priately. Consideration should be preparing for an event. The oper-

ent team exceeded expectations by made to establish turnaround coor- ations team is the asset owner and

reducing the shutdown and start-up dinators, or specialists, to oversee their normal business demands pro-

duration by over 30%. We accom- the planning and execution of main- ducing a quality product within a

plished this by challenging the tenance activities for each operating specified rate that meets or exceeds

established procedures. unit. The operations coordinator the goals for the site. Having to shut

These procedures had not been plays an integral role in managing down production every three to

reviewed and revised regularly in the flow of work for an upcoming five years for an STO is not always

order to account for new equip- turnaround. Most organisations real- an easy task because that is just out

ment, process changes, and obso- ise that a turnaround is not a single of the norm. However, defining the

lete safety guidelines. Further, occurrence. They are complex and objectives, planning thoroughly

there was no verification of actu- require multiple team members to and ensuring operator readiness

als during the previous STO some be responsible for planning. Holding through training will increase the

five years earlier. Therefore, the these team members accountable likelihood of the successful exe-

21-day shutdown and seven-day for results is also critical. At any cution of any STO. Organisations

start-up were essentially an estimate time during this planning process, will standardise processes across

based upon what they had always responsible designees should be all sites. What proves to be success-

done. Combing through each pro- able to prove that they are on track ful will be implemented by other

cedure with the cross-functional to meet deliverables. The milestone asset owners with the objective of

team revealed that there are incon- plan identifies all operations deliver- improving efficiency in activities

sistencies in how Plant A should ables in alignment with the STO pro- that are outside the norm. The utili-

be decommissioned and commis- ject plan. sation of staff will be more effective,

sioned. As a team, we were able to It is key to develop specific deliv- and operators will be better pre-

optimise the schedule and imple- erables based upon the milestone. pared to support and execute. The

ment the documentation of actuals. For example, Milestone 3.07: opera- quality of work being done will be

These actuals will be used to revise tions planning completed in common enhanced along with increased pro-

the durations for the next shutdown planning system (blinding, lock out/ ductivity. Alignment of equipment

and start-up, if needed. tag out, requirements for live sys- availability with the STO sched-

I consider this a success story tems, plans for vessel entry, rescue, ule will be exemplary by focusing

and the client was excited to real- decontamination). From this mile- on preparedness. The reporting

ise a positive outcome. When it stone, we can derive specific tasks of operations progress during the

came time to execute these pro- relating to making the plant safe for shutdown and start-up of the plant

cedures, the operations team was the mechanical work to begin. With will be more transparent, clear, and

more than prepared, fully staffed, roles and responsibilities established accurate. These are the steps that

and well-trained. While most of during the define phase, key per- lead to effective STO preparedness

the work is being done by mainte- sonnel have already been identi- for operations. Effective STO pre-

nance and managed by the turna- fied to complete these tasks within paredness will result in productive

round team, operations personnel the timeframe allowed. In order to execution during the event. Tip

have responsibility for making sure ensure accountability, a tracking tool the scales to gain a more strategic

the equipment is properly pre- is essential. A Gantt chart is very advantage.

pared, isolated, and safe. Daily per- useful in tracking the completion

mit meetings with the turnaround of deliverables. This tool not only Lee Williamson is Senior Consultant with T.A.

team are essential in preventing establishes accountability and target Cook Consultants North America. He has more

schedule delays. Ensuring that the dates, it provides tangible evidence than six years of experience providing strategic

equipment is available and pre- that the deliverables are progressing and operational advice to clients in asset-

intensive industries.

pared the shift before scheduled at an acceptable rate. The Gantt chart

work is to be done goes a long way should be reviewed regularly dur-

in maintaining schedule adherence. ing the STO FEL update meetings. LINKS

Communication of any equipment This serves two purposes: tracking

availability by operations is also deliverables and ensuring operations More articles from the following

important for schedule adherence is thoroughly engaged during the categories:

Revamps and Turnarounds

and resource utilisation. entire preparation process.

www.digitalrefining.com/article/1002564 Revamps 2020 7

You might also like

- KPIs FOR MEASURING THE SUCCESS OF SHUTDOWN PDFDocument67 pagesKPIs FOR MEASURING THE SUCCESS OF SHUTDOWN PDFMohamed F Morsy60% (5)

- ADMS 2320 Test 1 SheetDocument1 pageADMS 2320 Test 1 SheetJustin St Louis WoodNo ratings yet

- Circular Flow Model WorksheetDocument2 pagesCircular Flow Model Worksheetapi-320972635No ratings yet

- Case Study - Sabic Shutdown Optimisation PDFDocument8 pagesCase Study - Sabic Shutdown Optimisation PDFArielNo ratings yet

- Leadership For Shutdowns, Turnarounds and Outages: Developed by Joel Levitt and The Life Cycle InstituteDocument12 pagesLeadership For Shutdowns, Turnarounds and Outages: Developed by Joel Levitt and The Life Cycle Instituterams789No ratings yet

- Homeroom Pta Financial ReportDocument1 pageHomeroom Pta Financial ReportRoxanne Tiffany Dotillos Sarino100% (1)

- Tax ClearanceDocument1 pageTax ClearanceliuNo ratings yet

- Effective Guide To Forex Trading - Kelvin Lee PDFDocument67 pagesEffective Guide To Forex Trading - Kelvin Lee PDFoaperuchena100% (2)

- Shutdown Maintenance PlanningDocument6 pagesShutdown Maintenance PlanningvijaykmjNo ratings yet

- Plant TurnaroundsDocument12 pagesPlant TurnaroundsVaisakh KrishnaNo ratings yet

- Fundamentals of Maintenance PlanningDocument3 pagesFundamentals of Maintenance PlanningYousef AsmarNo ratings yet

- Turnaround Management Methodology For Fertilizer Plants - Document GuidanceDocument12 pagesTurnaround Management Methodology For Fertilizer Plants - Document Guidancerobertion100% (1)

- KBC White Paper - RAM Turnaround StrategyDocument6 pagesKBC White Paper - RAM Turnaround Strategywgzheng2001No ratings yet

- Shutdown Management PDFDocument8 pagesShutdown Management PDFEdmund Yoong100% (1)

- Turnaround-Shorter & SaferDocument5 pagesTurnaround-Shorter & SaferChem.EnggNo ratings yet

- Managing WorkscopeDocument7 pagesManaging WorkscopeLuis Rosi PoloNo ratings yet

- Tackle Refining Industry ChallengesDocument30 pagesTackle Refining Industry ChallengesProsperNo ratings yet

- Maintenance and Turnaround Planning Critical To Successful Ejector Vacuum System OperationDocument5 pagesMaintenance and Turnaround Planning Critical To Successful Ejector Vacuum System Operationganesh gundNo ratings yet

- ShutdownDocument6 pagesShutdownGuru Raja Ragavendran NagarajanNo ratings yet

- Planning For Shutdowns, Turnarounds and Outages: Developed by Joel Levitt and The Life Cycle InstituteDocument12 pagesPlanning For Shutdowns, Turnarounds and Outages: Developed by Joel Levitt and The Life Cycle Instituterams789No ratings yet

- IBM Oil - Turnaround Management SolutionsDocument2 pagesIBM Oil - Turnaround Management SolutionsIBM Chemical and PetroleumNo ratings yet

- Job Pack WP 509 e 001gDocument91 pagesJob Pack WP 509 e 001gdwivedipramodkumarNo ratings yet

- Enclosure-12 - GCC Quality FormsDocument502 pagesEnclosure-12 - GCC Quality FormsAndrei UrsacheNo ratings yet

- Shutdown 2010 BrochureDocument11 pagesShutdown 2010 Brochuret_saumitra100% (1)

- Managing Efficient ShutdownDocument5 pagesManaging Efficient ShutdownEhab AbowardaNo ratings yet

- Advanced Turnaround, Shutdown & Outage Management: Expert Course Faculty LeaderDocument5 pagesAdvanced Turnaround, Shutdown & Outage Management: Expert Course Faculty LeaderDominic LeeNo ratings yet

- Best Practices ParadasDocument40 pagesBest Practices ParadasCarlos Alberto Bardales Garcia0% (1)

- Attachment 1 - Prequalification Questionnaire - Main Execution Contract TAR 2023Document13 pagesAttachment 1 - Prequalification Questionnaire - Main Execution Contract TAR 2023BALAKRISHANANNo ratings yet

- Equipment Criticality AnalysisDocument20 pagesEquipment Criticality AnalysisArmandoNo ratings yet

- PETA-7.3 Step DescriptionDocument51 pagesPETA-7.3 Step DescriptionNack Abd Rauof100% (1)

- World Class ShutdownDocument6 pagesWorld Class ShutdownKmt_AeNo ratings yet

- AV ME SOP 02 Criticality AnalysisDocument4 pagesAV ME SOP 02 Criticality AnalysisjfejfeNo ratings yet

- Steam Turbine Risk Assessment - Project: Inspection and Overhaul Optimization of Steam TurbinesDocument8 pagesSteam Turbine Risk Assessment - Project: Inspection and Overhaul Optimization of Steam TurbinesAnonymous PkeI8e84Rs100% (1)

- Click To Go To IndexDocument16 pagesClick To Go To Indexrty2No ratings yet

- Design For MaintainabilityDocument7 pagesDesign For MaintainabilityEmilian PopaNo ratings yet

- Maintenance Function in RefineryDocument8 pagesMaintenance Function in RefineryMohammad Abubakar Siddiq0% (1)

- 2 Leading Indicators of Turnaround Performance OutcomesDocument12 pages2 Leading Indicators of Turnaround Performance OutcomesPrettyAnnie51No ratings yet

- Maintenance ActivitiesDocument44 pagesMaintenance ActivitiesHoang Thang100% (2)

- ME189 - Process Plant Shutdown, Turnaround TroubleshootingDocument6 pagesME189 - Process Plant Shutdown, Turnaround TroubleshootingKais RegaiegNo ratings yet

- Refinery TroubleshootingDocument5 pagesRefinery TroubleshootingDương Nguyễn TùngNo ratings yet

- Manpower List - Aims HCMLDocument5 pagesManpower List - Aims HCMLJuliyanto STNo ratings yet

- Why Asset Integrity Implementation FailsDocument2 pagesWhy Asset Integrity Implementation Failsmohsen m.aghabeglouNo ratings yet

- Introduction: TPM: Presented by Andy Ginder Vice President, ABB Reliability Consulting 281-450-1081Document31 pagesIntroduction: TPM: Presented by Andy Ginder Vice President, ABB Reliability Consulting 281-450-1081Suman TutooNo ratings yet

- Subject: Production and Operations Management Unit 5: Maintenance and Waste ManagementDocument19 pagesSubject: Production and Operations Management Unit 5: Maintenance and Waste ManagementAnonymous yL88Jj100% (1)

- Integrating Earned Value Management With CC ExecutionDocument12 pagesIntegrating Earned Value Management With CC ExecutionAntonio CalcinaNo ratings yet

- Coke Drum Structure Safety During Shutdowns Maintenance Moloney ExxonMobil DCU New Delhi 2013 PDFDocument38 pagesCoke Drum Structure Safety During Shutdowns Maintenance Moloney ExxonMobil DCU New Delhi 2013 PDFtogentongNo ratings yet

- PETA-7.1 Step DescriptionDocument44 pagesPETA-7.1 Step DescriptionNack Abd RauofNo ratings yet

- BP Toledo v6 LoDocument20 pagesBP Toledo v6 LoMarcos ArraezNo ratings yet

- HSE Verification & Validation Checklist - Energy IsolationDocument12 pagesHSE Verification & Validation Checklist - Energy Isolationhilmy100% (1)

- Sydney, NSW - Australia, March 8-9, 2010: E-Mail: Phone: +6053687732 Mobile: +60125012590Document19 pagesSydney, NSW - Australia, March 8-9, 2010: E-Mail: Phone: +6053687732 Mobile: +60125012590Rupesh Desai100% (1)

- Plant Modification Request Flowchart PLTUDocument3 pagesPlant Modification Request Flowchart PLTUsas13No ratings yet

- 4.0 Best Practice - Risk Based InspectionDocument29 pages4.0 Best Practice - Risk Based Inspectionramu100% (1)

- Sabp G 009aDocument10 pagesSabp G 009ammmNo ratings yet

- Service Specification For Mechanical Work in TurnaroundsDocument25 pagesService Specification For Mechanical Work in Turnaroundsjuncu100% (1)

- Tarnoaround PlanningDocument33 pagesTarnoaround PlanningShahnawaz BateyNo ratings yet

- AIMS Training (July 31, 2024)Document4 pagesAIMS Training (July 31, 2024)Arianta RianNo ratings yet

- Assetivity Asset Management Policy TemplateDocument1 pageAssetivity Asset Management Policy TemplateShashannk DoshiNo ratings yet

- Primavera Course Description and Course Content 4Document5 pagesPrimavera Course Description and Course Content 4Sheikh Muhammad NafeesNo ratings yet

- Blind List C101 ReactorDocument2 pagesBlind List C101 ReactorMadhan KannanNo ratings yet

- The Maintenance Management Framework - Models and Methods For Complex Systems Maintenance (SpringeDocument6 pagesThe Maintenance Management Framework - Models and Methods For Complex Systems Maintenance (Springefrank naranjoNo ratings yet

- HSE REMINDER-March 2012-Plant Turnaround SafetyDocument1 pageHSE REMINDER-March 2012-Plant Turnaround SafetyDarius DsouzaNo ratings yet

- Systematic Layout PlanningDocument5 pagesSystematic Layout PlanningNishant1993No ratings yet

- 00 PR PH 00002 - 2 Service Definition PhilosophyDocument8 pages00 PR PH 00002 - 2 Service Definition PhilosophyStevanNikolicNo ratings yet

- IBM Maximo Asset Configuration Manager A Complete Guide - 2020 EditionFrom EverandIBM Maximo Asset Configuration Manager A Complete Guide - 2020 EditionNo ratings yet

- Dry Gas Seal - SIEMENSDocument107 pagesDry Gas Seal - SIEMENSreguii100% (4)

- Controlling Contaminants in Vacuum GasoilDocument5 pagesControlling Contaminants in Vacuum GasoilreguiiNo ratings yet

- 3-TAL Trade Register-Company StatusDocument6 pages3-TAL Trade Register-Company StatusreguiiNo ratings yet

- GeneralDocument2 pagesGeneralreguiiNo ratings yet

- Schedule A. Scope of Works Hose Assembly TH005 EnglishDocument6 pagesSchedule A. Scope of Works Hose Assembly TH005 EnglishreguiiNo ratings yet

- Tenders and BiddingDocument10 pagesTenders and BiddingSrdjan KitanovicNo ratings yet

- Portfolio Theory Exam 2020 With SolutionDocument4 pagesPortfolio Theory Exam 2020 With SolutionFARAH BENDALINo ratings yet

- Managerial Economics - Chapter 1Document17 pagesManagerial Economics - Chapter 1NeighvestNo ratings yet

- Solution Manual For Interpreting and Analyzing Financial Statements 6th Edition by SchoenebeckDocument36 pagesSolution Manual For Interpreting and Analyzing Financial Statements 6th Edition by Schoenebeckthionineredeyeao9j100% (44)

- Introduction To Operations ManagementDocument22 pagesIntroduction To Operations ManagementJocelyn Dela RosaNo ratings yet

- Data Inventory Shipments of MTCDocument10 pagesData Inventory Shipments of MTCLNPTNo ratings yet

- Sim CBM 122 Lesson 3Document9 pagesSim CBM 122 Lesson 3Andrew Sy ScottNo ratings yet

- Lesson 8 - The Global CityDocument27 pagesLesson 8 - The Global CityBpNo ratings yet

- Data - Sheet - FP1 - 2102-100 - Active - Digital - 1060 (Refurb or Newer)Document2 pagesData - Sheet - FP1 - 2102-100 - Active - Digital - 1060 (Refurb or Newer)Basil HwangNo ratings yet

- Boarding Pass (COK HYD)Document20 pagesBoarding Pass (COK HYD)Nathan ManiNo ratings yet

- Chapter 11 Global and International Issues: Strategic Management: A Competitive Advantage Approach, 17e (David/David)Document30 pagesChapter 11 Global and International Issues: Strategic Management: A Competitive Advantage Approach, 17e (David/David)asdfghjklNo ratings yet

- An Integrated Location, Production, Distribution and Investment Model For A Multinational CorporationDocument16 pagesAn Integrated Location, Production, Distribution and Investment Model For A Multinational CorporationAlejandro Duvan Lopez RojasNo ratings yet

- Quiz 2Document5 pagesQuiz 2Yazmine Aliyah A. CaoileNo ratings yet

- Semester Syllabus First and Second, Higher Education, Madhya Pradesh, IndiaDocument1 pageSemester Syllabus First and Second, Higher Education, Madhya Pradesh, IndiaGarima GarimaNo ratings yet

- Marketing AspectDocument27 pagesMarketing AspectJustineAnneGRigonan100% (1)

- University of Santo TomasDocument1 pageUniversity of Santo TomasDennis Michael DyNo ratings yet

- Perhaps You Wondered What Ben Kinmore Who Lives Off inDocument2 pagesPerhaps You Wondered What Ben Kinmore Who Lives Off intrilocksp SinghNo ratings yet

- English Nomination FormDocument14 pagesEnglish Nomination FormroyshoaibNo ratings yet

- Pierson - Increasing Returns, Path Dependence, and Study of PoliticsDocument18 pagesPierson - Increasing Returns, Path Dependence, and Study of PoliticsSamuel AbebawNo ratings yet

- Chapter 5 - SolutionsDocument5 pagesChapter 5 - SolutionshnNo ratings yet

- Factsheet NIFTY50 Equal WeightDocument2 pagesFactsheet NIFTY50 Equal WeightS SinghNo ratings yet

- Total Cost of OwnershipDocument21 pagesTotal Cost of OwnershipthejeshwarNo ratings yet

- Value Chart For YES Prosperity Edge Credit CardDocument1 pageValue Chart For YES Prosperity Edge Credit CardRajeev KumarNo ratings yet

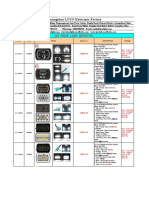

- Loyo Led Truck Light Quotation 2020Document7 pagesLoyo Led Truck Light Quotation 2020Mimmo Beniamino PennesiNo ratings yet

- Memorandum of UnderstandingDocument7 pagesMemorandum of UnderstandingDhruvik PatelNo ratings yet